Chicago Faucets elevates style within the commercial plumbing industry with its new 3600 Series. The 3600 Series is the latest addition to the Chicago Faucets Metermix® line of metering faucets. All 3600 Series faucets feature user-adjustable temperature control for a superior hand washing experience. Chicago Faucets’ popular MVP® metering cartridge, the heart of the 3600 Read more

Featured Articles

Chicago Faucets elevates style within the commercial plumbing industry with its new 3600 Series. The 3600 Series is the latest addition to the Chicago Faucets Metermix® line of metering faucets. All 3600 Series faucets feature user-adjustable temperature control for a superior hand washing experience. Chicago Faucets’ popular MVP® metering cartridge, the heart of the 3600 Series, provides precise water flow, automatic shut-off, and adjustable run time to save water with every use. A choice of flow rates from 0.35 GPM (1.3 L/min) to 1.5 GPM (5.7 L/min) allows specifiers and building owners to strike the right balance between water savings and user comfort. Threaded mounting studs and free-spinning, stainless steel hose connections make installation easy.

Chicago Faucets elevates style within the commercial plumbing industry with its new 3600 Series. The 3600 Series is the latest addition to the Chicago Faucets Metermix® line of metering faucets. All 3600 Series faucets feature user-adjustable temperature control for a superior hand washing experience. Chicago Faucets’ popular MVP® metering cartridge, the heart of the 3600 Series, provides precise water flow, automatic shut-off, and adjustable run time to save water with every use. A choice of flow rates from 0.35 GPM (1.3 L/min) to 1.5 GPM (5.7 L/min) allows specifiers and building owners to strike the right balance between water savings and user comfort. Threaded mounting studs and free-spinning, stainless steel hose connections make installation easy.

With a solid ECAST® brass, chrome-plated body, the 3600 Series provides unmatched durability while meeting national and local requirements for the reduction of lead in plumbing equipment. In addition, the 3600 Series meets ADA requirements.

The 3600 Series mounts to standard 4˝ sink openings and fits almost any lavatory application. Physicians’ offices, retail stores, restaurants, and other commercial settings can reap the many benefits of Chicago Faucets, the brand preferred by the finest universities, hospitals, and corporate campuses for over 100 years.

The Chicago Faucet Company is part of the Geberit Group, a European market leader and global provider of sanitary technology. Since 1901, The Chicago Faucet Company, located in Des Plaines, Illinois, has offered commercial faucets and fittings built to stand the test of time. A combination of the best engineering, finest materials and quality workmanship has made Chicago Faucets the specified choice in healthcare facilities throughout North America.

As European market leader, the Geberit Group is a global provider in the area of plumbing technology with sales of CHF 2.6 billion and about 12,000 employees in over 40 countries worldwide.

For additional information, www.chicagofaucets.com.

Barrel O’ Fun, a snack manufacturer with three locations across the U.S., distributes nationwide to retail stores, food service outlets and private labels. As the company continued to expand its reach, a distribution center was needed for the growing western market, which led them to build a new, multi-million dollar facility in Phoenix. Niemeyer Read more

Barrel O’ Fun, a snack manufacturer with three locations across the U.S., distributes nationwide to retail stores, food service outlets and private labels. As the company continued to expand its reach, a distribution center was needed for the growing western market, which led them to build a new, multi-million dollar facility in Phoenix.

Niemeyer Brothers Plumbing, Inc., also located in Phoenix, did the plumbing work on the new Barrel O’ Fun facility. They knew that stainless steel was the best option for the job because of its quality and performance in washdowns as well as its appealing design for areas where the piping penetrated the ceilings.

Rick Niemeyer, President of Niemeyer Brothers, estimated that the team installed thousands of feet of stainless pipe.

“Viega ProPress was the best choice for this project because of the labor savings and the availability of the products,” he said.

Niemeyer Brothers installed Viega 304 and 316 stainless pipe and fittings, ranging in sizes from ½” to 3″. Applications included nitrogen, process water, compressed air and domestic hot and cold water.

Approved for a variety of applications and available in a vast array of fitting configurations, Viega systems can be installed in multiple applications within the same project. Niemeyer Brothers installed the nitrogen line using Viega 304 stainless, but the potable water system utilizes the 316 stainless because of its NSF rating.

“The entire nitrogen system is all in stainless,” he said. “It worked fantastic. Not only does it look aesthetically pleasing, it’s just the right material for the application.”

As an experienced plumber, Niemeyer wasn’t sure that Viega ProPress would work when he first heard about it, but after installing it in 2008, he experienced the system’s labor savings and trustworthy connections firsthand. Since then, Niemeyer Brothers has continued to install Viega ProPress systems in a greater variety of projects.

