So, as the story goes, a sales rep out west who had spent decades selling a competitor’s plumbing products is hired by General Pipe Cleaners. After initial training, he returned to his territory with a smattering of cables, cutters and drain cleaning machines to get him started. The first time he demonstrated the Flexicore Cable Read more

Featured

So, as the story goes, a sales rep out west who had spent decades selling a competitor’s plumbing products is hired by General Pipe Cleaners. After initial training, he returned to his territory with a smattering of cables, cutters and drain cleaning machines to get him started.

The first time he demonstrated the Flexicore Cable, he called the company to complain that the pipe snake, “just didn’t feel right!” It felt “limp”, not “springy.”

As Dave Dunbar, National Sales Manager with General Pipe Cleaners explained, “the Flexicore engineering process has the effect of making the cable feel less springy than hollow cables.”

It took a few phone calls to get things straightened out with the rep, but then six months later, he was complaining that the cables lasted so much longer than his former brand’s that he was only selling a fraction of his previous replacement snakes. A small fraction.

It took a few phone calls to get things straightened out with the rep, but then six months later, he was complaining that the cables lasted so much longer than his former brand’s that he was only selling a fraction of his previous replacement snakes. A small fraction.

It was this story that interested a few of our contractor friends. Why would it be springy? Is it really that stiff and is that a good thing? Would it really last longer?

Knowing General Pipe Cleaners would be at the WWETT Show this past spring, I introduced the General’s team to a few drain cleaning contractors that we are big fans of and have worked with in the past. It was my hope that we could create some valuable and interesting content based on the original story and the contractors having never used Flexicore.

It was soon after the show that we asked for them to send a few of their Flexicore cables to a few of our ProStaff team members to get their thoughts on the cable. They obliged and three drain cleaning pros were sent the cables to use on their existing cable machines, which for transparency, were all competitor drum machines.

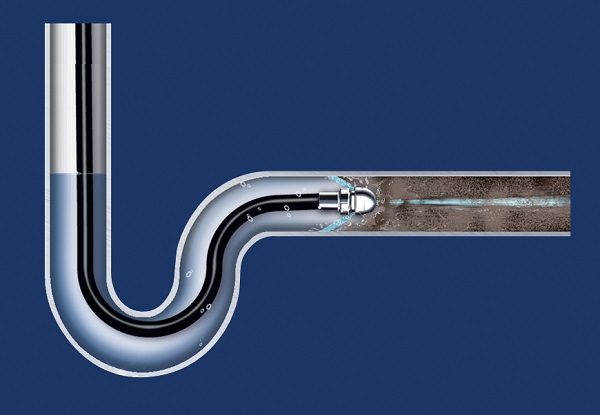

As you may know, the Flexicore cable is the result of a process, where instead of coiling a hollow cable, they tightly wrap spring steel around a 49 strand aircraft quality wire rope. This provides the cable additional strength when it is under torque.

Each member of our team received a variety of Flexicore cables based on their typical daily drain cleaning challenges with the request to use them over a couple of months and provide feedback. The team of contractors included Felix Delgadillo, DrainGuys (Chicago), Terence Chan, Impetus Plumbing (Vancouver) and Jeff Keller, Bulldog Contractors (Texas), all are longtime drain cleaning professionals in their area of the country.

Each member of our team received a variety of Flexicore cables based on their typical daily drain cleaning challenges with the request to use them over a couple of months and provide feedback. The team of contractors included Felix Delgadillo, DrainGuys (Chicago), Terence Chan, Impetus Plumbing (Vancouver) and Jeff Keller, Bulldog Contractors (Texas), all are longtime drain cleaning professionals in their area of the country.

As expected, those daily challenges included providing both residential and commercial services, addressing clogged kitchen drains, clogged bathroom drains, clogged outdoor drains, and clogged sewer lines using today’s best technology to unclog lines to keep the water flowing.

While Keller, Chan and Delgadillo confirmed that this was the first time using the cable, Chan stated what all three mentioned, “I’ve never used the product but very excited to see what it can do.”

