Innovation takes on many forms, but in the world of plumbing and HVAC piping systems, change and or progress has been somewhat slow to take place. Copper press fitting systems have been on the scene for nearly 20 years in the U.S., even longer in Europe, but industry-wide adoption is a work in progress. If Read more

Featured Articles

Innovation takes on many forms, but in the world of plumbing and HVAC piping systems, change and or progress has been somewhat slow to take place. Copper press fitting systems have been on the scene for nearly 20 years in the U.S., even longer in Europe, but industry-wide adoption is a work in progress. If you’ve been following us here on The Hub you already know my opinion that pressing copper or iron pipe for nearly every application is not only efficient but also profitable for any size contracting firm. But I’m not here to debate the merits of press versus soldering or threading; instead, I’d like to talk about a couple new tools we’ve had in the shop for review.

The new Gorilla™ pressing tool line features two unique tools: the inline battery pressing tool (INLNPRESS-KIT19kN) and the pistol grip battery powered pressing tool (PSTLPRESS-KIT32KN). I’ve personally put both tools to work on a handful of plumbing and heating projects over the last month, and I’m impressed.

Not unlike other press tools in the market the Gorilla press tools will complete a watertight connection, whether pressing copper, steel or PEX, with a 3-5 second cycle time. Here are the features of each tool kit broken down separately:

The larger of the two Gorilla press tools is capable of pressing up to 2″ copper or steel fittings with the included tongs/jaws. When equipped with compatible jaws such as the RIDGID XL-C or Milwaukee M18 ring sets the pistol tool is capable of joining 2-1/2″ thru 4″ copper and steel. Greenlee offers additional factory supplied jaw sets for PEX Press systems (NIBCO) as well.

The key here is jaw compatibility. For contractors who already own other press tools or for those looking at a new press tool as a first purchase knowing what tool is right for you based on its capabilities should be the focus. The PSTL tool is compatible with all of the Viega PROPRESS copper, stainless and iron pipe (MEGAPRESS) fitting systems when either using the Greenlee jaw sets for 2″ and smaller copper or the RIDGID or Milwaukee M18 jaws for XC copper fittings or MEGAPRESS. A list of compatible jaw sets is included at the bottom of this review.

The PSTL-KIT32kN kit includes six V-profile copper/steel press jaws in sizes from 1/2″ to 2″, two 3.0Ah 18V Makita battery packs, rapid battery charger and heavy duty case with foam tool organizer insert. The 7,200 lb (32kN) force is delivered to the jaw set at the end of the swivel shaft. The unique pistol-grip offers an ergonomic design, placing the majority of the weight directly over the users hand and wrist for more balanced control when using the large diameter jaws. A single trigger deploys the hydraulic piston for a 3-5 second press cycle but is not automatic, requiring the user to fully depress the trigger for the entire cycle. However, once the press is complete, the tool retracts automatically, which does not require the operator to hold the trigger. In addition, the tools have the ability to retract the jaws at any point in time. An indicator light illuminates if the tool senses insufficient force during a press cycle and AUTOSTOPP technology stops the piston once optimal force is reached to complete the press of a fitting. The tool carries a 5-year warranty from the manufacturer and boasts the ability to go 40K press cycles before factory authorized service is required.

Inline Press (INLNPRESS-KIT19kN)

This is the more compact tool of the Gorilla lineup. Measuring in at just over 17″ when geared up with the 3/4″ copper jaws this swivel shaft tool is sleek and capable of sitting in tight spaces where only one hand may be appropriate for tool operation. The 4,275 lb (19kN) force tool features a single trigger, swivel head and 18V Makita 2.0Ah 18V battery.

The inline tool is capable of pressing both PEX press [up to 1-1/2″, see video] and v-profile copper/steel fittings (Viega type) up to 1-1/4″ diameter making it prime for all residential applications. As with the pistol tool the inline tool carries a 5-year manufacturer warranty and is capable of pressing 40K times in between service intervals. Press cycle time is 3-5 seconds depending on fitting type and diameter. The user is required to depress the trigger for the entire press cycle until the AOTOSTOP technology feature senses sufficient force, the piston retracts automatically the same as the pistol tool. The kit includes two Makita 18V batteries, rapid charger and heavy duty case with rigid foam organizer insert.

