Peter DeMarco, Executive Vice President of Advocacy and Research – The IAPMO Group In 2019, the World Health Organization (WHO) started monitoring the outbreak of a new coronavirus which ultimately was named COVID-19. The virus was first identified in Wuhan, China. This paper is intended to provide practical guidance for plumbing professionals who work on Read more

Industry Blogs

Peter DeMarco, Executive Vice President of Advocacy and Research – The IAPMO Group

In 2019, the World Health Organization (WHO) started monitoring the outbreak of a new coronavirus which ultimately was named COVID-19. The virus was first identified in Wuhan, China. This paper is intended to provide practical guidance for plumbing professionals who work on sanitary waste and sewer systems on how to protect themselves, their loved ones and their coworkers during the current pandemic.

Coronaviruses are so named because, when viewed under a microscope, they have protrusions that resemble a crown. They belong to a family of viruses common in both humans and many animal species. In rare occurrences, animal coronaviruses can mutate to the point where they are able to also infect humans, which is likely what occurred in China late last year. The potential for viruses that cross over from animals to humans to develop into an epidemic, happens when the virus can then be transmitted between humans. The COVID-19 virus is highly transmissible between humans and can cause respiratory illness and even death.

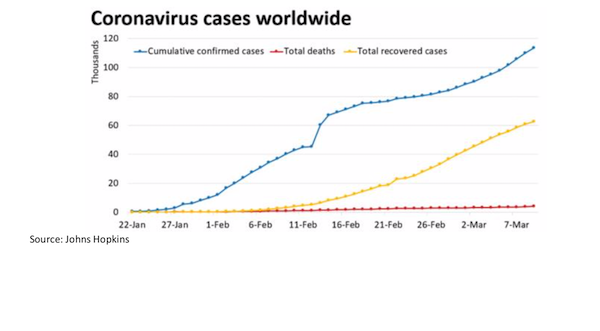

As of this writing on March 11, World Plumbing Day, the WHO has announced the outbreak qualifies as a pandemic, having spread on all inhabited continents. The worldwide number of humans diagnosed with COVID-19 has surpassed 120,000, with more than 4,300 deaths (see chart below). These numbers are predicted to grow. Unfortunately, there’s much we still don’t know about the virus, including important details about its transmissibility, how long it can survive on various surfaces or in water, and the range of illness severity amongst various population groups. It is known that the elderly and those who are immuno- compromised with pre-existing medical conditions are the most vulnerable for poor medical outcomes, which is consistent with other pathogen-based diseases, including influenza. However, contrary to some misinformation that’s currently available, the coronavirus is in fact considerably more dangerous than the current annual influenza virus.

So, what are the implications for those who work in the plumbing industry and what steps can plumbers take to stay safe? It is likely that the COVID-19 coronavirus can indeed be spread through building sanitary drainage systems. This became apparent when the Chinese government identified an outbreak in a Hong Kong high-rise building a few weeks ago (see the IAPMO white paper).

Therefore, for as long as the pandemic is still active, it should be assumed by anyone working on a sanitary drainage system that the virus is present. Considering the potential to come into contact with water and aerosols that contain the coronavirus when working on sanitary systems or sewers, it is highly recommended that plumbers wear proper personal protective equipment (PPE), including a full face shield that is worn over safety glasses, and gloves.

Of course, plumbers work on sanitary drainage systems that contain fecal matter and a host of dangerous pathogens every day. Taking careful precautions to prevent contact with wastewater and proper hand and arm hygiene is a matter of good practice for plumbers. In the United States, the Occupational Safety and Health Administration (OSHA) provides standards for worker protection. OSHA Standard 29 CFR 1926, Safety and Health Regulations for Construction provides the requirements for construction worker safety, including plumbers who work on sanitary drains, vent systems and sewers. The standards are available free at https://www.osha.gov/laws-regs/regulations/standardnumber/1926.

The most important subsections for plumbers to review are: 1926.20 – General safety and health provisions; 1926.21 – Safety training and education; 1926.22 – Recording and reporting of injuries; 1926.23 – First aid and medical attention; 1926.28 – Personal protective equipment; 1926.50 – Medical services and first aid; 1926.95 – Criteria for personal protective equipment; 1926.102 – Eye and face protection and 1926.103 – Respiratory protection.