Chan went on to say, “Initially seeing the product, I was a bit leery how it may hold on to the heads, but it did, really well. In fact, I’ve had trouble with heads from a competitor and the Flexicore held.”

“The screws to hold on the head versus a snap lock is a nice addition,” said Keller.

One of the unique byproducts of the Flexicore process is that the cable stiffens and gets stronger under torque, which Delgadillo agreed, “the cable feels less springy and it does get quite stiff when the operator needs it the most.”

Keller continued, “it caught me off guard and took some getting used to. Most if not all drain cleaners/plumbers are used to listening to their machines and the feel of the strain on the cable to evaluate the blockage, so this was a bit different, but did a solid job.”

Keller continued, “it caught me off guard and took some getting used to. Most if not all drain cleaners/plumbers are used to listening to their machines and the feel of the strain on the cable to evaluate the blockage, so this was a bit different, but did a solid job.”

As discussed in the WWETT video, when a drain cleaning machine rotates a pipe snake down the drain and it hits a clog or stoppage, tension or torque builds up in the cable. Because of the direction the drum is turning, the reaction of the outer coil of spring steel is that it wants to contract due to the tension. However, because the wire rope is in the way, the only thing that it can do is tighten, which makes it stiffer and stronger and the cable much less likely to kink or break when in use.

Chan concluded, “I would recommend this to peers in the field as it got the job done. I’m curious to see the long-term difference versus some of the cables we typically use and recommend everyone make sure they have the cable sizes they need for their machines.”

We second that Terence! Be sure to size your cables correctly so it all works perfectly.

While the contractors are still using the cables in the field, it was a unanimous decision that more time in the field was needed to truly understand the value of Flexicore cables and how it holds up long term versus other options.

We will continue to check in with the team to provide updates later in the year.

Contractor Bios:

Felix Delgadillo – He has been in the plumbing trades for over 15 years. Most of his experience has been in remodels & new construction for both commercial and residential. He is passionate about new construction and wanted to expand professionally to the service side. In 2019 he started his second company, Drain Guys, LLC. Drain Guys specializes in commercial and residential sewer cleaning, camera inspections & locating.

Felix Delgadillo – He has been in the plumbing trades for over 15 years. Most of his experience has been in remodels & new construction for both commercial and residential. He is passionate about new construction and wanted to expand professionally to the service side. In 2019 he started his second company, Drain Guys, LLC. Drain Guys specializes in commercial and residential sewer cleaning, camera inspections & locating.

IG: www.instagram.com/drainguyschicago

Facebook: www.facebook.com/Drainguyschicago

Terence Chan – He is a plumbing, heating and gas contractor out of Vancouver, BC, Canada. His company is Impetus Plumbing and Heating. Impetus stands for a force that makes something happen, which stands for everything their name defines them to be. We make everything happen and will never say no to any job. This company wants to be seen as the next up and coming generation that will make a difference and disturb the status quo in the current trade.

Terence Chan – He is a plumbing, heating and gas contractor out of Vancouver, BC, Canada. His company is Impetus Plumbing and Heating. Impetus stands for a force that makes something happen, which stands for everything their name defines them to be. We make everything happen and will never say no to any job. This company wants to be seen as the next up and coming generation that will make a difference and disturb the status quo in the current trade.

IG: www.instagram.com/impetuspandh

Facebook: www.facebook.com/impetuspandh

Jeff Keller – Bulldog Contractors allows him to work alongside his father Carl and other Bulldog team members. For over 35 years, Bulldog Contractors have brought areas of Northeast Texas first class plumbing and septic service, experience, and quality work with exceptional results. They are committed to exceed the expectations of our customers with quality service and expertise on every project we do. With a lot of repeat business, they have built long-term & trusting relationships over the years.

Jeff Keller – Bulldog Contractors allows him to work alongside his father Carl and other Bulldog team members. For over 35 years, Bulldog Contractors have brought areas of Northeast Texas first class plumbing and septic service, experience, and quality work with exceptional results. They are committed to exceed the expectations of our customers with quality service and expertise on every project we do. With a lot of repeat business, they have built long-term & trusting relationships over the years.