Recap

Overall the build quality of the Greenlee Gorilla press tools is high. Having been manufactured in Germany by the Greenlee owned Klauke tool company they’re developed from years of pressing experience and thousands of tools having been in use for many years. The 5-year warranty is impressive and compatibility with other manufacturer jaw sets makes both models very attractive in my opinion. Current jaw offerings open these tools up to the popular Sporlan Zoomlock refrigeration press fitting system as well even further expanding the capabilities and usefulness of these tools to HVAC contractors as well as plumbers. The Inline tool kit should be expected to price out between $2,100-$2,300, the more capable pistol tool will cost a contractor $3,300-$3,500 for the kit making both tools competitive in the press tool market.

https://www.youtube.com/watch?v=z9SXJYzzIGw

https://www.youtube.com/watch?v=Cys2STrvtRc

Are you ready to ditch the gas can and forever say goodbye to pesky 2-stroke engines that, for no matter how hard you try, never seem to run right come springtime? The big three tool manufacturers have hit the summer of 2017 running with cordless string trimmers, blowers, hedge trimmers and even chainsaws that operate Read more

Are you ready to ditch the gas can and forever say goodbye to pesky 2-stroke engines that, for no matter how hard you try, never seem to run right come springtime?

The big three tool manufacturers have hit the summer of 2017 running with cordless string trimmers, blowers, hedge trimmers and even chainsaws that operate on the same batteries you have in the shop or on the job.

Banking on the more power is better philosophy; these cordless yard machines are delivered with large capacity battery packs. The same batteries running high demand tools like right angle drills, rotary hammers and saws.

Whether you’re tired of finicky small engines or have better things to do with your time than make that last minute run to the gas station just so you can mix up a gallon or two to trim out the yard, these tools are definitely worth looking twice at.

Here is a quick rundown of my own experience with the Dewalt 60V, Milwaukee 18V and Makita 36V OPE. Watch for additional reviews as more tools are arriving weekly here at The Hub.

Milwaukee M18 FUEL String Trimmer

New product/tool design engineers are always tasked with designing the next best thing, the fastest or most powerful tool that will turn heads and ring in sales. One guiding principle in design is the “KISS” method. Standing for “keep it simple stupid” but it’s not necessarily a negative connotation in the final production model of the M18 string trimmer.

With a simple safety locking throttle trigger, high/low speed selection and a single 9.0Ah battery pack this trimmer is as simple as it gets. Oh yeah, and its extremely powerful. The 14”-16” cutting swath and straight shaft are perfect for clearing thick overgrowth or manicuring your 9th hole-like lawn.

With a simple safety locking throttle trigger, high/low speed selection and a single 9.0Ah battery pack this trimmer is as simple as it gets. Oh yeah, and its extremely powerful. The 14”-16” cutting swath and straight shaft are perfect for clearing thick overgrowth or manicuring your 9th hole-like lawn.

I only wish my video turned out a little better but you’ll have to take my word for it, this 18V tool is a beast when considering power and runtime. You’ll want to have a 9.0Ah battery but you’ll only need one to finish your yard. I trim about an acre and can complete the job on about 2 bars.

Dewalt 60V MAX String Trimmer If you’re familiar with the new FLEXVOLT tool lineup from Dewalt then take a look at this trimmer. Running on a single 60V 3Ah FLEXVOLT battery, this cordless trimmer has a ton of power upfront and decent battery runtime. Motor placement is different than all the others in this category in that it’s placed directly at the head/end above the line spool. Like the other two here the 60V MAX uses full-sized trimmer line, which absolutely rocks when comparing these trimmers to early models of electric/cordless trimmers. I have run this trimmer thru some pretty tough paces and have been thoroughly impressed with its power. I’m a little concerned with the amount of debris buildup on the motor housing but I believe most of that is from using it to clear heavy overgrowth in the field out back. Typical yard usage would likely not cause such buildup and therefor not pose a problem to the motor itself.

Makita 36V String Trimmer

If you’ve got a couple Makita 5Ah batteries and enjoy a tool truly designed with the user in mind then look no further.

The Makita XRU09 string trimmer has an outer rotor brushless motor direct drive system which provides for high power and high torque. The engineers included nearly all the bells with this one giving it two speeds and even reverse. You might be wondering “why reverse” and the answer is simple really. When clearing tall grass or weeds in heavy overgrowth areas the head of any trimmer will likely be wrapped up over time; the reverse rotation setting allows for quick clearing of the trimmer head and in my opinion that simple genius in design. They added a switch and circuitry to run the motor backwards for a short duration, why didn’t the others do that? I personally like the ergonomics of this trimmer best. Its also smoother and powerful enough to handle all my trimming needs over nearly and acre of yard and landscaping. Videos are still in the making.

