Restaurant grease traps are the devices design to intercept fats, oils and grease (FOG) from leaving a kitchen facility and entering a sewer system. Slimy FOG compounds that, by design, are trapped and held in place are chiefly byproducts of cooking that leach out of meats and dairy products. The idea is that wastewater flows Read more

Watts Water Technology

Restaurant grease traps are the devices design to intercept fats, oils and grease (FOG) from leaving a kitchen facility and entering a sewer system.

Slimy FOG compounds that, by design, are trapped and held in place are chiefly byproducts of cooking that leach out of meats and dairy products. The idea is that wastewater flows from sink, wash area and cleaning table drains into tanks that are designed specifically to trap the crap that shouldn’t enter sewage systems. In a grease trap, solids settle while oils, fats and grease—usually lighter that water—float to the top where they’re arrested, keeping them from flowing out with the wastewater discharge.

Typically, a grease interceptor works the same way as a grease trap, but on a much larger scale. They’re actually pretty simple devices, and their basic design hasn’t changed since the 1880s.

It’s flow rate that defines the difference between a grease trap and a grease interceptor. A grease trap is intended for use with flow measuring less than 50 gallons/minute. Larger operations—such as a poultry process plant—require the installation of a larger-scale “grease interceptor.”

Ask anyone in the municipal wastewater treatment business: one of the biggest environmental problems grease can have, outside of clogging pipes, is the disruption caused in the “digestive” process of water treatment plants. Bacterial processes are used to break down and clean sewage but FOGs can destroy these bacteria, causing all sorts of problems.

Design

Grease interceptors are designed with a high inlet/outlet, direction flow plate, vertical baffle and flow control device—all of which play a key role in the proper separation of grease.

High inlet/outlet layouts prevent the clogging of the inlet line, commonly seen in systems that have a lower inlet. This clogging, like that of the wastewater piping system, can result in a blockage or backup in the system or a reduction in separation percentage (grease to water) unsuitable for municipal wastewater systems.

Vertical baffle plates cause immediate disruption in the flow, forcing fluids directly to the bottom of the separation chamber where it is then met by the direction flow plate, initiating the separation process. From there, freshly separated water is reintroduced to the main water system and the grease is cleaned out by removing the cover and skimming it off the top.

Flow controls play a key role in the proper functionally of a grease interceptor because they’re designed to work properly under certain flow conditions.

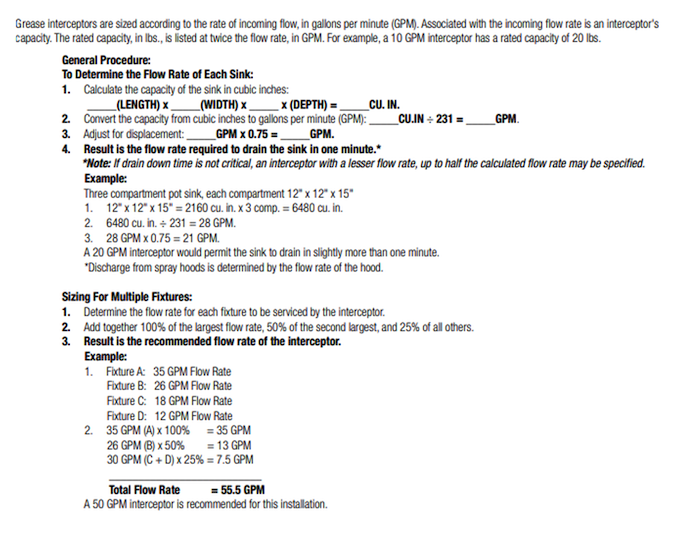

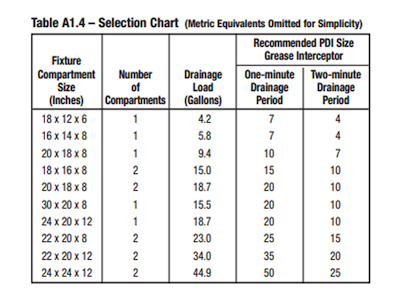

Sizing is important. Prior to installing an interceptor, check with local authorities for sizing requirements. They may differ according to specific locations.

The following will outline the most common method for grease trap/interceptor sizing along with a few variables, with solutions that may affect overall system performance.

Performance affecting variables:

In the scenario described above (with a flow rate of 55 GPM), additional flow control devices may be needed if the incoming velocity/flow exceeds the recommended velocity. A high velocity incoming flow results in a more turbulence, which reduces the systems efficiency and increases the separation time.

Interceptor size needs increase if . . .

- the incoming ratio of grease to water increases. If the ratio of grease to water is higher, the separation process will not work.

- there’s a possibility of detergents in the system (soap/cleaning products, etc.). Detergents break down the grease particulars into smaller particles that will not separate properly and can pass through a grease interceptor – polluting the flow of water released into municipal treatment systems.

By increasing the size of an interceptor unit, both the flow path and separation time are increased, allowing the system to capture the particles more effectively.

Install a solids interceptor in series (prior to the grease Interceptor) if . . .