Additionally, ASSE International’s Series 12000 Standard, Professional Qualifications Standard for Infection Control Risk Assessment for All Building Systems, is a standard that sets minimum criteria for the training and certification of pipe trades craftspeople, and other construction and maintenance personnel, on how to safely work in an environment with the potentially deadly diseases that may be present within

worksites. While the pandemic remains ongoing, ASSE International is making the ASSE Series 12000 Standard available for free at https://asse-plumbing.org/12000-2018 . The ASSE 12000 certification training addresses viruses, including the Sever Acute Respiratory Syndrome (SARS) virus, but does not specifically reference COVID-19. We welcome plumbers from across the globe to consider professional qualification for infection control risk assessment especially when working on sanitary systems that have a high probability of being contaminated with COVID-19, such as healthcare facilities and hospitals.

Finally, common sense still reigns supreme. Plumbers are advised to increase the frequency of hand washing and wash for at least 20 seconds with soap and water (even longer hand washing time is good practice after contact with wastewater); avoid touching of the face; cover any open cuts or wounds and wear proper PPE. If you personally come into close proximity, or into direct contact with an infected person, immediately report the incident to your supervisor and to your doctor or healthcare provider.

Good workplace and tool cleaning practices are also extremely important. Avoid sharing of tools with coworkers to the greatest extent possible. When choosing cleaning chemicals, look for cleaning agents with claims against viral pathogens. If such cleaning agents are not available, use soap and water and dry tools thoroughly after use. Keep your PPE clean as well by following manufacturer instructions carefully.

With no vaccine or treatment regimen currently available, it is important for all workers to be able to recognize the symptoms associated with contracting the coronavirus, which include fever, shortness of breath, and persistent cough. Symptoms can take between 2 to 14 days to become apparent after exposure to the virus. If you start to feel ill, stop work immediately so as to protect your coworkers and others around you, go home, contact your doctor and follow your doctor’s orders! This is critically important when working in a facility that houses immuno-compromised people.

The IAPMO Group sends its best wishes to plumbing professionals around the world. We hope that the information above is helpful. As usual, plumbers are on the front lines fighting the battles that keep people safe. By working carefully and thoughtfully, we can also keep ourselves and our loved ones safe as we deal with and defeat COVID-19!

Additional sources of useful information can be found at the links below:

https://www.who.int/emergencies/diseases/novel-coronavirus-2019

https://www.cdc.gov/coronavirus/2019-ncov/index.html

https://www.wef.org/resources/online- education/webcasts/ArchivedWebcasts/CoronavirusWebcastArchive/

Menomonee Falls, Wis. — For the past 11 years, Bradley Corporation has conducted its Healthy Hand Washing Survey to track American’s hand washing habits and their reactions to germs, the flu and colds. The annual survey queried American adults and youth online Dec. 11-16, 2019. Participants were from around the country, were 14 years and older, and were Read more

Menomonee Falls, Wis. — For the past 11 years, Bradley Corporation has conducted its Healthy Hand Washing Survey to track American’s hand washing habits and their reactions to germs, the flu and colds.

The annual survey queried American adults and youth online Dec. 11-16, 2019. Participants were from around the country, were 14 years and older, and were fairly evenly split between men and women (47% and 53%).

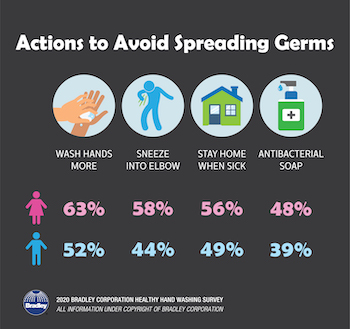

The findings revealed that:

- Even before COVID-19 hit the United States, 60% of Americans were extremely or quite concerned about catching the flu, compared to just 32% who felt that way four years ago. Among all age groups, Millennials expressed the most trepidation about getting sick.

- 50% of Americans said news coverage of cold and flu outbreaks has an impact on their hand washing behavior.

- In response to flu outbreaks, 79% of Americans said they wash their hands more frequently, more thoroughly or longer after using a public restroom.

- 89% of Americans in the workforce said they consciously take steps to avoid the germs of sick co-workers or colleagues.

- 64% of Americans correctly believe that hand washing is more effective in removing germs than hand sanitizer — a fact supported by the Centers for Disease Control and Prevention.

- When asked where they were MOST concerned about somebody not washing their hands, 40% said restaurants, 35% identified hospitals, clinics and doctors’ or dentists’ offices, 15% answered schools and 8% said airports.

- When they are sick, 54% of Americans said they simply wave hello to greet people, 48% avoid shaking hands and 18% use a fist or elbow bump.

- At home, if someone is sick or if a cold or flu virus is going around, Americans kick into action. 65% wipe down bathroom and kitchen surfaces. 47% wipe door knobs and handles. 46% wash sheets and/or towels.

