Taco is excited to announce its participation at Data Center World 2025, taking place April 14-17 at the Walter E. Washington Convention Center in Washington, D.C. Taco will be highlighting its latest innovations in energy-efficient cooling solutions at booth #424. Attendees will have the chance to explore Taco’s mission-critical products designed to optimize cooling systems Read more

Taco

Taco is excited to announce its participation at Data Center World 2025, taking place April 14-17 at the Walter E. Washington Convention Center in Washington, D.C. Taco will be highlighting its latest innovations in energy-efficient cooling solutions at booth #424. Attendees will have the chance to explore Taco’s mission-critical products designed to optimize cooling systems and drive sustainability in data centers.

Innovative Solutions for a Sustainable Future

The Taco booth will feature a range of groundbreaking products that offer exceptional performance and energy efficiency, including:

- Thermal Energy Storage Tanks

- SKV Self-Sensing Vertical In-Line Pumps

- Stainless Steel Pumps and Circulators

These solutions are engineered to improve cooling efficiency, reduce energy consumption, and support the increasing demands of data centers. Taco continues to lead the way with innovative technologies that deliver reliable, sustainable performance.

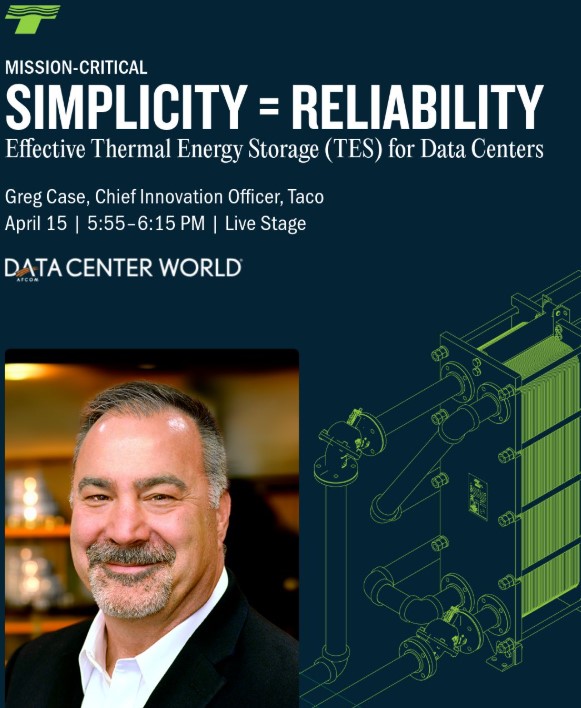

Special Presentation by Greg Case, Chief Innovation Officer

In addition to showcasing its products, Taco is pleased to share that Greg Case, Taco’s Chief Innovation Officer, will present at the Solution Spotlight session on Tuesday, April 15th, from 5:55 pm. to 6:15 pm. Greg will discuss the following topics:

- Current and emerging technologies for emergency backup cooling and surge compensation in data centers

- Developing realistic system requirements for optimal performance

- Selecting a reliable TES methodology that supports system criteria

This session provides an invaluable opportunity for attendees to learn about the latest advancements in data center cooling technologies and how they can help improve system efficiency and reliability.

Join us at booth #424 for an opportunity to network, explore new technologies, and discover how Taco can help optimize your systems for the future.

For more information, visit Mission Critical at tacoinc.com.

“I’m paying attention to the specifications of the planet,” said Bryan Uhler, second-generation builder, YouTuber and Instagram influencer. Long-term quality and conservation within the building trade are calling cards for Pioneer Builders Inc., which Bryan’s father, Tim Sr., founded in Port Orchard, Wash., nearly 50 years ago. Today, Bryan serves as vice president of the Read more

“I’m paying attention to the specifications of the planet,” said Bryan Uhler, second-generation builder, YouTuber and Instagram influencer.

Long-term quality and conservation within the building trade are calling cards for Pioneer Builders Inc., which Bryan’s father, Tim Sr., founded in Port Orchard, Wash., nearly 50 years ago. Today, Bryan serves as vice president of the company. His brother, Tim Jr., is lead carpenter.