- the system contains solid particles (such as food). Because grease has a lower specific gravity than water, it floats to the top with ease. But when a solid (such as a French fry) is introduced it sinks to the bottom and overtime can pass through the system. By introducing a solids interceptor prior to the grease intercepting process this French fry or any other solids are caught and will not be at risk of re-entering the cities drainage system.

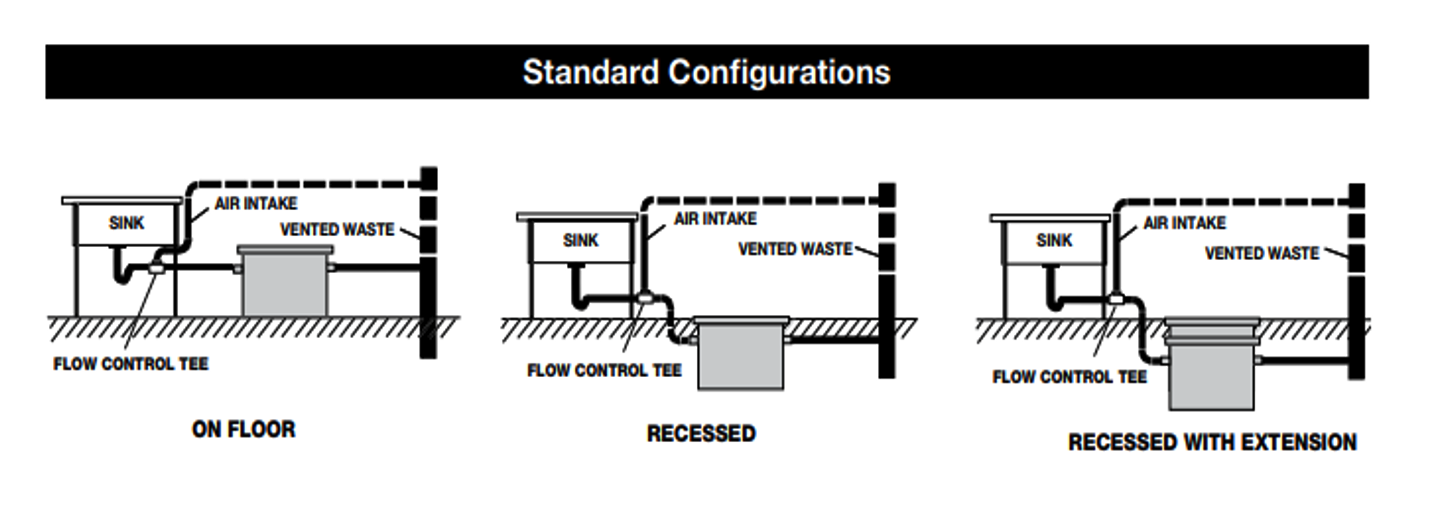

Installation

The installation of a grease interceptor is just as important in the operation of the system’s performance. First and foremost, the location of a grease interceptor should be as close as possible to the source of grease due to the cooling and solidification potential of grease over longer plumbing runs. For best results, the grease interceptor can be installed in any of the three orientations illustrated above.

Be sure—prior to finalizing the install location—to consider the clearance necessary to accommodate any connective piping and provide sufficient space for proper removal of the cover for cleaning purposes.

Key considerations

Grease interceptors are not designed to handle solid debris. In an application where solids are present, such as all sinks where garbage disposals are used, a solids interceptor is required to be used in conjunction with the grease interceptor. Due to the nature of greases—which have a natural attraction to solid particles—the presence of solids dramatically reduces a grease interceptor’s effectiveness. This can result in everything from unpleasant odors caused by the decay of solids, to the clogging of pipes or even the grease interceptor.

If an interceptor is installed outside, which is a common practice, it’s important to ensure all piping is installed below the frost line. In these applications, a single or series of extensions are common, allowing the interceptor to be buried low enough to avoid freezing.

Because proper flow through a grease interceptor plays an important role in its function, it’s important to regulate incoming velocities for proper separation to occur.

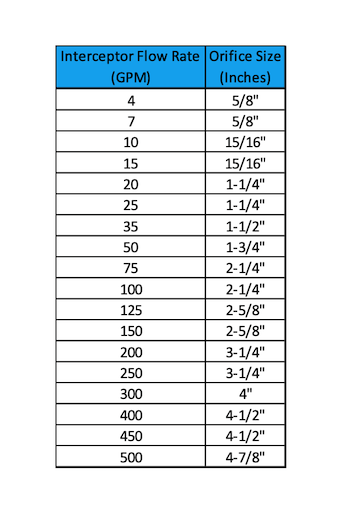

A flow control device is typically designed with an integral orifice (opening) to assure that an interceptor has optimal flow rate, and air intake. The following chart indicates the appropriate orifice size for gravity flow conditions (where no pressure or “head” is present).

Frequently specified options:

Maintenance + cleaning:

The cleaning frequency of a grease interceptor system is determined by the a.) capacity of an interceptor (measured in pounds of grease that can be trapped within it) and b.) the amount of incoming grease.

Because of this, grease removal intervals may vary from once a week to once every several weeks. When the necessary cleaning schedule has been determined based on a unit’s specific application and size, regular cleaning is necessary to maintain systems function and efficiency.

After the removal of accumulated grease and waste material, the interceptor should be thoroughly checked for any clogs or blockages in the inlet, outlet and air relief.

The following steps should be followed during the grease removal and cleaning process:

- Loosen and remove any fasteners used to secure the cover

- Remove the cover

- Clean out any grease.

- If applicable, use a scoop or shovel to remove any remaining solidified grease in unit

- If present, remove the sediment bucket; empty and clean thoroughly

- Using a clean water supply, hose down and wipe out the inside of the body

- Check integrity of cover sealing gasket (replace if needed)

- Reinstall cover and lock down hardware

If there is a semi-automatic interceptor in place, use the following steps for cleaning:

- With the outlet valve open, run a full stream of clean hot water (140°F min) through the interceptor for at least 2 minutes

- Allow unit to cool for approximately 3 minutes

- Close the valve on the outlet side of the interceptor

- Remove cap from top of interceptor and attach draw-off hose; position hose to drain into waste receptacle

- Run hot water through the interceptor at rate of 1.5 to 2.5 GPM

- Once filled, force the liquified grease out through the top draw-off hose

- When clear water begins to discharge through the draw-off hose, the interceptor is clean

- Disconnect the draw-off hose and replace the pipe cap

- Re-open the valve on the outlet and your interceptor is ready for normal use.

Robert DiPlacido, Mechanical Engineer, Watts, has eight years of experience in the plumbing market. The majority of his time was has been focused on commercial construction, chiefly with storm and wastewater management drainage systems, though also includes experience with roof and floor drainage systems, cleanouts, lavatory and urinal carriers, water separation systems (grease, oil and solids), trench drains, chemical waste and cross-linked polyethylene (PEX) tubing.

By Jana Summey A few months after the “reopening” of the economy, understandably, business owners and government officials welcomed a return to normalcy. However, new and different risks are faced when reopening dormant buildings with stagnant water systems. Several weeks of zero flow, low flow, and tempered water can result in microbiological growth, leeching heavy Read more

By Jana Summey

A few months after the “reopening” of the economy, understandably, business owners and government officials welcomed a return to normalcy. However, new and different risks are faced when reopening dormant buildings with stagnant water systems.

Several weeks of zero flow, low flow, and tempered water can result in microbiological growth, leeching heavy metals, and corrosion within our plumbing systems.

Planning is key

Let’s take a close look at steps building facility managers should consider in order to maintain water quality and safety in plumbing systems of unused or slightly used buildings (as defined by industry organizations including NSF International, Centers for Disease Control and Prevention (CDC), and the International Association of Plumbing & Mechanical Officials (IAPMO).

The IntelliStation digital water mixing system delivers mixed hot water throughout a hot water recirculation loop in commercial and institutional facilities. This digital solution can be integrated into a building automation system (BAS) to allow facilities managers to remotely monitor and control water temperatures.

Begin by documenting protection measures for staff and visitors. Consider working with a water quality expert or consultant. And, ask the local water utility the following questions:

- Have there been any recent water supply disruptions?

- Have standard checkpoints been inspected?

- What is the current disinfectant concentration?

If one isn’t already in place, create a map of the building’s plumbing system.

Before the initial flush, sketch out the building water system to identify low-use water outlets. Map out a flushing regimen in a unidirectional process starting at the water supply’s point-of-entry, to the peripheral distalpoints, and point-of-use outlets such as faucets and showerheads.

In large buildings, the water supply is often designed in zones and branches, such as different wings. Typically, each wing or set of branches will be served by the same riser. When mapping out the plumbing system, always start from the outlet nearest the water supply and proceed to the most distal outlets. Along this route, the flushing regimen should include the entire recirculating loop, both cold and hot water, all associated equipment and appliances, and all outlets including faucets, showerheads, eye wash stations, ice machines, hot tubs, therapy pools, and water features.

Establish or reestablish a flushing and cleaning regimen. Flushing is important because it clears out the low-quality water that accumulated during low use and replaces it with high-quality water from the municipal supply. The fresh water helps mitigate loss of protective scale as well as biofilm growth that emerged while the water was stagnant.

After the initial flush, ongoing flushes should be scheduled; continual flushes help to repair destabilized scale and minimize biofilm growth. Watts’ OneFlow System, shown here, uses a specially designed media where scale forming molecules are transformed into harmless crystals that won’t stick to pipes and components, eliminating scale for good.

These conditions need to be addressed because they proliferate the growth of Legionella and other waterborne pathogens, creating a high-risk environment for those with compromised immune systems. Proper flushing is a multi-step process including an initial flush, sequenced flushing, cleaning of fixtures and equipment, testing and monitoring, and additional flushing as needed.

