Project Goals: Replace old gas-fired boiler and 500-gallon storage tank supplying DHW Achieve sufficient DHW to meet demand in 99-room hotel Provide DHW for laundry, meeting spaces, kitchen areas Minimal disruption to guests The owners of the Best Western Plus New Englander Hotel located in Woburn, Mass., a suburb located about 10 miles north of Read more

Featured

Project Goals:

- Replace old gas-fired boiler and 500-gallon storage tank supplying DHW

- Achieve sufficient DHW to meet demand in 99-room hotel

- Provide DHW for laundry, meeting spaces, kitchen areas

- Minimal disruption to guests

The owners of the Best Western Plus New Englander Hotel located in Woburn, Mass., a suburb located about 10 miles north of Boston, decided to replace an old gas-fired boiler and tank serving its 99-room hotel equipped with two commercial washing machines after the existing 500-gallon tank began leaking.

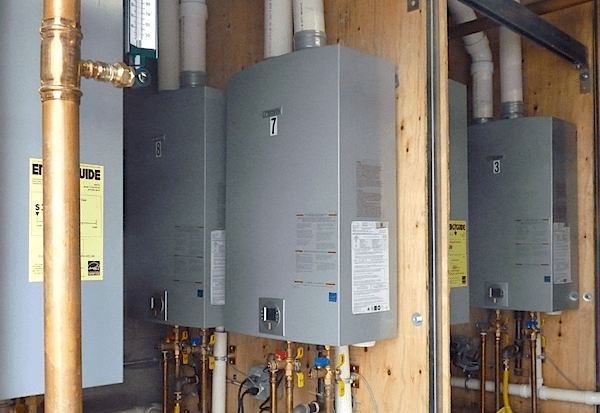

Heneghan and Sons Plumbing and Heating in Pepperell, Mass. quoted a system of 10-intelligent cascaded Bosch Greentherm C1050ES gas-fired condensing tankless water heaters, delivering up to 107 gallons of hot water per minute. The Bosch units were priced less than a competitive unit, and offer a superior warranty.

Heneghan and Sons Plumbing and Heating in Pepperell, Mass. quoted a system of 10-intelligent cascaded Bosch Greentherm C1050ES gas-fired condensing tankless water heaters, delivering up to 107 gallons of hot water per minute. The Bosch units were priced less than a competitive unit, and offer a superior warranty.

Heneghan Plumbing, with materials provided by PV Sullivan (Quincy, Mass.) was able to keep the existing hot water system running while installing the new system, and Colin added that “the changeover was a lot easier than we ever expected. We found the Bosch units easy to install, program and troubleshoot. It was made simpler with support from Bosch Sales Representative Dan McDermott and Craig Porter from Bosch technical support.”

Intelligent Cascading

A cascading application may be considered if the potential hot water demand exceeds the capacity of one gas tankless water heater. The cascading set up supports variable flow inputs and is designed for large homes and commercial applications. Use of the Intelligent Cascading Kit, unlike other parallel applications, maintains the activation flow rate of a single appliance.

Intelligent Cascading allows up to twenty four appliances to be connected in parallel to achieve flow rates up to 257 gallons per minute for Bosch Greentherm 1050ES (see figure). One of the appliances will serve as the controlling primary appliance and will attempt to meet the hot water demand. If the hot water demand is beyond the capacity of the primary appliance, a signal is sent to one or more of the secondary appliances to ignite. With the Intelligent Cascading, after each 100 hours of operation, the system will automatically rotate which heater serves as the primary; thus the primary control appliance is rotated throughout the cascade setup to distribute the load of each unit. One of the appliances serves as the primary control and attempts to meet the hot water demand. If the hot water demand is beyond the capacity of the primary appliance, a signal is sent to one or more of the secondary appliances to ignite.

Note: Refer to Bosch Greentherm Tankless Water Heaters Applications Guide at this link http://www.bosch-climate.us/support-center/download-center/downloads/bosch-manuals/bosch-tankless-manuals.html

The 10-unit Bosch Greentherm cascade installed in the Best Western Hotel delivers high efficiency hot water delivering up to 107 gallons per minute. This satisfies demand from guest rooms, meeting space, laundry, and kitchen areas throughout the busy hotel. The hotel owner reported fuel savings of approximately $1,500 to $2,000 per month in the first six months of operation. Compared with a competitive tankless installation at a similar hotel with same number of rooms, this Bosch installation saved about $500 more per month.

