“Can you believe some of the things that young man was saying?” was the question I overheard during a lunch conversation among a group of plumbing and heating business owners. “He’s going to tell me how to run my business?” That guy was a millennial guest speaker—at a recent industry function—addressing the importance of Millennials Read more

Articles

“Can you believe some of the things that young man was saying?” was the question I overheard during a lunch conversation among a group of plumbing and heating business owners. “He’s going to tell me how to run my business?”

That guy was a millennial guest speaker—at a recent industry function—addressing the importance of Millennials in the workplace. “Instead of working 9 to 5, give us a flexible work schedule. If I can get my work done before 5 pm, let me hit the gym for my workout or let me come in later so I can finish my paddle ball tournament,” said the speaker talking on behalf of Millennials.

You should have heard the ghastly groans from those business owners having heard this. Change in corporate policy? No way!

What about a change in corporate culture, then? Instead of giving Millennials an end-of-the-year bonus, how about paying for their monthly Netflix or gym membership? How about donating to the employee’s charity of choice? Is it a matter of placating them? Maybe, to some extent. According to the Bureau of Labor Statistics, Millennials are now the largest generation in today’s workforce, and instead of an “us vs. them” mentality, employers need to recognize that worn work philosophies need to be sharpened, and employers should try to work with this younger generation to get the most out of them.

The Survey Says …

The 2017 Deloitte Millennial Survey conveys that within the workplace itself, flexible working continues to be a feature of most Millennials’ working lives and is linked to improved organizational performance, personal benefit and loyalty. This year, Deloitte also observed the solid foundation of trust that enables organizations to increasingly offer and operate flexible working arrangements.

Interestingly, the survey also states that it is in the workplace where Millennials feel most influential and, in turn, accountable. This is an important point for businesses to acknowledge as it offers a platform from which to build each employee’s sense of purpose and, ultimately, a more engaged workforce.

Globally, two-thirds of Millennials surveyed say their employers have adopted flexible arrangements. Source: The 2017 Deloitte Millennial Survey

Where workplace opportunities are offered, the Deloitte survey reports, Millennials are significantly more likely to say they can influence social equality, the environment, the behavior of big businesses, and even the overall directions of their countries. Regardless of whether Millennials, as individuals, can make a tangible difference on such large issue, the key point is that employers can provide a sense of empowerment and, hence, create a far more positive mindset.

I think this is where employers, and older coworkers, need to perhaps change the mindset of the corporate culture within their companies. A recent article in Forbes magazine says that Millennials are known for speaking their mind, so all we really need to do is listen to their ideas. Listening and being more engaged with the younger generation can only be beneficial to the company’s success.

In the world of net zero, younger voices, filled with enthusiasm and exuberance relating to environmental issues and sustainable building, should and need to be heard. Gone are the days of “well, they are wet behind the ears so what can they really offer?” The answer is, if I ventured a guess, would be more than you would think. Better communication and understanding of the younger generation is simply a necessity in today’s workplace.

The Deloitte survey reveals that employees, who feel their jobs have meaning, or that they are able to make a difference, exhibit greater levels of loyalty. My best answer in understanding Millennials and what motivates them to be more productive and ultimately stay with a company—average tenure at a company is two years—is not to paint with a broad brush but rather get to know them as individuals.

Most of you have been there. Looking up to the heavens with outstretched arms, you exclaim loudly, “Why?!” I’m talking about working in the smallest mechanical rooms known to mankind. How does one navigate them to work efficiently? I asked some contractors and here are some quick tips: Have scene safety. Know your surroundings. Check Read more

Most of you have been there. Looking up to the heavens with outstretched arms, you exclaim loudly, “Why?!”

I’m talking about working in the smallest mechanical rooms known to mankind. How does one navigate them to work efficiently? I asked some contractors and here are some quick tips:

- Have scene safety.

- Know your surroundings.

- Check for sprinklers and smoke detectors.