Initial flushing and cleaning must be completed before resuming normal building operations. The sooner flushing is begun, the better. If possible, have staff start flushing now, even if the building’s reopening date is still unknown. The earlier a flushing regimen is initiated, the sooner water quality will return to normal. Prior to flushing, appropriate training for staff should be completed and PPE (personal protective equipment) should be provided. Guidance for this can be found on OSHA’s website.

It’s vital to flush the entire piping system from point-of-entry to point-of-use. This includes all water outlets, utility sinks, hose taps, piping currently used, as well as piping and fixtures in place for future installations. However, it doesn’t hurt to take special notice to the parts of the water system that have the greatest opportunity to make people sick. These include:

- Faucets used for drinking water or food preparation

- Drinking fountains

- Ice machines and refrigerators with ice makers

- Showers

- Kitchen sink sprayers

- Water features that generate aerosols (fountains, spas, etc.)

- Parts of the water system used by children, the elderly, and other susceptible people

An initial flush clears out contaminants that accumulated during stagnation and draws in fresh, high-quality water to the piping. Cleaning the fixtures removes contaminants from the complex internal structures at the point of discharge. Flushing requires an initial flush to get out low-quality water and contaminants, and follow up flushes that may bring the building back to pre-COVID-19 water quality. Ongoing flushing draws particles through and out of the system and brings in disinfectant from the municipal system that can help control biological growth. The longer service is interrupted, the more effort will be required for restoration.

Once the building is reopened, conduct normal process of ensuring tempering valves are maintaining the desired temperature.

Flush zone by zone, starting with the zone closest to the water building supply. In each zone, start with the cold water plumbing first, followed by the hot water. Within the zone, open taps starting with the outlet closest to the zone origin, working toward the farthest point. Flushing should not end until the farthest point-of-use tap has flushed for a minimum of five minutes, and the cold water temperature at the most distal tap is constant.

In order for flushing to be most effective, consider the following:

- All valves should be in a fully opened position during the entire flushing process

- All aerators should be removed. If continued use is planned, clean or replace the screens prior to reinstalling the aerators

- Showerheads and faucets should be disinfected and sterilized. Consider replacing outlets if vulnerable populations have access

- Prior to operating the system after flushing, adjust valves back to normal operating positions

As part of the flush, all locations where water is stored should be identified, drained, and flushed with clean cold water. Examples include humidifiers, ice machines, and dishwashers. Most buildings have some form of water treatment in their plumbing system such as filters and water softeners. These should run as normal, be included in the flush, and should not be bypassed.

Once flow has returned after this initial flush, all hot water tanks should be drained. Temperature should be maintained, and the heater should not be turned off. Continual operation is important to prevent microorganisms from growing. Make sure that water heat storage temperature are sufficient to kill bacteria (131 to 140°F).

After the initial flush, ongoing flushes should be scheduled; continual flushes help to repair destabilized scale and minimize biofilm growth. The American Water Works Association (AWWA) recommends continued flushing for a minimum of 12 weeks. This allows the protective scale to re-stabilize and for harmful lead particles to be washed through the plumbing system.

Recommendations for ongoing flushes include:

- Open each point-of-use tap at least once per day

- Flush the entire building once per week during ongoing flushing

- It is not necessary to drain water storage during ongoing flushing

- Continue to flush the cold and hot water systems separately; cold first, hot second

Monitoring and testing

Monitoring and testing should start for Legionella, other bacteria growth, and disinfectant levels prior to the initial flush, throughout the ongoing flushing, and on a predetermined schedule going forward. Monitoring and testing are the only ways to know the health of the plumbing system.

At the end of the initial flush, disinfectant levels should be checked. The concentration level of chlorine, the most commonly used disinfectant, should be measured at the point-of-entry and in the cold water of the most distant tap of each zone after the tap is flushed. Comparison of the point-of-entry concentration to the distal tap concentration will give an indication of the protection being provided to the entire plumbing system.

If other disinfectants are used, such as monochloramine, be sure to measure and compare its concentration at point-of-entry and distal outlets. Water temperature should be regularly tested and recorded.

The system should be tested for Legionella by a certified laboratory. Many facilities will choose to work with a consultant for this process. Samples should be collected at least 48 hours after final flushing and return of normal operation of the water system. Multiple samples should be collected to ensure accuracy and prevent false negative results. Samples should be taken at multiple locations throughout the system, from point-of-entry to point-of-use.

Hyperchlorination or shock disinfection should be conducted if testing proves unacceptable levels of Legionella. This is where a higher than normal level of chlorine is flushed through the plumbing system for a specific length of time, and the water temperature is raised for rapid kill. The cold water system should be flushed from point-of-entry to point-of-use, including all fixtures. The water should reach a CT of no less than 3,000 mg-min/L. “CT” value is the concentration of disinfectant and contact time with the water being disinfected.

Systems that have high levels of Legionella, or are known to have heavy biofilm, may require even higher CT targets. Higher chlorine dosage may allow for shorter disinfection contact times. Always take proper precautions to ensure there is no inadvertent exposure to occupants. Strict access controls should be in place. Conduct testing to ensure chlorine levels are in normal ranges at the conclusion of treatment. When hyperchlorination is complete, the system should go through an additional thermal flushing.