The Hub is in Missoula with ProStaff team member Andy Mickelson on a recent residential gas fired Hydronic comfort heating system installation. Featured here is the Neutra-Safe® System Feeder, which is designed to feed and maintain pressure in closed loop hydronic and thermal solar systems that require up to 50 PSI of cold static pressure Read more

The Hub is in Missoula with ProStaff team member Andy Mickelson on a recent residential gas fired Hydronic comfort heating system installation. Featured here is the Neutra-Safe® System Feeder, which is designed to feed and maintain pressure in closed loop hydronic and thermal solar systems that require up to 50 PSI of cold static pressure for use with water or glycol (up to 50%) solutions. For more info on Neutra-Safe, visit www.neutrasafe.com.

Mechanical Hub had the chance recently to speak with David Kohler, president and CEO, Kohler, about the company’s sustainability and marketing missions, and its positioning in a growing global market. “The Bold Look of Kohler” has been highly regarded as a turning point in Kohler’s marketing, and, I believe, overall company success. Can you talk Read more

Mechanical Hub had the chance recently to speak with David Kohler, president and CEO, Kohler, about the company’s sustainability and marketing missions, and its positioning in a growing global market.

“The Bold Look of Kohler” has been highly regarded as a turning point in Kohler’s marketing, and, I believe, overall company success. Can you talk about this marketing campaign, the era, and any interesting circumstances surrounding it?

David Kohler: The Bold Look of Kohler certainly did mark a turning point for Kohler in 1967 in terms of its advertising and brand voice. I believe that the sentiment of this statement has been a strong element of the DNA of this company since its beginnings, and the campaign gave us, and continues to give us, an outlet to share this passion and drive with the world. There is a statement that I feel fits our brand very well, and helps to further define what once was a tagline but has essentially always been embodied by our company: Bold means never compromising, never settling for what has always been and always challenging what could be. Today, Bold continues to reinvent reality and define a lifestyle. We believe strongly in this mindset, and it permeates all aspects of our company.

While visiting Kohler, the beauty of the area and the respite feeling of the surroundings almost makes you feel—intentional or not—that you are not actually visiting a plumbing fixture manufacturing facility but you are getting a full “Kohler experience.” Can you describe the intention behind the Kohler experience for contractor visits?

While visiting Kohler, the beauty of the area and the respite feeling of the surroundings almost makes you feel—intentional or not—that you are not actually visiting a plumbing fixture manufacturing facility but you are getting a full “Kohler experience.” Can you describe the intention behind the Kohler experience for contractor visits?

David Kohler: Kohler’s mission of enhancing the level of gracious living experienced by every individual who interacts with our brands and services is one of the driving forces behind the “Kohler experience” here in Kohler, Wis. At the main entrance of our headquarters in Kohler, we have the famous John Ruskin quote “Life without labor is guilt; Labor without art is brutality.” This inspirational quote carries many meanings, one of which speaks to the overall design of our campus and surrounding community.

There is an intricate and beautiful marriage in Kohler, Wis. between industry and art. The presence of the factories is a daily reminder that labor, innovation and craftsmanship is crucial to our society, and the beautiful settings and experiences surrounding this factory campus reminds us that there is a need and desire for art in our lives. It is the harmonious existence of these two ideals that creates the Kohler experience – unlike any other in my opinion.

David Kohler, left, breaks ground on LODGE KOHLER in April 2016. Herb Kohler, executive chairman Kohler, center, and Mark Murphy, president and CEO, Green Bay Packers.

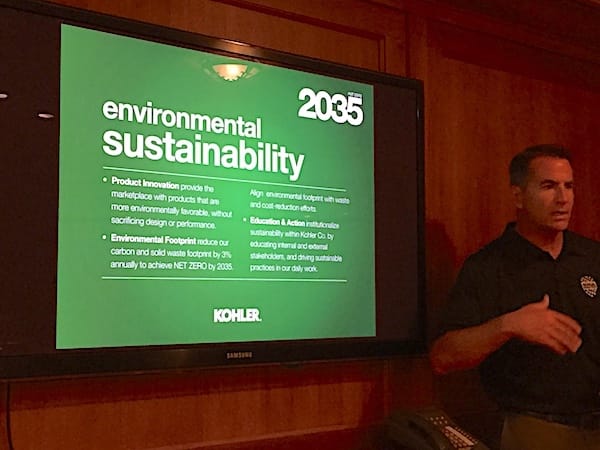

Can you talk about any Kohler’s initiatives toward sustainability? How do you achieve the goal of reduction of carbon and solid waste footprint by 3% annually to garner net zero by 2035?