- Pre-plan—Identify better piping routes, remote locate manifolds, pumps and or zone valves, nobody said they all have to be in the mechanical room. Create a scale isometric drawing or 3D model if needed, Google Sketch up works well to help identify shortcomings ahead of install day.

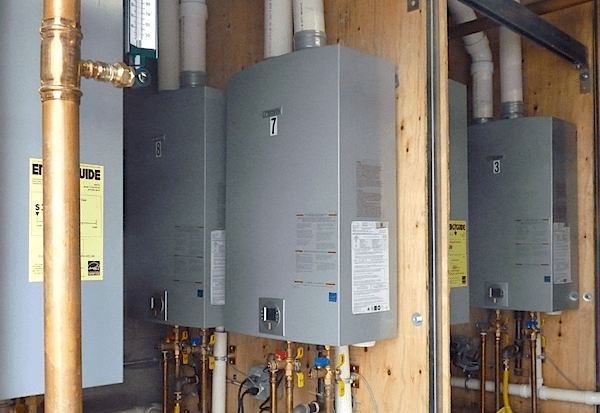

Planning is key to efficiency when it comes to working with limited space. Pictured here is mid-installation. Photo courtesy of Tim Kuhlman. - Build the mechanical room on paper first, or use a program like SketchUp to have your layout ready before you start cutting and connecting.

- Draw your manifolds out and measure twice.

- Measure twice, order once. The worst possible scenario is having equipment that won’t even fit in the room, let alone offer service clearances. Time spent planning and trial fitting will pay off in a successful project that can be serviced relatively easy.

- Planning is key to efficiency when it comes to working with limited space. When installing a boiler or tankless water heater, visit the site first to take measurements so you can draw a piping layout using a program like HydroniCAD or SketchUp. This allows one to work within the space given and have a plan ahead of time. If at all possible, try to prefab anything and everything so time on site is minimal.

- Layer your piping.

- Be sure it’s all accessible.

- Be the first guy in. There’s an old verse, “Do unto other as you would have them do unto you.” When in small spaces, change that to, “Do unto others, before others do unto you.” Because it’s gonna happen!

- Start big. Mount the equipment and immediately finish the venting, it is always the least flexible material, offering little or no forgiveness. In many cases, we will mount the boiler after the vent has been routed into the room, then the boiler will be fit to the venting. Proceed with the next largest piping.

- Get and stay organized. Your tool bags should include: Tape measure, 6″ magnetic level, pliers, carpenter’s pencil, fine tip marker, tubing cutter and pencil reamer and an aluminum speed square. Don’t overdo it and try and “wear” your entire toolbox!

- Keep a small space clear of boxes and packaging. A small broom and dust pan for keeping the floor surface clean, a small hand carry shop vac gets all the copper or plastic shavings when you are done.

- Look toward combination heating and domestic hot water units. In many cases they may be the only choice. Consider combi boiler DHW units. As long as you or the customer is aware and comfortable with the actual DHW production, they are a real space saver. Isolating/purge valves for deliming the unit are a must.

- Check out piping components that serve multi functions in the piping circuits. Combination air/dirt/magnetic separators are an example, or multi function hydraulic separators.

Photo courtesy of Tim Kuhlman. - Most equipment, valves, etc. require a minimum access clearance. When working in small spaces, it’s important to plan where the boiler, furnace or water heater have to be in order to maintain the required service clearance. Sometimes selecting the equipment to fit the available area is better than trying shoehorn a product that may not be dimensionally suitable into the space.

- Check out manufacturers’ pre-piped hydronic modules that mount to the wall and connect to the boiler and distribution. These are essentially plug-and-play modules that eliminate much of the onsite piping labor. These are often custom orders so plan ahead.

- Be aware of venting and combustion air in small space rooms. Consider through the roof for venting and sealed combustion in small spaces. Sidewall venting can be an option; be aware of prevailing winds and condensate drainage.

