Watts Celebrates 150 Years with Year-Long Sweepstakes for Customers in the U.S. and Canada North Andover, MA-based Watts is excited to announce the launch of the “Learn Today, Lead Tomorrow” 150th Anniversary sweepstakes, a year-long celebration in honor of a century and-a- half of water technology excellence and innovation. The sweepstakes is open to customers Read more

tekmar

Watts Celebrates 150 Years with Year-Long Sweepstakes for Customers in the U.S. and Canada

North Andover, MA-based Watts is excited to announce the launch of the “Learn Today, Lead Tomorrow” 150th Anniversary sweepstakes, a year-long celebration in honor of a century and-a- half of water technology excellence and innovation. The sweepstakes is open to customers of any brand in the Watts family of brands across the United States and Canada, offering an opportunity to “learn and earn” prize packages all year long.

Sweepstakes Period

The sweepstakes is live and will run through December 31, 2024. This program celebrates the customers whose support has allowed Watts to reach this milestone by offering monthly and quarterly prizes, along with a grand prize trip for two to Boston, MA.

Participation Details

Eligible participants can “learn and earn” limited time only tickets redeemable for sweepstakes entries. One ticket equals one entry. Customers can earn tickets through any of Watts’ professional training opportunities, including eLearning through Watts Works Online, Lunch & Learn sessions, and in-person training at any Watts Learning Center. For specific eligibility requirements, visit watts.com/150sweepstakesrules.

How to Participate

For more information, those interested are encouraged to visit watts.com/150sweepstakes. For the official rules, including how to enter, eligibility requirements, prize package details, and how to enter, please visit watts.com/150sweepstakesrules.

Way back in 1987, ASHRAE experts developed the BACnet protocol as a communications standard for Building Automation Systems (BAS). BACnet has since earned the respect of specifying engineers, facility managers, controls experts and service technicians worldwide as it’s now the leading technology in building automation. BACnet offers an open architecture and the ability to control Read more

Way back in 1987, ASHRAE experts developed the BACnet protocol as a communications standard for Building Automation Systems (BAS). BACnet has since earned the respect of specifying engineers, facility managers, controls experts and service technicians worldwide as it’s now the leading technology in building automation.

BACnet offers an open architecture and the ability to control and monitor any building automation process—from water sourced heat pumps and chillers to boilers and volume water heaters.

At North Andover, Mass.-based Watts, one of the largest and most diverse manufacturers in the plumbing and mechanical and HVAC market, BACnet has been incorporated into several of its brands’ technologies, most notably through its HVAC and snow-melting controls brand, tekmar; “IntelliStation” digital mixing stations for commercial domestic water control and tempering by their brand, Powers; and for Benchmark boilers and Innovation water heaters (via their “EDGE” controller), offered by the company’s brand, AERCO.

“For us, BACnet is so useful because it’s a standardized communication protocol that interconnects and ‘talks to’ all other BAS-connected technologies throughout an entire facility, and also facilitates remote monitoring and control,” said Amar Dhore, AERCO Software Engineering Supervisor. “When fully integrated, all communications can work through one BACnet device. That’s the advantage of standardization, and what it enables.”

New York-based AERCO is one of the nation’s leading suppliers of commercial condensing boilers and water heaters for a variety of industries. Several years ago two of AERCO’s brands—Benchmark boilers, andInnovation water heaters—adopted the use of BACnet to offer sophisticated communications through their EDGE controller and ProtoNode gateway, the key interfaces to BAS for legacy system communications.

AERCO offers a multi-protocol, communications gateway to support integration with customers’ building automation (BAS) and energy management systems (EMS). The plug-n-play package supports build in integration with BACnet/IP, BACnet MS/TP, Modbus RTU, Modbus MSTP. AERCO also has a ProtoNode Gateway to support legacy products like Benchmark standard, Modulex EXT boilers; Innovation and SmartPlate water heaters.

AERCO offers a multi-protocol, communications gateway to support integration with customers’ building automation (BAS) and energy management systems (EMS). The plug-n-play package supports build in integration with BACnet/IP, BACnet MS/TP, Modbus RTU, Modbus MSTP. AERCO also has a ProtoNode Gateway to support legacy products like Benchmark standard, Modulex EXT boilers; Innovation and SmartPlate water heaters.

