Streamlining HVAC/R connections for safer, faster installs QuickFitting®, a leader in plumbing and HVAC solutions, announces the launch of HVAC/R Push-to-Connect refrigerant fittings, an innovation that simplifies the installation and maintenance of HVAC/R systems. With no flaring, brazing or special tools required, installers can connect refrigerant lines in seconds simply by pushing the fitting onto Read more

brazing

Streamlining HVAC/R connections for safer, faster installs

QuickFitting®, a leader in plumbing and HVAC solutions, announces the launch of HVAC/R Push-to-Connect refrigerant fittings, an innovation that simplifies the installation and maintenance of HVAC/R systems. With no flaring, brazing or special tools required, installers can connect refrigerant lines in seconds simply by pushing the fitting onto the pipe. This approach enables contractors and technicians to make leak-free connections in seconds to reduce installation time and simultaneously enhance safety on the jobsite.

QuickFitting’s HVAC Push-to-Connect refrigerant fittings significantly cut back the time and risk involved in installing or repairing refrigerant lines. Compared to traditional methods, push-to-connect technology enables the rapid joining of copper or coated aluminum line sets in seconds. By eliminating the need for an open flame, the fittings enhance safety on the jobsite and provide technicians with greater flexibility to work in confined or sensitive environments. The result is a faster and safer installation process that helps HVAC professionals complete jobs more efficiently and with reduced risk.

“This innovation was derived from a true need in the market,” said Katie Zyra, marketing director at QuickFitting. “By removing the need to braze, obtain a hot work permit, and have fire spotters, you’re reducing risks while saving time and money on the jobsite. Our patented leak-proof technology significantly saves time, reduces the possibility of errors and improves worker safety without compromising performance.”

A patented double O-ring and grip ring seal delivers a secure, leak-free connection that withstands galling, vibration, pulsation and extreme temperature changes. The heavy-duty body is corrosion- and UV-resistant for long-lasting performance, while yellow protective caps keep debris out during handling and installation. These fittings are designed for residential and commercial HVAC/R applications and are compatible with copper and coated aluminum line sets, as well as HVAC/R units and unitary indoor coils. They are approved for use with industry-standard refrigerants, including A2L-class refrigerants R-452B and R-454B. Unlike permanent solder/ brazed fittings, QuickFitting’s Push-to-Connect fittings are removable using the patented HVAC Slip Clip™ Release Tool.

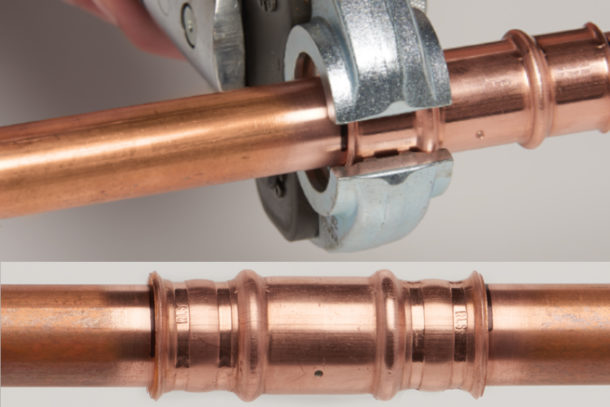

Installation is reduced to a simple four-step process: Clean, Debur, Mark and Push. The process begins with cutting the tube at a straight angle and thoroughly cleaning it using an abrasive cloth. The next step involves deburring the inside and outside edges to achieve a smooth finish. Once prepared, the tube should be marked with the correct insertion depth before pushing the fitting onto the tube up to the marked line – no additional tools are required. To remove installed fittings, the system charge must first be isolated or removed to ensure safety. The Slip Clip™ is then slid onto the fitting end, and once properly aligned, the fitting can be pulled away from the pipe to release the connection.

For more information about SurePress, visit www.quickfitting.com.

As more and more states and cities across the US are reopening, many HVAC/R installers are facing new rules and regulations on the job that will make it even harder to catch up on backlogs created by project delays, including both new construction and retrofit/replacement. While new COVID-19 workplace guidelines vary by state and municipality Read more

As more and more states and cities across the US are reopening, many HVAC/R

installers are facing new rules and regulations on the job that will make it even

harder to catch up on backlogs created by project delays, including both new

construction and retrofit/replacement.

While new COVID-19 workplace guidelines vary by state and municipality, most will share an emphasis on:

- Staggering work by trades to reduce the number of people on site at the same time

- Practicing established social distancing guidelines

- Wearing personal protective equipment like masks and gloves

- Following required personal hygiene practices

The specifics of the new rules will vary, but they will all result in projects taking

longer. Fortunately, there’s one sure way to overcome some of these new challenges, and to make up for lost time: using RLS flame-free press fittings rather than brazing. Here are a few reasons why:

- RLS fittings connect in 10 seconds, so you can get the job done faster.

- No flames mean no fire spotters, so less people are on the job at one time.

- Brazing in a mask – especially in summer heat – will be very uncomfortable.

In addition to the speed and ease of RLS press fittings, they also make the job site safer by removing the fire hazards of flammable gas – which also eliminates the time, trouble and cost of burn permits.

Although some of the benefits are new, RLS press fittings are not. They are the

original, patented, proven HVAC/R press-to-connect fittings that were introduced in 2015 and have been installed successfully millions of times. They are fully registered and listed to UL 207 for pressures up to 700 psi.

This proven alternative already helps HVAC/R contractors work faster and more efficiently. Now it can help them succeed in an environment no one could have anticipated just a few months ago. Learn more at www.rapidlockingsystem.com.

RLS is the manufacturer of the original, patented, proven press-to-connect fittings for high-pressure HVAC and refrigeration applications. These are the same reliable fittings that have been in widespread use – and fully registered and listed to UL207 for pressures up to 700 PSI – since 2015. Faster and Easier Using an RLS-approved battery-powered tool and Read more

RLS is the manufacturer of the original, patented, proven press-to-connect fittings for high-pressure HVAC and refrigeration applications. These are the same reliable fittings that have been in widespread use – and fully registered and listed to UL207 for pressures up to 700 PSI – since 2015.

Faster and Easier

Using an RLS-approved battery-powered tool and jaws, copper tube connections can be made in less than 10 seconds, resulting in jobs being completed up to 60% faster compared to conventional brazing. So RLS fittings help you get the job done sooner, get to the next job faster and get more jobs done. Plus, no brazing means no hauling brazing equipment and materials from jobsite to jobsite.

Safer

By eliminating the flame from the workplace, RLS press fittings create a safer work environment, removing all the dangers and precautions that come with brazing, as well as eliminating costs:

- No flammable gas

- No fire hazards

- No fire spotters

- No hot work permits

- No nitrogen purging

Reliable

The RLS patented design uses a double circular crimp that work hardens the copper to create a permanent mechanical joint that seals off the O-ring from outside air. The circular crimp also maintains the circular shape of the tube and results in a smooth ID. More than 8 million RLS fittings have been installed worldwide since 2015, so they have a proven track record of dependability. They are also backed by a 10-year limited warranty.

Full Product Line

RLS offers all the products you need to get the job done… couplings, tees, long-

radius elbows, reducers, caps and much more. Current sizes range from ¼” to 1-3/8”, with the “RLS XL” line of 1-5/8" and 2-1/8" press fittings coming later in 2020.

Check with your local distributor for RLS press fittings or visit

www.rapidlockingsystem.com for more information.