By Jacob Hamilton, General Manager at Tim Ferguson Plumbing, Air & Electric When my father-in-law called me into his office on an afternoon in 2010, I didn’t know my life was about to change. I had been working as a nurse before joining his plumbing business, Tim Ferguson Plumbing, Air & Electric, jumping headfirst into Read more

Featured Articles

By Jacob Hamilton, General Manager at Tim Ferguson Plumbing, Air & Electric

When my father-in-law called me into his office on an afternoon in 2010, I didn’t know my life was about to change.

I had been working as a nurse before joining his plumbing business, Tim Ferguson Plumbing, Air & Electric, jumping headfirst into a new industry I knew nothing about. But Tim trusted me to learn and saw something in me then that I couldn’t see in myself.

During our meeting, he laid out his plan for me: He wanted me to help continue to build the family business and take over when he retired. I told him I knew nothing about how to run a company; but I could sense he had complete confidence in my ability to learn. And I knew that, if he believed in me, for something as important as leading the family business into a new generation, I should trust his plan.

Tim Ferguson

It was Tim’s foresight and commitment to long-term planning that made his dream come to fruition when he sold the company to Leap Partners and retired. I took over on Oct. 1, 2023.

Leadership transitions are hard. But it was Tim’s patience and long-term planning that helped us all smoothly transition with minimal disruption. His intuition also prepared our 45 employees and me to easily and naturally transition into a new era and continue the legacy he’d built over more than 20 years.

How did we do it? Let me share some lessons we learned along the way.

Communicate, communicate, communicate

Without question, the most important piece of advice I can give to anyone undergoing a leadership transition is to communicate consistently. It’s imperative that you communicate clearly and often with your employees about your plans for leadership. You don’t want employees to fill in gaps with hearsay, and you definitely don’t want them to hear two conflicting or muddled messages at the same time. Overcommunicating is always going to be better than not communicating enough.

Let them know the plan, when it’s happening and how you expect the transition to go. If you don’t know the answers to some of these questions, let them know that too. Listening to feedback and being transparent will help cut down on the feeling of unease that can come with change. Treating all employees like integral partners in the business by being overly transparent with them can make everyone feel invested in what’s happening. Especially with small businesses, your team should feel comfortable with the transition and feel that their input is being considered.

Anticipate challenges and plan for them

How am I going to deal with the potential of losing managers or technicians? What if people don’t like the new leader? When should we change over? These are all normal questions to have, and it’s crucial to fully think through the answers before any plan is put into action.

Run through every scenario in your head and create a rational plan for each. Find the solution that will have the smallest impact on your business, and make sure you consult with your leadership team for feedback.

An aspect that is often overlooked is the timing of your transition. As best you can, try to implement your transition plan during a time of year that’s comfortable or slower for your industry. In our business, we know summers are often draining on our employees, so we looked at September or October to start transitioning duties rather than during the intensive summer period.

Give thought to potential pitfalls, and make sure you plan accordingly so you don’t panic when they arise.

It’s never too early to start planning

A lot of the success in Tim’s transition plan was due to his foresight and patience. Just as he did with me for the better part of a decade, I’m looking ahead and thinking about how I can prepare the next generation of company leaders.

There are many aspects to leading a business that you have to just learn in the role, but there are other skills that come naturally to any good leader. Identify those rising leaders with exceptional listening skills, emotional intelligence and strategic foresight. Engage them in tasks that foster the development of these skills and provide leadership opportunities where you can, preparing them for larger future roles.

Starting this process early will save you time and potential headaches down the road. If you’re not sure where to start, don’t be afraid to ask for help. We had the support of our parent company Leap Partners to help guide us through our transition, and their advice and helping hand were vital to our success.

A smooth transition of leadership does not happen overnight. It requires detailed planning and strong communication. It’s what Tim did for our company 14 years ago, and I thank him every day for it. By laying the groundwork years ago, he paved the way for a seamless transition and made it easier for me to keep his business growing and successful.

There’s time for you to put in the same work. Your future business will thank you for the time you put in today.

Jacob Hamilton is general manager at Tim Ferguson Plumbing, Air & Electric, a member of the Leap Partners family, operating across Western Tennessee.

Jacob Hamilton is general manager at Tim Ferguson Plumbing, Air & Electric, a member of the Leap Partners family, operating across Western Tennessee.