AERCO’s EDGE features built-in translation for BACnet/IP, BACnet MS/ TP, Modbus RTU and Modbus TCP protocols; these communications are selectable and configurable via touch screen (No DIP switch needed). With this easy access to data, customers have ready access to more data. They can also choose and map BAS points of his interest to access, control and monitor devices.

In fact, the company’s Benchmark Platinum boilers can be managed effectively with an app that connects with the EDGE controller. With the app, a service technician or facility manager can monitor or balance hydronic system flow, perform a wide variety of system diagnostics, or combustion analysis and calibration.

For building owners, the EDGE permits trouble-free management of all boiler/water heaters functions—whether one unit or up to 16 units, connected in a cascade.

The EDGE controller also permits flow balancing—a function that allows elimination of balancing valves and also reduces commissioning costs, one of many operations enabled through the built-in communications via BACnet IP, BACnet MS/TP, Modbus IP or Modbus RTU.

Start-up and maintenance functions are also simplified. Boilers +/or water heaters can be calibrated through assisted or manual operations, a big time-savings advantage. The assisted options offers guided steps that automatically adjust precise air/fuel ratios for optimal performance.

AERCO access and control security:

AERCO managers understand the importance of security and have taken steps to make BAS communication secure. EDGE offers built in security using IP and MAC address. Once the security is enabled, user needs to enter front end BAS MAC and IP address. Once done, Edge will only accept the communication from the BAS with specified MAC and IP address.

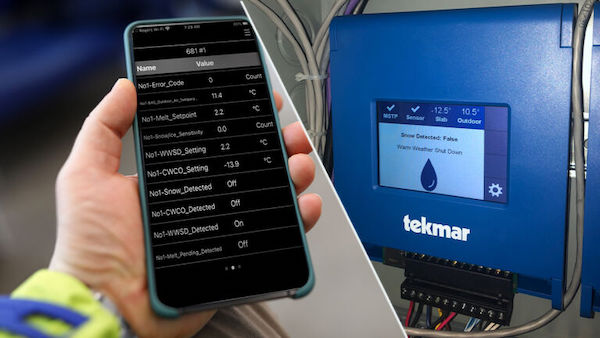

tekmar’s 680, 681 + 284

Vernon, BC-based tekmar Control Systems, a Watts brand, is a world class integrated engineering and manufacturing company that provides solutions for the HVAC industry. For the past 38 years, tekmar has earned a reputation as the leader in complete control solutions for hydronic radiant floor and baseboard heating systems, multi-stage boilers plants, and automatic snow melting controls.

tekmar provides energy-saving control solutions for a broad range of hydronic systems—whether within a building, or outside (for snowmelt or turf-warming)—while assuring no-compromise comfort control, system efficiency and durability.

The company’s technologies provide:

- Setpoint controls—offering precise temperature control for domestic water storage tanks, pools and hot tubs.

- Boiler + domestic water controls—These technologies are designed to control temperature and operation of multiple boilers or volume water heaters. Multi-staging controls provide significant energy savings while also enhancing system reliability.

- Heating controls—Here, tekmar offers controls to provide zoning solutions for heating systems; specific models are designed for use in hydronic heating, radiant heating, HVAC systems, and baseboard or “hydro-air” applications.

- tekmarNet 4 zoning controls—These technologies connect to thermostats to control operation of heating system zone valves or heat pumps for precise delivery of heat.

- Snowmelt control and sensors—Snowmelt control systems measure and control road, driveway or walkway surface temperatures to provide safe, snow- and ice-free surfaces, and at the lowest operating cost. Controls may connect to electric or hydronic systems as the source of warmth. Fully automatic controls, or manual controls can be chosen.

“Our specialties are boiler and snowmelt system controls,” explained tekmar’s Cleber Alves. “One of our unique products is the new BACnet snow/ice sensor interface 681—designed to measure the presence of snow or ice and interfaces with the BAS to activate or deactivate electric or hydronic snow melting systems.”

