Whether you’re dealing with a compact hatchback, a luxury sedan, or a full-size twelve wheeler truck, an air conditioning system is a staple across all categories of vehicles. Drivers want efficient and reliable AC for cooling and heating but unfortunately, many of them often use it inadequately, causing dysfunctions and sometimes serious damage which can Read more

Whats Next

Whether you’re dealing with a compact hatchback, a luxury sedan, or a full-size twelve wheeler truck, an air conditioning system is a staple across all categories of vehicles. Drivers want efficient and reliable AC for cooling and heating but unfortunately, many of them often use it inadequately, causing dysfunctions and sometimes serious damage which can jeopardize onboard safety and induce hefty repair costs. In this dedicated guide, we’ll delve into the consequences of poor vehicle HVAC maintenance and provide useful troubleshooting tips.

Improper Cooling

One of the most common effects of inadequate AC maintenance is improper cooling. An onboard air conditioning system that isn’t blowing air as cold as it used to is generally a sign of a malfunctioning or damaged compressor. Whether it’s due to overuse, lack of care, or a simple clog, this vital component is no longer able to regulate the flow of refrigerant in the AC system. This results in the air flowing being warmer but it doesn’t necessarily affect ventilation.

Overheating Engine

Like most elements found inside a vehicle, an HVAC system uses power from the engine. With wear and tear, the compressor’s clutch can start to give out; it can either seize or break, both of which are very problematic. An unmoving clutch will cause unnecessary pressure on the engine, overheating, and early fuel exhaustion. A broken clutch usually requires the entire compressor to be replaced altogether.

Loud Noises

Odd noises from an operating AC unit are a typical sign of poor maintenance. A worn compressor bearing can cause a loud grinding sound to emanate directly from the engine, while other noises from inside the cabin call for a blower fan clean or replacement. This can be particularly bothersome for drivers who spend countless hours on the road. In addition, you’ll want to ensure meticulous and periodic checks are done to increase the longevity of your vehicles.

Foul Odors

Foul odors are another commonly reported onboard HVAC problem. Mold or mildew smells generally indicate a moisture build-up in the air conditioning filters, which can be taken care of with regular disassembly and cleaning. Now, if a pungent smell emanates from the vents, it might be that you’re dealing with a pest infestation or a dead rodent lodged somewhere in the vehicle. In such cases, an air freshener just won’t cut it!

Water Leakage Inside the Cabin

Lastly, because of inadequate maintenance, drivers can come to notice water inside their vehicle cabin. There may be refrigerant flowing through the evaporator, which gets condensed and forms water. When the draining tube that redirects the liquid outside is clogged, this residual water will seep directly into the cabin, causing all sorts of damages to carpets and possibly onboard navigation.

Ultimately, HVAC systems can be just as problematic inside homes as they are in cars or trucks. Because its components are not immediately visible, except for the vents, many drivers will often fail to take care of their onboard AC system properly, resulting in all kinds of setbacks that can hinder comfort and jeopardize the occupants’ safety.

Countertop dishwashers offer as much cleaning power as full-size models. Countertop dishwashers use less water and detergent than full-sized models, and often have significantly shorter cycle times.The Streamline compact size dishwasher is perfect for situations where you need a dishwasher but cannot fit a built in dishwasher or you simply have little counter space to Read more

Countertop dishwashers offer as much cleaning power as full-size models. Countertop dishwashers use less water and detergent than full-sized models, and often have significantly shorter cycle times.The Streamline compact size dishwasher is perfect for situations where you need a dishwasher but cannot fit a built in dishwasher or you simply have little counter space to spare. If you have a smaller home, apartment or small business that has trouble filling a full-size dishwasher, a countertop dishwasher may be the perfect answer.

The Streamline affordably priced sink/dishwasher combo is top mounted and comes with a complete accessories package which includes a draining basket,sealing tape, mounting clips, waste fittings and overflow plastic pipe. The brushed stainless steel sink measures; 35 1/2″ x 19 3/4″ x 23 3/4″

The sink bowl material is 304 stainless steel with a .4″ thickness with black tempered glass.The dishwashers electrical rating is offered in 220v,50hz or 110v,60hz. The sinks bowl volume is 12.25 gallons

To view the complete Streamline product line, visit www.streamlinehoods.com.