IG: www.instagram.com/jkeller1.0

Facebook: www.facebook.com/builditlikebulldog

Rusty and Randy Tigges, co-owners of R&R Septic Services of Carroll, Iowa built a profitable business niche—fast. R&R uses the JM-1000 Mini-Jet, a compact, powerful water jet from General Pipe Cleaners, to service and clean modular wastewater treatment installations. Decentralized modular septic systems like AdvanTex are becoming more common in rural areas not served by Read more

Rusty and Randy Tigges, co-owners of R&R Septic Services of Carroll, Iowa built a profitable business niche—fast.

R&R uses the JM-1000 Mini-Jet, a compact, powerful water jet from General Pipe Cleaners, to service and clean modular wastewater treatment installations.

Decentralized modular septic systems like AdvanTex are becoming more common in rural areas not served by municipal-style treatment plants—including housing subdivisions, apartments, golf courses, RV parks, campgrounds and more.

Rusty Tigges says that the Mini-Jet’s hose and nozzle are the perfect size to clean pipes and orifices of a modular septic system filter pod. And since R&R offers fixed-price septic maintenance contracts, work productivity remains key to profitability.

Rusty Tigges says that the Mini-Jet’s hose and nozzle are the perfect size to clean pipes and orifices of a modular septic system filter pod. And since R&R offers fixed-price septic maintenance contracts, work productivity remains key to profitability.

“Most septic maintenance guys use a bottle brush at the end of fish tape—too slow and slipshod for us,” he adds. “But our JM-1000 Mini-Jet does a faster, more reliable job!”

More Installations In Less Time

The compact, lightweight, electric-powered JM-1000 Mini-Jet—smallest in General’s popular gas and electric powered Jet-Set water jets—is excellent for clearing sludge, sediment, grease, and ice from small, 1-1/2 to 3 inch lines, up to 50 feet long.

With 1500 psi of raw cleaning power, General’s powerful little water jet hits soft stoppages with wall-to-wall high-pressure water—and flushes them away.

“General’s nozzle head design really helps negotiate the twists and turns of septic system pipes, Randy says. “And it’s far more thorough than hand-cleaning with a bottle brush.”

JM-1000 Mini-Jet performance also offers R&R the speed and reliability to service multiple septic installations in a shorter period of time.

“It’s definitely improved our productivity and profitability,” Rusty smiles. “When doing several systems a day, just one technician can knock a half-hour off each job with the JM-1000. And that really helps.”

Portability & Pulse Technology Aid Productivity

Pulse technology helps slide the hose around tight bends and farther down lines. It breaks the initial tension between the hose surface and pipe walls, increasing cleaning power. And it separates General’s Jet-Set from ordinary pressure washers.

Rusty Tigges likes the Mini-Jet’s compact size, too.

As large as a typical toolbox, the JM-1000 Mini-Jet’s rugged, diamond plate metal case containing pump and motor assemblies measures just 24” L x 10-1/2” D x 11” H. At just 23 lb, it’s easy-to- carry—making it perfect for one-person operation.

Including servicing septic system installations. “With the right knack, one technician can go seamlessly from pipe to pipe on an AdvanTex filter pod,” he says. “It works pretty slick!”

Equipment Arsenal Built From Trust

Performance like that also lets R&R use the JM-1000 Mini-Jet on a range of inside drain cleaning jobs.

Rubber feet on the carrying case help protect delicate counter tops in kitchens and baths. It also sports key safety features—like a sensor to shut-off the motor if water stops flowing, and a 3-wire Ground Fault Circuit Interrupter.

“Trust in our tools is very important for daily operations,” says Rusty Tigges. “And General has a great reputation for making highest quality tools.”

Mechanical Hub recently chatted with Bryan Cordill, director of residential and commercial business development for the Propane Education & Research Council (PERC) to discuss his role and efforts to support and grow propane demand in the residential and commercial construction markets. Cordill spent 17 years working as a sales manager for his family’s propane business Read more

Mechanical Hub recently chatted with Bryan Cordill, director of residential and commercial business development for the Propane Education & Research Council (PERC) to discuss his role and efforts to support and grow propane demand in the residential and commercial construction markets.