David Kohler: Reducing our global environmental footprint to Net Zero by 2035 is the cornerstone of our sustainability goal. Given the types of products we manufacture, we believe monitoring and eliminating our output of greenhouse gases and solid waste along with decreasing our water consumption will have the greatest impact. Our initiatives vary from capital investment in process improvement and equipment to switching from incandescent to LED lighting fixtures. We still have a long road ahead to reach Net Zero, but every step puts us closer to our goal.

In Kohler, Wis., the more waste we repurpose, the less goes into the landfill. Kohler’s exceptionally high standards for our vitreous products sometimes create “rejects” that we remove from the production line. Because the material cannot be reworked, the rejects become “cull” – which in days gone by, would have gone to landfills. Today, we work with customers, like Wausau Tile, that can use our cull as a ceramic aggregate for concrete products, such as benches, tables and tile flooring. In Brownwood, TX, water reused is water saved. Our Brownwood pottery connected a condensate return system to eight air-handling units. The collected water routes to the cooling tower and irrigation system, effectively reducing the burden on the local water supply by 4.5 million gallons of water per year.

In Kohler, Wis., the more waste we repurpose, the less goes into the landfill. Kohler’s exceptionally high standards for our vitreous products sometimes create “rejects” that we remove from the production line. Because the material cannot be reworked, the rejects become “cull” – which in days gone by, would have gone to landfills. Today, we work with customers, like Wausau Tile, that can use our cull as a ceramic aggregate for concrete products, such as benches, tables and tile flooring. In Brownwood, TX, water reused is water saved. Our Brownwood pottery connected a condensate return system to eight air-handling units. The collected water routes to the cooling tower and irrigation system, effectively reducing the burden on the local water supply by 4.5 million gallons of water per year.

Is there optimism for growth in global markets? (India, Middle East, Latin America, etc.)

David Kohler: Absolutely there is optimism for global growth. We are seeing positive growth in many key global markets like China, India, and the Middle East. Our brand is number one in the U.S. and China, and the number one import brand in India. We see opportunities for growth in markets such as Brazil, Sub Saharan Africa, and throughout Asia. We aim to lead in every market that we have a presence in, and with our global footprint and global design centers, we are able to create specialized collections and experiences for each market to focus on the needs and demands of the consumers within that region.

Is e-commerce a significant driver for Kohler’s business? Explain.

David Kohler: In the U.S., e-commerce certainly is an important part of our business model. We know through extensive research that consumers not only research online, they are making purchases online, even for large items like bathtubs and shower doors. And, studies have shown that brick-and-mortar retail sales are highly influenced by online shopping activity and online shopper research.

We want to enhance the experience with Kohler during that process by ensuring that Kohler products are presented in a way that is reflective of the high quality of our brand. Kohler has established an Authorized E-Tailer Program designed to reward all the stakeholders of our brand: end consumers with the best possible online experience, authorized e-tailers with the exclusive right to sell KOHLER brand plumbing products online, and Kohler distributors with the opportunity to tap into this growing channel.

By partnering with authorized e-commerce sites, Kohler is simultaneously strengthening its online brand presence and its offline distributor relationships while also ensuring that consumers have a consistent experience with the KOHLER brand. The KOHLER Authorized e-tailer program has been positively received by our distributor partners because it supports the brick-and-mortar distributors and authorized e-tailers alike who are working synergistically to promote the KOHLER brand while providing an enhanced experience to consumers.

LODGE KOHLER

Finally, Kohler is all systems go in its LODGE KOHLER project, a Four-Diamond hotel development Titletown, a destination created on 34 acres immediately west of Lambeau Field, in Ashwaubenon, Wis. The hotel will have a panoramic 5th floor restaurant, bar and outdoor cigar terrace; a full-service garden spa; an indoor/outdoor pool; an indoor/outdoor café opening to the plaza, and 144 rooms and suites—all with unique showering systems.

One of three anchor tenants in the Titletown District, LODGE KOHLER is the first to break ground as construction begins for the destination. Part of the Kohler Co. Hospitality & Real Estate portfolio, LODGE KOHLER will offer guests a high level of accommodation, services and amenities.

The ProStaff team moves to the Pacific Northwest as Bend Radiant Heating Inc., Bend, Ore., installs a Noritz CB180 combi boiler for a residential remodel in Madras, Ore. In business for 12 years, Bend Radiant Heating performs hydronic heating and tankless water heater systems work, which includes radiant floor in several applications, radiators, air coil Read more

The ProStaff team moves to the Pacific Northwest as Bend Radiant Heating Inc., Bend, Ore., installs a Noritz CB180 combi boiler for a residential remodel in Madras, Ore.