Virtual and simulation training isn’t necessarily new to the industry but its acceptance has been met with intrigue, and trepidation. But to say that this is the future of training? Not so fast. The consensus thoughts regarding this type of training is that will never replace in-person or on-the-job training, but it will become a Read more

Virtual and simulation training isn’t necessarily new to the industry but its acceptance has been met with intrigue, and trepidation. But to say that this is the future of training? Not so fast. The consensus thoughts regarding this type of training is that will never replace in-person or on-the-job training, but it will become a cog in the overall “wheel” for training assets.

According to Taco Comfort Solutions’ Product & Application Instructor-East, Dave Holdorf, Taco doesn’t want to change its training necessarily, rather seek to enhance the training experience.

“We ask many attendees how we can improve our classes and seminars. One of the most frequent replies is: ‘Add a hands-on section to the class; the theory is great and useful, but I want to install.’

“In a classroom setting, this can sometimes be difficult for the space needed, the time it takes, and to accommodate the different skillsets of attendees. We believe we’re now on a track with virtual reality (VR) training to give that experience to attendees—whether they’re seasoned pros, or new to the trade. VR can help to guide participants in what to look for, and more importantly what not to do on a project,” says Holdorf.

F.W. Webb’s Michael DelConte checks out the VR display at the Taco booth during the AHR Expo.

Ken Midgett, former teacher and apprenticeship Instructor, Lehigh Career & Technical Institute, now Plumbing, Marketing Director with Interplay—whose mission statement is “Better Careers Better Lives”—believes that they can play a part in a person’s career trajectory with that person using Interplay’s content. “When a person engages in learning and increases both their fundamental knowledge and the steps to do a task, we are helping that person upskill and creating more career opportunities for them. The value of a product that interplay offers is the demand function. You do not have to wait until a class is offered you can just connect and learn,” says Midgett.

Adaptation to simulation and on-demand training is paramount to success for the learner and the business. Midgett says that traditional classroom learning for skilled trades is becoming more and more challenging for several reasons:

- Finding good instructors: Many think that because they know a skill, they can teach it effectively. As a former educator, this is not always the case. This leads to poor instruction and marginal learners who are not engaged.

- The cost: The cost of running and maintaining a hands-on training center is much higher than instructor salaries and consumables.

- Change or die: Young learners are not inept at learning from lectures. Most skilled trade learners need to be engaged with learning and it must represent meaningful learning.

- The disruption of classroom learning to the workday: A rationale for going to class in the evening for 2-3 hours is losing traction to young learners. Business owners become frustrated with learning times and days as they view this as unproductive time. Young learners need to be met where they are with training that fits their lifestyle.

Interplay Learning training, combined with the new employee with the right attitude who is coachable and willing to learn, can be an explosive combination with a win-win result. “Taking an apprentice and having them spend time training and learning with on-demand training and then pushing that person into the field with a skilled person to watch and do in the real world is the best way to train this person or persons at scale,” says Midgett, who says there are numerous other advantages to this model:

- On-job efficiency increases as the apprentice now possesses the foundational knowledge and skills to perform a given task.

• Relationships are better between the journeymen and the apprentice, as the journeyman perceives the apprentice as engaged and productive.

• Business owners experience low turnover, better culture, and increased revenue as these new hires have direction and are leaning at scale.

• Technicians feel confident in their work due to training and upskilling.

• Callbacks are reduced and remediation training for the technician to increase their confidence

• Service managers can focus on coaching and maintaining technician stats instead of being the only technical lifeline for numerous techs.

• When sending these apprentices to “factory training,” they can engage and understand this much better due to the foundational knowledge.

Nonetheless, Midgett says there are a few things to note and understand about simulation and on-demand training:

• On-the-job or hands-on training with higher skilled supervision cannot be replaced.

- Simulations are great at teaching steps and muscle memory of a task.

- Simulation or any on-demand training cannot teach “feel.” As an example, simulation training cannot teach the skill of what “tight” feels like with a pair of wrenches on threaded steel piping or how tight to make a tank-to-bowl connection on a closet, or how tight a screw should be on the control board. This is what the onsite skilled person or journeyman must understand and teach effectively on site.

“While VR, AR and simulation-based technology are great resources, I do not think that any one particular learning system or style is the future,” says Rich Camacho, CEO & Co-Founder, BlueRecruit. Having said that, Camacho utilizes Interplay’s services (all of Interplay’s certifications and courses live on BlueRecruit, and when a person completes an Interplay course, they can then add that qualification to their BlueRecruit profile to strengthen their profile for Employer) and he thinks Interplay is a fantastic tool to augment in-class learning and a great launch point for someone either just entering the trades or seeking to upskill a particular technique.

“However, at the end of the day true craft mastery will occur in the field with a wrench. As technology continues to improve and costs continue to decline, Interplay will play a larger and larger part of building the next generation of skilled trades professionals and we’re excited to work alongside them in building “Better Careers and Better Lives,” says Camacho.

If last month’s attendance during the IBS/KBIS Show in Vegas is any sort of indicator for anything, in-person trade shows are still thriving. We’re hearing that this was the most attended show of the past 15 years. According to the National Association of Home Builders (NAHB), more than 76,000 builders, remodelers, developers and other home Read more

Running into friends while enjoying the Vegas nightlife.

If last month’s attendance during the IBS/KBIS Show in Vegas is any sort of indicator for anything, in-person trade shows are still thriving. We’re hearing that this was the most attended show of the past 15 years. According to the National Association of Home Builders (NAHB), more than 76,000 builders, remodelers, developers and other home building professionals filled the halls, “the highest level since 2009, which reflects the bullish outlook of the residential construction industry.”

This year also marked the 11th anniversary of Design & Construction Week® (DCW), the co-location of IBS and the National Kitchen & Bath Association’s (NKBA’s) Kitchen & Bath Industry Show (KBIS). DCW drew over 117,000 attendees, and more than 2,400 exhibitors occupied over one million net square feet of indoor and outdoor exhibits.

Pfister Faucet’s Spencer Brown, the Hub’s John Mesenbrink, Tim Goff, Pfister Faucets, and Dominic Sims, ICC, talk about the importance, and popularity, of the American Plumber Stories series.

Anyone who has visited the Las Vegas convention center knows that there are basically four separate halls—North, Central, South and West. I am of the opinion that the Central Hall usually gets the influx of traffic initially—over the course of the three-day event—with crossover to the North Hall fairly fluid. The North Hall is generally reserved for big bathroom players, and Central and South are filled with construction/builder booths. The West Hall, honestly, is almost at a different location where, in order to get there most of the time, you are sent underground, blindfolded and whisked through a tunnel via a manned Tesla. Pretty cool experience, actually, but not necessarily ideal if you are exhibiting in West because that’s where the trickle or “if I have enough time” traffic goes. My opinion, of course.

Oh, I almost forgot. There are a number of exhibitors set up outside—our friends from the Propane Education & Research Council (PERC), for example—right in front of Central Hall. The blue sky, 70° temps didn’t hurt those outdoor experiences either.

Dominic Sims CEO, International Code Council (ICC), talks about the partnership with American Plumber Stories for upcoming season 5 of the wildly popular docuseries.

Just a note of interest here, getting the show is getting easier with access to the monorail, which makes stops to a number of hotel locations—if it looks full, just keep nudging, you’ll find space—and hotel bus routes, which can be found in front of the Central Hall and to the side of the South Hall. Depending on when you are entering or leaving the show, Uber and taxi at your own risk.

Now, if you’ve been to the IBS/KBIS trades shows in recent past, you’ll know that the setup is pretty formulaic, but it was brought to my attention that this year they pretty much simplified the approach with similar products located near each other so you don’t have to break your Fitbit traversing the LVCC universe trying to find something.

Everything from low-flow toilets, ADA & Living in Place to the latest in bidets, KBIS had it all. From the Bemis booth.

Invariably during every trade show I attend I get asked, “what was the most interesting thing you saw on the show floor?” Well, I gotta say it was the Genesis Systems WaterCube 100, which basically creates water out of the air. I was fairly shocked when I saw the size of this unit—large—to be installed on the exterior of the home. The company contends that the product sustainably generates more than 100 gallons of fresh water daily from the air around it—enough for a household of four, and it operates in humidity ranges of >40-100% and ideal climate temperatures of >59 degrees F.

Genesis Systems WaterCube 100

In the North Hall, we saw everything from the latest in bidets, low-flow toilets, high-end kitchen and bathroom fixtures to fancy multi-colored bathtubs—a kitchen and bath designer’s fantasy space, if you will.

Moen’s 3-in-1 Water Filtration Pulldown faucets dispense filtered cold water and hot and cold tap water, including a three-function pultdown wand. 3-in-1 Water Filtration Kitchen Pulldowns pair with any Moen filtration system and are available in many styles and finish options.

