By joining forces with Uponor, GF is set to become a global leader in sustainable water and flow solutions. To support this ambition, complementary businesses will be grouped together under one roof: the new division GF Uponor will focus on Building Technology, whereas the infrastructure and utility business will move to GF Piping Systems. Michael Read more

Uponor

By joining forces with Uponor, GF is set to become a global leader in sustainable water and flow solutions. To support this ambition, complementary businesses will be grouped together under one roof: the new division GF Uponor will focus on Building Technology, whereas the infrastructure and utility business will move to GF Piping Systems. Michael Rauterkus will join GF’s Executive Committee and will lead the new division together with his Uponor leadership team.

After all conditions of the tender offer have been fulfilled, GF closes the transaction as of 13 November 2023.

To accelerate the implementation of GF Piping Systems’ Strategy 2025 and to further benefit from global megatrends, GF will start an ambitious value creation program to unleash the full potential of this acquisition. GF Piping Systems will focus on the industrial and utility business, providing its customers with sustainable leak-free piping solutions for numerous end markets such as microelectronics, water treatment, energy, chemical processing, marine, data centers or water & gas utilities. Uponor’s infrastructure business will become part of GF Piping Systems and will further strengthen the division’s portfolio to provide customers with combined solutions.

In the new division, GF Uponor, the building technology businesses will be combined to offer a complementary portfolio for safe and clean water, as well as energy efficient heating and cooling. The consolidation of complementary businesses provides an ideal platform to develop markets with high potential for both divisions. As the brand Uponor stands for high quality and innovation, it will drive growth in intelligent Building Flow Solutions.

These organizational changes will be implemented during the course of 2024 while GF will ensure operational excellence and business continuity to customers.

“We will continue to implement our strategy, and leverage powerful global trends, such as the need for safe and clean water, or more efficient energy use,” GF CEO Andreas Müller said. “On behalf of all my colleagues, I am happy to welcome Uponor employees and start this new chapter together.”

Beginning in early 2020, supply-chain disruptions and unprecedented construction-materials demand resulted in an influx of F1960 engineered polymer (EP) fittings from various manufacturers and suppliers located around the globe. Unfortunately, some of these “F1960” fittings are not actually manufactured or tested to the same standards as the Uponor ProPEX® F1960 fittings, and contractors are learning a Read more

Beginning in early 2020, supply-chain disruptions and unprecedented construction-materials demand resulted in an influx of F1960 engineered polymer (EP) fittings from various manufacturers and suppliers located around the globe. Unfortunately, some of these “F1960” fittings are not actually manufactured or tested to the same standards as the Uponor ProPEX® F1960 fittings, and contractors are learning a hard lesson about the differences when they experience a failure in their piping system.

In truth, not all fittings conforming to the ASTM F1960 standard are the same. Manufacturers and suppliers that claim their fittings are compliant to ASTM F1960 feel that, in their opinion, they meet the standard. However, there is no third-party agency to confirm that compliance. Uponor ProPEX fittings are a highly engineered product certified by a third-party agency — NSF — to ensure the raw materials, manufacturing process, and resulting product accurately meet the ASTM F1960 standard. In fact, the companies that mold ProPEX EP fittings are partners that are integrated into the codes, helping ensure the highest-quality product. ProPEX fittings also undergo internal quality testing that extends beyond the ASTM F1960 standard requirements to provide customers with the strongest value available on the market.

“It’s important that installers are aware they need to ask for the Uponor brand name from distribution and make sure they are getting what they are paying for in ProPEX fittings,” says Ann Studnicka, director, Channel Marketing at Uponor. “The differences are far beyond just the brand name. Uponor testing on generic F1960 fittings has exposed various manufacturing design and quality inconsistencies, and some fittings can’t even pass the ASTM F1960 standard requirements. This is putting projects at considerable risk for failures and potentially voids the associated system warranties.”

Over the past two years, Uponor has seen a significant increase in claims for failed connections that turned out to be other suppliers’ F1960 fittings. This trend confirms the theory that many contractors simply are not aware of the visual differences between ProPEX and generic F1960 fittings.

“Contractors and distributors need to be aware of the visual differences between ProPEX and low-quality F1960 fittings,” says Studnicka. “How can you tell? The easiest way is to look for the Uponor logo on the fitting.”

Other markers of ProPEX fittings include thicker tube stops and thicker sealing barbs. The thin tube stops on the generic, low-quality fittings are especially problematic as the expanded PEX pipe can extend past the stops and cause leaks.