As an experienced plumber, Niemeyer wasn’t sure that Viega ProPress would work when he first heard about it, but after installing it in 2008, he experienced the system’s labor savings and trustworthy connections firsthand. Since then, Niemeyer Brothers has continued to install Viega ProPress systems in a greater variety of projects.

“Change is always a little challenging,” Niemeyer said. “But now we install it in more and more projects all the time, especially in hospital and medical work.”

With trustworthy system solutions, Niemeyer Brothers Plumbing, Inc. can count on Viega to help this snack food manufacturer focus on meeting the needs—and taste buds—of its customers.

“It eliminates the welding process, which is definitely slower,” Niemeyer said. “You can press a lot faster than you can weld. The fittings are more expensive, but the installation time you pick up is worth the cost.”

For more information, call 800-976-9819 or visit www.viega.us.

Watts unveiled new drainage products specifically designed to address the drainage challenges of elevated parking structures. They include the new Watts Dead Level® Z and Dead Level® S channel drains, which are engineered for both precast and cast-in-place parking structures, respectively. The shallow profile and frame-anchored channel design simplifies installation and properly marries the channel Read more

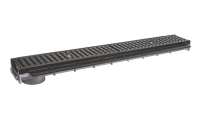

Watts unveiled new drainage products specifically designed to address the drainage challenges of elevated parking structures.

They include the new Watts Dead Level® Z and Dead Level® S channel drains, which are engineered for both precast and cast-in-place parking structures, respectively. The shallow profile and frame-anchored channel design simplifies installation and properly marries the channel with the structural deck.

Watts Parking Deck drains and channels provide a complete package to address the rigorous demands of parking deck drainage specification and installation.

Learn more at go.Watts.com/Hero.

For more information, visit www.watts.com.

The room was filled with some of the brightest people in the plumbing industry, as more than 120 industry experts, water utility and academia participants attended the fifth International Emerging Technology Symposium (IETS) last month in Rosemont, Ill. “We were thrilled with the high quality of presentations, and the experience and expertise that were brought Read more

The room was filled with some of the brightest people in the plumbing industry, as more than 120 industry experts, water utility and academia participants attended the fifth International Emerging Technology Symposium (IETS) last month in Rosemont, Ill.

“We were thrilled with the high quality of presentations, and the experience and expertise that were brought to the 2016 International Emerging Technology Symposium by our speakers,” said IAPMO Group CEO Russ Chaney. “These biennial symposiums have grown into a successful and useful gathering of experts from academia, engineering, manufacturing, labor, codes and standards development, as well as test laboratories from throughout the world.”

Tim Keane, Marc Edwards and Jamie Bartram sit in on a panel on mitigating pathogen risk in plumbing systems.

Co-convened by nine major mechanical alliances — the Alliance for Water Efficiency (AWE), American Society of Plumbing Engineers (ASPE), the Canadian Institute of Plumbing and Heating (CIPH), the International Association of Plumbing and Mechanical Officials (IAPMO®), the Mechanical Contractors Association of America (MCAA), the Plumbing-Heating-Cooling Contractors National Association (PHCC), Plumbing Manufacturers International (PMI), the United Association (UA), and the World Plumbing Council (WPC) — the event gathered nearly 30 respected experts in the fields of water, energy efficiency, plumbing and civil engineering, and microbiology to discuss their areas of expertise.

The featured topics included Opportunistic Pathogens in Premise Plumbing: The prime directive of the plumbing industry is to design and install safe water supply and sanitary systems for our nation’s buildings. However, water scarcity resulting from persistent drought and declining water quality are causing problems that the plumbing trade, plumbing engineers, building and facility managers, health officials, and even the public-at-large need to be aware of in order to mitigate the potential for opportunistic pathogens to thrive in premise plumbing and infect at-risk building occupants.

Pete DeMarco (c), presents a birthday cake to Stephanie Tanner (l) of the EPA’s WaterSense, marking the 10th anniversary of WaterSense. The Alliance for Water Efficiency’s Mary Ann Dickinson participates.