“2024 marks the 60-year anniversary of KBIS—a tremendous accomplishment and an opportunity to not only celebrate our growth but to set goals for how we want to continue to elevate the show and help drive the industry forward,” said Bill Darcy, Global President & CEO of NKBA|KBIS. “We’ve had great success collaborating with NAHB and IBS and are proud to announce our continued partnership as part of this milestone year. As the kitchen, bath, and wider residential building, architect, design, and remodeling sectors continue to grow it’s more important than ever to provide a central source for inspiration and innovation.”

NAHB and NKBA announced an agreement to extend the co-location of IBS and KBIS for four years through 2030.

Next year, DCW will return to Las Vegas, Feb. 25-27.

See you next year in Vegas!

Training in 2024 is just as important as ever. How do you integrate training, education and continued learning with today’s busy contractor? Power Points, sales pitches and doughnuts. Tried and true methods of training gone by, that’s for sure. But what does today’s training look like, especially in the purview of the younger generation of Read more

Training in 2024 is just as important as ever. How do you integrate training, education and continued learning with today’s busy contractor?

Power Points, sales pitches and doughnuts. Tried and true methods of training gone by, that’s for sure. But what does today’s training look like, especially in the purview of the younger generation of contractors that digests information in 90 seconds or less?

“What was that? Sorry, I was looking at my phone,” jokes Max Rohr, Director, Education and Technical Marketing, Caleffi. “Five years ago, a three-minute-long video was a good option, now it will seem long if it is over that 90-second threshold. Ideally, you get to the point in the first five seconds and work the explanation back from there. Like showing the cake and then going back to bowls of ingredients.”

According to, Dave Holdorf, Residential Trainer & Rep Training Manager—Eastern Region, Taco Comfort Solutions, it’s a challenge. “We’ve found that it helps to bring different instructors in for specific segments of the training. Each instructor brings their own perspective; even hearing a different voice in the room makes for a more compelling presentation. Every facet of our training is now geared to maintain the attention of participants. We also make sure to schedule breaks so that the attendees can attend to business, or need at home. By creating the curriculum with attendees in mind, their focus remains with the topic in front of them.”

Nevertheless, the training department at Taco has always looked at training not from a product view but from an application perspective, giving attendees the information they need to do their job better, and to give their customers the comfort they deserve. “We use real world experiences to solve real world problems with personal experiences and a bit of humor—as you know, John, it ain’t worth doing if you’re not having fun as well,” says Holdorf.

Caleffi’s Bob “Hot Rod” Rohr brings his props and his wealth of experience and knowledge to trainings.

But what about those PowerPoints and doughnuts? “Every learning style is different, so you have to be adaptable. If you see the audience tuning out a PowerPoint, stop and grab a product to bring to an attendee and talk about a case study that is related instead,” says Rohr.

In addition, everything falls apart for a trainer if the audience gets the impression they are overpromising, adds Rohr. For example, “Honesty is something Hot Rod is specifically good at in contractor training sessions. As a former installer, he always has tips for getting the job done and workarounds that are really tangible,” says Rohr.

The New Normal?

The Covid pandemic saw what we thought was going to be a new normal with virtual training, but what we are now seeing is the importance, and return, of in-person training.

This past year Taco saw a huge jump of in-person training, on the road as well as at Taco HQ in Rhode Island. So much so that the company had to dramatically increase the number of sessions back in Rhode Island to accommodate. “However, that does not mean to diminish the virtual training, Taco Tuesday and Taco After Dark webinars are still posting a large number of attendees that are hungry for information in bite size chunks, not as large as when we all locked down at home, but still popular,” says Holdorf.

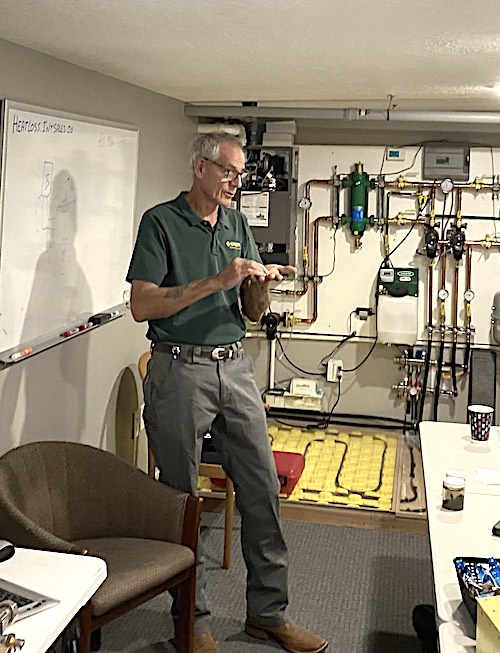

Taco’s Holdorf conducts a training at the Cranston, R.I. HQ.