Project Summary:

Best Western Hotel, Woburn Massachusetts

Equipment: Bosch Greentherm C1050ES natural gas fired condensing tankless water heaters in 10-unit cascade

Installing Contractor: Heneghan & Sons Plumbing &Heating, Pepperell, MA

Wholesale Supplier: P.V. Sullivan, Quincy, MA

Project Completion: 2014

This Tiny House on wheels may be small, but it is big on features. At a cozy 150 square feet, the home is nothing short of luxurious, with high-tech building systems combined with high-end appliances and furnishings. Designed in collaboration with 30 architects, engineers, and materials specialists, this safe and sustainable home has helped educate Read more

This Tiny House on wheels may be small, but it is big on features. At a cozy 150 square feet, the home is nothing short of luxurious, with high-tech building systems combined with high-end appliances and furnishings. Designed in collaboration with 30 architects, engineers, and materials specialists, this safe and sustainable home has helped educate and inspire over 50,000 people who have toured it since 2015.

The homeowner, Tracey Powell, also happens to be its designer and builder. She and her brother, Trever Powell, wanted to ensure her home was safe, sustainable, durable, functional and technological. When it came to choosing a plumbing system to meet all of her needs, she first did her research, and then called Uponor.

Like many homes in this growing community, Powell’s tiny house is on wheels, and code-compliant for frequent transport. “We were worried that most plumbing connections wouldn’t hold up to vibration and movement during transport,” said Powell. “So thank goodness we found ProPEX® expansion fittings, which are highly leak-resistant and get stronger over time.”

Like many homes in this growing community, Powell’s tiny house is on wheels, and code-compliant for frequent transport. “We were worried that most plumbing connections wouldn’t hold up to vibration and movement during transport,” said Powell. “So thank goodness we found ProPEX® expansion fittings, which are highly leak-resistant and get stronger over time.”

Sustainability was an extremely important aspect of the project, especially when choosing a plumbing system.

“I wanted the quality of my drinking water to be high,” explained Powell. The fact that the ProPEX® expansion fittings don’t need adhesives and glues like other fittings was very important to me. I don’t want chemicals seeping into my water.”

Every inch counts in a tiny home, so Powell was pleased with the flexibility of the ½” Uponor AquaPEX® tubing. The bend-radius made it easy to install quick turns with each change in direction, without having to stop and cut a fitting. Building a tiny house comes with challenges, but Uponor helped tackle these challenges with a little creativity.

Every inch counts in a tiny home, so Powell was pleased with the flexibility of the ½” Uponor AquaPEX® tubing. The bend-radius made it easy to install quick turns with each change in direction, without having to stop and cut a fitting. Building a tiny house comes with challenges, but Uponor helped tackle these challenges with a little creativity.

“We wanted to prevent the PEX tubing from touching the spray foam insulation, but needed it located as close to the interior conditioned space as possible and in a very narrow wall cavity,” said Powell. “Even though ProPEX resists freezing and condensation, we took extra precautions and used Uponor’s Ecoflex® insulation to protect the PEX tubing—it’s worked out great.”

Because the tiny house includes numerous high-end technologies, there are many plumbing fixtures with metal fittings. Powell was impressed with how easy and seamless it was to connect the ProPEX expansion fittings with the wide-array of metal fittings.

In the future, Powell plans to consult other homeowners in designing their very own tiny houses and wants to help navigate them through best products, practices and processes—and she says an Uponor AquaPEX plumbing system is definitely on her list.

“The Uponor plumbing system is the easiest and most efficient piping for any tiny house,” she said.

Project Highlights:

• 150-square-foot tiny home

• Uponor AquaPEX plumbing system

• Distributor: The Granite Group

• Engineer: RW Sullivan

Project Data:

• ½” Uponor AquaPEX

• ProPEX Fittings

As the market for commercial building restroom renovations and construction picks up steam, more attention is being focused on what matters most to all facility stakeholders – owners, employees, business patrons, facility maintenance, and so on. While most of today’s restroom design trends aim to increase durability, maintainability, ease-of-installation, convenience and sustainability within restrooms, perhaps Read more

As the market for commercial building restroom renovations and construction picks up steam, more attention is being focused on what matters most to all facility stakeholders – owners, employees, business patrons, facility maintenance, and so on.