Their father remains involved as an advisor, and the third generation is beginning to take shape. Bryan’s son, Ethan, helps with digital content production.

From l to r: Bryan, Ethan, Tim Sr. and Tim Jr.

In addition to handling land acquisitions, project development, permitting, sales, job costing, and payroll, Bryan emphasizes constructing homes with a strong emphasis on conservation.

While the company constructs spec homes almost exclusively, it has also built all variety of custom and pre-sale homes. Over the years, Pioneer’s emphasis on efficiency and green building technologies has outpaced Washington state’s stringent energy code, which is one of the strictest in the nation.

Taking the Next Step

“In 2024, we made a commitment to construct Zero Energy Ready homes,” said Uhler. “This is a certification through the Department of Energy (DOE) for homes built to a rigorous set of requirements, providing high levels of energy conservation, comfort, health and durability. Through the Inflation Reduction Act, homes built to this standard can qualify for the 45L tax credit worth $5,000.”

The goal behind Zero Energy Ready homes is to provide residences that are so efficient, a renewable energy source could offset the home’s power consumption. All of Pioneer’s spec homes are also ENERGY STAR certified.

As important as energy conservation is, the recent fires in southern California are the latest reminder that water conservation may soon be the nation’s greatest challenges.

Concentrating on Water Conservation

“Conserving water is as big an environmental concern as reducing energy consumption,” said Bryan. “If you curb domestic hot water use, you achieve both.”

For years, Pioneer Builders has specified water-conserving fixtures. They use Gerber’s line of faucets, toilets and shower heads.

“With properly designed equipment, the homeowner can reduce household water consumption without sacrificing comfort or even being aware of the fact that they’ve reduced water use,” said Bryan.

Bryan Uhler displays how Pioneer Builders pairs a heat pump water heater with Taco’s SmartPlus-e recirculation system.

This principle is carried into the mechanical room, where Pioneer Builders partners with Herdman Plumbing. Heat pump water heaters are used in all Pioneer’s homes. While this provides energy savings and eliminates on-site fossil fuel consumption, it does present one challenge.

“Our homes feature domestic hot water circulation, which saves a great deal of potable water, not to mention increasing the comfort level,” said Bryan. “The issue is that heat pump water heaters and conventional DHW recirculation systems don’t play well together. I’m willing to admit that we’ve done everything wrong at least once, and this is no exception.”

By using the Taco SmartPlus-e, Pioneer Builders avoids the pitfalls caused by pairing a heat pump water heater with a DHW recirculation pump.

The number one issue when pairing these two technologies is that a DHW recirculation system that runs continuously tends to disrupt stratification within the water heater. Recirculation lines, even when properly insulated, also shed heat while circulating, causing the heater to recover when the cooler water returns to the tank.

This often causes the heater to operate when there isn’t a call for DHW or switch the unit from heat pump mode to electric resistance backup. Not all recirculation pumps are created equally. Some pumps – specifically those that don’t feature ECM motors – are inefficient, and this raises the HERS rating. That’s a bad thing for an energy conscious contractor.

“I didn’t know there was a solution until Eric Aune from Mechanical-Hub suggested I look at Taco’s SmartPlus-e recirculation system,” said Bryan. “He explained that the system paired a small ECM circulator with a smart control, eliminating the problems caused by constant circulation. That’s a winning combination.”

The recirculation system’s temperature sensor is installed under pipe insulation on the hot water supply line.

The SmartPlus-e includes two components, a 006e3 circulator and a SmartPlug control, which can be paired with any recirculation pump. The SmartPlug can operate in Pulse mode, which continuously cycles the pump on and off, or Smart mode. In Smart mode, the control records hot water use patterns in the home and only operates the pump according to those patterns.

“We’ve found that the SmartPlus-e system helps us hit some of the benchmarks needed to achieve ENERGY STAR certification,” Bryan shared. “Our projects range from around 2,500-4,000 square feet with about the bathrooms. With the water heater in the garage, the potential to save water and energy with a recirculation system is considerable.”

A Holistic Approach

Bryan makes it evident that creating a durable, healthy, energy efficient home can’t be achieved by selecting one or two energy-efficient products and adding a bit more insulation. It’s a holistic approach that begins in the design phase and continues through to educating the homeowner during the final walk-through.