Once a manufacturing mecca in the 1920s and 30s, the small eastern Ohio town located in the Rust Belt region of America is host to American Standard’s Americast plant. As members of the trade press assembled at the American Standard facility in Salem, Gray Uhl, Brand Education Director, Lixil Water Technology—one of the trusted tour Read more

Once a manufacturing mecca in the 1920s and 30s, the small eastern Ohio town located in the Rust Belt region of America is host to American Standard’s Americast plant. As members of the trade press assembled at the American Standard facility in Salem, Gray Uhl, Brand Education Director, Lixil Water Technology—one of the trusted tour guides for the day—explained that the plant has continued to produce Americast bathtubs for nearly 30 years—one Americast tub per minute, as a matter of fact—in addition to porcelain enamel on steel bathtubs, and acrylic tubs and whirlpools.

A long-time employer in eastern Ohio, the invention of Americast in the 1980s helped to revitalize this plant and local economy that had been depending on steel for so many years. “The materials and the intellectual skill to work with them was already there in the area,” says Uhl.

Americast is an exclusive, patented material used in American Standard bathtubs, which features American Standard’s unique patented process that fully bonds a high quality porcelain surface with an enameling grade steel and a molded reinforcement composite backing. It is durable and weighs less than cast iron so it costs less to install. “American Standard reached out to the automotive and aerospace industries; the Americast composite material is similar to those used in those particular industries,” says Uhl.

Americast is an exclusive, patented material used in American Standard bathtubs, which features American Standard’s unique patented process that fully bonds a high quality porcelain surface with an enameling grade steel and a molded reinforcement composite backing. It is durable and weighs less than cast iron so it costs less to install. “American Standard reached out to the automotive and aerospace industries; the Americast composite material is similar to those used in those particular industries,” says Uhl.

Although it weighs half as much as traditional cast iron, making it less costly to install, Americast’s patented three-layer construction offers superior durability, heat retention and sound dampening qualities. These characteristics have made Americast the bathtub of choice for commercial specifiers, installers and end users for decades. Americast has its benefits over cast iron, say Uhl, “Cast iron is difficult to install/ship and the warping and twisting that occurs in the firing process leads to dimensional instability. In addition, cast iron sucks the heat out of the hot water in the tub.”

When coated, the tub is put into a mold and pressurized. The Americast resin technology (third of three-layer process) is applied to back of porcelain enamel coated steel bathtub.

The patented Americast three-layer construction, combining a porcelain enamel finish with enameling grade metal and a structural composite, was invented and introduced to the building and construction market. Americast was used in the first Princeton bathtubs, offering builders and homeowners a durable, lightweight alternative to cast iron with superior heat retention and noise reduction.

Pioneered following several years of research and development, the unique three-layer construction of Americast consists of a smooth porcelain-enamel finish on high-quality alloy, backed by an injection-molded structural composite. The composite material helps protect the porcelain finish from surface chipping and crazing—lines/cracks in surface—caused by reverse impact damage. The patented Americast composition gives bathtubs a tight radius at corners for maximum useable space in residential and hospitality bathroom settings.

The Americast process was also used to craft the company’s popular collection of Silhouette kitchen sinks, which showcased a range of fashion colors while offering flexible installations options. The unique composition of Americast gives products a tight radius at corners for maximum usable space in tubs and sinks.

The Americast process was also used to craft the company’s popular collection of Silhouette kitchen sinks, which showcased a range of fashion colors while offering flexible installations options. The unique composition of Americast gives products a tight radius at corners for maximum usable space in tubs and sinks.

A pre-fabricated leveling grid underneath the tub provides extra support to the tub floor to prevent warping and cracking. This grid allows the tub to be easily slid into place or bedded in mortar, while also saving time when leveling. “We recently improved the skid pattern and the reformatted design increases coverage by 40%,” says Uhl.

Offering added flexibility for builders, an optional above-the-floor rough installation leaves a few inches of clearance between the tub’s underside and the flooring so that pipe can be routed without breaking ground or relocating the drain.

Mechanical Hub had the chance recently to speak with David Kohler, president and CEO, Kohler, about the company’s sustainability and marketing missions, and its positioning in a growing global market. “The Bold Look of Kohler” has been highly regarded as a turning point in Kohler’s marketing, and, I believe, overall company success. Can you talk Read more

Mechanical Hub had the chance recently to speak with David Kohler, president and CEO, Kohler, about the company’s sustainability and marketing missions, and its positioning in a growing global market.