Cordill spent 17 years working as a sales manager for his family’s propane business, Cordill Butane-Propane Service — an independent propane supplier in Monroe, Louisiana. He was then named business development officer at Ajasent Inc., where he provided cloud hosting services for propane and related service companies. Most recently, Cordill co-founded Proponent LLC — a consulting company — where he worked with company leadership to develop and deploy new strategies.

Cordill has a master’s degree in industrial and organizational psychology from Louisiana Tech University. He lives in Monroe, Louisiana.

Bryan Cordill is the director of residential and commercial business development for the Propane Education & Research Council.

MH: Bryan, great to run into you at AHR Expo and glad that you can give us a few minutes to beter understand your role with PERC. Can you give us a bit about yourself: How long have you been involved with the Propane Education & Research Council. (PERC), in the industry, and what has your journey in this industry looked like up to this point? What is a day like for you at PERC?

BC: Thanks Tim, I started with PERC as the director of business development for residential and commercial markets in June of 2019. My family has been active in the butane or propane industry since about 1932 when my grandfather started the Winnsboro Butane Company in Louisiana. He and his partners ended up selling that business as WWII was starting and they knew they wouldn’t be home to work it. He had several other companies with partners, but eventually opened Cordill Propane with my grandmother in 1963. I started working there part-time when I was about eight years old — riding with drivers, pulling hoses for them, and fetching tools for service techs. After college, I went to work full-time mostly in growth area for the company and did that until my dad retired and sold the business a few years ago. So, I have pretty much had every job there is in a propane company.

A day in the life a PERC looks different every day. We met at the AHR Expo and I spend a lot of those days walking tradeshow floors meeting with our OEM partners to talk about ongoing projects. Sometimes, I help them by being a subject matter expert on what propane marketers or customers are looking for in a product. I like to be available for media interviews like this and have even been interviewed on a couple of podcasts lately. I set our communications strategies for both markets, but fortunately I have a ton of help executing that. Commercial and residential markets are just under 70 percent of all propane sales today, so in growing that across 50 states, no two days are alike.

MH: Please provide us with a quick elevator speech about today’s PERC, including the mission and vision of PERC?

BC: Our overall goal at PERC is to grow users and uses of propane here in the United States. To that end, we educate and train today’s propane industry workers on safety, as well as the skills necessary to provide superior customer service. We partner on research to hopefully find the next big thing, or maybe the next several little things, that will help develop those uses and grow users. And we act as a conduit of information between industry, builders, site planners, equipment manufacturers and distributors, specifiers, architects, designers, allied trades, and the end user of the products.

MH: The market has seen significant growth over the past 10+ years, how is the current economic climate affecting the industry? What are some of the challenges and how is PERC addressing those challenges?

BC: When you consider where we were in new residential construction prior to the housing or lending crisis of 2007, we haven’t seen a return to new installs of that level, but we have experienced a more sustainable, steady growth in year-over-year market share. One challenge is the continued efficiencies in products and busy lifestyles of families. The same home today uses less energy than 10 years ago. There has been a good bit of consolidation in our industry, just like my family selling its business, many families have sold to larger regional or national companies. It’s important to PERC that those surviving companies remember that their competition is not another propane company. Our industry only grows and gets stronger if we focus on our competing fuels and their use in our homes, offices, warehouses, cars, trucks, busses, and on our farms. The truth is, propane can and is successful in all those places. We just can’t take our eye off the ball. PERC has to continue sharing our stories so customers know that propane can do that.

MH: How is PERC addressing environmental issues in the industry and the “Green” movement?