Even if unacceptable Legionella levels are not found after thermal flushing, hyperchlorination should still be considered, especially in buildings where high risk or immune compromised populations could be exposed.

Following, adjusting, and creating a water management plan

A facility management team should record all monitoring and testing practices including the frequency, locations, and results. If there is a water management plan, those findings should be integrated into the record keeping portion of the plan. If a water management plan does not exist, we strongly encouraged the creation of one. Most healthcare facilities are required under the Centers for Medicare & Medicaid (CMS) mandate to have a water management plan. Failing to do so can cause a facility to lose Medicaid and Medicare reimbursements.

Implementing a water management plan as outlined in ASHRAE 188 will help maintain a high-quality level in a building. The Centers for Disease Control (CDC) has developed a water management plan toolkit based on ASHRAE 188. The toolkit aids in the understanding of risk levels of different building types and devices and walks step by step through the requirements of a healthy water management plan.

Maintenance and Recommissioning

As part of the process of reopening a building, all mechanical equipment should be inspected. Examples include cooling towers, boilers, pumps, backflow preventers and digital mixing stations. Essentially, the water systems and equipment should be recommissioned as if it were a new building. Make sure any scheduled maintenance that may have been missed during building closings are completed and recorded in accordance with normal practices.

Some general guidelines include:

Digital thermostatic mixing

During/before closing

- Drain the piping system prior to closing if planning for a long-term building closure

- If draining the system isn’t an option, increase production and storage of hot water above 150° F, and keep the building pump running at full temperature by bypassing a TMV or setting the DMV to full hot

- Conduct a periodic purge of all dead legs to keep the system reasonably clean

At reopening

- Conduct either a high temperature water purge, hyperchlorination shock, or both

- Generally, calibration of mixing valves is not needed

- Once the building is reopened, conduct normal process of ensuring tempering valves are maintaining the desired temperature

Backflow

- Conduct a visual inspection

- If the water supply was completely shut off and the pressure decreased, all reduced pressure zone units need to be repressurized correctly, and the relief valve should be closed

- All pressure breaker valves also need to be repressurized correctly and the relief valve should be closed.

- The pressure breaker valve should be spill resistant, but it should still be checked

Gas connectors

- Assuming equipment has been turned off, a device such as FloPro™-MD can assist with a startup check to ensure each piece is operating at manufacturer’s specification

- Verify proper gas supply to any gas burning appliance with a BTU rating of 325,000 BTU’s or less, whether it is in a commercial kitchen or not

Drainage systems

- For general drains, there are no special requirements. However, a visual inspection should be part of the reopening plan

Stainless steel piping and drainage systems

- Other than the absence of water in the traps from either back siphonage or evaporation, stainless steel piping systems require no special considerations when being returned to full service after periods of non-use

- Stainless steel pipe and fittings are resistant to corrosion caused by decomposition of organic matter and the subsequent formation of hydrogen sulfide gas or microbiologically-influenced corrosion

Rainwater harvesting

- Purge the system via the hose bibs or flush out the system by opening the flush valves to create a steady flow of water

- Check the tanks to ensure the aerator is functioning and the inlet pre-filter is in service

Water quality solutions

For most water quality devices, it is a good idea to flush the unit. However, it’s always best to consult manufacturer guidelines for each device.

UV systems

- Inspect to ensure the light is working correctly

- Check to make sure any scheduled maintenance wasn’t missed

- Visually inspect the vessel

Sediment/point-of-entry filtration

- Visually inspect

- Clean any clogs and replace filters when needed

Point-of-use filters

- Visually inspect

- Clean any clogs and replace filters when needed

- Check to make sure any scheduled maintenance wasn’t missed

Measuring instrumentation

- In measuring instruments such as the CIX Instrument from HF scientific (chlorine measurement), there is a potential for reagents to crystallize in the tubes if there is a sudden loss of power or power is off for an extended time

- During inspection, in the rare event that crystallization has occurred, the unit needs to be primed and reagents replaced

Snow melt

- The snow/ice detector should be cleaned with soap and water

- Inspect the control display to ensure there are no error messages due to faulty sensors

Water Heaters

- Determine if the manufacturer recommends draining the water heater after a prolonged period of non-use

- Ensure that all maintenance activities are carried out by professionals or according to the manufacturer’s instructions

- Make sure the water heater is set to at least 122°F and consider higher temperatures (131°F -140°F) for a quicker kill

- Ensure that measures are taken to prevent scalding if the water heater is set to >130°F

- Wipe down the outside and control with disinfectant

- Conduct proper startup by authorized service agent

- Conduct a significant blowdown of all components

- Check combustion and calibration, perform all safety device testing, and verify all system operating parameters are correct and functioning

Additional Equipment to Be Inspected:

Hot tubs, spas, therapy pools

- Check for existing guidelines from local or state regulatory agency(ies) before opening for use

- Visually inspect for slime and biofilm prior to refilling

- Perform a hot tub/spa disinfection procedure before use per CDC guidance

Cooling towers

- Revisit startup and shutdown procedures

- Follow manufacturer guidelines and industry best practices

- Visually inspect for slime and biofilm prior to use

- Assuming the cooling tower has been well maintained, proceed with disinfection procedures. Guidance can be found from the Cooling Technology Institute: http://www.cti.org/downloads/WTP-148.pdf

Maintaining system after reopening

Planned and detail cleaning should be part of the reopening process. This includes proper maintenance of all equipment and fixtures, and the replacement of filters from point-of-entry to point-of-use. Be sure to follow manufacturer guidelines and contact the proper authorities when necessary.