While most of today’s restroom design trends aim to increase durability, maintainability, ease-of-installation, convenience and sustainability within restrooms, perhaps the two most important goals are cleanliness and operational efficiency.

Bradley Corp. recently conducted research, which shows the condition of restrooms has taken a nosedive, according to consumer perception. Almost 70 percent of Americans reported experiencing unpleasant conditions in restrooms in 2015 – a 20 percent increase since 2012. When asked the most important improvement they’d like to see in restrooms, survey respondents overwhelmingly said “clean them more regularly.”

As for building owners, the challenge is optimizing the appearance and cleanliness of restrooms while minimizing time and costs for installation, maintenance repairs and replacement parts. Gaining operational efficiency on the front end of restroom design can free up valuable staff time and extend the lifespan of restroom fixtures.

Here are some restroom design trends that enhance cleanliness and efficiency in the eyes of both restroom users and building owners.

Touch-free fixtures. Touchless fixtures can help users in their quest to avoid touching restroom surfaces, reduce the transmission of germs and bacteria from users’ hands, and improve overall facility hygiene as users leave the restroom area and enter other parts of the building. These fixtures are also easier for staff to keep in good working condition. The “hands-free” design reduces wear and tear from usage, and helps discourage vandalism attempts such as leaving a faucet running to create a mess. Sensored faucets, and automated soap and towel dispensers prevent waste and overflows with an automatic shut off.

Some newer touchless fixtures use 0.38 GPM faucets vs. 0.5 GPM, which achieves a 24 percent water savings. A new “all-in-one” completely touchless hand washing fixture – with touch-free soap, faucet and hand dryer in the same unit – eliminates dripping water on the floor and safety in commercial restrooms since the user’s hands stay within the sink area until they are dried.

Sustainable materials. Made of natural and recycled materials, sustainable materials can increase the durability, maintainability, life span and aesthetic of countertops, basins and lavatory systems. For example, molded natural quartz material, which has the resilience of granite, can be sculpted into a range of design options for lavatories. Natural quartz is virtually maintenance-free, since it does not require sealing, buffing or reconditioning like granite.

In addition, solid surface material made of recycled materials and rapidly renewable material is also a popular choice. Solid surface resists stains, chemicals, scratches and heat, which reduces the likelihood of repairs and the need for replacements. Both natural quartz and solid surface utilize integrated bowl designs, which eliminate crevices for microbes to hide, are easy to clean and help prevent the spread of germs. These materials also have nonporous properties, helping them to stay cleaner and germ-free longer.

Flexible and durable products. Choosing products that are engineered to address specific restroom needs and environments also promotes operational efficiency. Products that optimize flexibility require few connections and parts help to simplify installation, adjust easily to low or fluctuating water pressure and reduced water flow, stand up to harsh water conditions and high restroom traffic, and are adaptable to both aged infrastructures and new construction. Flexible product features also include universal design and vandal resistance. The result of using such products optimizes time and costs and minimizes headaches.

In all, today’s commercial restroom design innovations improve the customer experience, promote lasting durability and efficiency, and increase satisfaction for all stakeholders.

Sidebar

Restroom Trendwatch:

express® Elx-series Lavatory System offers updated and cost-effective multi-user design

Bradley Corp., introduces its Express® ELX-Series Lavatory System – a contemporary alternative to china sinks and laminate counter tops designed for commercial restrooms. Its single bowl, multi-user design is easy to install and maintain, while offering contoured styling and personal hand washing space.

A step up from ordinary lavatories, the award-winning Express ELX-Series is a cost-effective fixture that is easy to specify, install, clean, and maintain. With the look and feel of an individual lav, this streamlined hand washing system provides the economies and conveniences of a group fixture, which accommodates up to three people at one time.

Made of Bradley’s Terreon® Solid Surface material, the Express ELX-Series Lavatory offers superior durability and is easy to clean and repair. In addition, its contemporary contoured design elevates the look of commercial restrooms while being easy to clean. The bowl’s seamless construction eliminates mold and delamination, offering a more hygienic and attractive washroom solution.

Due to its long-term durability and simplified maintenance qualities, the ELX-Series is a cost-effective choice for high-traffic washroom applications, such as schools, retail, recreation centers, municipal office buildings and transit stations.