According to Alves, the 681 uses tekmar sensor technology to automatically detect precipitation, then communicates with the BAS through BACnet MS/TP. This operation allows the BAS to automatically turn the heat source and distribution system on, or off, and provide operational status for all snow-melt functions. The 681 is ideally suited for commercial applications such as hospitals, schools, airports, ski resorts, business entrances, driveways, loading docks, and shopping malls.

According to Alves, the 681 uses tekmar sensor technology to automatically detect precipitation, then communicates with the BAS through BACnet MS/TP. This operation allows the BAS to automatically turn the heat source and distribution system on, or off, and provide operational status for all snow-melt functions. The 681 is ideally suited for commercial applications such as hospitals, schools, airports, ski resorts, business entrances, driveways, loading docks, and shopping malls.

The 681’s features include slab target temperature, automatic snow and ice detection, error codes, warm weather shut-down, melt pending function, cold weather shutdown, and supports both in-slab and retrofit aerial sensors—all with BACnet MS/TP communication.

IntelliStation digital water control

Public safety relies chiefly on the availability of clean water. As it can affect water quality, the condition of premise (building-specific) plumbing systems have a direct impact on the safety of those within the facility. The ability to remotely monitor and control water temperature, flow, and other parameters in a quick and precise way is vital to delivering healthy, safe water in an efficient manner.

Patents held by Powers, a Watts brand, function as the backbone for many products in commercial and industrial water temperature control markets. The company develops and manufactures thermostatic and digital mixing solutions to bring safety and comfort to modern plumbing systems.

“IntelliStation and IntelliStation Jr. [a smaller version] digital water mixing systems are designed to deliver tempered hot water throughout a recirculation loop in commercial and institutional facilities,” explains Sr. Product Manager Bruce Fathers. “Our digital solutions can be integrated into a BAS to allow facilities managers to remotely monitor and control water temperatures.

“We offer most of the common protocols, with gateways to others if need be,” added Fathers. “Modbus and BACnet are native to our controller, so it’s integrated into our IntelliStation products with no additional cost. Most of our competitors do require an additional module at an added cost to facilitate BACnet. So, it’s become a competitive edge for us, one our customers have come to appreciate.”

According to Fathers, BAS is used to seamlessly monitor and control important facets of system operation—such as mixed outlet temperature, pressure, flow, and inlet temperature. The sensors all require connection/input points.

“For commercial domestic water systems, mixed outlet temperature is most important,” explained Fathers. “It’s typically set at 120°F, or 140°F—to either render [biogens/pathogens] unable to reproduce, or to outright kill them [point-of-use mixing valves are then used at showers and faucets to protect users. Facility managers have remote visibility to all critical datapoints.

Fast, responsive digital technology enables the collection of a large amount of data which can be stored and communicated through a building automation system (BAS) or locally at the controller, providing intelligence at the foundation of the entire plumbing system.

Internet of Water

Control of the water recirculation loop ensures safe, precise, and consistent water temperatures (+/- 2oF), supports energy conservation, and reduces energy costs. BACnet IP, BACnet MSTP, and Modbus protocols are supported.

Technology helps to fulfill these needs with digital mixing and connected components like sensors and cloud-based monitoring.

The extent to which COVID-19 has impacted public health and the increased prevalence of Legionella bacteria have highlighted the need for:

- Visibility of water temperature, flow, and quality even when off-site

- A way to remotely control water temperatures

- Automated monitoring and reporting of premise plumbing water parameters and facility management activity

- Connected products that help increase safety and efficiency

- Reliable ways to reduce the risk of Legionella and other harmful bacteria

BAS empowers facility managers and engineers to proactively prevent issues before they arise, rather than having to react to or attempt to mitigate issues once they’ve occurred,” added Fathers.

There are three main technology-driven components in a digital mixing solution:

- Sensors, serving as eyes and ears

- The controller’s algorithm (the “mind”)

- Electronic, high-speed actuated valve, continually responds to sensor inputs, to maintain set point

“Our digital mixing controller algorithm processes data from the mixed temperature outlet sensor and signals the actuator to make adjustments to maintain set-points in real time,” continued Fathers. “Sensors relay key system data for pressure, temperature and flow for troubleshooting and optimization.”

