As fall turns to winter, it becomes more important to have a cozy home to retreat to on cold days. However, it may become challenging to preserve a respectable home within one’s budget, given the rising cost of power. Thankfully, there are many options available to reduce heating costs. Here we’ll go through five tried-and-true Read more

Uncategorized

As fall turns to winter, it becomes more important to have a cozy home to retreat to on cold days. However, it may become challenging to preserve a respectable home within one’s budget, given the rising cost of power. Thankfully, there are many options available to reduce heating costs. Here we’ll go through five tried-and-true methods for accomplishing this objective.

Invest in Proper Insulation

Investing in proper insulation is one of the best methods to save money on heating your home. Lack of proper insulation can cause heat to escape, increasing the workload of your heating system. The insulation in your home’s walls, ceiling, and floors should be checked first. Invest in better insulating materials if the current ones are inadequate or damaged. Additionally, ensure that all cracks and openings in windows and doors are sealed. The long-term savings on heating costs from this initial expenditure can be substantial.

Schedule Regular Maintenance

Keeping up with routine maintenance on your heating system is essential to keeping it running smoothly and efficiently. System efficiency decreases with neglect, which in turn increases energy consumption and costs. Get a professional to tune up your furnace to keep it in tip-top shape. They are able to check and clean parts, change filters, and find any problems. Preventing malfunctions and maximizing efficiency can save you a lot of money throughout the life of your system if you maintain it regularly.

Upgrade to Energy-Efficient Heating Systems

An upgrade could be in order if your current heating system is somewhat old. The energy costs associated with heating your home can be greatly reduced by installing a state-of-the-art heating system. You should think about upgrading to a modern, more energy-efficient heating system. Heat pumps and radiant heating are two alternative heating methods worth looking into because of their low energy use. Despite a greater purchase price, this option will prove to be cost-effective over time.

Implement a Programmable Thermostat

You may have greater precision over the temperature in your home by using a programmable thermostat. When you’re not there or asleep, you may set the thermostat to a cooler setting, and when you need it, you can turn it up. When the weather is mild, it’s unnecessary to have the heat on, therefore this helps save electricity. Smart thermostats can optimize energy use by learning your habits and adjusting themselves accordingly. By turning down the heat when it’s not needed, the savings from using a programmable thermostat can be substantial.

Practice Energy-Efficient Habits

A significant reduction in your heating costs may also result from simple lifestyle adjustments. Keeping doors and windows closed when the heat is on, using curtains or blinds to trap heat, and dressing in layers to be warm indoors are all easy ways to reduce your heating needs. Leave the oven door open after you’re done cooking to allow the leftover heat to warm the room. You can save a lot of money in the long run by making these minor adjustments.

Endnote

It is not only conceivable, but also practical, to reduce the cost of heating your home. You can keep your house toasty and warm without breaking the bank if you put money into good insulation, upgrade to energy-efficient heating systems, use a programmable thermostat, adopt energy-efficient practices, and schedule routine maintenance. Your heating costs will go down and your home will be more eco-friendly and sustainable as a result of taking these measures.

During the Milwaukee Tool Pipeline influencer event, the company announced the M18 REDLITHIUM FORGE XC6.0 Battery Pack, which delivers HIGH OUTPUT 12.0 power in a smaller size, 15-minute supercharge up to 80%, and the longest life vs REDLITHIUM batteries. REDLITHIUM FORGE are Milwaukee’s most powerful, fastest charging, and longest-life batteries. The REDLITHUM FORGE XC6.0 delivers Read more

During the Milwaukee Tool Pipeline influencer event, the company announced the M18 REDLITHIUM FORGE XC6.0 Battery Pack, which delivers HIGH OUTPUT 12.0 power in a smaller size, 15-minute supercharge up to 80%, and the longest life vs REDLITHIUM batteries. REDLITHIUM FORGE are Milwaukee’s most powerful, fastest charging, and longest-life batteries.

The REDLITHUM FORGE XC6.0 delivers the same power as the M18 REDLITHIUM HIGH OUTPUT HD12.0 in a smaller size and lighter weight design. The optimized combination of size, weight, and increased power provides the best solution for power-demanding overhead work and tight work areas.

The REDLITHIUM FORGE XC6.0 is the fastest charging battery pack within its class on M18, charging in just 15 minutes to 80% with the new M18 Dual Bay Simultaneous Super Charger. This lithium-ion battery has the longest life, the most recharges, and the best performance over the life of the battery.