BC: I think we see the electrification of everything as a major challenge and concern for the industry. Propane can play a significant role in reducing carbon emissions as well as greenhouse gasses. Propane has a very attractive carbon footprint, it is not a greenhouse gas, and is incredibly more efficient than electricity when compared on a source-to-site evaluation. Source-to-site includes all of the energy required to produce, transport, go through transformers, and then finally delivered to the appliance. On a national average, it takes over 3 units of energy at a power plant (3.03) to get 1 unit of energy at the power plug. It takes 1.15 units of energy at the propane plant to get 1 unit of energy at the home in a burner. To make things worse for electricity, we are able to use all of the renewable energy that is produced in our country, and nuclear plants work best at stable output rates. If we keep moving to require more electrical demand the plants that can meet that need are fueled by either coal or natural gas. In all reality, electrification does not equal de-carbonization. If anything, using more electricity in our homes and business will cause greater emissions of carbon dioxide and greenhouse gasses.

I believe we have to understand there is no one-size-fits-all approach that will solve this. If we use the right fuel, in the right place, for the right thing, we will all be better off. I have no desire to go back to coal lamps or candles — I really like my led light bulbs. But we also don’t want to see consumers being told they have to use lesser-quality, more expensive electric appliances than the high comfort products that deliver continuous supplies of hot water, warm air and chef-preferred cooking.

In addition, PERC is working to increase the availability of renewable propane. We currently have two plants in production and working to grow more. PERC is also in the process of getting resources to our marketers so they can speak confidently with their customers about propane’s role in a clean environment. Part of that may be talking to school districts about clean, quiet propane-fueled school busses that have over 90 percent fewer emissions than a clean diesel competitor, and studies have shown students that ride on these busses actually score better on standardized test. Another component may be talking to the school about converting their older, inefficient boilers to newer, high-efficiency units. And that by planning that installation and budgeting the cap ex, you save tremendously over having to do an emergency repair. Or maybe it’s talking to customers in California that have experienced regular and prolonged power outages to meet their onsite needs with generators or even combined heat and power units.

MH: What are a few trends that PERC has identified in the industry?

BC: There is a lot of discussion and traction for the rapidly growing cannabis industry. A lot of these facilities are built in places without access to natural gas, and many don’t have adequate high voltage power lines to meet their demand in a cost-effective means. We see increased adoption of gas heat pumps in those and other commercial spaces where electric rates continue to climb. There are still many oil-fired boilers in the northeast and mid-Atlantic. Converting those to clean propane boilers or commercial water heaters is seeing continued growth. Tankless water heater technology continues to improve, and we see new installations that free up so much floor space in the mechanical room you hardly recognize it. There’s also tremendous growth in hospitality, not just restaurants but also hotels. CHP, CCHP and micro-CHP are all getting attention from manufacturers. We saw four or so different manufactures and approaches to delivering these products while at the show.

MH: How do you see PERC changing in the future, and how do you see yourself helping in creating that change?

BC: We are really in the middle of the change. We have completely rebuilt what business development looks like for PERC, we have taken full control of the industry safety and training program, and we are building out a modular training curriculum that will be available soon. We will also be able to deliver propane safety training to our allied industries — particularly the plumbing and HVAC communities. I get to be in the middle of delivering all of that knowledge to our commercial and residential partners. Last week alone, our team met directly with over 20 different companies about their products and commercialization efforts. It really is an exciting time.

MH: How are standards used in the industry, and what have they meant to its overall history and development?

BC: There are a number of different standards that impact the propane industry. Many are the ones that affect how products are built and certified, so ANSI, ASME, UL, CSA, CARB, and plenty of others. But the ones that directly affect the delivery and installation of the product are things like CFR49, Pipeline Safety, and NFPA 54 and 58, those are the main fuel gas codes. These have helped to provide a very safe and dependable storage and delivery plan that allows builders, engineers, specifiers, or owners to feel comfortable using propane in their projects.

MH: How are you strengthening and building on your brand, training and resources available to members and non-members?

BC: PERC doesn’t really have members and non-members. We are funded by an industry-adopted mandatory assessment. We are a non-profit, so our resources are available to all. Just last year we migrated a ton of different websites to a single destination, Propane.com, which is a great source for everything we do. There are separate sections for commercial buildings and operations, as well as residential construction. We have a ton of information that is just focused on the consumer and answering questions they have. This is also the portal for our new learning center and all of the associated training that will be housed there. On top of all of that, we have resources that are designed and set up to help propane marketers grow their business.