Building automation systems give facility managers the ability to see vital data, quickly make informed decisions, and act, even remotely. Digital water mixing controls hot water delivery through a programmable valve or system that processes temperature, flow, and pressure data.

Serious risks, such as Legionella growth, scalding, and thermal shock are associated with mismanaged water temperature. Legionella bacteria are destroyed almost instantly at water temperatures above 160°F, but at temperatures between 70°F and 115°F, their growth is abundant. The Catch 22 is that uncontrolled and unmonitored water distribution systems can create high-temperature scalding hazards in bathtubs, sinks, and showers.

A proactive monitoring program can help reduce risks, predict trends, and improve operational efficiency. Proactive monitoring enables three key control measures that help address modern-day public safety risks:

- Allows for quick decisions based on real data

- Allows facility managers to more easily manager their systems

- Generates automatic reports showing trends and performance

Fortunately, there’s no Catch 22 to the use of BACnet technology. It facilitates fast, reliable communications between all facets of the network it operates in. Watts and its brands rely on BACnet for many operational uses, successfully, and with no compromise.

Domestic Water’s Creepy Challenge It’s a, well, creepy sort of problem. That is, when hot water recircs lose their ability to govern themselves. So, there’s the problem. But, let’s back up just a bit. Let’s start with an explanation. Then we’ll talk to the experts. There’s little debate that residential or light commercial domestic hot Read more

Domestic Water’s Creepy Challenge

It’s a, well, creepy sort of problem. That is, when hot water recircs lose their ability to govern themselves. So, there’s the problem.

But, let’s back up just a bit. Let’s start with an explanation. Then we’ll talk to the experts.

There’s little debate that residential or light commercial domestic hot water recirculation (DHWR) technology has proven its value in the world of plumbing and mechanical systems. The devices guard our safety, comfort and health. Hot water recirc systems move potable hot water to fixtures quickly, without waiting for the water to get hot, so there’s less wasted water, and time.

The key challenge to these simple systems is the problem of “hot water creep.” Let’s take a closer look, beginning with an examination of the components that have a role in the recirculation of a home’s domestic hot water.

Let’s first define the “system” After all, the various components, if not connected intelligently and working in concert, would accomplish nothing:

- Water heater without a tempering/mixing valve. Essentially, an unprotected, full-on arrangement that places anyone at risk.

- Water heater with a distribution tempering/mixing valve (typically, and ASSE 1017, or ASSE 1070 valve). This is most common, and became the point of introduction for DHWR systems.

- Water heater with distribution tempering/mixing valve with a DHW recirculation pump and a bypass valve or pump located at the domestic water system’s most remote fixture – with use of the cold water line as a means of returning water to the water heater.

- Water heater with distribution tempering/mixing valve with a DHW recirculation pump and a dedicated return line from the most remote fixture on that particular hot water zone. Ideally, this is how a DHWR system is installed.

- Finally, all of the above, to include a control of some means; aquastat, timer or combination control with some kind of logic.

“It takes some, or several of the components above, to make a DHWR system,” explained Rick Mayo, product and applications instructor, Western region, Taco Comfort Solutions.

Most recirc systems, by design, have a tempering valve that continuously adjusts its temperature when water flows through it – while tempering (that is, mixing) it with cold water – to maintain proper outlet water temperature for rapid release at points of use.

The challenge is to maintain the mixed water temp during periods of no demand. The reason for this: the recirc’s pump enables flow through the valve, even when there’s no demand, or draw, from points of use – such as faucets and other fixtures. For this reason, recirc pumps must be piped so that the recirc’s returning flow can reach both the cold connection of the valve as well as the cold connection of the heat source. Some balancing may be required.

Smart, by design

Typically, a water heater’s storage temperature is set for about 140°F for legionella mitigation, and the DHWR’s hot water temperature is reduced to under 120°F at the mixed outlet connection of the valve (with the reduced temp made possible by mixing with cold water, by design).

This cause the valve assembly to adjust temperature; that is, until it reaches the hot water’s set-temp. The internal thermostat adjusts the piston to open the cold port and close the hot port, allowing hot water to recirculate. Unfortunately, there can be challenges to the intended function of these systems.

- Creepy situation #1: If the hot water distribution system isn’t insulated, this can cause the distribution loop temperature to creep down during periods of no demand.