One of the biggest changes Pioneer has made over the past decade, especially with the use of air-to-air heat pumps, is to bring the ductwork into the conditioned space. This saves a great deal of energy being lost to the attic.

Another improvement is the careful selection of building materials in the interest of indoor air quality. Natural materials like hardwood flooring and rockwool insulation reduce the VOCs in newly constructed homes.

“We insist that each of our homes provides comfort while actively contributing to the health of its occupants and the preservation of our environment,” said Bryan. “That typically means making a lot of little improvements to the built environment, rather than one big change.”

Check out Pioneer Builders at pioneerbuildersonline.com.

Taco has announced the launch of its innovative Manager Development Program (MDP), a transformative global initiative designed to cultivate leadership and foster professional growth. Developed in partnership with DDI and DiSC, the program reflects Taco’s dedication to investing in the development and success of its people. “At Taco, our employees are at the heart of Read more

Taco has announced the launch of its innovative Manager Development Program (MDP), a transformative global initiative designed to cultivate leadership and foster professional growth. Developed in partnership with DDI and DiSC, the program reflects Taco’s dedication to investing in the development and success of its people.

Taco has announced the launch of its innovative Manager Development Program (MDP), a transformative global initiative designed to cultivate leadership and foster professional growth. Developed in partnership with DDI and DiSC, the program reflects Taco’s dedication to investing in the development and success of its people.

“At Taco, our employees are at the heart of everything we do,” said Cheryl Merchant, CEO of Taco Family of Companies. “By nurturing our team’s talents and equipping them with essential tools, we not only unlock their full potential but also drive our collective success and growth as a global organization.”

The MDP is designed to meet the unique needs of managers while aligning with Taco’s strategic vision. With a focus on clarity and effective communication, the program ensures that content is accessible and actionable, thereby enhancing overall interactions and interpersonal skills.

“Taco is committed to advancing global employee development through cutting-edge programs and key alliances,” said Victoria McCoy, EVP of Global Human Resources at Taco. “Our collaboration with DDI and DiSC marks a significant shift from traditional learning and development practices to a more strategic approach that aligns with our organizational goals. Together, we’ve crafted a program that embodies Taco’s values, culture, and objectives, ensuring a unified leadership strategy worldwide,” concluded McCoy.

In essence, the MDP integrates modules that aim towards developing self, managing others and leading the organization. By providing a cohesive leadership framework across all regions, the program helps Taco forge meaningful connections and empowers its employees to reach new heights.

For additional information about the MDP or to explore career opportunities at Taco, please visit the Careers page at www.tacocomfort.com/careers.

Providence, R.I. – The first annual John Hazen White III Memorial Tribute was held under sunny skies on Saturday, April 27, at Narragansett Brewery. It was a memorable day filled with unity and celebration. Participants included Taco employees, cherished family members, dear friends, and valued partners at Community Preparatory School. The event began with a Read more

Providence, R.I. – The first annual John Hazen White III Memorial Tribute was held under sunny skies on Saturday, April 27, at Narragansett Brewery. It was a memorable day filled with unity and celebration. Participants included Taco employees, cherished family members, dear friends, and valued partners at Community Preparatory School.

The event began with a meaningful one-mile walk/run, symbolizing the shared commitment to our community and its well-being. The slogan, “Come Walk or Run in Memory of Maddie’s Daddy,” provided an extra special, heartfelt incentive.

Following the walk/run, the festivities continued at the brewery, where attendees enjoyed live music, delicious food, and the joyous camaraderie of being together. It was a time to reflect on the impact of John Hazen White III’s legacy and to honor his vision of making a positive difference in the lives of others.

“Seeing everyone here today means so much to us,” said Kate White, Corporate Social Responsibility Partner at Taco. “This is exactly the type of event that John would have loved—an opportunity to spend time together with family and friends for such a wonderful cause. We wish he was still here, but we know he lives on in all of us,” Kate mused.