With more than 150 variations of couplings, tees, elbows, plugs, and multiports in sizes up to 3″, Uponor provides the most comprehensive offering of F1960 EP fittings in the market. The ProPEX connection system is also covered by an industry-leading, 25-year limited transferable warranty when used with Uponor PEX-a pipe and ProPEX rings. And, it is important to note that mixing different suppliers’ fittings, rings, and pipe will lower the term or even void the warranty in some cases.

For further details about the differences with ProPEX connection systems, visit uponor.com/askforuponor. For information about all other Uponor products, systems, services, and solutions, visit uponor.com.

Vetter Plumbing, that is. If you’re ever in the Pacific Northwest, look up Doug Vetter, owner of Vetter Plumbing, Longview, Wash., and successful plumbing and heating contractor who has worked with the tools almost nonstop since graduating from high school in 1990. We recently rain into Doug at the pipe-cutting ceremony for Uponor’s Experience Center Read more

Vetter Plumbing, that is. If you’re ever in the Pacific Northwest, look up Doug Vetter, owner of Vetter Plumbing, Longview, Wash., and successful plumbing and heating contractor who has worked with the tools almost nonstop since graduating from high school in 1990. We recently rain into Doug at the pipe-cutting ceremony for Uponor’s Experience Center, and his passion for the trades is palpable.

Doug Vetter, right, has an infectious attitude, and enjoys living life like no one else.

In fact, you might say that young people searching for their true passion won’t likely encounter a more inspiring ambassador than Doug to a life in plumbing and heating.

There are, of course, a great many proud, highly accomplished professionals in this industry. But you’d be hard-pressed to find a tradesperson with a more robust and, at times, fearless outlook on life than Doug. He readily insists that much of this bring-it-on attitude derives from the sheer thrill of working as a service technician. “I just love my job,” he says over and over again.

For a small sampling of the sunny-side-up attitude Vetter brings to work each day, consider his morning routine of delivering doughnuts to the counter and warehouse staff at his favorite local supply house. Whoever heard of a plumber bringing free food to a wholesaler? “They have done lots of special stuff for me,” he cheerily reasons, “and, besides, it doesn’t cost that much.”

“My customers are always asking me, ‘Why are you in such a good mood today?’” he continues. “Well, when you contact me, we both know it’s not a social call. You have problems and fixing them may not be a ‘fun’ time for either of us. Why dump more stress on your situation by carrying a chip on my shoulder because I need to, let’s say, squeeze into your crawl space? Believe me, I hate crawl spaces. But being a plumber was my choice, and squeezing into crawl spaces is my job. That’s why you pay me.”

Doug willingly, happily, eagerly does his job 10 hours a day, seven days a week. But these are mere average—the actual totals could be much more in any given week. He would not have it any other way in a business that seldom lets him even slow down, let alone rest.

“I’ve never had a down time, even during the recent recession,” he says. “I just can’t say ‘no’ to people. That’s one of my downfalls and an issue with my significant other. But I love working.”

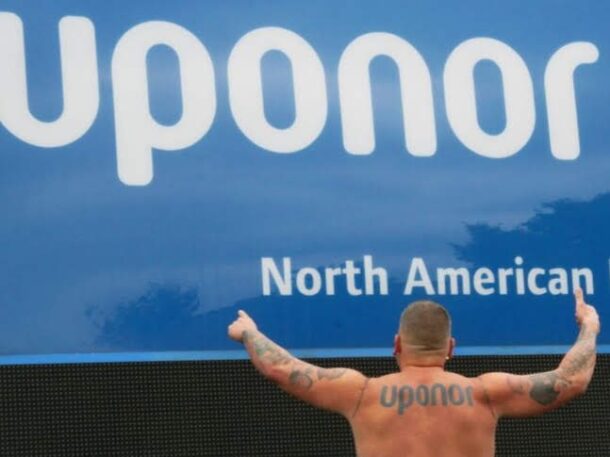

Back to the Uponor visit, Doug tells us that he is particularly proud of his tattoos, even the jaw-droppingly large U-P-O-N-O-R logo. Its six block letters span the full width of his back, left shoulder to right. Just as amazing: Every last ink mark strictly adhered to corporate style guidelines, right down to the correct shade of blue.

“I had a large blue Uponor sticker of the sort I put on my two trucks. I told my tattoo guy to put this exact thing on my back. He said, ‘Really?’ and I said, ‘Absolutely!’” Three grueling sessions over eight hours later, the tattoo was exquisitely in place and ready for show time whenever Doug decides to remove his shirt.