“The Bold Look of Kohler” has been highly regarded as a turning point in Kohler’s marketing, and, I believe, overall company success. Can you talk about this marketing campaign, the era, and any interesting circumstances surrounding it?

David Kohler: The Bold Look of Kohler certainly did mark a turning point for Kohler in 1967 in terms of its advertising and brand voice. I believe that the sentiment of this statement has been a strong element of the DNA of this company since its beginnings, and the campaign gave us, and continues to give us, an outlet to share this passion and drive with the world. There is a statement that I feel fits our brand very well, and helps to further define what once was a tagline but has essentially always been embodied by our company: Bold means never compromising, never settling for what has always been and always challenging what could be. Today, Bold continues to reinvent reality and define a lifestyle. We believe strongly in this mindset, and it permeates all aspects of our company.

While visiting Kohler, the beauty of the area and the respite feeling of the surroundings almost makes you feel—intentional or not—that you are not actually visiting a plumbing fixture manufacturing facility but you are getting a full “Kohler experience.” Can you describe the intention behind the Kohler experience for contractor visits?

While visiting Kohler, the beauty of the area and the respite feeling of the surroundings almost makes you feel—intentional or not—that you are not actually visiting a plumbing fixture manufacturing facility but you are getting a full “Kohler experience.” Can you describe the intention behind the Kohler experience for contractor visits?

David Kohler: Kohler’s mission of enhancing the level of gracious living experienced by every individual who interacts with our brands and services is one of the driving forces behind the “Kohler experience” here in Kohler, Wis. At the main entrance of our headquarters in Kohler, we have the famous John Ruskin quote “Life without labor is guilt; Labor without art is brutality.” This inspirational quote carries many meanings, one of which speaks to the overall design of our campus and surrounding community.

There is an intricate and beautiful marriage in Kohler, Wis. between industry and art. The presence of the factories is a daily reminder that labor, innovation and craftsmanship is crucial to our society, and the beautiful settings and experiences surrounding this factory campus reminds us that there is a need and desire for art in our lives. It is the harmonious existence of these two ideals that creates the Kohler experience – unlike any other in my opinion.

David Kohler, left, breaks ground on LODGE KOHLER in April 2016. Herb Kohler, executive chairman Kohler, center, and Mark Murphy, president and CEO, Green Bay Packers.

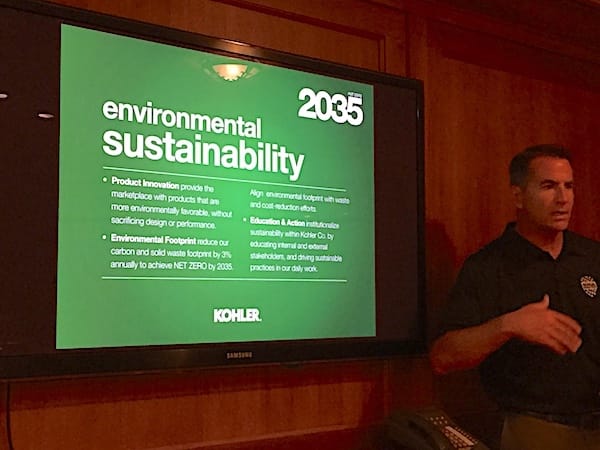

Can you talk about any Kohler’s initiatives toward sustainability? How do you achieve the goal of reduction of carbon and solid waste footprint by 3% annually to garner net zero by 2035?

David Kohler: Reducing our global environmental footprint to Net Zero by 2035 is the cornerstone of our sustainability goal. Given the types of products we manufacture, we believe monitoring and eliminating our output of greenhouse gases and solid waste along with decreasing our water consumption will have the greatest impact. Our initiatives vary from capital investment in process improvement and equipment to switching from incandescent to LED lighting fixtures. We still have a long road ahead to reach Net Zero, but every step puts us closer to our goal.

