Let’s face it. The way that Americans shop has changed. The COVID-19 pandemic has been a boon to online retailers and delivery services. Consumers who are leery about walking into a store will buy online for delivery or order it for curbside pickup. You and your family members probably ordered something online today. There’s a Read more

COVID-19

Let’s face it. The way that Americans shop has changed. The COVID-19 pandemic has been a boon to online retailers and delivery services. Consumers who are leery about walking into a store will buy online for delivery or order it for curbside pickup. You and your family members probably ordered something online today. There’s a temptation to let that drift into your professional life as well, but it may not work for securing the brands or quality of products that you are used to securing and providing to your customers.

Plumbing wholesalers must acknowledge that home improvement retailers are not going to go away. But both plumbing wholesalers and plumbing contractors must realize that they, themselves, are offering their customers so much more than a product. Anybody can offer a product for sale but wholesalers and contractors succeed by offering services that the competition either cannot or will not offer.

The big box stores are doing their best to offer services and incentives that mimic those offered by plumbing wholesalers. The issue for now, however, is they can only offer these in a general, corporate way, while the local wholesaler takes great pride in knowing the personality and needs of its contractor customers. A wholesaler knows who those contractors are, what their specialties are, what they want. They know what their customers buy, and they don’t have to look it up in their computer records because they and their counter people have an ongoing business relationship with their contractors. They interact with contractors and their plumbers all the time and deliver to their shops or jobsites.

Another avenue for wholesalers to create relational equity and provide value is to provide on-site training, by leveraging manufacture resources. Heating and plumbing manufacturers and wholesalers realize that one of the best ways to form lasting relationships with contractors is to offer technical training. Contractors will sell products with which they are familiar and comfortable; that’s how they make a profit. If a product is difficult or confusing to install or results in call-backs, they won’t sell it. Homeowners are doing their homework online on space and water heating systems and, while they are well-informed, they certainly don’t know as much as contractors. Contractors must be able to demonstrate a thorough knowledge of their products so that they can discuss, with confidence, why their customers should want to buy what they’re selling.

The way to get that recommendation is through training. Plumbing wholesalers should be set up to offer training, both in-person and virtually. Most training has become virtual because of COVID-19 and we will undoubtedly see some of that continue in the years ahead. It’s incumbent on wholesalers to have the equipment to record video training or to livestream training to their customers. But they should also invest in a proper classroom setup in their facilities in which manufacturers’ trainers and reps can conduct in-person training.

Distributors should emphasize the inventory management and financing services that they offer. They can help contractors keep up with code changes and changes to licensing requirements in their area. They can inform contractors about manufacturers’ rebate offers or give them advice on postcard mailings and other marketing tactics. Everything you do and every bit of information you can provide to help your contractors creates that level of “stickiness” that makes it hard for them to want to go elsewhere.

When thinking about the differences between a local plumbing wholesaler and a big box store, contractors should think about the differences between themselves and a big box store. Any homeowner can walk into a big box store and buy plumbing products. Some will install what they buy on their own and others will reach out to their handy friend. The biggest trend here, however, is that consumers are walking into the box store to buy their plumbing and HVAC needs and the installation that goes with it. It’s one-stop shopping for the consumer. The box stores have swung away to a degree from the DIYers and have now positioned themselves as the seller and installer for today’s consumers.

But what wholesalers offer is individualized support and personal relationships. When one of a contractor’s customers has an emergency on a Saturday night, the contractor has the cell phone number of the wholesaler manager who’s going help them get the replacement equipment they need. Some wholesalers even have formal 24×7 programs to address both residential and commercial emergency installations or repairs. Try doing that through a big box store. And when it comes to a homeowner installing his new bathroom or kitchen, some wholesalers have showrooms they can walk through to find unique fixtures that they will never be able to get in a retail environment.

Bradford White continues to count on wholesale distribution to support the professional specification and installation of its products. Our distributors bring a level of service and support to the equation that keeps contractors coming back and helps them better serve the end-user.

GUEST BLOG BY: Matt Kozak, Vice President – Sales for Bradford White Water Heaters.

GUEST BLOG BY: Matt Kozak, Vice President – Sales for Bradford White Water Heaters.

