Upgraded Technology Meets Consumer Need with Sustainable Solutions EcoSmart™, a leader in green, economical tankless electric water heaters, has announced the launch of its new EcoSmart Element™ family. Available in three sizes (12 kW, 18 kW, and 27 kW), these tankless electric water heaters are ideal for residential use and new construction. “We are committed to making Read more

Product Spotlight

Upgraded Technology Meets Consumer Need with Sustainable Solutions

EcoSmart™, a leader in green, economical tankless electric water heaters, has announced the launch of its new EcoSmart Element™ family. Available in three sizes (12 kW, 18 kW, and 27 kW), these tankless electric water heaters are ideal for residential use and new construction.

“We are committed to making energy-efficient water heaters more budget-friendly,” said Neda Ahmaripour, director, global product and center of excellence, at EcoSmart. “We are continually upgrading our technology to fulfill customer needs and provide more sustainable solutions for future generations with the EcoSmart Element.”

EcoSmart, part of the Rheem® family of brands, designed these compact models to provide endless hot water at the point-of-use (12 kW) or to the whole home (18 kW and 27 kW). These models are more efficient than a standard electric tank, plus the on-demand heating eliminates energy waste by heating water only when needed.

Features include copper immersion heating elements that fit into a single chamber with threaded brass connections for easy replacement. Additionally, the stainless-steel heat exchanger reduces corrosion for a longer life.

Housed in a durable engineered polymer shell, each EcoSmart Element tankless electric water heater is designed with safety top-of-mind. Each model incorporates SafeStart™ technology upon start-up, as well as during power outages, to help avoid dry-fire occurrences. A manual reset thermal cut-out also comes equipped on every unit, which senses when the system has exceeded the high-temperature limits.

Designed with a variable temperature range of 60 – 140 degrees Fahrenheit, the EcoSmart Element models have a flow rate capacity ranging between 1.2 to 6.6 gallons per minute (GPM). In warmer climates, the 18 kW and 27 kW can run a kitchen faucet plus a shower and bathroom faucet simultaneously depending on the model and inlet water temperature. In colder climates, installing multiple point-of-use water heaters as a dedicated hot water source for appliances such as a dishwasher or washing machine reduces water heat loss and waiting on hot water.

EcoSmart Element tankless electric water heaters are available on Amazon.com and backed by a five-year warranty for leaks and a one-year warranty for its parts. To learn more about the EcoSmart Element as well as the brand’s full line of tankless electric water heaters, visit ecosmartus.com.

The new Pro-Pal® Multi-Port Transition Tee from Webstone®, a brand of NIBCO®, is a compact alternative to installing gangs of tees. It combines multiple components to save space and time, with patented technology that suits a variety of water distribution needs. These products feature lead-free, forged dezincification-resistant brass, your choice of press or press x Read more

The new Pro-Pal® Multi-Port Transition Tee from Webstone®, a brand of NIBCO®, is a compact alternative to installing gangs of tees. It combines multiple components to save space and time, with patented technology that suits a variety of water distribution needs. These products feature lead-free, forged dezincification-resistant brass, your choice of press or press x hose drain run, and F1960 or F1807 PEX branches. Sizes include ¾” or 1”, with or without reduced branches. Customization options are also available for additional sizes, connection types, and accessories.

Learn more: www.webstonevalves.com/propal

Franklin Electric Co., Inc. (NASDAQ: FELE) recently announced its planned expansion to its line of condensate pumps with the introduction of the VCMA-20-PRO series. With the slimmest footprint of all Little Giant condensate pumps, the VCMA-20-PRO Series offers the broadest range of installation flexibility, allowing for critical condensate removal from air conditioning, refrigeration, and dehumidification equipment Read more