Why would he do something so “out there”? Why not? he shrugs. How better to express his unwavering loyalty to a brand he has supported nearly his entire career? “Uponor is the only brand I will put on my skin,” insists Doug, offering what is for him the ultimate compliment.

He fondly remembers his very first encounter with PEX more than 20 years ago, working for a Seattle plumbing wholesaler in the mid-1990s. Mark Walther — then a sales agent for the Portland-, Ore.-based Hollabaugh Brothers & Associates (still Uponor’s rep in the Pacific Northwest); and later a mentor for Doug when both worked at Merit Mechanical in Seattle—demonstrated the thermal memory of PEX with the familiar heat-gun demonstration that thousands have witnessed at countless trade shows over the decades.

Vetter’s work truck is radiantly heated.

“Mark said to me, ‘Watch this, Doug!’ After kinking the pipe in his hand, he used a simple heat gun to make that kink vanish in minutes. I will never forget that moment—it was the coolest thing, just incredible. Every chance I get, I love showing people the same demo with the heat gun.”

Doug readily embraces the problem-solving aspect of service work: “I love going into someone’s house, learning what’s wrong, explaining the situation in ways the customer can understand and appreciate, and then fixing the problem—and fixing it in the right way.

“I can’t just throw something together for a customer. I do my plumbing a certain way—the way I was taught all those years ago at Merit Mechanical, where I earned my journeyman’s license.”

As noted earlier, those young people you’re trying to steer toward a trade career won’t likely snag a first job with Doug, who has happily—defiantly even—worked solo for the vast majority of his professional life since starting his own business. Although, his wife, Liz, is going through her apprenticeship to join him as a licensed plumber in the business.

Vetter has a certain way of running his business. “I want my cords wrapped in a one-foot circle and put away in a particular spot. My truck, a big-box van, is spotless and organized a certain way, and I want to keep it that way. That one employee I had just couldn’t do it.”

Same thing for working with the tools, if not more so: “I’m not a hard ass, but my No. 1 job is to protect the health of my customers. If I fail to create a sewer-line joint properly, the customer will have a disaster. If I expand a pipe incorrectly, I’m flooding someone’s house. I do it right because my reputation depends on it, and my reputation is all I have.”

Another, equally critical facet of “Doug’s Way” is treating every customer the same—fairly and nicely. “Nobody, it seems at times, does customer service any more. For example: promptly calling someone back who has called you. I feel badly if a day goes by before my returning a call. Many don’t do it at all and think nothing of it.

“I was taught to treat people with the utmost respect, regardless of what they look like, where they’re from, or how much money’s in their pockets. I want to fix their plumbing, of course, but I also want to give them the best service they can get anywhere.”

Currently in his 50s now, Doug plans to work “until I just can’t do it any more”—before retiring to Puerto Rico, where he says the people are warm, the weather’s warmer, and the water’s warmest of all. Until then, he will stick to his 70-hour work week as a highly motivated service plumber who gladly shoulders more work than any one man should handle, despite doing no advertising or promotion other than word-of-mouth.

“I thrive on service work. I love the instant gratification of solving problems. I get up in the morning, hit the road to meet new people, and figure out how to help. Every job is different, and the days just fly by.”

“It’s like Disney World for engineers and contractors,” said one visitor on the tour. The Mechanical Hub team made a quick visit to Apple Valley, Minn., to visit Uponor North America as the company celebrated the grand opening of its newly constructed Uponor Experience Center with a “pipe-cutting” ceremony. The team was treated to a Read more

“It’s like Disney World for engineers and contractors,” said one visitor on the tour. The Mechanical Hub team made a quick visit to Apple Valley, Minn., to visit Uponor North America as the company celebrated the grand opening of its newly constructed Uponor Experience Center with a “pipe-cutting” ceremony.

Andres Caballero (fifth from left) performs the pipe cutting for the new Uponor Experience Center.

The team was treated to a behind-the-scenes tour of the new 4,500-sq.-ft. customer experience center, which features hands-on displays, full-scale residential and commercial training areas, and cutting-edge innovation showcases, and a place to bring MEP students from the area to get a taste of the trades. The new Uponor Experience Center is a flexible education and discovery space designed to advance the technical skills of current and potential customers. In addition, it will help foster innovation within the plumbing and HVAC industry and provide an immersive experience for employees and visitors alike.

Some displays mimicked true applications.

The new Uponor Experience Center occupies the company’s previous customer training area, which was originally built in 2000 and renovated in 2010. It is at the center of the North American headquarters campus, surrounded by corporate offices, an R&D facility, and manufacturing space.

Andres Caballero thanks his staff for all of the hard work and dedication that went into planning and constructing the experience center.

