If you have experience installing gas appliances, you have installed a sediment trap. It’s an assembly that many plumbers have fabricated hundreds of times in the field, lauded for its simple design that protects expensive gas appliances like water heaters and boilers. It is even required by code in the United States and many other Read more

Product Spotlight

If you have experience installing gas appliances, you have installed a sediment trap. It’s an assembly that many plumbers have fabricated hundreds of times in the field, lauded for its simple design that protects expensive gas appliances like water heaters and boilers. It is even required by code in the United States and many other places across the world. So, why is it so important?

All gas appliances rely on a supply line to receive fuel from a building’s main utility source. This line, however, exposes the appliance to certain vulnerabilities. Debris such as dirt, metal, or other foreign matter can accumulate in this line during installations and repairs. If these loose particles enter the appliance, they can cause serious damage including malfunctions or even fires. Because of this, every gas appliance installation is required by code to ensure protection from sediment.

Plumbers have protected against gas sediment for years using the simple law of gravity and a clever assembly of fittings. With the understanding that debris will naturally settle at the lowest point in the piping line, a strategically placed tee with an elongated, capped branch is installed between the supply and the appliance to form a trap. The flow travels downstream from the gas supply, entering the tee through the top and continuing through the side branch at a 90° angle to the appliance. This sharp change in direction causes the loose particles to separate from the flow and drop into the capped nipple.

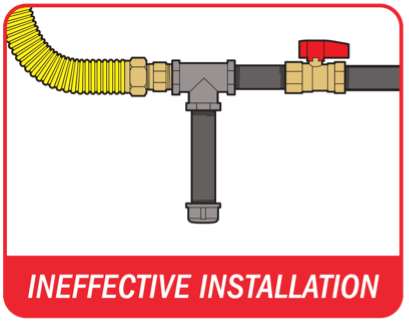

This trap assembly is widely accepted as the solution to guarding against gas sediment, but it has room for improvement. Assembling individual components not only takes time and introduces leak paths to the system, but it also aesthetically leaves much to be desired. Most importantly, the design is only functional if installed correctly, by a plumber who understands the significance of the 90° directional change. Unfortunately, it’s not uncommon to see sediment traps assembled with an improper tee orientation, resulting in ineffective horizontal flow path that allows particles to bypass the trap and enter the unit.

Enter the Gas Sediment Trap from Webstone®, a brand of NIBCO®. It’s the industry’s first integral trap solution – a forged brass tee with an elongated capped branch that meets the 3” length that’s required by code. Created as an all-in-one installation kit, it includes a CSA-certified full port gas ball valve, with the choice of an optional flex line. It’s available in ½” or ¾” connections, making it ideal for a wide array of applications including high BTU appliances.

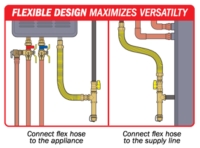

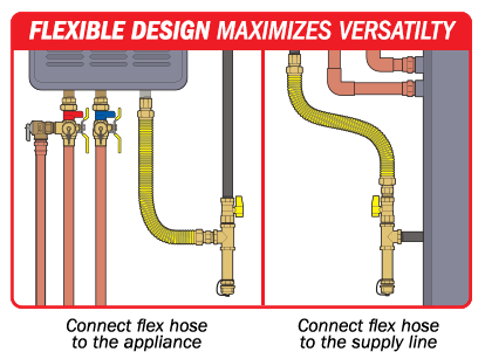

Choosing the Gas Sediment Trap has several advantages over field fabrication. Its attractive forged brass design results in cleaner, consistent quality professional installations that eliminate the possibility of an ineffective flow path. It saves time, replaces several components, and eliminates multiple leak paths. Kit models provide everything needed to complete the job, including a versatile flex hose that connects to the appliance or the supply line. For more information and other products that help you work smarter, visit webstonevalves.com.

Protect work sites and equipment from dripping video cable reels with the new Reel Cage Cover for Gen-Eye sewer cameras from General Pipe Cleaners. The heavy-duty, 600 denier poly canvas cover fits snuggly around General’s full size camera reels. Three times more durable than standard covers, it’s securely affixed with Velcro tabs – and easily removed for Read more

Protect work sites and equipment from dripping video cable reels with the new Reel Cage Cover for Gen-Eye sewer cameras from General Pipe Cleaners.