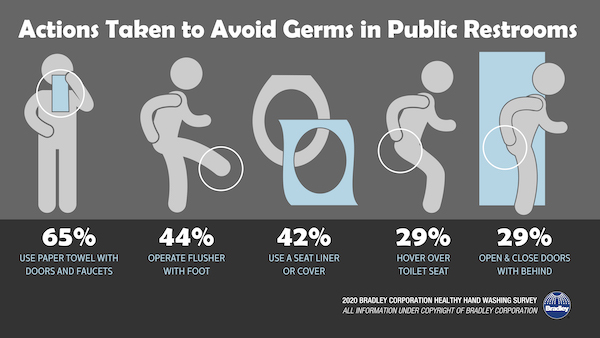

- In a public restroom, 93% of Americans try to avoid coming in contact with germs by employing evasive measures. 65% use a paper towel when touching door handles, faucets or toilet flushers, 44% operate the toilet flusher with their foot, 42% use a seat liner or cover, 29% hover above the toilet seat, 29% use their butt to open and close doors and 27% use their elbow to operate towel dispensers.

- 97% of Americans believe it’s important to wash up after using a public restroom. However, hand washing doesn’t happen all the time. Respondents said they washed their hands 86% of the time after using a public restroom.

- 67% of Americans admit they’ve skipped the soap and simply rinsed their hands with water after using a public restroom.

“Thorough hand washing with soap and water remains the best way to reduce the spread of disease-causing microorganisms like COVID-19,” says medical microbiologist Michael P. McCann, Ph.D., professor of biology, Saint Joseph’s University. “Soap and water, used as per the evidence-based recommendations of the Centers for Disease Control and other government agencies, will help reduce the spread of flu and other illnesses in the home and work place.”

Bradley Corp. is a leading manufacturer of commercial plumbing fixtures, washroom accessories, restroom partitions, emergency fixtures and solid plastic lockers.

For more information, visit www.bradleycorp.com/handwashing.

By Pete DeMarco, Executive Vice President of Advocacy and Research, IAPMO Health officials in Hong Kong have determined that plumbing systems in certain high-rise buildings are implicated in recent cases of the COVID-19 coronavirus. Based on the limited information available, it’s clear that transmission paths that would allow for the virus to spread between individual apartment Read more

By Pete DeMarco, Executive Vice President of Advocacy and Research, IAPMO

Health officials in Hong Kong have determined that plumbing systems in certain high-rise buildings are implicated in recent cases of the COVID-19 coronavirus. Based on the limited information available, it’s clear that transmission paths that would allow for the virus to spread between individual apartment units in at least one high-rise building have been identified. In order to understand how this has happened, it’s important to have some very basic knowledge of how wastewater systems work in high-rise buildings and to also look back at the SARS outbreak of 2003; the parallels are striking. In fact, the SARS virus is also a strain of coronavirus, so it’s not surprising that COVID-19 has been identified as having the potential to spread through plumbing systems.

High-rise buildings present unique challenges in plumbing design. The following simplified explanation is intended to help illustrate the problem: When toilets in high-rise buildings are flushed, fecal matter and wastewater are discharged into a vertical wastewater pipe, called a “drainage stack.” As the wastewater descends in the stack, it creates pressure changes within the pipe. The wastewater flowing down a stack will push air down ahead of it and drag air behind it, creating both positive and negative pressures within the drainage system. These pressures can affect trap seals by either siphoning the water or pushing the water out of the trap. A second vertical pipe, called a “vent stack,” typically runs parallel to the drainage stack and introduces air into the drainage stack every fifth floor to avert excessive changes that could deplete trap seals and allow contaminated air and aerosols to enter apartments on other floors.

High-rise buildings present unique challenges in plumbing design. The following simplified explanation is intended to help illustrate the problem: When toilets in high-rise buildings are flushed, fecal matter and wastewater are discharged into a vertical wastewater pipe, called a “drainage stack.” As the wastewater descends in the stack, it creates pressure changes within the pipe. The wastewater flowing down a stack will push air down ahead of it and drag air behind it, creating both positive and negative pressures within the drainage system. These pressures can affect trap seals by either siphoning the water or pushing the water out of the trap. A second vertical pipe, called a “vent stack,” typically runs parallel to the drainage stack and introduces air into the drainage stack every fifth floor to avert excessive changes that could deplete trap seals and allow contaminated air and aerosols to enter apartments on other floors.

