From the 2021 UPC Illustrated Training Manual, Chapter 6, WATER SUPPLY AND DISTRIBUTION 603.3.4 Double Check Valve Backflow Prevention Assembly (DC). A double check valve backflow prevention assembly consists of two independently acting internally loaded check valves, four properly located test cocks, and two isolation valves. The double check valve backflow prevention assembly (DC) is Read more

Backflow

From the 2021 UPC Illustrated Training Manual, Chapter 6, WATER SUPPLY AND DISTRIBUTION

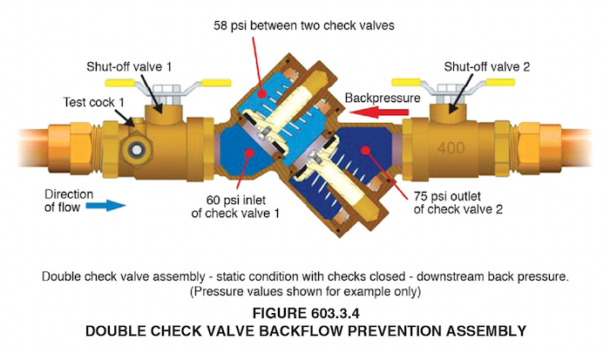

603.3.4 Double Check Valve Backflow Prevention Assembly (DC). A double check valve backflow prevention assembly consists of two independently acting internally loaded check valves, four properly located test cocks, and two isolation valves.

The double check valve backflow prevention assembly (DC) is just what it says – two check valves in series to prevent backflow (see Figure 603.3.4). The first check will close in a backflow condition. Usually one psi of backflow pressure will close the check. The second check is incorporated as a backup if the first check fails; however, there is no way to know if the second check has failed until it is tested. If the device fails, there is no means for removal of the polluted or contaminated water, which may then travel into the potable line. Therefore, the DC may only be used on low-hazard applications. Any liquid connected to the piping downstream of a DC should be a pollutant and not a contaminant.

The DC provides backpressure and backsiphonage protection. A DC may be used as meter-service protection as a containment, or on individual fixtures and appliances as isolation protection. A field test is required on installation, at least annually thereafter, after any repair and when relocated. The device must be installed a minimum of 12 inches above the surrounding ground or floor.

Jones Stephens introduces our new trap seals, designed to prevent sewer gas odors from escaping infrequently used floor drains. Made with durable EPDM, they meet ASSE standards and are UPC approved. They can be used for new construction or retrofit applications. As an alternative to trap primer, trap seals eliminate the need to pour water Read more

Jones Stephens introduces our new trap seals, designed to prevent sewer gas odors from escaping infrequently used floor drains. Made with durable EPDM, they meet ASSE standards and are UPC approved. They can be used for new construction or retrofit applications.

As an alternative to trap primer, trap seals eliminate the need to pour water down the drain. They’re the ideal choice to minimize evaporation and odors in residential and commercial applications, as they prevent sewer gas leakage and mitigate backflow. The seal opens to allow the flow of drainage and closes when there is no flow.

Installation is quick and easy with no special tools required. Simply remove the drain grate, push the trap seal firmly into the drain throat, and replace the grate to complete installation. Jones Stephens’ trap seals are available in 4 commonly used sizes: 2”, 3”, 3 ½”, and 4”.

For more information visit Jones Stephens.