Twenty-four hours before reopening the building, it’s recommended to conduct a round of checks. Bring the hot water system back up to 140° F. Open all outlets and flush until they reach a minimum of 131° F. After flushing, conduct a final round of sampling to ensure there is no contamination.

Once the building has resumed normal operation and the water system is back to standard function, the main priority will be maintaining water system quality and safety. If there is no water management plan prior to the disruption, create one immediately. This should include a schedule for monitoring and testing disinfectants, bacteria levels, and water temperature. Follow the plan, document activities, and adjust as needed. If an issue arises, promptly address it and notify authorities if deemed necessary.

If the building is scheduled to reopen within one month, continue a normal control regimen if possible. If the time to reopen the building is unknown, or if its scheduled to reopen longer than 1 month away, there are precautions that can be taken during that time to increase water quality prior to pre-open flushing and chlorination.

Consider the following:

- Conduct low-usage weekly maintenance

- Conduct weekly visual inspections

- Initiate operation of moving parts such as pumps for at least 10 minutes per week to prevent seizure and failure

- Increase water temperature to 140° F for at least 1 hour per week to reduce bacteria growth

- If equipment such as a water heater has a thermal sterilization cycle, utilize it per manufacturer recommendations

- Maintain normal disinfectant levels

- Flush outlets on a weekly basis

- Ensure all storage maintains proper disinfectant levels

- Document all activity, monitoring, and testing

- If it is decided to close certain systems, drain and dry if possible

If the decision has been made to not heat water within the plumbing system during closure, then consider the following:

- Close the building and do not drain the system

- Turn off storage tanks, drain, and the water supply

- Consider conducting thermal flushing and hyperchlorination prior to shutdown

If a building is not being fully shut down but will be under low-use conditions, consider the following options to maintain the system:

- Flush cold water systems on a regular schedule to maintain temperature and disinfectant. Free chlorine residual should be at or above .2 mg/L

- Monitor and maintain the hot water system at distal outlets

- Monitor and record supply water temperature and disinfectant concentration

- Restrict access to any unused portions of the building

- Document all monitoring, testing, and maintenance

Additional Resources

There are a multitude of tools and guidance to assist in maximizing water safety and minimizing water risks when preparing to reopen an unused or slightly used building:

- CDC Toolkit: https://www.cdc.gov/legionella/wmp/toolkit/index.html

- Preventing Legionnaires’ Disease: A Training on Legionella Water Management Programs: https://www.cdc.gov/nceh/ehs/elearn/prevent-LD-training

- Hotel Guidance: Considerations for Hotel Owners and Managers: How to Prevent Legionnaires’ Disease: https://www.cdc.gov/legionella/wmp/hotel-owners-managers.html

- From Plumbing to Patients: https://www.cdc.gov/hai/prevent/environment/water.html

- Preventing Occupational Exposure to Legionella: https://www.cdc.gov/niosh/docs/wp-solutions/2019-131/default.html

- CDC Model Aquatic Health Code

- CDC Healthcare Water System Repair and Recovery Following a Boil Water Advisory or Disruption of Water Supply

- ASHRAE Standard 188: Legionellosis Risk Management for Building Water Systems

- ASHRAE Guideline 12: Minimizing the Risk of Legionellosis Associated with Building Water Systems

- Cooling Technology Institute Legionellosis Guideline 2008 (WTP-148)

- Cooling Technology Institute Legionellosis Guideline 2019 (GLD 159)

Learn more about ensuring safety in commercial buildings by mitigating the risk of Legionella and other waterborne bacteria at www.legionella-strategies.com.

Jana Summey, MBA, Watts Healthcare Vertical Market Manager, has nearly 20 years’ experience in the MEP (mechanical/electrical/plumbing) design and architectural design industries. She is a popular speaker on mitigating Legionella through a multi-barrier approach in on-premise plumbing systems – from point of source to tap. Recently Jana navigated her mother through the experience of being exposed to Legionnaires’ as a hospital patient, gaining valuable insight into the serious threat Legionella poses for at-risk populations.

Jana Summey, MBA, Watts Healthcare Vertical Market Manager, has nearly 20 years’ experience in the MEP (mechanical/electrical/plumbing) design and architectural design industries. She is a popular speaker on mitigating Legionella through a multi-barrier approach in on-premise plumbing systems – from point of source to tap. Recently Jana navigated her mother through the experience of being exposed to Legionnaires’ as a hospital patient, gaining valuable insight into the serious threat Legionella poses for at-risk populations.