MH: What are some of the things you’re doing to boost PERC’s visibility and grow market share?

BC: Obviously, one is getting the chance to visit with professionals like you and telling our story to your audience. We also invest in case studies and research to give real examples that propane can do that. I work on reaching every level of the decision chain — from site selectors, to planners and engineers, to installers. For the site selectors who are looking for land to build a project, I want them to know gas is available to them even when natural gas might not be. To the planners and engineers that are laying out the project and specifying the mechanical components, I want them to be sure they understand all of the products that are available to them. To the installers, we want to help them feel comfortable and confident in propane. And through all of that engagement, we will grow market share by having a well-informed customer reaching out to a well-prepared and knowledgeable propane marketer at the time of purchase. I don’t get to actually sell or deliver propane anymore. I just get the great job or working across the country with all of our wonderful partners to deliver that market share growth.

MH: In closing, is there anything you’d like to add?

BC: I would just suggest that your readers reach out to us at PERC if they have questions or concerns. I am available bryan.cordill@propane.com and as I mentioned, Propane.com is a great resource.

“The compact size makes it great for one-man operation – and it’s perfect for much of the work I do!” That’s Craig Casteen describing the lightweight JM-1000 Mini-Jet™ from General Pipe Cleaners. Owner of Casteen Plumbing & Repair in Rose Hill, NC, Casteen can find himself in some pretty tight spots. “There are lots of Read more

“The compact size makes it great for one-man operation – and it’s perfect for much of the work I do!”

That’s Craig Casteen describing the lightweight JM-1000 Mini-Jet™ from General Pipe Cleaners.

Owner of Casteen Plumbing & Repair in Rose Hill, NC, Casteen can find himself in some pretty tight spots.

“There are lots of crawl spaces beneath homes in North Carolina,” he says. “And I’m often under someone’s house – by myself – doing plumbing and drain cleaning work.”

Inside jobs can be cramped, too. “I clear lots of kitchen clogs – and do contract service work on apartments,” Casteen adds. “So I can get into even tighter spots!”

Compact Water Jet Provides The Solution

That’s why Casteen chose General’s JM-1000 Mini-Jet.

The compact, lightweight, electric-powered JM-1000 Mini-Jet is great for clearing grease, sand and ice from small, 1-1/2” to 3” lines – up to 50 feet long.

For extensive outside jobs, Casteen uses the larger, more powerful, gas-powered JM-3000 water jet. “General water jets are great for clearing grease and slurry – but kitchen sinks are the number one place for inside grease problems,” he observes. “And the JM-1000 is perfect for spot-clearing kitchen stoppages.”

It’s excellent on laundry drains and other small lines, too. General’s 1500 psi of raw cleaning power hits soft stoppages with high-pressure, wall-to-wall water streams – and flushes them away.

Design Meets Tough Requirements

General offers an option of tough stainless steel braid hose to help the hose slide smoothly down 1-1/2” to 3” drain lines – and more easily navigates tight bends. The 3/16” Teflon core also reduces flow resistance, further improving small line cleaning power.

Pulse technology also helps slide the hose around tight bends and farther down lines. It breaks the initial tension between the hose surface and pipe walls, increasing cleaning power. And it separates General’s Jet-Set from ordinary pressure washers.

“General’s nozzle design negotiates twists and turns very well,” Casteen remarks. “I think General’s R&D crew a great job!”

As large as a typical toolbox, the rugged, diamond plate metal case protects the pump and motor assembly. And at just 23 lb, the JM-1000™ is easy-to-carry.

“It’s lighter than my tool bag,” Casteen smiles. “Although small, it’s powerful!”

It’s maneuverable, too. “If I’m in a sink cabinet, the JM-1000 size lets me easily move around – and, if problems occur, quickly back-off and shut off the water.”