When the SARS outbreak occurred in 2003, problems with dry traps were indicated, allowing contaminated air and wastewater aerosols to enter into apartments on lower floors through floor drains that are required by Chinese and many other Asian national construction codes. A full explanation of how the SARS outbreak occurred and technical solutions providing health and safety associated with proper plumbing practices can be found in The Health Aspects of Plumbing, a publication produced by the World Health Organization and the World Plumbing Council.

Sadly, with the current coronavirus outbreak in Hong Kong, history seems to have repeated itself. According to the Associated Press, a 2016 Hong Kong Housing Department policy change has allowed tenants in certain high-rise apartments to alter the pipe design in their bathrooms without requiring an inspection by a plumbing official, causing the problem that might have helped spread COVID-19. In one of the apartment units, the vent pipe was completely disconnected inside the bathroom, apparently by the occupant, which provided a pathway for contaminated air to enter the apartment, especially when the bathroom ceiling fans were activated. When health officials became aware of this problem, the building was evacuated, hopefully limiting the number of additional illnesses among building residents.

Can the COVID-19 coronavirus be spread in high-rise buildings in the United States in a similar manner? In short, the answer is yes, but unlikely. Due to U.S. plumbing codes, any modification to a building’s water, waste or vent system must be performed by a qualified professional and necessitates an inspection by a code official. In addition, wastewater stacks and vent pipes are typically hidden behind walls in high-rise buildings, reducing the opportunity for residents to easily cut into pipes and create unsafe conditions.

Both the SARS and the current COVID-19 coronavirus outbreaks in Hong Kong illustrate the importance of proper plumbing design and practice in keeping building residents safe from disease and the profound problems that can develop when unqualified individuals decide to work on building water systems. The axiom “the Plumber Protects the Health of the Nation” is more than a slogan. Improper deviations to building plumbing systems can, and indeed often do, result in very significant loss of life and property.

We have made it to the new year, a new decade. And with the turn of every calendar comes the rush of industry trade shows. Next week we will be traveling to Las Vegas for the IBS/KBIS Show or the Builder’s/Kitchen & bath Show. Following that, we will be in Orlando for the AHR Show Read more

We have made it to the new year, a new decade. And with the turn of every calendar comes the rush of industry trade shows. Next week we will be traveling to Las Vegas for the IBS/KBIS Show or the Builder’s/Kitchen & bath Show. Following that, we will be in Orlando for the AHR Show, North America’s largest HVAC show. Oh yeah, let’s not forget about World of Concrete, back in Vegas. The goal is to see, feel and test new products, learn and network with fellow attendees.

The AHR Expo is one of the largest annual North American trade shows.

When attending these trade shows, it is best to have a plan. Having attended dozens of these show in the past, I have come up with some tips and strategies for a better trade show experience.

- Map Out Your Plan — All of these shows have corresponding websites with maps, and a list of exhibitors and events. I can’t stress enough to map out your day so you are the most efficient with your time, energy and steps on the trade show floor. (ahrexpo.com & www.buildersshow.com & www.worldofconcrete.com) Downloading the appropriate trade show apps is a must.

- Wear Comfortable Shoes & Clothing — We all want to look good, and professional, but gone are the days of stuffy apparel. I’d rather feel comfortable and fresh at the end of the day than out of sorts, sweaty and dogs a barking.

- Give Yourself Enough Time — The stress of a trade show can be daunting in and of itself. Take as much time as you need to take a deep breath and move freely on the show floor. It’s always a good idea to come in the day or night before a show to make sure all is in order and registration for the show is set. If you are planning a night out, make sure you make any necessary reservations ahead of time.

- Afterparty Over-Indulging — We all love to go out and enjoy ourselves, especially after a long day at a show. There are numerous manufacturer parties, dinners, soirees, etc. where one can relax and wind down. But staying out all night—and drinking—can be fun, and up to your discretion, but it isn’t advisable, especially if you intend to be at the show the following day. Nobody is impressed with the over-perspired, alcohol lingering on breath, bags under the eyes, headache pounding visit from on overserved attendee. Pro Tip: Keep hydrated and carry a protein bar just in case you get the munchies. The IAQ in these large buildings is usually very poor and the air can get dry.

- Plan Accordingly for Transportation — Most of the time at busy trade shows, transportation can, well, be a bitch, especially after a show. Keep this in mind as long taxi lines will form to and from the shows. Download your favorite rideshare app so you are locked and loaded.

- Travel in Packs — If traveling in groups, try to stay in one place or area. It alleviates costs on transportation and makes meetings much more amenable.