A graduate of Loyola College in Baltimore, Matt joined Bradford White in 2007 as a regional sales manager in the southeast.

He progressed to become director of sales for the Eastern U.S. and now oversees sales management and business development teams as vice president of sales for the U.S.

Matt has been actively involved in industry organizations such as the American Supply Association (ASA) and the Association of Independent Manufacturers’/Representatives, Inc. (AIM/R).

What lessons did the Bradford White team learn in 2020? In a year dominated by COVID, COVID, COVID, we learned the value of flexibility and communication above all else. Early in the pandemic we were able to successfully assert that we—as a company, in our factories, our distributors and our contractors—are essential to the health Read more

What lessons did the Bradford White team learn in 2020? In a year dominated by COVID, COVID, COVID, we learned the value of flexibility and communication above all else.

Early in the pandemic we were able to successfully assert that we—as a company, in our factories, our distributors and our contractors—are essential to the health of the country. We can’t do without hot water for sanitation, cooking, cleaning, and bathing in hospitals, nursing homes, military installations, food processing plants and in America’s homes. Our contractor customers are vital and essential providers of heat and hot water. There was much that we didn’t know back then, and supply chains began to shut down. Adding to the confusion, the U.S.-based supply chain was operating under different COVID rules and restrictions than what we saw with non-U.S. suppliers. We worked through the initial uncertainty about how we could best protect our employees and stabilized our factories in Middleville and Niles, Michigan, and Rochester, N.H.

Early in the pandemic we were able to successfully assert that we—as a company, in our factories, our distributors and our contractors—are essential to the health of the country. We can’t do without hot water for sanitation, cooking, cleaning, and bathing in hospitals, nursing homes, military installations, food processing plants and in America’s homes. Our contractor customers are vital and essential providers of heat and hot water. There was much that we didn’t know back then, and supply chains began to shut down. Adding to the confusion, the U.S.-based supply chain was operating under different COVID rules and restrictions than what we saw with non-U.S. suppliers. We worked through the initial uncertainty about how we could best protect our employees and stabilized our factories in Middleville and Niles, Michigan, and Rochester, N.H.

We’re entering a new phase of COVID-19 these days, with an evolving sense of normalization. We’re still currently running our plants to maximize employee safety, and we’re doing so in a market where there is high demand for our products.

Photo Credit: Alan Carlson, Armbrust Plumbing & Heating

We follow state and national requirements for PPE. We run through health protocols daily with a questionnaire and a temperature check for all employees, and we’ve adjusted our scheduling to handle that. We exercise social distancing where possible and employ contact tracing measures when necessary. We clean and sanitize our factories frequently. It’s been gratifying to hear feedback from those business partners who are authorized to come into the factory that we are going above and beyond to keep employees safe compared to what they’ve seen elsewhere. I feel very good about what we’re doing to look out for the health of our employees while striving to meet our customer commitments.

You can’t communicate enough. Constant communication with our customers is crucial. We understand our distributors’ day-to-day demands and frequently communicate with them through our sales team and rep network. All their manufacturers have been affected and in different ways, so distributors have a lot of questions. We share information with contractors through our For the Pro® site, and the contractors we talk with have all been busy.

The same goes for our employees. Communicate and then communicate some more. It’s imperative to share reliable (and factual) information with our employees to avoid confusion. If people can’t get reliable information, they may fill in the blanks and fuel an already overflowing COVID rumor mill. We had about 150 employee communications last year and 80% of them were associated with the pandemic. You have to make sure your employees understand what it takes to be safe both in and out of the workplace. The coronavirus has been particularly difficult because information on the disease and availability of vaccines varies from state to state and even county to county.

The same goes for our employees. Communicate and then communicate some more. It’s imperative to share reliable (and factual) information with our employees to avoid confusion. If people can’t get reliable information, they may fill in the blanks and fuel an already overflowing COVID rumor mill. We had about 150 employee communications last year and 80% of them were associated with the pandemic. You have to make sure your employees understand what it takes to be safe both in and out of the workplace. The coronavirus has been particularly difficult because information on the disease and availability of vaccines varies from state to state and even county to county.

