In electronics, a heat sink is a passive component that transfers heat generated by an electronic device to a cooler external environment. By absorbing and dissipating heat, heat sinks enable electronic devices to remain within their safe operating temperature limits.

Heat sink design

Heat sink design is an important aspect of many different types of devices and machinery. Proper heat sink design is critical in ensuring that these devices and components function properly and do not overheat. Overheating can lead to a number of problems, including decreased efficiency, shortened lifespan, and complete failure. Heat sink designs vary depending on the specific application. For example, larger heat sinks are typically used for high-powered lasers, while smaller heat sinks are sufficient for LED lights.

The size, shape, and material of the heat sink must be carefully considered when designing a heat sink for a specific application.

If the heat sink is not properly matched to the device or component it is cooling, it will not be effective and overheating may still occur. In some cases, multiple heat sinks may be used in order to dissipate heat more effectively. For example, a heat sink with a large surface area may be used in conjunction with a heat sink with good heat conductivity in order to cool a particularly heat-generating component.

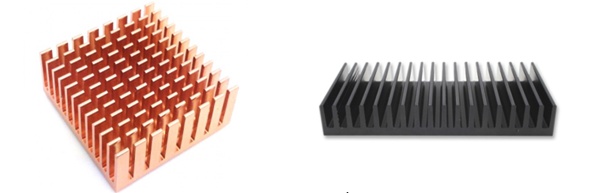

The material used in the heat sink also varies depending on the application. For example, aluminum is a popular choice for heat sinks due to its good heat conductivity. Copper is another common choice due to its even better heat conductivity. However, copper is more expensive than aluminum and can be difficult to work with, so it is not always the best choice for every application.

It is important to note that heat sinks are not the only way to manage heat in electronic devices and components. In some cases, other methods such as forced air cooling or water cooling may be used instead of, or in addition to, heat sinks.

However, heat sinks remain a popular choice for many applications due to their simplicity and low cost.

Common applications for heat sinks include:

- Regulating the temperature of electronic devices and components

- Cooling high-powered lasers

- Dissipating heat from LED lights

- Managing heat in power amplifiers

All in all, when properly designed and installed, a heat sink can help to keep your devices and components running cooler and perform better for longer.

Types of heat sinks

A heat sink is a device that helps to cool an electronic or mechanical device by absorbing and dissipating heat from it. There are many different types of heat sinks available on the market, each designed for specific applications.

Some common types of heat sinks include:

- Fan-cooled heat sinks: These heat sinks have a fan attached to them which helps to circulate air and dissipate heat more quickly. They are often used in high-power devices such as CPUs and GPUs.

- Liquid-cooled heat sinks: These heat sinks use liquid cooling instead of air to help dissipate heat more quickly. They are often used in high-performance devices such as servers and gaming PCs.

- Passive heat sinks: These heat sinks do not have any fans or other active cooling methods, and instead rely on convection and radiation to dissipate heat. They are often used in low-power devices such as laptops and smartphones.

There are many factors to consider when choosing a heat sink for a particular application, such as the size and power of the device, the environment in which it will be used, and the required cooling performance. The type of heat sink you choose will also depend on your budget and the level of noise you are willing to tolerate.

Advantages of machining a heat sink using a CNC

When looking at heat sink design and manufacture, there are several key factors that come into play in order to create an effective heat sink. One important factor is the method of machining the heat sink. A CNC machine can offer a number of advantages over other methods of machining, making it the ideal choice for heat sink production.

Some of the benefits of using a CNC machine to machine a heat sink include:

Increased accuracy

When heat sinks are produced using a CNC machine, the process is much more accurate than other methods such as hand grinding or milling. This increased accuracy results in a better finished product with less waste.

Greater repeatability

The use of a CNC machine also allows for greater repeatability in the manufacturing process. This means that heat sinks produced using a CNC machine will be more consistent in terms of quality and performance.

Faster production times

The increased accuracy and repeatability of the manufacturing process also results in faster production times. This is particularly beneficial if heat sink demand is high or if deadlines need to be met.

Reduced manpower requirements

As the CNC machine can handle the majority of the machining process, there is less need for manual intervention. This reduces the amount of skilled labor required and can lead to reduced costs.

Overall, there are many advantages to using a CNC machine to machine heat sinks. The benefits of increased accuracy, repeatability, and faster production times can make a significant difference in the quality and performance of the heat sink. When considering heat sink design and manufacture, it is worth considering the use of a CNC machine to ensure the best possible results.

Join the conversation: