Want to be a reputable contractor in your area? Want to grow your business? Servicing and maintenance with ADEY’s NEW ChemPack is a great way to do just that It’s all well and good installing a brand-new system, or replacing an existing boiler for a new one, but is it protected by clean water? If Read more

ADEY

Want to be a reputable contractor in your area? Want to grow your business? Servicing and maintenance with ADEY’s NEW ChemPack is a great way to do just that

It’s all well and good installing a brand-new system, or replacing an existing boiler for a new one, but is it protected by clean water? If not, is it protected by the warranty if it were to fail due to bad water quality?

The answer to the latter is becoming more frequently, a no. More and more manufacturers are no longer covering warranties if there’s proof of negligence. Imagine the loss of reputation and loss of income by installing components without validating the warranty.

The cost of protecting systems from the onset far outweighs the cost of replacing components due to bad water quality and is this something you should incorporate into your quote to the homeowner.

We all know it’s not as simple as that though and this is how you get over that obstacle!

- Show the homeowner the installation manual and warranty card– Installing a new boiler? Show the homeowner the warranty clauses to prove that servicing is a requirement and explain that their boiler will not be covered under warranty if it is to fail due to bad water quality.

- Replacing failed components? Show the homeowner– showing the homeowner the physical effects of corrosion and explaining how this happened is the “low hanging fruit”!

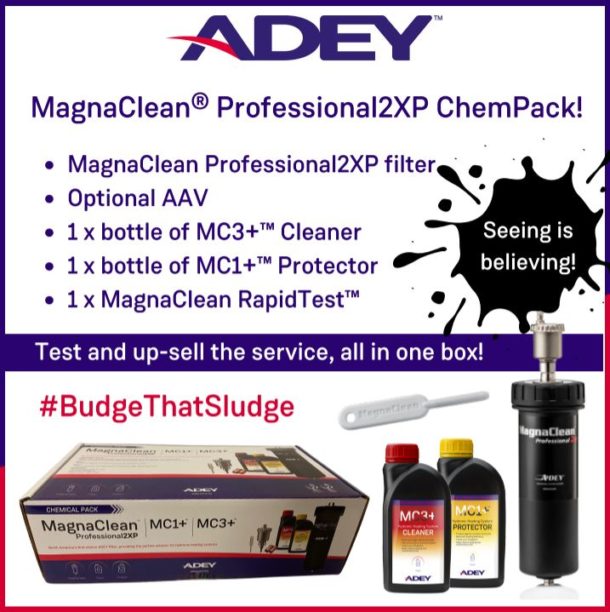

- ADEY’s MagnaClean® Professional2 ChemPack! Test and Solve, all in one box!

- Use the MagnaClean RapidTest on both new and retrofit installs to show the homeowner the magnetite content in any system. Seeing is believing!

- Up-sell the service: use the MC3+™ cleaner, MagnaClean® Professional2XP magnetic filter, and MC1+™ inhibitor for complete system protection!

For more information, please call ADEY on 412 979 7653.

For your local ADEY Rep, please visit https://www.adey.com/us/how-to-buy

We are approaching the end of the 2018-2019 heating season in North America, although homeowners in the colder northern sections of the United States and throughout Canada will likely need their heating systems for another two, maybe even three months. As you know, our long cold seasons can take a heavy toll on hydronic heating Read more

We are approaching the end of the 2018-2019 heating season in North America, although homeowners in the colder northern sections of the United States and throughout Canada will likely need their heating systems for another two, maybe even three months. As you know, our long cold seasons can take a heavy toll on hydronic heating systems. Here’s a rundown on some of the more common boiler and component problems facing home and business owners and what can be done to remedy them.

Radiator cold spots

Radiator cold spots

If your home’s or business’s radiators are not uniformly hot throughout, the following could be the culprit:

- air in the piping and components;

- a malfunctioning component or part, such as a circulator or a valve; and, finally, our “favorite” villain —

- rusty or corroding system pipes that ultimately fill the radiators with magnetite.

What is magnetite? As air and water mix inside the pipes of an untreated hydronic heating system, an iron oxide sludge, called magnetite, forms. As these small (.0003-micron) particles circulate and accumulate inside the system, they begin to adversely affect heat-transfer rates and boiler efficiency. Eventually, iron oxide buildup can lead to equipment damage and/or failure, resulting in costly repairs. Just how extensive is this problem? A recent study analyzing returns to European pump manufacturers found that nearly 70 percent of circulator returns consisted of failures triggered by iron-oxide buildup. The study also showed that more than 95 percent of the debris in hydronic heating systems consists of iron oxide*.

The fix? To eliminate air in the system, first try bleeding your radiators. But if the cold-spot problems persist, bring in a professional plumbing and heating contractor to:

- conduct a full system inspection;

- upgrade failing parts;

- fully cleanse the system with a magnetic dirt filter, as well as a chemical cleaner, such. This maintenance should remove not only the rust, but also all the other debris.

Noisy system

Maybe your boiler rattles every time it rolls into action. Maybe you are routinely treated to a chorus of bangs, gurgles, whistles and rumbles from elsewhere in the system. Regardless, such noise goes beyond mere annoyance; it might indicate more serious problems. Once again, air as well as a buildup of limescale are the most common culprits.

The fix? To eliminate the pipe noise, get rid of any trapped air by bleeding your radiators. If that doesn’t work, call a professional to flush the entire system of limescale and air. If the noise originates in your boiler, your service technician will work to remove limescale in the heat exchanger.

Leaks and drips

Water leakage from your boiler is never a good sign. Leakage usually means a breakdown is imminent. It’s a simple problem to spot. Is there any water beneath the boiler or around its pipes and tank? Causes can range from broken parts to corroded pipes.

The fix? Whether the problem stems from a damaged component or simple wear and tear, there’s only one answer for leaks and drips: Call a professional to check your boiler.

On the subject of leaks, it is often questioned whether cleaning chemicals cause leaks within hydronic systems. The answer to this is — no, if, of course, you are using correctly formulated chemicals, which includes surfactants, dispersants, and inhibitors that make it pH neutral. The surfactants and dispersants help dislodge, lift and move the corrosion, while the inhibitors protect the vulnerable metals during cleaning.

Complete protection

Complete protection

The rising popularity of high-efficiency boilers and the increased use of high-efficiency ECN (electronically commutated motors) pumps with these boilers, have helped lower fuel bills. That’s the good news. The downside: both of these positive trends can also create system-performance headaches for home and business owners. We will explore the why behind these problems in a future blog. For now, understand that both trends can lead to premature system and component failure because of the buildup of iron oxide sludge (magnetite) and other nonmagnetic debris. Both can rob hydronic heating systems of their high efficiency and superior performance.

The solution is magnetic dirt filtration, along with regular and proper system cleansing and protection. This is the only way to prevent the buildup of magnetite and the costly problems it can cause.

GUEST BLOGGER: Brian Salem, ADEY Western/Central North America area sales manager.

Growing up in his Dad’s plumbing company, Brian has a wealth of experience within the HVAC/P industry. Professionally, Brian has been in the industry since 2004 and joined ADEY in 2017 – his role began as OEM Manager for North America but due to ADEY’s growing network of North American Reps, Brian has now taken the reigns as ADEY’s Western/Central North America Area Sales Manager. Brian Salem: brian.salem@adey.com, (847) 440-6665

Growing up in his Dad’s plumbing company, Brian has a wealth of experience within the HVAC/P industry. Professionally, Brian has been in the industry since 2004 and joined ADEY in 2017 – his role began as OEM Manager for North America but due to ADEY’s growing network of North American Reps, Brian has now taken the reigns as ADEY’s Western/Central North America Area Sales Manager. Brian Salem: brian.salem@adey.com, (847) 440-6665

As we work out our first few installs of the the ADEY MagnaCleanse I wanted to share a few quick videos ProStaff’er Andy Mickelson has posted on his Instagram account. Andy has a older radiant system he’s been working on in Montana that has thousands of feet of Onyx tubing and some major corrosion with Read more

As we work out our first few installs of the the ADEY MagnaCleanse I wanted to share a few quick videos ProStaff’er Andy Mickelson has posted on his Instagram account. Andy has a older radiant system he’s been working on in Montana that has thousands of feet of Onyx tubing and some major corrosion with a terrible buildup of iron oxide within the heating solution.

The ADEY products; the MagnaClean magnetic filter, MagnaCleanse magnetic filter flush station and chemicals all work together to filter an entire hydronic system of efficiency-robbing elements. The magnetic sludge, as you’ll see in the short 60 second video posts can cause failure of system components such as circulators, valves, air eliminators and flow controls; depending on the type of heat-exchanger used at the heat source the debris can even cause total failure from restricted flow and over-heating. Please watch for future posts here on The Hub and our social media pages as I will be installing and using the ADEY products on some of my installs as well.