The two-day symposium addressed a diverse spectrum of water and sanitation issues, including: “Innovation in Urban Onsite Water Reuse” by Paula Keyhoe, director of Water Resources, San Francisco Public Utilities Commission; “Sustainable Water Reclaim Systems” by Jonathan Gray, CPD, Principal, Interface Engineering; “Estimating Peak Water Demands in Buildings with Efficient Fixtures” by Steven Buchberger, College of Engineering and Applied Science, University of Cincinnati; “Plumbing Technologies from Down Under” by Jeff Patchell, publisher, Connection Magazines Pty Ltd – Australia; “Advancing Energy Efficiency in Urban Water Systems” by Lorraine White, GEI Consultants; “Common Mistakes in Managing Legionella in Large Buildings” by Janet E. Stout, PhD, director, Special Pathogens Laboratory; and “Water Quality, Water Savings and Water-Energy Nexus – Three Issues, One Solution?” by Tim Keane, Consulting Engineer, principal, Legionella Risk Management, Inc.; Gary Klein, president, Gary Klein and Associates, Inc.; Dr. Marc Edwards, professor, Virginia Tech.

“The water and energy conservation communities have seen the technological advancements being made in our industry over each two-year period of this symposium, dating back to the first International Emerging Technology Symposium conducted in 2008. These advancements have presented society with safer and more reliable water supplies, and sanitation protocols are being presented in a safe and sustainable manner,” said Chaney.

Highlights from the 2016 IETS:

- A compelling Q&A panel discussion—moderated by CONTRACTOR Editorial Director Bob Mader, hosted Dr. Mark Edwards, Virginia Tech University; Dr. Jamie Bartram, The Water Institute at the University of North Carolina; Dr. Janet Stout, Special Pathogens Laboratory; Tim Keane, consulting engineer, principal Legionella Risk Management; Gary Klein, president, Gary Klein and Associates; and Dr. Andrew Whelton, associate professor, Purdue University, as they discussed mitigating opportunistic pathogen outbreaks from water in premise plumbing systems.

- Bill Gauley, P.E., principal, Gauley Associated, Ltd.’s presentation “First — Do No Harm” conveyed that overbuilding as not good engineering. “We can’t keep going down this road of oversizing. We need to start designing systems as if it is our own money,” said Gauley.

- “Estimating Peak Water Demands in Building with Efficient Fixtures” by Buchberger revealed that an IAPMO/ASPE/WQA task group recently completed a draft report on estimating peak water demands in residential buildings fitted with efficient fixtures. The draft report proposes a new probability-based method similar in principle to Hunter’s Curve for determining peak water demands. The new method replaces fixture units with probability of fixture use. “The Hunter’s Curve is often faulted for giving overly-conservative designs,” said Buchberger.

- Dr. Michael Gormley, Institute for Building and Urban Design, The School of the Built Environment, Heriot-Watt University, Scotland presented “Toilets, Turbulence and Public Health” in which he stated, “Our approach to engineering design must be flexible and robust enough to deal with major challenges facing our society.”

- Mary Ann Dickinson, president and CEO for the Alliance for Water Efficiency, in her presentation, “Water Policy and New Technology: Examining the Connection” stated that water hasn’t been a major topic in a presidential election since 1936. “Water needs a federal champion,” said Dickinson. Perhaps, based on recent events with the drought in California and the tragedy in Flint, Mich., this election could be different.

- The symposium included another fascinating panel discussion on “Hot Water System Efficiency and Research” featuring Gary Klein, president, Gary Klein and Associates; J. Joe Scott, CPD, FASPE, vice president and senior plumbing designer for Cannon Design; Jerry Calahan, CEO, Heatworks; David Epstein, President, Orbital Systems. “We have to understand how the physics in the plumbing works,” reported Klein.

- Celebrating its 10-year, lead engineer at EPA’s WaterSense, Stephanie Tanner, was presented a “birthday cake” in recognition of all of WaterSense’s efforts — it has helped U.S. consumers save more than 1.1 trillion gallons of water — more than the amount of water used by all the households in Texas for a year. WaterSense also has helped reduce the amount of energy needed to heat, pump and treat water by 146 billion kilowatt hours and has eliminated 54 million metric tons of greenhouse gas emissions — the equivalent of planting nearly 1.4 billion trees.

- The discussion with Keane, Klein and Edwards reiterated the fact that good engineering can provide cost effective and simple solutions without conflicting unintended consequences to the issues of Legionella, scald prevention, energy and water conservation.

“With high-profile issues such as the Flint lead crisis and the increase in reported legionellosis events, industry experts are placing a higher degree of focus on the unintended consequences of water and energy conservation,” Chaney said.

Perhaps the new rallying cry for the industry should be this: smart plumbing design; mitigate risk; save some money along the way.

For the residents of Gloucester, Mass., the name Gorton’s Seafood means more than the fish the company is famous for. Gorton’s promotes a feeling of life, love and trust. Founded in 1623, Gloucester is America’s oldest seaport and the birthplace of the U.S. fishing industry. Gorton’s originated as a father and son duo in 1849 Read more

For the residents of Gloucester, Mass., the name Gorton’s Seafood means more than the fish the company is famous for. Gorton’s promotes a feeling of life, love and trust.