The Express ELX-Series Lavatory also cuts down on installation time and costs, and requires few connections and parts. It incorporates a unique mounting plate for faster installation, and requires only a single drain and supply rough-in for new construction, or for an easily installed retrofit.

For more information, visit https://www.bradleycorp.com/elx-series-express-sinks.

Kris Alderson is a Senior Marketing Manager at Bradley Corporation, a leading manufacturer of plumbing fixtures, washroom accessories, partitions, emergency fixtures and solid plastic lockers. She can be reached at Bradley Corp., W142 N9101 Fountain Blvd., Menomonee Falls, Wis., 53052-0309. For more information, call (800) BRADLEY or visit www.bradleycorp.com.

The leadership team at Milwaukee Tool continues to push the “disruptive innovation” ideology—an idea that a product takes root initially in simple applications at the bottom of a market and then relentlessly moves up market, eventually displacing established competitors to a new level—when talking about new tools. As a company that professes itself as a Read more

The leadership team at Milwaukee Tool continues to push the “disruptive innovation” ideology—an idea that a product takes root initially in simple applications at the bottom of a market and then relentlessly moves up market, eventually displacing established competitors to a new level—when talking about new tools. As a company that professes itself as a solutions provider first, releasing dozens of new tools every year, the disruptive part fits this narrative, sometimes with its own products. With 88 new tools at this year’s New Tool Symposium to show off, there was plenty of jaw-dropping moments, and Milwaukee showed off some plumbing tools that not only disrupted the space, they obliterated it.

In particular, there were four new plumbing offerings—coming to market in November (minus the short throw press tool below)—that really caught my eye:

• M18 FUEL Sectional Drum Machine — Almost 75% of the time spent on secondary drain line jobs is in the preparation for the job, and then packing all equipment back up. The M18 FUEL Sectional Drum Machine aims to change all that through the use of an interchangeable drum that allows users to select the right cable for the job, the ability to backpack transport the entire unit (including the ability to separate the drum from the machine to lighten the weight), and an electronic drum break so users can react faster when the cable starts to bind up in a pipe.

• M18 FUEL Sectional Drum Machine — Almost 75% of the time spent on secondary drain line jobs is in the preparation for the job, and then packing all equipment back up. The M18 FUEL Sectional Drum Machine aims to change all that through the use of an interchangeable drum that allows users to select the right cable for the job, the ability to backpack transport the entire unit (including the ability to separate the drum from the machine to lighten the weight), and an electronic drum break so users can react faster when the cable starts to bind up in a pipe.

• M18 FUEL Drain Snake with CABLE-DRIVE Locking Feed System—Building off Milwaukee’s current M12 Drain Snake, the M18 FUEL Drain Snake represents the next level in performance for hand-held units by offering more power, cable drive locking feed system, and zero drum contact. With 2X more power than corded, it boasts a max power of 50′ down the line and is the first brushless drain cleaner. The CABLE-DRIVE Locking Feed System is the only automatic cable feed system that allows users to select and maintain a desired feed speed.

According to Corey Dickert, vice president of Product Management-Plumbing & Electrical at Milwaukee Tool, “The simple cordless setup of the M12 Drain Snake frees users from the hassle of wrestling with cords, carrying extension cords, or spending time looking for outlets—allowing them to get back to the job at hand. In addition, this is the only handheld unit with a fixed drum shield to protect the fixture and user from the spinning drum. When we combine these cordless benefits with our new-to-world design, we’re able to truly provide a level of productivity that these users have never experienced before.”

• M12 AirSnake Drain Cleaning Air Gun—The first cordless alternative in pipe cleaning tools, the M12 AirSnake Drain Clearing Air Gun drastically changes the way users clear grease clogs, slow drains, and other non-retrieval clogs. The tool is the first cordless version on the market to use compressed air to flush away clog build-up. Completely cable-free, the tool allows for fast setup time and no disassembly of fixtures, drain covers and p-traps. With a 0-50 variable PSI gauge, the tool can instantly reach clogs 35′ out. To see the demo in person was impressive; the process does not affect the integrity of the piping installation.