Great for one-man operation, General’s tough little tool respects surroundings, too. Rubber feet on the carrying case help protect counter tops in kitchens and baths. It also sports safety features like a sensor to shut off the motor if water stops flowing.

General Equipment Inspires Confidence

Water jets aren’t the only General products in Craig Casteen’s equipment mix. “When you’re safeguarding a 34-year reputation for quality work, you get the best tools for the job.”

So with his JM-1000 and JM-3000, Casteen’s arsenal also includes Super-Vee® hand-held drain cleaners for small-line work – and a Speedrooter 92® cable machine for long, tough jobs.

On his residential, agricultural and commercial jobs, Craig Casteen stresses, “I only use tools I trust.”

“General wrote the book on drain cleaning equipment,” he concludes. “And I foresee using my JM-1000 a whole lot!”

For more information, contact the Drain Brains® at General at 800-245-6200, or visit www.drainbrain.com/jets.

“I grab two things when I leave my truck: my flashlight and my VersaPlunge”. That’s Michael Williams, Field Manager for Just Drains LLC – the “the Number 1 drain cleaning company in Philadelphia” – on the revolutionary new plunger from General Pipe Cleaners. “It’s what pros use,” he quickly adds. “And it’s what we recommend!” Read more

“I grab two things when I leave my truck: my flashlight and my VersaPlunge”.

“I grab two things when I leave my truck: my flashlight and my VersaPlunge”.

That’s Michael Williams, Field Manager for Just Drains LLC – the “the Number 1 drain cleaning company in Philadelphia” – on the revolutionary new plunger from General Pipe Cleaners.

“It’s what pros use,” he quickly adds. “And it’s what we recommend!”

Williams knows what he’s talking about. With six expert crews, Just Drains LLC serves Southeastern Pennsylvania from the Delaware River to Harrisburg. And their seasoned professionals demand maximum performance from all the tools they have.

Innovative New Plunger Design

With its patented, extremely pliable VersaFlange™ cone, the VersaPlunge® plunger easily conforms to nearly any shaped toilet bowl opening, creating a tight seal in virtually any toilet design.

Williams pulls no punches: “It works better than any other plunger on the market. Period.”

Traditional plungers, by contrast, have hard rubber round cones – incompletely and loosely sealing the bowl drain, risking messy, germ-laden splash-back.

“VersaPlunge gives both the suction and tight seal you need,” Williams notes. “Where you put it, VersaPlunge stays.”

Extra Performance When It Counts

“Its remarkable,” he continues. “You don’t get any back-pressure – and no blow-back. If you push down on a conventional plunger, it can actually collapse on you – and you gotta fight to bring it back up.”

Not with VersaPlunge, he declares.

General’s innovative tool sports a convenient relief valve in the handle to minimize overflow. And its super-compressible, accordion-style bellows lets users apply extra force on stubborn stoppages.

“VersaPlunge comes back up – and actually ‘breathes’,” Williams contends. “As you push down, it stays in place – gives what you need to get the full plunge each time.”

For More Than Just Toilets

VersaPlunge is extremely versatile, too.

Roll up the VersaFlange end – and make a flat bottom to clear sinks, tubs, and other drain openings.

“You can use in floor drain traps to make sure the trap doesn’t have debris in it,” said Williams. “If it still holding water you can plunge it to get it open without using the big machine.”

That’s why many professionals carry extra VersaPlunge plungers to handle a range of problems.

“The flexibility of the handle and bellows lets you precisely position VersaPlunge for maximum performance,” he explains. “It’s good in sinks with a fixed faucet. If you can’t move the spout, the accordion style bellows let you flex the handle to the side and plunge effectively from an angle. You can’t do that with conventional plungers.”

The Bottom Line

Michael Williams thinks “every drain cleaning and plumbing professional” should carry a few VersaPlunge plungers for a range of stoppages.

He says that VersaPlunge helps clear clogs faster than old-fashioned plungers do – and keeps surroundings cleaner.

“With VersaPlunge, you’re not just getting a plunger – you’re getting the plunger!” he smiles. “VersaPlunge is like a plunger on steroids!”