“Seeing everyone here today means so much to us,” said Kate White, Corporate Social Responsibility Partner at Taco. “This is exactly the type of event that John would have loved—an opportunity to spend time together with family and friends for such a wonderful cause. We wish he was still here, but we know he lives on in all of us,” Kate mused.

John H. White, Jr, Executive Chairman and Owner of Taco, reflected on the day. “Today’s event was truly special. Sharing time together with friends, family and the Taco community is the perfect way to celebrate John’s life and the joy he brought to all those who knew him,” said John.

“We are so thankful for everyone joining us here to pay tribute to John,” said Ben White, Program Manager, Business Operations at Taco. “He made us all better people and continues to have a positive impact on our lives. As we have been saying, love is not a big enough word when it comes to John,” concluded Ben.

“We are so thankful for everyone joining us here to pay tribute to John,” said Ben White, Program Manager, Business Operations at Taco. “He made us all better people and continues to have a positive impact on our lives. As we have been saying, love is not a big enough word when it comes to John,” concluded Ben.

We invite you to consider donating to the John Hazen White III Endowed Scholarship fund at Community Preparatory School. Your generous donations will help us continue his legacy of empowering young minds and transforming lives. Details on how to donate can be found at https://bit.ly/44inhTJ.

Taco Hydroflo Pump Solutions has opened a new state-of-the-art facility in Lubbock, Texas. The site opened on February 21, and substantially expands the operations of the Taco Family of Companies. Taco is headquartered in Cranston, RI. Hydroflo’s new 45,000 s.f. location in Lubbock, Texas, is in the manufacturing and transportation hub of northwest Texas, 40 Read more

Taco Hydroflo Pump Solutions has opened a new state-of-the-art facility in Lubbock, Texas. The site opened on February 21, and substantially expands the operations of the Taco Family of Companies. Taco is headquartered in Cranston, RI.

Hydroflo’s new 45,000 s.f. location in Lubbock, Texas, is in the manufacturing and transportation hub of northwest Texas, 40 miles north of its prior location in Brownfield, Texas. With the new facility also comes the advantage of added space for future growth, additional capabilities and team expansion.

“The opening of this new Taco Hydroflo Pump Solutions facility signifies a renewed focus on ensuring that our customers have access to the most dependable high quality vertical and submersible pumps in the market,” noted Cheryl Merchant, President and CEO, Taco Family of Companies. “Our investment in the infrastructure, testing equipment and expanded workforce is just the beginning of the next phase of the Hydroflo story.

“I would like to extend my thanks and gratitude to our new landlord, Randy Teinert, the City of Lubbock, and the Lubbock Chamber of Commerce,” continued Merchant. “Family is at the core of everything we do at Taco, and I want to thank all of you for making us feel like family. Your warm welcome to this community has made all the difference.

“The Hydroflo team, along with the more than 1,200 Taco team members, are leading us into the future,” she added. “A future of opportunity, a future of growth and a future of well-earned success.”

According to Hydroflo’s Director of Sales, Clay Williams, the facility substantially expands their manufacturing, warehouse and quality control operations. New manufacturing equipment was purchased for the facility, and a state-of-the-art test pit have expanded their testing capabilities as well.

“The new test pit is much larger and deeper and greatly improves our range of testing,” explained Larry Jones, Hydroflo VP. “We now have the ability to test all current pump models, something we previously had to outsource.”

Hydroflo manufactures a wide range of submersible turbine, vertical axial-flow, vertical mixed-flow, and vertical turbine pumps for use in the agricultural, commercial, industrial, municipal, marine, mining, and power generation markets. The company uses high-quality ductile iron discharge heads and fabricated steel or 316 stainless steel L, F, and T style heads. Ductile Iron bowl castings with impellers in 201 stainless steel impellers are also used for greater strength. For applications that require resistance to corrosion, Hydroflo offers castings and impellers in 316 stainless steels in order to provide the best materials of construction to meet specific application needs.

Taco Hydroflo Pump Solutions is an integral part of the Taco Family of Companies, an expanding global network of industry-leading brands that strive to be the first source for durable, high-efficiency heating, cooling, plumbing and fluid-control solutions that help its customers save money, energy and resources while maximizing comfort and productivity.