• M12 AirSnake Drain Cleaning Air Gun—The first cordless alternative in pipe cleaning tools, the M12 AirSnake Drain Clearing Air Gun drastically changes the way users clear grease clogs, slow drains, and other non-retrieval clogs. The tool is the first cordless version on the market to use compressed air to flush away clog build-up. Completely cable-free, the tool allows for fast setup time and no disassembly of fixtures, drain covers and p-traps. With a 0-50 variable PSI gauge, the tool can instantly reach clogs 35′ out. To see the demo in person was impressive; the process does not affect the integrity of the piping installation.

• M18 Short Throw Press Tool—Milwaukee touts pressing 40% faster than competition, delivering force optimized for PEX installation, and eliminating downtime caused by calibration intervals. With the introduction of the M18 Short Throw Press Tool w/ PEX Crimp Jaws, Milwaukee is able to provide a solution that can accomplish the majority of residential installations.

The lightweight, in-line design of the new M18 Short Throw Press Tool enables the installer to press with just one hand. And, with a 3-second cycle time, and the ability to press 400 1” connections on a single charge, this new tool allows residential installers to do their job faster and easier than any solution they’ve had up until now—without paying for more force than is needed,” said Alex Boll, product manager for Milwaukee Tool.

Whereas hand tools often cause difficult and inconsistent ring positioning on fittings, the spring-loaded design of the Short Throw Press Tool’s jaws assists in holding the ring for precise alignment to the fitting. With no calibration interval, the new tool delivers consistency in installation over the entire life of the tool.

A pre-press battery check prevents the user from starting a press the tool cannot complete due to insufficient battery charge, while Auto-Cycle ensures a full press every time and indicates to the user via a green light that the connection is complete. The new M18 Short Throw Press Tool w/PEX Crimp Jaws is compatible with the F1807/F2159 copper crimp ring system, one of the leading systems in residential PEX installations today. The Short Throw Press Tool is also compatible with the Viega PureFlow Jaws, which are optimized for the PureFlow PEX Press System.

By Francesca Dunbar, Group Marketing Director, McWane Plumbing Group The “green and sustainable” building movement has evolved from a marginal movement to fully evolving as an acceptable mainstream force. The increased adoption of sustainable building materials is having a positive impact as they have many attributes including; increasing energy efficiency, ensuring life safety and even Read more

By Francesca Dunbar, Group Marketing Director, McWane Plumbing Group

By Francesca Dunbar, Group Marketing Director, McWane Plumbing Group

The “green and sustainable” building movement has evolved from a marginal movement to fully evolving as an acceptable mainstream force. The increased adoption of sustainable building materials is having a positive impact as they have many attributes including; increasing energy efficiency, ensuring life safety and even improving building air quality. Companies are continuously looking for ways to be “green” and the appearance to be friendlier to the environment. It’s just good business!

For many, “green” conjures up visions of the hippie counter culture movement with granola eating tree-huggers that adorn themselves with tie-dyed t-shirts and ugly sandals. No offense to those that live this lifestyle as they spurred the “green” movement and were way ahead of the curve as visionaries. Now, it’s widely acceptable to embrace our inner “GREENIE” in business by adopting strategies for a long-term sustainability plan. The scrap metal dealers also saw the future in sustainability as they carefully put in place a large network of yards to ensure a steady stream of scrap supply. Not only has the general public demanded change but the market has been the driving force in green and sustainable building practice. In the recent past, a number of state and local governments began to adopt regulations and initiatives focusing on green and sustainable building where new codes and laws have been put in place such as the Energy Policy Act of 2005 and the Energy Independence and Security Act (EISA 2007). But there are also standards such as ASTM E2432 Standard Guide for the General Principles of Sustainability Relative to Building and ASHRAE 189.1 Standard for Design of Green Building – these codes and standards ensure for optimization of energy use, building space and indoor environmental quality (IEQ). It is government regulation that will push this movement forward. Now, Builders, Developers and Contractors are taking a look at re-evaluating building materials and opting to use sustainable products that are not only non-toxic, but also non-combustible.