Where’s the best guidance coming from? It’s difficult to say what’s the best source, but the CDC appears to have been the most consistent central source for national guidance on what to do for health and safety during the pandemic. Local information can vary by county or parish or municipality. In southwestern Michigan and southeastern Pennsylvania for example, where two of our facilities are located, the guidance varies from county to county, so one county may be on the second phase of shots while another county is barely in phase one. Our Canadian-based team must look to the Canadian government for guidance nationally and then understand what each of the provinces are saying.

How many of these practices will live on beyond the COVID-19 era? As far as products, we’ll continue to see increasing levels of connectivity and remote diagnostics, particularly on the commercial side of things where building management systems are commonplace for monitoring performance. This is not new, but the constraints of COVID have caused an acceleration in the development of more remote capabilities. Virtual learning will continue, but we believe that “hands-on” training experiences will continue to be preferred. In terms of our general industry dynamics, a lot of us are anxious to reduce our time in the virtual/remote world. For us, this is a relationship industry and we like to see our customers and suppliers face to face. We’re most effective when we can be with a contractor in their own space to understand their challenges. You need to ride shotgun in the truck so you can see what they see and hear what they see and hear. And a virtual trade show is not a substitute for the discoveries you can make seeing and touching new products. For a company like Bradford White that prides itself on its face-to-face customer relationships, this has been painful.

This pandemic has altered almost everything in our lives, including food, water, healthcare supply, healthcare delivery, supply chains, insurance plans and contracts. As we prepare for the next pandemic, the planning must include economic recovery along with the health aspect. We were looking at the bullseye, but we missed many of the rings around it. Now we can see how big of an impact COVID-19 has on all facets of our lives.

When it comes to doing business during a pandemic, you can’t deny the human element. When you talk about somebody’s health and well-being, including any challenges they’re experiencing regarding their financial health and well-being, it becomes emotional. As much as you might want to employ common sense and logic when it comes to work, people have lost loved ones and lost jobs. Plus, the coronavirus has become part of the partisan political landscape when we need to be bipartisan when it comes to taking care of the health of the country.

Carl Pinto, Jr. is senior director of marketing communications for Bradford White.

Carl Pinto, Jr. is senior director of marketing communications for Bradford White.

Jobber’s Latest report reveals full quarter of positive year-over-year revenue growth for Cleaning, Contracting, and Green segments Jobber, the leading provider of home service management software, today released the Home Service Economic Report: Summer Edition, which showcases market trends and insights pertaining to Home Service businesses in the first three quarters of 2020. Year-to-date, the Home Read more

Jobber’s Latest report reveals full quarter of positive year-over-year revenue growth for Cleaning, Contracting, and Green segments

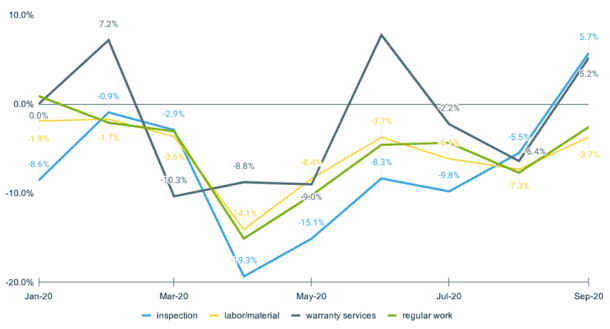

Type of Work Performed – Contracting (YoY)

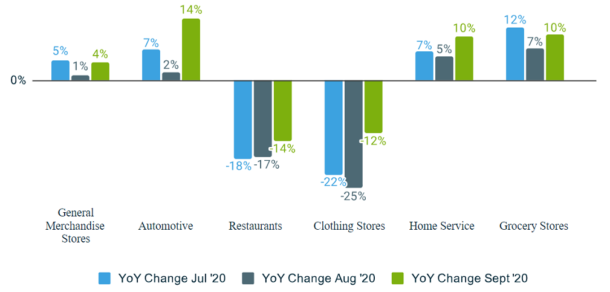

Category Comparison YoY (Q3 2020)

Jobber’s Home Service Economic Reports are compiled using proprietary performance data aggregated from the 100,000+ home service professionals the platform serves. Category performance is also compared to other major categories for context. New to this quarter’s report is data revealing trends in type of work completed, digital payment adoption, and consumer communication. Key findings from the summer report include:

- New Work Finds Pre-Pandemic Success—New-work-scheduled started to show signs of recovery from May onwards, hitting a record high for the year in June with 17% growth year-over-year. The growth continues to look healthy year-over-year in Q3, exceeding pre-COVID levels.