- Really think ahead and make sure what you’re putting in isn’t going to block access to something you’re going have to attach down the road like an electric or gas connection or that one 6″ pipe to nowhere.

- Have homeowners move as much out of the way as possible .

- Set space aside in garage or elsewhere to stage and build fittings as needed.

- Extra manpower will not help!

- Charge extra. It’s gonna take longer. You can’t get 2-3 guys in spaces; you’re sending your smallest guy.

- Eat healthy. Don’t be the smallest guy.

Of course, this could be a running list. If you have any suggestions you’d like to share, please comment below or email John Mesenbrink: jmesenbrink@mechanical-hub.com.

Thank you to the contractors that added their feedback to this list: Tim Kuhlman, Grasser’s Plumbing and Heating; Eric Aune, Aune Plumbing; Andy Mickelson, Mickelson Plumbing & Heating; Jason Ridgeway, Ridgeway Home Services; Bob ‘Hot Rod’ Rohr; Robert O’Brien, Technical Heating Co.

Project Goals: Replace old gas-fired boiler and 500-gallon storage tank supplying DHW Achieve sufficient DHW to meet demand in 99-room hotel Provide DHW for laundry, meeting spaces, kitchen areas Minimal disruption to guests The owners of the Best Western Plus New Englander Hotel located in Woburn, Mass., a suburb located about 10 miles north of Read more

Project Goals:

- Replace old gas-fired boiler and 500-gallon storage tank supplying DHW

- Achieve sufficient DHW to meet demand in 99-room hotel

- Provide DHW for laundry, meeting spaces, kitchen areas

- Minimal disruption to guests

The owners of the Best Western Plus New Englander Hotel located in Woburn, Mass., a suburb located about 10 miles north of Boston, decided to replace an old gas-fired boiler and tank serving its 99-room hotel equipped with two commercial washing machines after the existing 500-gallon tank began leaking.

Heneghan and Sons Plumbing and Heating in Pepperell, Mass. quoted a system of 10-intelligent cascaded Bosch Greentherm C1050ES gas-fired condensing tankless water heaters, delivering up to 107 gallons of hot water per minute. The Bosch units were priced less than a competitive unit, and offer a superior warranty.

Heneghan and Sons Plumbing and Heating in Pepperell, Mass. quoted a system of 10-intelligent cascaded Bosch Greentherm C1050ES gas-fired condensing tankless water heaters, delivering up to 107 gallons of hot water per minute. The Bosch units were priced less than a competitive unit, and offer a superior warranty.

Heneghan Plumbing, with materials provided by PV Sullivan (Quincy, Mass.) was able to keep the existing hot water system running while installing the new system, and Colin added that “the changeover was a lot easier than we ever expected. We found the Bosch units easy to install, program and troubleshoot. It was made simpler with support from Bosch Sales Representative Dan McDermott and Craig Porter from Bosch technical support.”

Intelligent Cascading

A cascading application may be considered if the potential hot water demand exceeds the capacity of one gas tankless water heater. The cascading set up supports variable flow inputs and is designed for large homes and commercial applications. Use of the Intelligent Cascading Kit, unlike other parallel applications, maintains the activation flow rate of a single appliance.

Intelligent Cascading allows up to twenty four appliances to be connected in parallel to achieve flow rates up to 257 gallons per minute for Bosch Greentherm 1050ES (see figure). One of the appliances will serve as the controlling primary appliance and will attempt to meet the hot water demand. If the hot water demand is beyond the capacity of the primary appliance, a signal is sent to one or more of the secondary appliances to ignite. With the Intelligent Cascading, after each 100 hours of operation, the system will automatically rotate which heater serves as the primary; thus the primary control appliance is rotated throughout the cascade setup to distribute the load of each unit. One of the appliances serves as the primary control and attempts to meet the hot water demand. If the hot water demand is beyond the capacity of the primary appliance, a signal is sent to one or more of the secondary appliances to ignite.