This is something companies such as AB&I Foundry, a leading American producer of cast iron pipe and fittings, has been doing for decades. Their products are made from 100-percent post-consumer scrap metal and even used pipe and fittings are recyclable bringing it back full-circle. They are basically a GIANT recycler diverting discarded waste such as engine blocks, wheels, and other scrap metals and then melt it in their cupola in order to make cast iron pipe and fittings. These materials otherwise would have ended up in landfills. There are significant advantages to recycling and repurposing metals as it can be sourced within 50-miles of the foundry and AB&I was one of the earliest pioneers of the upcycling movement. The advantages of metallic piping far outweighs the perceived benefits of low-cost plastic as cast iron is durable, it’s non-combustible and it’s 100% recyclable at the end of service life. The advantages of metallic piping far outweighs the perceived benefits of low-cost plastic as cast iron is durable, it’s non-combustible and it’s 100% recyclable at the end of service life. Whereas plastics are sourced from petroleum, continuously off-gas toxins and are combustible releasing toxins when burned.

The plumbing industry had a motto with the iconic plumber silhouetted by the moon “The Plumber Protects the Health of the Nation” – this is true as the lack of sanitation brought disease wiping out hundreds of thousands of people throughout history. The protection and conservation of water is paramount to today’s society and building owners and developers have implemented water efficiencies from low flow toilets to water efficient fixtures. Also measures are being taken to reclaim graywater through recovery systems using the non-potable water for toilet flushing and landscape irrigation.

Science is a driving factor in identifying ways to produce better materials. There’s a project called Materials for Life (M4L), researchers from the School of Engineering at the University of Cardiff, in Wales are undergoing tests for self-healing concrete technologies where shape-memory polymers can be activated by electrical current, one with healing agents made from both inorganic and organic compounds and another with capsules containing bacterial and healing agents. The goal is to develop an autonomous infrastructure for roads, tunnels, bridges and buildings that can self-repair without human intervention. A sort of A.I. for building materials – the creation of sustainable and resilient systems that continually monitor, regulate, and adapt and then repair themselves.

The construction of healthier buildings is driving owners and developers as they are realizing the benefits of healthier building and the attraction for occupants that are increasingly more aware of their environment. There are simple ways to eliminate the presence of volatile organic compounds (VOCs) in building products that benefit not only occupants, but in a fire also reduce exposure to first responders. It’s no coincidence that schools and high-rise buildings use cast iron soil pipe and fittings for the drain, waste and vent plumbing systems as plastic is a known toxic product and life safety is paramount.

Products include; wall coverings, flooring and even upholstered furnishings. Many products continue to off-gas vapors and gases and these can affect occupants’ health from respiratory tract issues, headaches and dizziness and even long-term exposure that can cause organ damage. Green is not a fade, it’s a movement that is environmentally friendly and is here to stay. There was a movement to “get the lead out” of plumbing fixtures that was a known cause to contaminating drinking water.

Furthermore, In order to create more transparency in the manufacturing of building products, programs have been developed to declare that products meet certain environmental standards – Environmental Product Declarations (EPDs) and Health Product Declarations (HPD). They concentrate on disclosing the product’s list of ingredients or recipe. While EPDs focus on the impact of the product on the environment from cradle to grave in their lifecycle. The EPDs focus on the Life Cycle Assessment or (LCA).

In 2014, the WELL Building Standard was launched with the mission to enhance the health and well-being of building occupants. This newly implemented standard not only measures, certifies and monitors occupant health and well-being but it also addresses key areas including; air, water, nourishment, light, fitness and comfort — taking the green and sustainable practices to their highest level. In a recent study conducted by Booz Allen Hamilton for the USGBC, they expect green construction spending to increase from $150.6 billion in 2015 to $224.4 billion in 2018. The study also predicts that between 2015 and 2018, green construction will generate $303.4 billion in Gross Domestic Product (GDP), support 3.9 million jobs and provide $268.4 billion in labor earnings.

Now, isn’t it time to embrace the “green” movement and start reducing the toxic load of buildings?

About Francesca Dunbar

Francesca has been the Group Marketing Director of McWane Plumbing Group since 2012. She has a diverse background building and promoting companies with innovative and strategic leadership. In 2016 she was recognized as Industry Leading Ladies. She has spent decades building a respected reputation with major corporations and non-profit foundations. Her roots were deep in leadership for a high-tech industry before departing corporate life in 2000 to launch her marketing consulting career. She is also passionate about giving back and served on several non-profit foundation boards. As an officer on the board of directors for The National Brain Tumor Foundation, she was an integral member of the team that led a successful merger. Dunbar is also a published writer of industry articles and technical papers, and previously a contributing editor for a lifestyle magazine. Dunbar is a member of ASA, American Society of Plumbing Engineers and trained Installer of fire protection products.