“The opening of our new Uponor Experience Center signifies the importance we place on keeping the needs of our customers, employees, and key stakeholders top of mind as we continue our mission of becoming the global leader in sustainable water and energy solutions,” says Uponor North America President Andres Caballero. “The ‘X’, as our employees have begun to call it, is a culmination of our rich history and decades of innovation coming together to generate awareness and create enthusiasm for moving water more efficiently, effectively, and sustainably.”

With original concepts beginning back in 2020, the Uponor Experience Center was several years in the making. The thoughtful design, which takes into consideration the company’s rich Finnish roots, resulted from many months of internal team collaboration, as well as feedback from customers, partners, and industry influencers.

Mechanical Hub took the opportunity to record parts of the Appetite for Construction podcast with Des Clancy, director of training, Uponor, and the “architect” for the new center.

As guests move through the front doors toward the back of the space, they first experience displays depicting who Uponor is as a company along with the customers served and the unique value provided to key audiences and the industry.

Experience center visitors will get the full hands-on treatment as seen here with one of its gracious partners Milwaukee Tool and its PEX Expander.

Then, there are product showcases and interactive displays for plumbing, fire safety, radiant heating/cooling, hydronic piping, and pre-insulated piping system solutions for residential and commercial markets. Finally, there is an oversized training area, featuring both wood and steel structures, where professionals will learn proper hands-on installation techniques as well as how Uponor’s emphasis on problem-solving and productivity delivers results for their businesses.

Doug Vetter, center, and Brian Spjut, left, from Vetter Plumbing, came all the way from Seattle to get a first glimpse of the space. (Pictured right is Uponor’s Dan Hubbard.)

“We wanted the Uponor Experience Center to extend beyond simply training customers on our products and systems,” says Vice President of Sales Matt Bahr. “As a result, we’ve created a holistic experience that spans a broad spectrum of who we are as a company, showcasing the depth and breadth of our product portfolio and sustainable solutions as well as providing access to the best trainers in the industry.”

With the focus not only on customers but also employees and those in the community, Director of Training Des Clancy says the planning team was very thoughtful about creating an elevated experience for everyone.

“At any given time, we will have contractors, builders, engineers, owners, students, employees, civic leaders, and other guests coming through the doors,” he says. “From tours and training, to onboarding and education sessions, the Uponor Experience Center offers something for everyone, and we are proud to showcase all we are offering to the industry and our community.”

Mechanical Hub’s John Mesenbrink (l) and Tim Ward (r) complete the “Uponor sandwich” as they also toured Uponor’s Distribution Center in Lakeville, Minn., with tour guide and director of logistics and warehousing, Nate McIntosh.

Uponor North America (Uponor) announced Anna Picchetti as the new Vice President of Marketing & Strategy, effective May 8, 2023. In her role, Anna will oversee Channel Marketing, Portfolio, Analytics, Sustainability, Segment, Engagement, Brand, and Communications. She will report to Uponor North America President Andres Caballero and be a key member of the company’s Senior Management Committee. Anna joins Read more

Uponor North America (Uponor) announced Anna Picchetti as the new Vice President of Marketing & Strategy, effective May 8, 2023. In her role, Anna will oversee Channel Marketing, Portfolio, Analytics, Sustainability, Segment, Engagement, Brand, and Communications. She will report to Uponor North America President Andres Caballero and be a key member of the company’s Senior Management Committee.

Anna joins Uponor with 20 years of experience in Marketing and Operations across industrial, technology, and medical device industries. She brings a wealth of experience developing forward-thinking strategies with a strong track record of execution at industry-leading brands such as Tennant, SPS Commerce, and Honeywell. She has worked at the forefront of innovations like autonomous vehicles and renewable energy, managed high-growth SaaS products and positioning, and transformed customer experiences.

“To help us move our business and aggressive growth goals forward, it was important we found a senior leader who can lead market disruption and drive innovation and segment growth initiatives all while guiding channel development, portfolio management, and go-to-market strategies,” says Caballero. “I’m confident Anna’s approachable leadership style will be a good cultural fit, as she has a proven track record of engaging teams by intentionally listening, learning, and setting clear expectations and outcomes.”

Anna earned a Master of Business Administration degree from the Carlson School of Management at the University of Minnesota. She is a member of the Women United Committee for the Greater Twin Cities United Way chapter and is also a member of Chief, a network for women in the C-Suite as well as senior executives and vice presidents. In addition, she is a USA Hockey-certified coach with a local youth hockey program.

For information about Uponor products, systems, services, and solutions, visit uponor.com.