Note: Refer to Bosch Greentherm Tankless Water Heaters Applications Guide at this link http://www.bosch-climate.us/support-center/download-center/downloads/bosch-manuals/bosch-tankless-manuals.html

The 10-unit Bosch Greentherm cascade installed in the Best Western Hotel delivers high efficiency hot water delivering up to 107 gallons per minute. This satisfies demand from guest rooms, meeting space, laundry, and kitchen areas throughout the busy hotel. The hotel owner reported fuel savings of approximately $1,500 to $2,000 per month in the first six months of operation. Compared with a competitive tankless installation at a similar hotel with same number of rooms, this Bosch installation saved about $500 more per month.

Project Summary:

Best Western Hotel, Woburn Massachusetts

Equipment: Bosch Greentherm C1050ES natural gas fired condensing tankless water heaters in 10-unit cascade

Installing Contractor: Heneghan & Sons Plumbing &Heating, Pepperell, MA

Wholesale Supplier: P.V. Sullivan, Quincy, MA

Project Completion: 2014

As the market for commercial building restroom renovations and construction picks up steam, more attention is being focused on what matters most to all facility stakeholders – owners, employees, business patrons, facility maintenance, and so on. While most of today’s restroom design trends aim to increase durability, maintainability, ease-of-installation, convenience and sustainability within restrooms, perhaps Read more

As the market for commercial building restroom renovations and construction picks up steam, more attention is being focused on what matters most to all facility stakeholders – owners, employees, business patrons, facility maintenance, and so on.

While most of today’s restroom design trends aim to increase durability, maintainability, ease-of-installation, convenience and sustainability within restrooms, perhaps the two most important goals are cleanliness and operational efficiency.

Bradley Corp. recently conducted research, which shows the condition of restrooms has taken a nosedive, according to consumer perception. Almost 70 percent of Americans reported experiencing unpleasant conditions in restrooms in 2015 – a 20 percent increase since 2012. When asked the most important improvement they’d like to see in restrooms, survey respondents overwhelmingly said “clean them more regularly.”

As for building owners, the challenge is optimizing the appearance and cleanliness of restrooms while minimizing time and costs for installation, maintenance repairs and replacement parts. Gaining operational efficiency on the front end of restroom design can free up valuable staff time and extend the lifespan of restroom fixtures.

Here are some restroom design trends that enhance cleanliness and efficiency in the eyes of both restroom users and building owners.

Touch-free fixtures. Touchless fixtures can help users in their quest to avoid touching restroom surfaces, reduce the transmission of germs and bacteria from users’ hands, and improve overall facility hygiene as users leave the restroom area and enter other parts of the building. These fixtures are also easier for staff to keep in good working condition. The “hands-free” design reduces wear and tear from usage, and helps discourage vandalism attempts such as leaving a faucet running to create a mess. Sensored faucets, and automated soap and towel dispensers prevent waste and overflows with an automatic shut off.

Some newer touchless fixtures use 0.38 GPM faucets vs. 0.5 GPM, which achieves a 24 percent water savings. A new “all-in-one” completely touchless hand washing fixture – with touch-free soap, faucet and hand dryer in the same unit – eliminates dripping water on the floor and safety in commercial restrooms since the user’s hands stay within the sink area until they are dried.

Sustainable materials. Made of natural and recycled materials, sustainable materials can increase the durability, maintainability, life span and aesthetic of countertops, basins and lavatory systems. For example, molded natural quartz material, which has the resilience of granite, can be sculpted into a range of design options for lavatories. Natural quartz is virtually maintenance-free, since it does not require sealing, buffing or reconditioning like granite.

In addition, solid surface material made of recycled materials and rapidly renewable material is also a popular choice. Solid surface resists stains, chemicals, scratches and heat, which reduces the likelihood of repairs and the need for replacements. Both natural quartz and solid surface utilize integrated bowl designs, which eliminate crevices for microbes to hide, are easy to clean and help prevent the spread of germs. These materials also have nonporous properties, helping them to stay cleaner and germ-free longer.