Nonetheless, “when we’re online, we know it’s so easy to stray off to the next shiny thing online, so to keep attendees engaged, we encourage two-way communications. If participants have questions, we want them to ask immediately,” continues Holdorf.

In fact, Holdorf says that people who attend Taco’s webinars typically take it to the next level and seek live training. A combination of both virtual and live training can help attendees dial in on what they want to learn—or perhaps didn’t initially develop a full understanding of what it is they most needed to know. “These options allow them to fine-tune their training experience to make them as good as they want to be. And, ideally, we help them raise the bar. We routinely heard from trade pros who came to us for a better understanding of a single application or concept, and through that experience come away with an energized desire for much more,” says Holdorf.

In 2023, Caleffi performed almost a 50/50 mix of in-person and virtual. Contractors like hands-on training, says Rohr, so it is good to be back on job sites for that type of interaction. And, engineers didn’t all go back to the office after COVID. “Many of the engineering sessions we do are virtual because that firm may be scattered all over the region. You might catch 20 people in a virtual training, where only 10 of them are in the office that day,” says Rohr.

Know-It-Alls

What about those who are stubborn enough to think that they don’t need further education and training? “I love this question and see and hear it often in the industry,” says Ken Midgett, L.M.P, Plumbing, Marketing Director, Interplay Learning, and former Teacher and Apprenticeship Instructor, Lehigh Career & Technical Institute.

Those in skilled trades should embrace the concept of being “lifelong learners,” consistently expanding their knowledge in their current specialty and exploring related disciplines. Whether licensed or not, individuals in skilled trades should assess their goals, career paths and professional growth within their field. It’s common for some to reach a point where they feel adequately skilled and think further education is unnecessary. According to Midgett, this assumption is misleading for several reasons:

• For example, a residential plumber could benefit from learning about commercial plumbing, Med Gas, Backflow, Water Well work, Water Conditioning, HVAC, Electrical, etc. Diversifying skills not only enhances one’s expertise but also increases their marketability across various skill sets, intern boosting income and long-term employability.

• Despite advancements in safety measures within the construction industry, the misconception that skilled trades workers are immune to injuries persists. While the overall safety landscape has improved, life-changing injuries can still occur. In such unfortunate instances, if an individual can only rely on skills specific to their trade and lacks versatility, their career may face irreparable damage. Therefore, investing in ongoing training, education, and professional development becomes crucial for ensuring resilience in the workforce and mitigating the impact of unforeseen challenges. Repurposing skillsets may be challenging when there has been no prior skill or professional development planning before the injury event.

• The industry, codes, tools, and methods to do a task are constantly changing. Skilled trades workers need to educate themselves and stay on top of new developments. This is critical to the success of a technician and company.

In the end, it’s what ends up in the ol’ noggin as useful information that translates to the jobsite. “Students only retain a tiny amount of the information that you present to them, but they will remember their feelings about the trainer for a very long time,” says Rohr. “It is hard to know if a bigger win is when customers retain a piece of information you presented or if they remember that you seem like you know what you are talking about. “If they trust that you did a good job, that memory will stay with them for a career, potentially.”

Mechanical Hub recently talked with Rich Camacho, CEO, Blue Recruit, about the hiring of qualified candidates to potential trade jobs. Blue Recruit is a company that provides skilled workers with a revolutionary path to success. While that mission is straightforward, reaching that goal requires tremendous collaboration between industry, educational systems and supporting organizations. Here is Read more

Mechanical Hub recently talked with Rich Camacho, CEO, Blue Recruit, about the hiring of qualified candidates to potential trade jobs. Blue Recruit is a company that provides skilled workers with a revolutionary path to success. While that mission is straightforward, reaching that goal requires tremendous collaboration between industry, educational systems and supporting organizations. Here is our discussion with Rich:

MH: What do you think the industry (PHVAC) can be doing better to recruit more to the trades?

CAMACHO: An issue we hear constantly amongst PHVAC companies, to a far greater extent than any other trade, is the idea that their company is “different.” I don’t know if it is a culture issue within PHVAC or a lack of competitor awareness, but many PHVAC owners have this misguided belief that the services they provide are more complicated than their competitors and thus must only hire highly experienced technicians and installers. Guess what, 95% of y’all provide the exact same services as the other five shops in your town and you are all fighting over the same technician or plumber that has seven years under their belt.

