The modular system with pre-mounted hydraulics is flexible, durable and compact, offering a lightweight and affordable solution for water and electrical line projects. PE Equipment, an innovator in trenchless technology solutions, has announced the launch of its PE-10 2-in-1 system that includes both pipe bursting and rod pushing capabilities in a single machine. The advanced Read more

trenchless technology solutions

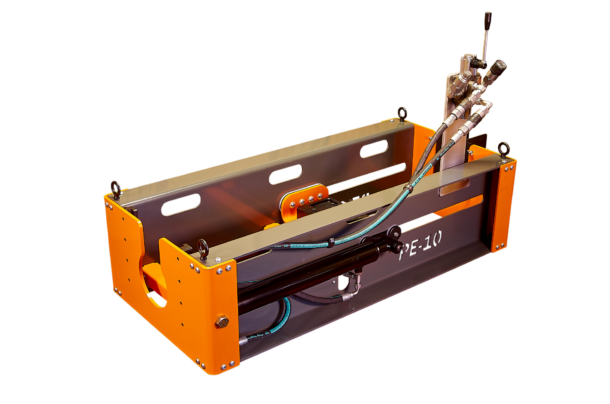

The modular system with pre-mounted hydraulics is flexible, durable and compact, offering a lightweight and affordable solution for water and electrical line projects.

PE Equipment, an innovator in trenchless technology solutions, has announced the launch of its PE-10 2-in-1 system that includes both pipe bursting and rod pushing capabilities in a single machine. The advanced design simplifies operation and enhances productivity, setting a new standard in the trenchless technology industry. This system, measuring 47 inches long, 23 inches wide and 31 inches tall, offers unmatched portability and is easily carried by two people. Engineered for quick adaptability, the PE-10 allows for seamless module changes in just 5-10 minutes, eliminating the need for multiple machines on the job site.

Key Features:

- Hydraulic Operation: The system plugs directly into excavators, running off their existing hydraulic capabilities, negating the need for additional power units.

- Modular Design: The tool’s unique design allows for easy attachment exchange, enabling pipe bursting and rod pushing on a single chassis.

- Flexibility: Designed to adapt to various ground conditions, including rocky clay and other challenging soils, excelling in diverse terrains and environments.

The rod pushing module is designed for installing or replacing service lines, either following existing ones or pushing through new ground. After pushing rods, a pullback device brings the new line through. Its quick-access rod locking mechanism simplifies insertion and removal, and different piercing heads offer flexibility for various tasks. The standard Pushing Head handles fresh ground, while the Bladed Pilot Head follows and replaces existing lines. An optional sonde housing provides real-time tracking during the push.

The pipe bursting module replaces service lines from ¾″ to 3″ in diameter, with cable pull lengths up to 150′ and speeds up to 13′ per minute, depending on soil conditions. The Chassis Mount Pipe Splitter prevents pipelines from blocking the pulling module’s function due to pipe pullout. The Open-Pathway Gripper System allows easy cable removal if broken pipes interfere. In small pit spaces, the Vertical Cable Guide efficiently routes the cable, making it ideal for small crews or solo operators. For pipes under 2″, the 4-blade pre-splitter splits the pipe ahead of the bursting head and can be re-sharpened to reduce replacement costs.

“Our PE-10 evaluation unit has been in constant use, and it’s still going strong,” said Kurt Fosson at Trenchless Solutions. “The machine is reliable. Because of the 2-1 design, we’ve been able to complete jobs faster with fewer resources, saving us time and money.”

“Our goal was to simplify the process for contractors and plumbers in the field,” said Brandon Boyce, CEO of PE Equipment. “Traditional systems often require separate machines for different tasks. With our design, operators can switch between pipe bursting and rod pushing modules, saving time, space and money on equipment.”

For more information or to watch a demonstration video, please visit our website or contact Ethan Waltman at info@pe-equipment.com.

PE Equipment will demonstrate the 2-in-1 pipe bursting and rod pushing system at WWETT25, February 17-20, 2025, Booth #3418. Attendees can speak with company representatives.