- Creepy situation #2: Domestic water systems installed with a domestic hot water recirculation pump may cause downstream water to overheat if it’s not piped properly or is running longer than required. This overheating of temps within the piped system may go unnoticed for quite a while and could cause risk of scalding at points of use.

Mayo offers this insight: The ASSE 1070 valve does a better job of restricting flow of the hot water than the ASSE 1017 and is more effective at preventing “creep.” He clarifies: “Don’t get me wrong. Those ASSE 1017 valves work as intended in non-recirc systems. If the temperature is set for 115°F, they regulate the temperature to that point, almost assuredly. But as soon as you match ‘em up with a (DHW) recirc, problems can begin.”

- Creepy situation #3: Make sure there’s always sufficient flow to meet the DHWR valve’s minimum flow requirement. All DHWR control valves need a certain amount of flow to function properly. A properly sized, recirc pump will usually assure sufficient flow.

- Creepy situation #4: A point-of-distribution, ASSE 1017 mixing valve (or, for that matter, even the ASSE 1070 valve) that does not have a full or completely closed function for its hot inlet port can cause thermal creep if not properly piped and controlled; many mixing valves with an electronic actuator have a fully-closed position so that this doesn’t occur.

Piped conundrum

“It’s often a piping challenge,” said tekmar’s General Manager, Greg Leupin. “For many hot water recirc ‘creep’ challenges, the challenge has to do with incorrect piping. When the recirc is off or at rest, thermal ‘ghost flow’ can affect the amount of hot water that makes its way into the [distribution] piping.

Leupin added that many recirc loops lack a mixing valve, causing excessive – sometimes unsafe – temperature in the recirc loop, increasing the risk of scalding. This can also lead to inefficiency from heat loss, especially when the domestic water lines aren’t insulated.

Smart technology

Manufacturers have stepped in to help negate the risk of domestic water creep when recirc systems are installed. “Installation instructions are more explicit and the technology’s improved,” said Mayo.

“The problem begins when there’s an inability to dissipate the heat during periods of no demand,” added Mayo. “As referenced earlier Some [DHWR] devices close the hot side better than others, so both the built-in control strategy may help, as does the installation piping. Of course, the recirc shouldn’t be running when the distribution system’s already sufficiently full of hot water, readily accessible at taps and other points of use.”

- Taco SmartPlug (which won AHR Expo’s Product of the Year Award in 2017) was developed to eliminate the hassle of a “timer;” because of their design they only allow water to be circulated for short periods of time, this can help fight the challenge of thermal creep. The small device instantly changes any corded hot water recirc – for instance, those with just timer and on/off function – into a “smart” device by giving it the intelligence it needs to learn a household’s usage patterns to improve and regulate hot water distribution, increasing comfort and efficiency. It can also be set into a ‘pulse only’ mode for light commercial applications, or for homeowners who don’t have a predictable schedule.

Other hot water recirc solutions include:

- TacoGenie allows homeowners to simply push a button when hot water is desired at a tap, on demand.

- Watts/Premier 500800 – an ideal solution for retrofitting existing domestic water systems with hot water recirc. The device uses the pump at the water heater (though not tankless systems) and an under-sink sensor valve to create a pressure differential – allowing the cold and cool water in the hot water supply line to bypass into the cold water supply line at a low volume through the thermostatically-controlled sensor valve, keeping the water in the hot water supply line at a “no-wait” temperature throughout the home.

ASSE 1070 valve

As Mayo stated earlier, ASSE 1017 thermostatic valves installed at the water heater or heat source may not close off sufficiently in some instances (while the circulator is running) to stop the outward flow of heat. If this happens, and a recirc pump continues to run, temperatures within the distribution piping can creep upward – creating the potential for unexpectedly hot water at taps.

In a situation like that one, the need for hot water [in the distribution piping] is satisfied, but if the [DHWR] pump’s running, ‘creep’ can occur,” concluded Mayo. “Yet another solution protects users from unexpectedly high temps at the tap with or without replacement of the distribution safety valve – and that is the installation of 1016 or 1070 point-of-use valves. They’re most often used for commercial installations, though there are many residential uses of the valves.”