In Kohler, Wis., the more waste we repurpose, the less goes into the landfill. Kohler’s exceptionally high standards for our vitreous products sometimes create “rejects” that we remove from the production line. Because the material cannot be reworked, the rejects become “cull” – which in days gone by, would have gone to landfills. Today, we work with customers, like Wausau Tile, that can use our cull as a ceramic aggregate for concrete products, such as benches, tables and tile flooring. In Brownwood, TX, water reused is water saved. Our Brownwood pottery connected a condensate return system to eight air-handling units. The collected water routes to the cooling tower and irrigation system, effectively reducing the burden on the local water supply by 4.5 million gallons of water per year.

In Kohler, Wis., the more waste we repurpose, the less goes into the landfill. Kohler’s exceptionally high standards for our vitreous products sometimes create “rejects” that we remove from the production line. Because the material cannot be reworked, the rejects become “cull” – which in days gone by, would have gone to landfills. Today, we work with customers, like Wausau Tile, that can use our cull as a ceramic aggregate for concrete products, such as benches, tables and tile flooring. In Brownwood, TX, water reused is water saved. Our Brownwood pottery connected a condensate return system to eight air-handling units. The collected water routes to the cooling tower and irrigation system, effectively reducing the burden on the local water supply by 4.5 million gallons of water per year.

Is there optimism for growth in global markets? (India, Middle East, Latin America, etc.)

David Kohler: Absolutely there is optimism for global growth. We are seeing positive growth in many key global markets like China, India, and the Middle East. Our brand is number one in the U.S. and China, and the number one import brand in India. We see opportunities for growth in markets such as Brazil, Sub Saharan Africa, and throughout Asia. We aim to lead in every market that we have a presence in, and with our global footprint and global design centers, we are able to create specialized collections and experiences for each market to focus on the needs and demands of the consumers within that region.

Is e-commerce a significant driver for Kohler’s business? Explain.

David Kohler: In the U.S., e-commerce certainly is an important part of our business model. We know through extensive research that consumers not only research online, they are making purchases online, even for large items like bathtubs and shower doors. And, studies have shown that brick-and-mortar retail sales are highly influenced by online shopping activity and online shopper research.

We want to enhance the experience with Kohler during that process by ensuring that Kohler products are presented in a way that is reflective of the high quality of our brand. Kohler has established an Authorized E-Tailer Program designed to reward all the stakeholders of our brand: end consumers with the best possible online experience, authorized e-tailers with the exclusive right to sell KOHLER brand plumbing products online, and Kohler distributors with the opportunity to tap into this growing channel.

By partnering with authorized e-commerce sites, Kohler is simultaneously strengthening its online brand presence and its offline distributor relationships while also ensuring that consumers have a consistent experience with the KOHLER brand. The KOHLER Authorized e-tailer program has been positively received by our distributor partners because it supports the brick-and-mortar distributors and authorized e-tailers alike who are working synergistically to promote the KOHLER brand while providing an enhanced experience to consumers.

LODGE KOHLER

Finally, Kohler is all systems go in its LODGE KOHLER project, a Four-Diamond hotel development Titletown, a destination created on 34 acres immediately west of Lambeau Field, in Ashwaubenon, Wis. The hotel will have a panoramic 5th floor restaurant, bar and outdoor cigar terrace; a full-service garden spa; an indoor/outdoor pool; an indoor/outdoor café opening to the plaza, and 144 rooms and suites—all with unique showering systems.

One of three anchor tenants in the Titletown District, LODGE KOHLER is the first to break ground as construction begins for the destination. Part of the Kohler Co. Hospitality & Real Estate portfolio, LODGE KOHLER will offer guests a high level of accommodation, services and amenities.

Viega introduced its line of Viega ProPress Zero Lead Ball Valve press x hose thread for copper fittings. The bronze ball valves are full port and designed for potable water applications. The ball valves are available in 1/2″ and 3/4″ press sizes and 3/4″ hose sizes. Other features include a lockable metal handle, stainless steel Read more

Viega introduced its line of Viega ProPress Zero Lead Ball Valve press x hose thread for copper fittings. The bronze ball valves are full port and designed for potable water applications. The ball valves are available in 1/2″ and 3/4″ press sizes and 3/4″ hose sizes. Other features include a lockable metal handle, stainless steel ball and EPDM sealing element. The Viega ProPress Copper system is available in more than 600 configurations, in sizes ranging from 1/2″ to 4″. Viega. Connected in quality. Learn more here.