The insistence that you can only hire extremely experienced workers is a major hurdle to growth. Too often people complain “young people don’t want to work,” “they’re lazy,” “they are avoiding the trades to be social media influencers,” etc. Well, guess what? When you refuse to even interview someone trying to launch their skilled trades career, you become a major part of the problem. That business owner needs to remember that they were once a brand-new Apprentice, and someone took the time to train them. We will never train the trades’ next generation if we do not give them the opportunity to get started.

The insistence that you can only hire extremely experienced workers is a major hurdle to growth. Too often people complain “young people don’t want to work,” “they’re lazy,” “they are avoiding the trades to be social media influencers,” etc. Well, guess what? When you refuse to even interview someone trying to launch their skilled trades career, you become a major part of the problem. That business owner needs to remember that they were once a brand-new Apprentice, and someone took the time to train them. We will never train the trades’ next generation if we do not give them the opportunity to get started.

MH: Piggybacking off of this, how do we do a better job highlighting pay, lifestyle, for example, as huge positives while reducing the negative stereotypes with the trades?

CAMACHO: A major trend we have seen in recent years is that the average person is now well aware of the compensation potential in the trades. Trade and vocational schools are seeing higher enrollment than ever before. After all, if you’ve had your AC replaced or made an emergency plumbing call in the last three years you can vividly recall how many zeros where in that invoice.

However, what we as an industry are failing to promote is the flexibility the trades provides and the intrinsic benefit of the work itself. Compensation is actually the third most important factor for Job Seekers in deciding between job offers. A lasting impact of COVID is the desire for flexible schedules, and the trades often provide this freedom. Second, an astounding 87% of trades workers report being either satisfied or very satisfied in their work, while 62% of white-collar workers describe their work as “drudgery.” Remember those data points next time you hear a parent tell their child that the only way to succeed in life is by going to traditional 4-year college.

MH: During Covid, contractors were deemed essential workers. Do you think this heightened awareness to the trades as pandemic-proof and recession-proof to a certain extent?

CAMACHO: There is ZERO doubt that the trades are and will forever be the most recession-proof career track. After all, in a downturn economy, a family may decide not to take a planned vacation, might delay that planned home renovation, but they will still make the service call when their air goes out or the sink is overflowing.

With all the terrible that COVID brought us, a lasting positive legacy it left is the light it shined on what I’ll be bold enough to call the “Higher Education Cartel.” Insane student debt levels, often meaningless degrees, and social issues has shown many young people—just as importantly their adult influencers—that the trades are not a secondary option but a true avenue to success. Afterall, graduate enrollment rates are down about 15% from their 2010 highs, but construction focused trade school enrollment is up over 19% in that same period!

MH: We’ve been hearing a lot lately regarding hiring based on work ethic, abilities, desire, etc., and companies can the train the “skill.” Are you in agreement with this? Explain.

CAMACHO: Socrates once said the following, “The children now love luxury; they have bad manners, contempt for authority; they show disrespect for elders and love chatter in place of exercise. Children are now tyrants, not the servants of their households.”

In other words, the older generation has ALWAYS thought that the younger generation is lazy, lacks discipline, etc. I’ll be the first to say that categorizing all young people in this way is simply incorrect. Every single day, whether it be in the interactions we have with students at one of our partnered trade schools, a SkillsUSA classroom, or feedback from a customer, we’re exposed to motivated young people working hard to grow their skills and build a lasting career.

I believe that such character traits are mostly built at a very young age in the home, and unless your company is operating a three-month bootcamp and shaving heads, it is unlikely you can truly develop such soft skills. The best way to see a person’s values and ethics before hiring, is to include personality assessments within your interview process which will identify strengths and weaknesses.

We also recommend having that potential candidate spend a half day onsite, shadowing your team, touring your facility, and ending the interview with a group lunch. This allows your employees to play a part in the hiring process and allows you to see how they will interact with others (including restaurant staff) on a social or personal level.

MH: How does someone get involved with Blue Recruit?

CAMACHO: Couldn’t be easier, go to www.BlueRecruit.com and create your free account in about 5 minutes. You can view live available talent in your area, hire when you’re ready, and if you have any questions, we host live training demos every workday at 10, 12, and 2 pm EST.

Finally, we love working with partners like Mechanical Hub, and we continue to do our part in connecting the workers that keep our country moving forward with tremendous employers.