Watts has announced new leaders for several key business units as it continues to strengthen its commitment to customers. Jim Koepsell has been appointed the General Manager of Watts’ Drains and Industrial businesses. Previously, Koepsell led Watts’ Commercial Operations organization. He is responsible for Watts’ cast iron, BLÜCHER stainless steel, and Orion chemical waste drainage Read more

Watts has announced new leaders for several key business units as it continues to strengthen its commitment to customers.

Jim Koepsell has been appointed the General Manager of Watts’ Drains and Industrial businesses. Previously, Koepsell led Watts’ Commercial Operations organization. He is responsible for Watts’ cast iron, BLÜCHER stainless steel, and Orion chemical waste drainage solutions, along with Watts’ Mueller Steam industrial strainer, check valve, and butterfly valve solutions.

Jim Koepsell has been appointed the General Manager of Watts’ Drains and Industrial businesses. Previously, Koepsell led Watts’ Commercial Operations organization. He is responsible for Watts’ cast iron, BLÜCHER stainless steel, and Orion chemical waste drainage solutions, along with Watts’ Mueller Steam industrial strainer, check valve, and butterfly valve solutions.

Atul Sharma has been appointed the Director of Watts’ Commercial Operations and General Manager for Watts’ Syncta business. Previously, Sharma led multiple strategic projects for Watts and served on the Corporate Strategy & Business Development team.

Atul Sharma has been appointed the Director of Watts’ Commercial Operations and General Manager for Watts’ Syncta business. Previously, Sharma led multiple strategic projects for Watts and served on the Corporate Strategy & Business Development team.

Carlos Haddad has been appointed General Manager for Watts’ Dormont Gas Business Unit in addition to his existing role as Vice President of Marketing and Business Development (Americas and Europe). He is responsible for Watts’ Gas connector and Gas safety systems for residential, commercial, and food service applications.

Carlos Haddad has been appointed General Manager for Watts’ Dormont Gas Business Unit in addition to his existing role as Vice President of Marketing and Business Development (Americas and Europe). He is responsible for Watts’ Gas connector and Gas safety systems for residential, commercial, and food service applications.

“In appointing these leaders, we are positioned to provide the highest level of support to our customers,” according to Andrew Windsor, Watts Senior Vice President, Sales. “As always, our top objective is to deliver the products and solutions that will help our customers succeed.”

For more info, watts.com.

One of Pennsylvania’s oldest and largest school districts has opted for advanced technology to solve an age-old problem: precise temperature control for domestic hot water, installed for pragmatic reasons and as a valuable “insurance policy.” The Bethlehem Area School District (BASD) has been around since the 1920s. The sixth largest school district in Pennsylvania, BASD Read more

One of Pennsylvania’s oldest and largest school districts has opted for advanced technology to solve an age-old problem: precise temperature control for domestic hot water, installed for pragmatic reasons and as a valuable “insurance policy.”

The Bethlehem Area School District (BASD) has been around since the 1920s. The sixth largest school district in Pennsylvania, BASD covers more than 40 square miles and has 14,000 students enrolled throughout 22 schools, including two high schools, four middle schools, and 16 elementary schools.

Scott Yandrasitz, BASD master plumber, completes the IntelliStation Jr. install.

The school buildings, dating back nearly 100 years, have seen their fair share of mechanical systems. The latest: mechanical mixing valves that have far outlived their lifespan.

According to one of BASD’s full-time master plumbers, Scott Yandrasitz—in 2010, the district managers dove headfirst into an effort to modernize plumbing and mechanical systems throughout the century-old school district, beginning with the building of their first green-certified school.

Supervisors of facilities at Bethlehem Area School District say, “Just because we’re an old school district doesn’t mean we can’t have the latest and most advanced technology.” BASD’s modernizing effort snowballed from there.

In August 2018, the district’s manufacturers’ rep for all things mechanical—Warminster, Pa.-based Vernon Bitzer—came through with an ultra-modern solution for the buildings’ outdated domestic water mixing valves.

“The old systems were leaking and deteriorating,” said Vernon Bitzer’s Dick Filer (recently retired). “They had far outlived their lifespan.”

“At the beginning of each week, when we’d walk into the mechanical room, we’d check the systems and the temperatures had always drifted several degrees,” added Yandrasitz. “We wanted a solution that would be something similar to what we already had, but we needed a solution that would be precise, reliable, and would also eliminate the need for routine maintenance.”

“The old systems had too many moving parts,” said Carlo Angelone, another BASD master plumber. Invariably, there was always something to deal with. “Each school’s domestic water system had two mixing valves: one for high flow and one for low,” he noted. “By their nature, the many moving parts were prone to challenge, and as they aged, we were faced with the need for constant maintenance and repair.”

Catch 22

According to Filer, facility managers are typically caught in a mechanical systems Catch 22: turning down domestic water storage temps ensures reduced risk of scalding, yet greatly increases the risk of germ proliferation—including the infamous legionella bacteria, the source of Legionnaires’ Disease. Yet, bumping up storage temperatures increases the risk of scalding.