This solution is designed with resistant housing for increased protection against exposure to common oils, greases, and solvents. Built-in REDLINK Intelligence protects the battery from overloads, preventing you from damaging your cordless power tools in heavy-duty situations. The REDLITHIUM FORGE XC6.0 battery is fully compatible with 250+ M18 solutions.

In recent years, the plumbing industry has undergone significant changes, with technology playing a pivotal role in these transformations. A key area of focus has been the financial management side of the business. This article delves into how the USDT TRC Wallet is impacting the efficiency and security in the plumbing business. It explores how Read more

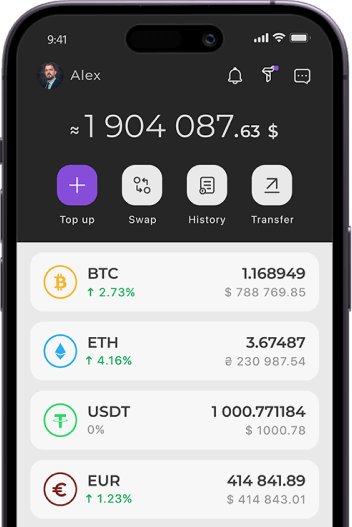

In recent years, the plumbing industry has undergone significant changes, with technology playing a pivotal role in these transformations. A key area of focus has been the financial management side of the business. This article delves into how the USDT TRC Wallet is impacting the efficiency and security in the plumbing business. It explores how the digital wallet is facilitating smoother transactions, providing enhanced security, and improving overall business operations.

Improving Financial Management in the Plumbing Industry: USDT TRC Wallet Advantages

Improving Financial Management in the Plumbing Industry: USDT TRC Wallet Advantages

The plumbing industry, like any other trade, often grapples with financial management challenges. From managing payments and expenses to ensuring secure and efficient transactions, the financial aspect is integral to the operational success of a plumbing business. Recognizing this, many plumbing professionals are turning to digital solutions like the USDT TRC Wallet to streamline their financial management processes.

The USDT TRC Wallet is a digital wallet that uses Tether (USDT), a type of cryptocurrency, on the TRON (TRC) blockchain. The wallet offers several advantages for businesses. First, it provides a fast, secure, and efficient method for transactions. USDT is a stablecoin, which means its value is linked to the US dollar, thus offering stability and predictability in terms of value. This allows businesses to conduct transactions without worrying about the volatility often associated with other cryptocurrencies.

Second, the USDT TRC Wallet provides a high level of security. The wallet utilizes blockchain technology, which is designed to be tamper-proof and provides transparency for all transactions. This protects businesses from fraud and other security risks associated with traditional banking systems. Additionally, the wallet’s encryption technology ensures that sensitive information is protected from unauthorized access.

Lastly, the wallet simplifies financial management. It allows businesses to track and manage their expenses and cash flow with ease. It offers a comprehensive dashboard with real-time data, which is a valuable tool for businesses to monitor their financial health and make informed decisions.

TrusteeGlobal.eu USDT TRC Wallet for Plumbing Businesses: Enhancing Efficiency and Security

TrusteeGlobal.eu, a leading provider of digital wallets, offers the USDT TRC Wallet designed to meet the unique needs of businesses, including those in the plumbing industry. The wallet is designed to enhance both efficiency and security, creating a more streamlined and secure environment for businesses to manage their finances.

The efficiency of the USDT TRC Wallet from TrusteeGlobal.eu is evident in its user-friendly interface and functionality. It offers a seamless process for making transactions, whether it’s paying suppliers, receiving payments from clients, or managing internal expenses. The wallet eliminates the need for traditional banking processes that often involve paperwork, long wait times, and additional fees.

In terms of security, the TrusteeGlobal.eu USDT TRC Wallet employs advanced encryption technology and the robust security features of the TRON blockchain. This ensures that all transactions and sensitive data are protected from unauthorized access and potential breaches.

Moreover, the TrusteeGlobal.eu USDT TRC Wallet provides businesses with the tools they need to effectively manage their finances. It offers real-time tracking of transactions and balances, allowing businesses to have a clear overview of their financial status at any given time. This feature is particularly beneficial for plumbing businesses that often have to manage multiple projects and expenses simultaneously.

TrusteeGlobal.eu USDT TRC Wallet: Tracking Expenses and Managing Cash Flow for Plumbing Professionals

For plumbing professionals, managing expenses and cash flow is critical to the success of their business. With the TrusteeGlobal.eu USDT TRC Wallet, they have a powerful tool at their disposal that can simplify these tasks.

The wallet provides a platform for tracking expenses in real-time. This feature allows businesses to monitor their spending patterns, identify areas where they can cut costs, and ensure that they are staying within their budget. It can also help them plan for future expenses and make more informed financial decisions.