The heavy-duty, 600 denier poly canvas cover fits snuggly around General’s full size camera reels. Three times more durable than standard covers, it’s securely affixed with Velcro tabs – and easily removed for reel inspection or cleaning between jobs.

The new Reel Cage Cover now comes standard with all full size Gen-Eye POD®, Gen-Eye X-POD®, Gen-Eye SD®, and Gen-Eye USB® video inspection systems. It’s also available for separate purchase by existing Gen-Eye equipment owners – and is not intended for Gen-Eye mini-reel designs.

Easy to move, easy to use, and easy on budgets, General’s lightweight, compact Gen-Eye POD® sewer cameras include integral Wi-Fi to record and share inspections from tablets and smartphones.

The Gen-Eye X-POD® features a powerful Command Module with USB port to record video inspections on flash drives. It also includes a 7” LCD color monitor, one-touch recording, digital zoom, voice-over recording, and more.

The Gen-Eye USB® Premium packs potent features into a compact package. Included are a USB port, 10.4” sunlight-readable screen, waterproof keyboard, rechargeable battery that lasts up to 4 hours, and Wi-Fi capability – all protected by a heavy-duty Pelican case.

For additional information, contact the Drain Brains® at General Pipe Cleaners at 800-245-6200, or visit www.drainbrain.com/geneye

U.S. Boiler Company has released the new Alta Combi boiler, the industry’s first and only gas-adaptive combi boiler with 10:1 turndown. The all-new Alta Combi high efficiency condensing boiler offers best in class, next-generation gas adaptive technology that provides the shortest installation time and lowest operating costs. The powerful gas-adaptive technology offers true “no touch” Read more

U.S. Boiler Company has released the new Alta Combi boiler, the industry’s first and only gas-adaptive combi boiler with 10:1 turndown.

The all-new Alta Combi high efficiency condensing boiler offers best in class, next-generation gas adaptive technology that provides the shortest installation time and lowest operating costs. The powerful gas-adaptive technology offers true “no touch” combustion setup. There are no manual throttle or offset adjustments. Engineered for five-minute start-up, the boiler’s control system provides continuous, automatic self-calibration of burner combustion by adapting to component wear, variations in fuel, environment, and vent air pressure to provide safe, efficient, and clean combustion at all times.

Converting from natural gas to LP is simple. No additional parts or conversion kits are needed. The Alta also includes a sensor-less reset, which performs the functions of a conventional outdoor reset without the need to install an outside sensor.

Domestic hot water response time is virtually instantaneous. Domestic hot water temperatures are maintained under all demand conditions, and the unit’s DHW recirculation system can be set to either economy or comfort mode.

At 95% AFUE, The Alta Combi is currently available with 136 MBH DHW input (3.7 GPM) / 120 MBH heating input. However, stay tuned! U.S. Boiler Company will be releasing a larger Alta Combi boiler (200 MBH DHW / 150 heating) and numerous heating-only Alta models (80, 120, 150 and 180 MBH) later this year.

Each Alta comes with value-added components and features, including an AltaFastPipe primary/secondary piping assembly, lift-away front and side panels for three-sided access, boiler flow safety switch (UL353) and display indicator, ProPress compatibility and a five-year parts warranty.

For more information, please visit www.usboiler.net

The Rinnai® BMS Gateway creates a unique solution for hot water management Having a way to control and monitor hot water usage creates efficiencies for business leaders and facility managers but is often critical to keeping businesses’ doors open. That’s why Rinnai has launched the Building Management System (BMS) Gateway, a new product that will provide commercial Read more

The Rinnai® BMS Gateway creates a unique solution for hot water management

Having a way to control and monitor hot water usage creates efficiencies for business leaders and facility managers but is often critical to keeping businesses’ doors open. That’s why Rinnai has launched the Building Management System (BMS) Gateway, a new product that will provide commercial and vertical markets a software system used to remotely control and monitor Rinnai Commercial Tankless Water Heaters.