Steve Zettle, owner/operator of Bend Radiant Heating Inc., after installing the Noritz CB180 combi unit.

In business for 12 years, Bend Radiant Heating performs hydronic heating and tankless water heater systems work, which includes radiant floor in several applications, radiators, air coil hot water, snow melt systems and tankless water heaters for both residential and commercial installations.

This is pre-DHW connection with the hydronic piping. Zettle used the Noritz supplied primary loop, Grundfos Alpha pump, controls via Honeywell AQ w/ floor sensors, manifolds (one shown and another in a remote closet) were Uponor EP w/actuators for zone controls, a single switching relay (S/R) to the air unit in the garage (not shown here yet but connected to the manifold in this photo). They opted to run the water temp to the air unit at the same temp as the floors just to simplify things; the garage is really small and the load was met using the heater at a lower temp.

The retrofit for the 1,500-sq.-ft. Madras home features a 3-zone hydronic and domestic hot water system powered by a Noritz CB180 combi boiler, with a hydronic fan coil in the garage to heat that space. The benefits of the hydronic fan coil are that it allows for a separate zone, and it is a less expensive option than running in-floor radiant heat in the garage. Bend Radiant Heating techs insulated the existing slab floor, installed PEX tubing and had the gyp-crete poured for the in-floor radiant heat.

The unit allows different temperature settings for the domestic hot water heating and space heating applications. For domestic hot water, temperatures range from 90 to 140 degrees Fahrenheit. On the space heating side, the range is 100 to 180 degrees F.

Installing the Noritz CB180 combi boiler made sense due to its space savings, productivity, efficiency and reliability. The unit delivers hot water at a 95% efficiency—95% of the fuel consumed goes to heating the water to the preset temperature, as opposed to being lost up the flue into the atmosphere. This fuel-saving performance earns it the highest Energy Star rating, allowing homeowners to qualify for state energy rebates.

Weighing only 85 pounds, the wall-hung CB Combi is also significantly lighter than a traditional boiler, requiring only one installer to do the job instead of two. In fact, its compact size allows it to take up as much as 80% less space than a traditional floor-standing boiler and water heater.

Bend Radiant Heating has installed Noritz products for years, and has had good results. “Our confidence in the product and its reliability and its ease of installation make it a trusted boiler unit,” says Steve Zettle owner/operator, Bend Radiant Heating Inc.

The combi model contains three superior-grade stainless steel heat exchangers as well as scald prevention for domestic hot water safety. Venting can be accomplished using PVC, CPVC or PP piping through a sealed combustion direct vent or single vent. According to Zettle, “The piping was very simple, the internal pump is really nice, venting is super easy with all the options available, and the control setup was very straightforward, allowing for a lot of flexibility.”

The customer reports that the house is very comfortable, and the hot water production is seamless. “After I did a detailed explanation of how the system would work and educated the customer on the need to have the pump run at a very minimal time frame, the homeowner set up a recirc system,” says Zettle.

According to Zettle’s overall ProStaff assessment, this is the third project using the Noritz combi. “I think there is a huge market for the combi boiler, and I see our installation of these units becoming more frequent. I am using them on small snow melt jobs where we would typically install a separate boiler, now we are combining a new appliance that does both—so the customer gets a new water heater, tankless style, with a new snowmelt system—no additional appliances to do separate jobs,” says Zettle.

The unit allows different temperature settings for the domestic hot water heating and space heating applications. For domestic hot water, temperatures range from 90 to 140 degrees Fahrenheit. On the space heating side, the range is 100 to 180 degrees F.

Same situation on radiant heat systems. We have a job doing a floor warming in combination with a forced air furnace, using a combi was an easy sell. If they have recirc, we are trying to set up a 40 – 50-gallon electric water heater off the combi so no flow issues, and so the recirc does not interfere with the space heating. “Pre-heat the water at 95% efficient and let the tank just trickle in a little extra to accommodate for recirc or for high volume use when applicable,” says Zettle.

Weighing only 85 pounds, the wall-hung CB Combi is also significantly lighter than a traditional boiler, and its compact size allows it to take up as much as 80% less space than a traditional floor-standing boiler and water heater.

The CB Combi delivers up to 9.2 gallons per minute of domestic hot water and can be used on a whole host of applications including radiator, baseboard or in-floor radiant hydronic heating; as well as HVAC systems using water-to-air heat exchange with an air handler, and pavement snow melting.