- Be Prepared to Exchange Contact Info — Make sure you have business cards on hand and be prepared to exchange info digitally, so make sure your phone is charged or bring extra chargers! Also, make sure you have proper badges for the show. For example, attendee, exhibitor and press badges all provide different access and different access times. Make sure you understand the limitations of your particular given badge.

- Follow-up with Contacts — Once the show is over, what it your end game? What better way to measure the results of a show personally than to document leads, follow up with new contacts, and were you satisfied with your expectations of information, contacts and overall impressions?

- Cellular/WiFi Service — Most shows do not offer WiFi on the show floor, or if they do, it usually sucks. There are certain spots at different venues you may be able to sneak a signal, maybe. Make sure your service is covered in the areas where you are, or be prepared to go without in the dark recesses of a concrete building.

- If Unable to Attend … — Be sure to follow your favorite social media outlets that are attending (Search Mechanical Hub on Facebook, Twitter & Instagram) and keep up to date on what’s going on from the show floor. First of the year trade show events are when companies have big product announcements, launches and press briefings.

Good luck, and have a great trade show experience!

Blustery days with chilling winds can cause heating problems in many facilities with high volumes of foot traffic. While the main rooms within the building may be warm from the primary heating source, many areas are left out in the cold as drafts bring the temperatures down. Vestibules, lobbies, entrance ways and hallways can all Read more

Blustery days with chilling winds can cause heating problems in many facilities with high volumes of foot traffic. While the main rooms within the building may be warm from the primary heating source, many areas are left out in the cold as drafts bring the temperatures down. Vestibules, lobbies, entrance ways and hallways can all see a steady flow of people moving in and out throughout the day, opening doors and letting in chilly air.

To counteract these cold drafts, facilities should consider fan-forced wall heaters that provide continuous comfort through optimized airflow. Gentle heating sources are often not powerful enough to provide sufficient warmth in drafty areas. Fan-forced wall heaters however, push back on the infiltrating cold air, ensuring occupants feel the warmth as soon as they enter the building and until the moment they leave.

Functionality is Key

Cold air manages to find its way into facilities by any means necessary – whether it’s through vents, cracks, crevices or unsealed windows. Specialized heating units can stop these drafts before they spread throughout a building, bringing down temperatures and reducing overall heating efficiency.

Fan-forced wall heaters with an automatic delay eliminate cold drafts on start-up and discharge residual heat from the heater body during shut down. This helps attack drafts at their source while making the best use of available heat. In addition, consider fan-forced wall heaters that come with an integrated thermostat allowing for easy adjustment of room temperature to maintain a desired comfort level.

Perhaps a lobby is experiencing high foot traffic at the beginning and at the end of the workday, but have less heating requirements in the middle of the day. The adjustable thermostat allows occupants to alter the wall heater’s output based on need, ensuring no heat is wasted and temperatures remain comfortable. QMark and Berko’s commercial fan-forced wall heaters offer contemporary styles to match any room décor while ensuring adjustable warmth throughout the year.

Safety First

As with any heating unit, it is imperative to select high-quality products that offer protection against common safety risks. In terms of general design, fan-forced wall heaters come with a clear, easily accessible power on/off switch for added safety during maintenance, as well as a tamper-proof plug for the thermostat hole.

Also, look for fan-forced units with a manual reset thermal overheat protector that disconnects the power in the event of accidental blockage. This will ensure a quick repair while mitigating risk of injury. Furthermore, units that include permanently lubricated fan motors report increased longevity and lower maintenance needs, while gently distributing warmth throughout a designated area. Make sure the fan is powerful enough to offset drafts while quiet enough to eliminate unnecessary noises that may disrupt daily activities.

Key Takeaways

Every time a door opens during the cooler months, drafts blow in and bring a chilling effect into heated spaces. To neutralize the draft threats, consider installing a fan-forced wall heater to regain warmth and ensure comfortability for all occupants. Commercial fan-forced wall heaters from Berko and QMark provide strong yet safe sources of heat for the draftiest of spaces.

About the author: Andrew Martin is a product manager at Marley Engineered Products®, a leading North American designer and manufacturer of reliable comfort heating and ventilation solutions for residential, commercial and institutional buildings. Recognized by contractors, architects, engineers and HVAC professionals for providing a wide range of high-performance, reliable heating and ventilation solutions, Marley Engineered Products’ brands include QMark®, Berko®, Fahrenheat® and Leading Edge®.

Marley Engineered Products’ manufacturing operations are based in Bennettsville, S.C., with regional sales representatives located throughout the U.S. and an administrative office in Burr Ridge, Ill. For more information, please visit www.marleymep.com.