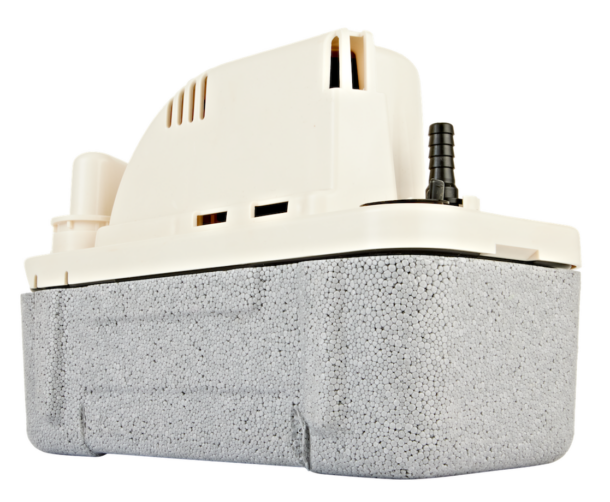

Franklin Electric Co., Inc. (NASDAQ: FELE) recently announced its planned expansion to its line of condensate pumps with the introduction of the VCMA-20-PRO series. With the slimmest footprint of all Little Giant condensate pumps, the VCMA-20-PRO Series offers the broadest range of installation flexibility, allowing for critical condensate removal from air conditioning, refrigeration, and dehumidification equipment even in tight spaces. The pump is also suitable for high efficiency oil and gas-fired condensing furnace and condensing boiler equipment.

The vertical-type pump measures only 6.5″ x 10.2″ x 4.8″ and features a 3/8″ O.D. barbed with 1/4-turn quick release locking discharge adapter plus built-in check valve. This allows the unit to be serviced without removing tubing to help eliminate water spills. Three 1-1/8″ diameter inlet openings (two fitted with removal cap plugs) allow the pump to be used with multiple types of equipment, including air conditioners and furnace systems. Additional benefits include:

- An external float-activated switch that automatically detects high water levels

- Rubber feet to absorb vibration on hard surface installations and reduce noise from the unit

- An optional anti-sweat sleeve for applications where high humidity would otherwise result in condensation on the tank exterior

The VCMA-20-PRO Series joins an extensive line of Little Giant condensate pump equipment, including standard condensate removal pumps, low profile condensate removal pumps, in-pan condensate removal pumps, plenum and high-temperature pumps, mini-split pumps, and specialty pumps like evaporative cooler pumps and ice machine replacement pumps. The VCMA Series, originally launched in 1999, has long been trusted by HVAC professionals.

The Leak Defense System continuously monitors your properties for hidden leaks and automatically shuts off the water and alerts you if one is detected. Easily control the water flow using the on-site control panel or access it on the go with the mobile app. With multiple ways to monitor, you’ll always feel protected against potential Read more

The Leak Defense System continuously monitors your properties for hidden leaks and automatically shuts off the water and alerts you if one is detected. Easily control the water flow using the on-site control panel or access it on the go with the mobile app.

With multiple ways to monitor, you’ll always feel protected against potential loss, expense and hassle from water damage. Our full line of accessories allows Leak Defense to work with any type of residential or commercial plumbing system.

The Leak Defense System:

- Installs easily with your existing plumbing

- Monitors your flow with the most sensitive detection technology available

- Alerts you immediately if potential flood conditions are detected and shuts off the water supply

- Can stop water flow in a specific zone, or to your entire building until you can assess the situation, stopping damage in its tracks.

- Is fully customized to fit your unique plumbing system. Point of leak detectors (POLDs) can be added for an additional layer of protection in places with a high risk for flooding.

To learn more, visit LeakDefense.com/products.

BitRip® is a FREE app that seamlessly tracks any type of physical asset using pre-printed BR Code™ labels. BitRip easily integrates with existing software workflows, and each code stores any data and tracks every scanned location, unlocking field-level visibility. The app is incredibly user friendly and provides excellent visibility of building materials, tools, and any Read more

BitRip® is a FREE app that seamlessly tracks any type of physical asset using pre-printed BR Code™ labels. BitRip easily integrates with existing software workflows, and each code stores any data and tracks every scanned location, unlocking field-level visibility. The app is incredibly user friendly and provides excellent visibility of building materials, tools, and any other assets on a jobsite. They also make it easy to associate warranty or installation information, links to videos, schematics, and many other types of data. Download BitRip via the App Store or Google Play, and purchase BR Code tape by clicking here.

BitRip® is a FREE app that seamlessly tracks any type of physical asset using pre-printed BR Code™ labels. BitRip easily integrates with existing software workflows, and each code stores any data and tracks every scanned location, unlocking field-level visibility. The app is incredibly user friendly and provides excellent visibility of building materials, tools, and any other assets on a jobsite. They also make it easy to associate warranty or installation information, links to videos, schematics, and many other types of data. Download BitRip via the App Store or Google Play, and purchase BR Code tape by clicking here.