Flexible and durable products. Choosing products that are engineered to address specific restroom needs and environments also promotes operational efficiency. Products that optimize flexibility require few connections and parts help to simplify installation, adjust easily to low or fluctuating water pressure and reduced water flow, stand up to harsh water conditions and high restroom traffic, and are adaptable to both aged infrastructures and new construction. Flexible product features also include universal design and vandal resistance. The result of using such products optimizes time and costs and minimizes headaches.

In all, today’s commercial restroom design innovations improve the customer experience, promote lasting durability and efficiency, and increase satisfaction for all stakeholders.

Sidebar

Restroom Trendwatch:

express® Elx-series Lavatory System offers updated and cost-effective multi-user design

Bradley Corp., introduces its Express® ELX-Series Lavatory System – a contemporary alternative to china sinks and laminate counter tops designed for commercial restrooms. Its single bowl, multi-user design is easy to install and maintain, while offering contoured styling and personal hand washing space.

A step up from ordinary lavatories, the award-winning Express ELX-Series is a cost-effective fixture that is easy to specify, install, clean, and maintain. With the look and feel of an individual lav, this streamlined hand washing system provides the economies and conveniences of a group fixture, which accommodates up to three people at one time.

Made of Bradley’s Terreon® Solid Surface material, the Express ELX-Series Lavatory offers superior durability and is easy to clean and repair. In addition, its contemporary contoured design elevates the look of commercial restrooms while being easy to clean. The bowl’s seamless construction eliminates mold and delamination, offering a more hygienic and attractive washroom solution.

Due to its long-term durability and simplified maintenance qualities, the ELX-Series is a cost-effective choice for high-traffic washroom applications, such as schools, retail, recreation centers, municipal office buildings and transit stations.

The Express ELX-Series Lavatory also cuts down on installation time and costs, and requires few connections and parts. It incorporates a unique mounting plate for faster installation, and requires only a single drain and supply rough-in for new construction, or for an easily installed retrofit.

For more information, visit https://www.bradleycorp.com/elx-series-express-sinks.

Kris Alderson is a Senior Marketing Manager at Bradley Corporation, a leading manufacturer of plumbing fixtures, washroom accessories, partitions, emergency fixtures and solid plastic lockers. She can be reached at Bradley Corp., W142 N9101 Fountain Blvd., Menomonee Falls, Wis., 53052-0309. For more information, call (800) BRADLEY or visit www.bradleycorp.com.

The leadership team at Milwaukee Tool continues to push the “disruptive innovation” ideology—an idea that a product takes root initially in simple applications at the bottom of a market and then relentlessly moves up market, eventually displacing established competitors to a new level—when talking about new tools. As a company that professes itself as a Read more

The leadership team at Milwaukee Tool continues to push the “disruptive innovation” ideology—an idea that a product takes root initially in simple applications at the bottom of a market and then relentlessly moves up market, eventually displacing established competitors to a new level—when talking about new tools. As a company that professes itself as a solutions provider first, releasing dozens of new tools every year, the disruptive part fits this narrative, sometimes with its own products. With 88 new tools at this year’s New Tool Symposium to show off, there was plenty of jaw-dropping moments, and Milwaukee showed off some plumbing tools that not only disrupted the space, they obliterated it.

In particular, there were four new plumbing offerings—coming to market in November (minus the short throw press tool below)—that really caught my eye:

• M18 FUEL Sectional Drum Machine — Almost 75% of the time spent on secondary drain line jobs is in the preparation for the job, and then packing all equipment back up. The M18 FUEL Sectional Drum Machine aims to change all that through the use of an interchangeable drum that allows users to select the right cable for the job, the ability to backpack transport the entire unit (including the ability to separate the drum from the machine to lighten the weight), and an electronic drum break so users can react faster when the cable starts to bind up in a pipe.