“Our brand promise is Creating a Healthier Way of Living® and we are focused on providing simple, affordable solutions for businesses,” said Frank Windsor, President of Rinnai North America. “The Rinnai BMS Gateway is the next step to empowering customers to actively manage hot water and help it run seamlessly through any building.”

Whether using the optional Touch Screen User Interface that acts as an enhanced controller or working directly through the BMS Gateway, businesses can remotely turn tankless water heaters on or off, adjust water temperature, monitor flow rates, operation hours and more. The BMS Gateway and Touch Screen User Interface also allows up to 15 view-only parameters such as water flow rates, combustion cycles, operation hours and error code history.

Businesses can pair up to six Rinnai Commercial Condensing Water Heaters per BMS Gateway, with up to four gateways per network, for a maximum of 24 tankless units connected thereby enabling greater reach. Additionally, the BMS Gateway works with Rinnai CU199 and CU160 condensing tankless models and uses BACnet, Modbus or LonWorks communication protocols.

“Many commercial settings, such as school campuses, healthcare facilities, multifamily and government buildings, are often required to have BMS capabilities,” said Dale Schmitz, Rinnai Marketing Segment Manager. “We are now able to provide customers with an intuitive gateway to remotely control and monitor Rinnai Commercial Tankless Water Heaters through a customer-supplied BMS system.”

Businesses can upgrade their tankless water heaters to include the BMS Gateway or install a whole new system and save thousands in acquisition, maintenance and energy costs. Rinnai tankless units offer precise load tracking, so the amount of energy consumed is directly correlated to the amount of water heated at any given time versus having to heat and re-heat stored water with boilers and tanks.

The Rinnai Tankless Rack System comes in Wall-hanging or Freestanding configurations, includes factory assembled manifolds for gas and water that are tested and warrantied, provides built-in redundancy and can be combined with up to 24 units to provide 4.8 million Btu.

Rinnai is here to solve the needs of businesses while also providing easy, affordable turnkey solutions. With the latest and greatest addition of the BMS Gateway, Rinnai is here to keep hot water running for businesses to stay in business.

To learn more about Rinnai, visit www.rinnai.us.

Revamped and rebranded Nexia™ platform aims to streamline smart comfort experiences and complement Smart Thermostat offerings American Standard launches American Standard Home, a smart home integration platform that offers advanced HVAC system control and diagnostic features. Formerly Nexia™, the new integrated app will continue to give homeowners a secure, convenient method to manage their indoor comfort through a connected experience, while HVAC professionals can ensure their HVAC systems are optimized for performance. American Read more

Revamped and rebranded Nexia™ platform aims to streamline smart comfort experiences and complement Smart Thermostat offerings

American Standard launches American Standard Home, a smart home integration platform that offers advanced HVAC system control and diagnostic features. Formerly Nexia™, the new integrated app will continue to give homeowners a secure, convenient method to manage their indoor comfort through a connected experience, while HVAC professionals can ensure their HVAC systems are optimized for performance.

American Standard Home integrates with several smart home platforms, including major voice control platforms, Google Home and Amazon Alexa, and is compatible with hundreds of Z-Wave devices. The most common use is connecting an American Standard smart thermostat to remotely update your temperature, apply a schedule, and automate your home comfort experience.

“As we look at the time we’ve spent indoors over the last several months, we know how important it is for our HVAC systems to create comfortable living spaces, while providing the convenience homeowners crave,” shares Mel Fox, Senior Product Manager Trane Technologies. “Innovative, user-friendly and practical, American Standard Home provides a seamless integrated experience for our connected homeowners.”

With homeowner consent, American Standard Home’s sister platform, American Standard Diagnostics, provides HVAC dealers with real-time alerts, remote access to update a homeowner’s system, and historical data to help extend the life of the HVAC system, resulting in a reliable homeowner experience. The American Standard Diagnostics platform prevents minor maintenance issues from turning into major repairs.

The American Standard Home app will be available for download from any smart phone, tablet, or computer through the App Store and Google Play. Download the application from your device or reach out to your American Standard dealer to learn more.