Founded in 1623, Gloucester is America’s oldest seaport and the birthplace of the U.S. fishing industry. Gorton’s originated as a father and son duo in 1849 under the name John Pew & Sons, and has evolved into the most recognizable and best selling seafood brand in the U.S. Operating out of the original 1906 building, Gorton’s prides itself on its heritage and quality products.

The third floor of the Gorton’s Seafood Center had been out of commission for the last decade but was remodeled to make room for a new fry line. Eric Sweet, President of Northeast Process Systems Inc. (NEPSI), has worked in Gorton’s facilities for the last 15 years and was tasked with remodeling the 20,000-square-foot facility.

“We specialize in FDA-regulated manufacturing facilities, including food and beverage, pharmaceutical and cosmetics,” Sweet said. “Gorton’s is one of our very good customers. They’re actually our closest customer, located in the same town as our shop. It’s also where we got our first exposure to Viega ProPress and that was more than 10 years ago. It was Gorton’s that actually specified it for their project the first time around.”

Rob Sinico, Senior Innovation Project Engineer for Gorton’s, has chosen NEPSI for nearly every mechanical repair the company has had. So when it came to the remodel, Sinico trusted Sweet at NEPSI when he suggested using Viega ProPress for stainless.

“We look at NEPSI as a supplier and installer to recommend the latest and greatest to us,” Sinico said. “We use their expertise in the field to tell us what’s new and what products are out there.”

NEPSI installed 10,000 feet of Viega ProPress for 304 stainless fittings with piping in sizes ½” to 3″ for applications including compressed air, hot and cold water, and a water/glycol mix. NEPSI chose stainless knowing it would stand up to the chemicals used for cleaning the Seafood Center. Everything that can be – even the floor drains – are stainless steel. They also used Viega’s 3-piece ball valves for shutoffs throughout the Center.

NEPSI installed 10,000 feet of Viega ProPress for 304 stainless fittings with piping in sizes ½” to 3″ for applications including compressed air, hot and cold water, and a water/glycol mix. NEPSI chose stainless knowing it would stand up to the chemicals used for cleaning the Seafood Center. Everything that can be – even the floor drains – are stainless steel. They also used Viega’s 3-piece ball valves for shutoffs throughout the Center.

“Almost all of our machines and equipment are stainless steel,” Sinico said. “Because we are in food production, it has to be highly sanitary and easy to wash and clean. We use corrosive chemicals to do that, and the stainless holds up. When they wash, they wash floor to ceiling, so wherever the pipes are, they’re going to get hit.”

According to Sinico, NEPSI also chose stainless because it was better suited to the application. “Once you go stainless,” Sinico said, “you should never have to repair or replace that again. So it might cost more upfront, but in the long run we knew we’d never have to touch it again.”

While Sweet at NEPSI appreciates the fact that it saves him time and labor, it’s the end user’s confidence that makes him glad he chose Viega.

“A lot of the factories we’re in like the Viega system too, because if there is a problem, they can do repairs on site with their own personnel,” Sweet said. “Gorton’s, among others, have actually purchased the products and tools to do small jobs. Personally, the Viega ProPress system has added to our versatility. It was something our customers welcomed.”

Sinico agrees, also noting that the quality is more valuable than the upfront cost of the fittings. Knowing that the connections are secure is more important, and, with Viega press technology, he gets the security he needs.

“With solder, you don’t know how well it held up until you put it under pressure, but with Viega press technology you have a better feeling that it was secured properly,” Sinico said.

“You’d be hard pressed to find any soldered fittings around here.”

The time was also a consideration for Sweet, who was concerned about how much time it would take to get the new system in place and not interrupt Gorton’s production schedule.

“I think the two biggest benefits are time savings and that there’s no requirement for hot work. Sometimes in a working facility that would mean that you probably couldn’t do it during business hours. You’d have to do it on an off shift or on a weekend,” Sweet said.

“With Viega ProPress, we can work while the production line is running.”

Gorton’s went the extra mile and even installed a fire protection system utilizing Viega ProPress for stainless steel, which exceeds the company’s Current Good Manufacturing Practice standards. Along with exceeding the requirements, the project was completed in four months and was worth the upgrade for America’s best seafood brand.

“It’s pretty impressive when you go out and look at that floor,” Sinico said. “Everything is neat. Our entire electrical conduit is also stainless, so aesthetically it looks nice. And it’s all durable, and that was the main driver for going with stainless. I can certainly say, big or small, we use Viega systems. That’s our standard.”

For more information, call 800-976-9819 or visit www.viega.us.