• M18 FUEL Sectional Drum Machine — Almost 75% of the time spent on secondary drain line jobs is in the preparation for the job, and then packing all equipment back up. The M18 FUEL Sectional Drum Machine aims to change all that through the use of an interchangeable drum that allows users to select the right cable for the job, the ability to backpack transport the entire unit (including the ability to separate the drum from the machine to lighten the weight), and an electronic drum break so users can react faster when the cable starts to bind up in a pipe.

• M18 FUEL Drain Snake with CABLE-DRIVE Locking Feed System—Building off Milwaukee’s current M12 Drain Snake, the M18 FUEL Drain Snake represents the next level in performance for hand-held units by offering more power, cable drive locking feed system, and zero drum contact. With 2X more power than corded, it boasts a max power of 50′ down the line and is the first brushless drain cleaner. The CABLE-DRIVE Locking Feed System is the only automatic cable feed system that allows users to select and maintain a desired feed speed.

According to Corey Dickert, vice president of Product Management-Plumbing & Electrical at Milwaukee Tool, “The simple cordless setup of the M12 Drain Snake frees users from the hassle of wrestling with cords, carrying extension cords, or spending time looking for outlets—allowing them to get back to the job at hand. In addition, this is the only handheld unit with a fixed drum shield to protect the fixture and user from the spinning drum. When we combine these cordless benefits with our new-to-world design, we’re able to truly provide a level of productivity that these users have never experienced before.”

• M12 AirSnake Drain Cleaning Air Gun—The first cordless alternative in pipe cleaning tools, the M12 AirSnake Drain Clearing Air Gun drastically changes the way users clear grease clogs, slow drains, and other non-retrieval clogs. The tool is the first cordless version on the market to use compressed air to flush away clog build-up. Completely cable-free, the tool allows for fast setup time and no disassembly of fixtures, drain covers and p-traps. With a 0-50 variable PSI gauge, the tool can instantly reach clogs 35′ out. To see the demo in person was impressive; the process does not affect the integrity of the piping installation.

• M12 AirSnake Drain Cleaning Air Gun—The first cordless alternative in pipe cleaning tools, the M12 AirSnake Drain Clearing Air Gun drastically changes the way users clear grease clogs, slow drains, and other non-retrieval clogs. The tool is the first cordless version on the market to use compressed air to flush away clog build-up. Completely cable-free, the tool allows for fast setup time and no disassembly of fixtures, drain covers and p-traps. With a 0-50 variable PSI gauge, the tool can instantly reach clogs 35′ out. To see the demo in person was impressive; the process does not affect the integrity of the piping installation.

• M18 Short Throw Press Tool—Milwaukee touts pressing 40% faster than competition, delivering force optimized for PEX installation, and eliminating downtime caused by calibration intervals. With the introduction of the M18 Short Throw Press Tool w/ PEX Crimp Jaws, Milwaukee is able to provide a solution that can accomplish the majority of residential installations.

The lightweight, in-line design of the new M18 Short Throw Press Tool enables the installer to press with just one hand. And, with a 3-second cycle time, and the ability to press 400 1” connections on a single charge, this new tool allows residential installers to do their job faster and easier than any solution they’ve had up until now—without paying for more force than is needed,” said Alex Boll, product manager for Milwaukee Tool.

Whereas hand tools often cause difficult and inconsistent ring positioning on fittings, the spring-loaded design of the Short Throw Press Tool’s jaws assists in holding the ring for precise alignment to the fitting. With no calibration interval, the new tool delivers consistency in installation over the entire life of the tool.

A pre-press battery check prevents the user from starting a press the tool cannot complete due to insufficient battery charge, while Auto-Cycle ensures a full press every time and indicates to the user via a green light that the connection is complete. The new M18 Short Throw Press Tool w/PEX Crimp Jaws is compatible with the F1807/F2159 copper crimp ring system, one of the leading systems in residential PEX installations today. The Short Throw Press Tool is also compatible with the Viega PureFlow Jaws, which are optimized for the PureFlow PEX Press System.