In addition to tracking expenses, the TrusteeGlobal.eu USDT TRC Wallet also enables businesses to manage their cash flow effectively. With its real-time data and comprehensive dashboard, businesses can monitor their income and expenditures, ensuring that they have enough funds to cover their operational costs and invest in growth opportunities.

In conclusion, the USDT TRC Wallet is more than just a digital wallet. It is a comprehensive financial management tool that can significantly enhance the efficiency and security of a plumbing business. By adopting this technology, plumbing professionals can not only streamline their financial management processes but also gain a competitive edge in the industry.

Contest recognizes outstanding customer service; Winner receives $500 cash! Malco Products, one of the nation’s leading solution developers and manufacturers of a variety of high-quality tools for the building trades, today announced the launch of its brand-new Counterperson of the Year Contest. Malco is looking to recognize and celebrate outstanding counter staff at its U.S. wholesale distribution locations who demonstrate Read more

Contest recognizes outstanding customer service; Winner receives $500 cash!

Malco Products, one of the nation’s leading solution developers and manufacturers of a variety of high-quality tools for the building trades, today announced the launch of its brand-new Counterperson of the Year Contest.

Malco is looking to recognize and celebrate outstanding counter staff at its U.S. wholesale distribution locations who demonstrate the same values that make Malco great: dedication to superior customer service and going above & beyond to ensure contractors have the Malco tools they need to get the job done.

There are great prizes lined up not just for the winner, but for the contractors and distributors who nominate as well:

- The winner will receive $500 cash.

- If the winner is nominated by a contractor, the contractor receives $100 in Malco tools of their choosing, plus the distributor/contractor team will receive lunch!

- All qualifying nominees and nominators will receive a Malco golf shirt, hat and product catalog.

Malco is also making it easy for contractors to nominate counter staff, with 3 options to enter:

- Grab a printed form at your local distributor location and mail it in (PO Box 400, Annandale, MN, 55302)

- Enter online at www.malcoproducts.com/counterperson-of-the-year

- Submit a brief video, which can be emailed or texted to Malco’s marketing department at 612-325-1502 or marketing@malcotools.com.

All entries must be received by Thursday, August 31, and the winner will be announced in October. Please note, this contest is only open to nominees in the United States.

For more information about Malco Products and to enter the contest, visit www.malcoproducts.com/counterperson-of-the-year

By Sean Comerford Plumber’s putty and silicone sealant are two common types of sealants used by plumbing professionals. But which one does what? And when should each be applied? This article provides a detailed breakdown of the key differences between these two popular products and when to use them. What is plumber’s putty? Plumber’s putty Read more

By Sean Comerford

Plumber’s putty and silicone sealant are two common types of sealants used by plumbing professionals. But which one does what? And when should each be applied?

This article provides a detailed breakdown of the key differences between these two popular products and when to use them.

What is plumber’s putty?

Plumber’s putty is a sealing staple for professional plumbers. This easy-to-use product will prevent the migration of water between two rigid surfaces, keeping your fixtures leak-free. A malleable, clay-like compound, plumber’s putty creates a watertight seal by filling in the space under a flange to prevent water from seeping through.

What is silicone sealant?

You’ve probably noticed the terms ‘caulk’ and ‘sealant’ are often used interchangeably. The two products serve a similar purpose, which is to act as sealing agents to fill gaps and cracks, as well as bonding agents between building materials, such as joining countertops to sink bases. Intended to prevent leaks, they are both applied to surfaces using a caulking gun, which likely explains why a sealant is technically categorized as a type of caulk.

The key distinction between a caulk and sealant? Elasticity.

— Caulk is typically made from a mixture of latex and acrylic materials, which make it more rigid and prone to shrinking when cured.

— A sealant offers superior elasticity and water resistance, because it primarily contains silicone. The silicone material allows a sealant to easily expand and contract during changing temperatures without losing its airtight/watertight seal.

Therefore, sealants are a smart choice for areas that experience frequent weather fluctuation and high moisture levels, such as kitchens, bathrooms, as well as around doors and windows.

The two most important factors to keep in mind when selecting a caulk or sealant are the temperature range and moisture level at the site of application. Silicone sealant can be applied at temperatures between 0 to 120 degrees Fahrenheit and can withstand operating temperatures of -70° F to 400° F.

4 key differences between plumber’s putty and silicone sealant

1. Dry time: Plumber’s putty has no dry time, whereas silicone requires cure time. Typically, most siliconized sealants or caulks need approximately 24 hours to cure completely or a minimum of eight hours before exposing it to water or moisture.