Carlo Angelone, BASD master plumber (l) and Scott Yandrasitz, BASD master plumber, look over the install diagrams.

Filer’s suggestion was the Powers IntelliStation® Jr.—a Watts brand product for smart digital water mixing and recirculation. The technology would give facility managers the precise temperature control they wanted and also integration with BAS to allow remote monitoring and control.

The IntelliStation Jr.’s sanitization mode addresses waterborne bacteria while a programming schedule for the set-back of temperature improves energy efficiency when the building is unoccupied. It controls water temperature to a +/- 2°F for enhanced safety, prevents overnight creep, and automatically balances the hot water distribution system during low-to-zero demand periods—all ideal features for a school building application.

Yandrasitz and Angelone, along with the district’s master electrician, Chad DePaolis, and Bitzer’s Filer, presented the solution to the supervisor of facilities, who approved their plan enthusiastically.

First digital mixing upgrade

Eager to test out the new technology from Watts, BASD plumbers installed the first IntelliStation Jr. in Freemansburg Elementary School—which, up until that point, had the greatest number of repairs.

With three master plumbers and three master electricians employed by BASD, they were able to avoid outsourcing the work to contracting firms.

Having in-house resources for quality installation and maintenance was a substantial advantage, but they quickly learned that ease of installation and commissioning, and operational reliability were the decisive factors. All the experts agreed: digital mixing valves would become an answer to many of the challenges they faced, district-wide.

From left to right: Dick Filer, Vernon Bitzer (retired); Scott Yandrasitz, BASD master plumber; Carlo Angelone, BASD master plumber; Chad DePaolis, BASD master electrician; David Steele, Vernon Bitzer. Yandrasitz demos the IntelliStation Jr. to the group.

“I believe that, in five years, digital mixing valves will be predominant,” said Vernon Bitzer’s David Steele, who took over Richard Filer’s role of working with BASD after his retirement. “I think they’ll be predominantly used for their ease of maintenance, accuracy, and flexibility in today’s age of low flow fixtures.

“Digital mixing will most likely migrate from the water heater to other items,” he continued.“ There will be smarter technology for many items throughout the plumbing system. We’re proud to be a Watts rep and are clearly devoted to our future with IOT.”

Plan for the future

According to Yandrasitz and Angelone, BASD managers recently received three more IntelliStation Jr. systems now slated for installation. For the 2018 budget submittal, they stated the need to purchase three more of the systems for 2019. And in ’99, they requested more for 2020.

“The way I see it,” said Yandrasitz, “we’ll continue budgeting for them at three or more a year. We have at least 20 schools that will need them, and the improvements have won the admiration of senior managers without fail.”

“Less maintenance and greater accuracy of water storage and distribution temperature control—this is just what we need for our schools,” he said. “There are other advantages to digital mixing, including the ease with which we’ve been able to disconnect the old mechanical mixing systems and to install and commission the new digital mixing technology. When the control is in place, connected and online, we simply set the new temperature parameters, and the computer controls everything, regardless of the level of water use and flow.”

An electrician’s friend, too . . .

DePaolis, says the IntelliStation Jr. meets his exact requirements. “The system is an incredibly easy hook-up to electricity and to building management systems. It’s user-friendly and there’s no maintenance for me once it’s in and operational.”

BASD’s second IntelliStation Jr. was installed in Calypso Elementary School in February 2019.

Lack of complaint calls–no lack of hot water

According to several members of the installation team, if a school doesn’t have hot water, complaint calls and emails come in from everywhere—from administrators, teachers, and parents. That means team members receive urgent calls and texts from administrators, and those can be unpleasant.

“Since installing the new digital mixing valves, we haven’t received a single complaint call for hot water loss,” said Yandrasitz. “That’s a good thing. And it’s one of the measures of success for us, that’s for sure.

“The more important assurances we’ve had with the successful operation of the digital mixing systems have been reliable operation and easy control of the domestic water system storage and delivery temperatures,” he concluded. “We know we made the right decision. We’ll have more orders for the technology soon.”

Attendees Eligible for 0.1 CEUs through ASPE Watts has announced the next installment in a series of webinars for their engineer, architect, designer, and facility manager customers. The webinar, Ultra-Hygienic Drainage Solutions,will be broadcast live on Thursday, September 26, 2019. This latest webinar will focus on why the factory floor poses the toughest sanitation challenges for Read more

Attendees Eligible for 0.1 CEUs through ASPE

Watts has announced the next installment in a series of webinars for their engineer, architect, designer, and facility manager customers. The webinar, Ultra-Hygienic Drainage Solutions,will be broadcast live on Thursday, September 26, 2019.

This latest webinar will focus on why the factory floor poses the toughest sanitation challenges for food processing and beverage plants.

Key takeaways will includehow a hygienically designed, efficient drainage system:

- Minimizes the risk of bacterial contamination & costly production stoppages

- Can lead to increased operational efficiency & long-term cost savings

By attending the entire webinar, attendees can receive 0.1 Continuing Education Units (CEUs) through the American Society of Plumbing Engineers (ASPE).

To register for this webinar, please visit this page.