After plumber’s putty has been applied and the fixture put in place, the latter can be used immediately. However, if putty is being used in colder applications, we suggest waiting 10 minutes after the initial installation to confirm the product does not need an extra turn to ensure it is properly secured.

Typically, most types of sealants need approximately 24 hours to cure completely or a minimum of eight hours before exposing it to water or moisture.

2. How it dries: Silicone sealant or siliconized caulk is an adhesive and cannot be remolded or replaced after it has dried. Plumber’s putty is an easily workable, soft, pliable, fixture-setting compound. Unlike some other sealants, plumber’s putty remains soft over time and can be easily modified after its first application.

Plumber’s putty will remain pliable when not exposed to air and can be used as a bedding compound for strainers, faucets, and tub waste and overflows once out of the container. However, if the putty is exposed to air for an extended period of time, it will harden and become brittle. Once the putty has dried, nothing can be added to regenerate the putty without affecting the quality of the product.

3. Clean-up: Plumber’s putty is also easier to clean than silicone, because it does not stick to hands and requires no additional tools. Applying silicone can get messy. As a result, many contractors carry additional products, such as a caulking gun or a silicone spray, to make the application easier. In contrast, when using plumber’s putty, you need no more than a tub of putty to get the job done.

4a. When and where to use it — Plumber’s Putty: Plumber’s putty is specifically designed for plumbing applications. It is ideal for setting faucets, sink basket strainers, shower and pop-up drains. It’s easy to wipe away after installation and will not be visible from the outside of the plumbing fixture once installed. Oatey Plumber’s Putty, for example, will last two years from the manufacture date if the lid is sealed properly.

Because plumber’s putty is oil-based, it can stain porous materials, such as granite, marble, quartz and sandstone. For application on these surfaces, use a stain-free plumber’s putty, as this product is oil-free and will not stain the porous material.

Plumber’s putty is shaped by hand before it is applied to the plumbing part. Prior to using plumber’s putty, ensure all surfaces are dry and free from hardened putty, dirt, wax, oil and grease. Remove debris by wiping with a cloth, scraper or wire brush as needed and dry the surface.

Read this blog for the steps to apply plumber’s putty.

Do NOT use plumber’s putty in these instances:

- On plastics (acrylic or ABS — Acrylonitrile Butadiene Styrene), because it will affect the integrity of the material and lead to product failure.

- In any pressurized connection, such as a gasketed fitting or on the thread of pipes. Although plumber’s putty creates a watertight seal, it is not an adhesive or glue.

- To seal a leaky toilet or toilet bowl to a finished floor, because plumber’s putty will dry out in the applications and is not waterproof. Cleaners and urine can also compromise the integrity of the putty if they come in contact with one another on the bathroom floor.

- To seal windows or doors, because plumber’s putty lacks any insulating qualities

- To install a drain on an acrylic tub and/or shower uni Stain-free and regular plumber’s putty can have an adverse effect on the finish of acrylic surfaces, similar to its effect on ABS plastic materials. You should use only 100%-silicone for this application.

4b. When and where to use it — Silicone Sealant: Due to a silicone sealant’s strong adhesiveness, elasticity and water-resistant properties, it’s an excellent choice for kitchen and bath applications, including:

- bonding top-mount and undermount sinks to countertops;

- bathtub/shower surrounds, doors and drains;

- sealing gaps and seams in gutters;

- filling exterior holes made by nails or screws;

- HVAC applications.

The bottom line

Plumber’s putty and silicone sealants are both great products to use on your projects, but they each have their own set of uses and benefits.

- If you’re looking for something that will withstand frequent weather fluctuation and high moisture levels, silicone sealant might be the best option.

- On the other hand, if you need something to prevent the migration of water between two rigid surfaces, keeping your fixtures leak-free, plumber’s putty is a smart choice.

About the author: Sean Comerford is a Technical Applications Manager at Oatey Co. He is a third-generation tradesman with nearly 20 years of plumbing experience, including serving as the lead plumber for commercial/residential new-construction, service and fire protection jobs. He holds a State of Ohio Fire Protection License for Sprinkler and Standpipe.

About the author: Sean Comerford is a Technical Applications Manager at Oatey Co. He is a third-generation tradesman with nearly 20 years of plumbing experience, including serving as the lead plumber for commercial/residential new-construction, service and fire protection jobs. He holds a State of Ohio Fire Protection License for Sprinkler and Standpipe.

Improving Financial Management in the Plumbing Industry: USDT TRC Wallet Advantages

Improving Financial Management in the Plumbing Industry: USDT TRC Wallet Advantages