- Employment Growth Sees Upward Trajectory—Compared to Total Nonfarm employment growth, which saw an average decline of around -7% year-over-year in Q3, Home Service fared much better with a decline of around -4%. The category has seen rapid recovery, starting with a decline of -12.9% in April to -4.9% year-over-year in June 2020, followed by continued improvement in Q3.

- Home Service Outperforming Most Categories—With the exception of Grocery Stores and General Merchandise Stores, Home Service was the most stable category through the peak of the pandemic. It has also recovered very well through June and Q3 compared to others such as Clothing Stores and Restaurants.

- Electronic Payments On the Rise—From January to May, there has been a 5% increase in e-payment collection when compared to other methods such as cash or cheque, which can be largely attributed to social distancing measures that came into effect earlier this year.

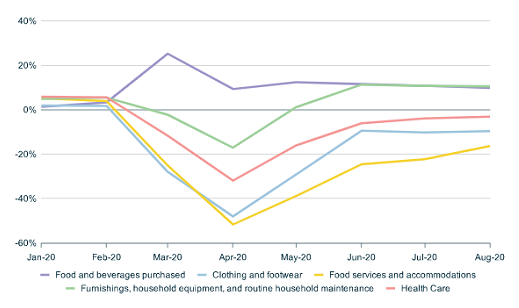

Consumer Spending Comparison YoY

“Analyzing measures such as consumer demand, employment, and revenues, we see encouraging results for the Home Service category,” said Abheek Dhawan, VP, Business Operations at Jobber. “Home Service businesses have rebounded better than most other categories, and it’s fair to say that businesses and consumers remain optimistic, but cautious, as we enter the final quarter of 2020.”

To download the full Home Service Economic Report: Summer 2020 Edition, visit Jobber Homes Services Report.

Agency examines COVID-19 effects on professional tradesmen, manufacturers, trade media and influencers Sonnhalter, a communications firm marketing to the professional tradesman in the construction, industrial and MRO markets, created a comprehensive resource guide full of information regarding COVID-19 and its effects on the Business-to-Tradesmen (B2T) niche that Sonnhalter serves. Sonnhalter’s COVID-19 Tip Sheet is available Read more

Agency examines COVID-19 effects on professional tradesmen, manufacturers, trade media and influencers

Sonnhalter, a communications firm marketing to the professional tradesman in the construction, industrial and MRO markets, created a comprehensive resource guide full of information regarding COVID-19 and its effects on the Business-to-Tradesmen (B2T) niche that Sonnhalter serves. Sonnhalter’s COVID-19 Tip Sheet is available for download at www.sonnhalter.com/covid-19-tip-sheet.

Through extensive research and interviews with a number of key industry stakeholders, Sonnhalter created content at the start of the COVID-19 pandemic and continued throughout the ensuing months to examine the effects and compare them to effects that were initially predicted for the future of the industry. The coverage of the topic includes a five-part series with several editors, publishers and key personnel from the trade media industry, a three-part series of interviews with industry influencers, advice for COVID-19 internal and external communications and content and interviews from the distributor’s perspective.

“As an agency dedicated to the business-to-tradesmen (B2T) industry, Sonnhalter quickly realized the tremendous impact COVID-19 would have on all facets of our business, so we wanted to not only provide communications resources to help businesses during the pandemic, but also educate ourselves by hearing from all types of industry voices on the effects of the pandemic,” said Matt Sonnhalter, vision architect at Sonnhalter. “Discovering how manufacturers, media, distributors and influencers adjusted to the challenges of this new normal has been a fascinating learning experience and we have been wholly impressed with their ingenuity and resilience during this pandemic.”

To review Sonnhalter’s COVID-19 posts, visit our blog or download the COVID-19 Tip Sheet: Sonnhalter.com/covid-19-tip-sheet.

BY JOHN O’REILLY 35-year industry veteran discusses why his employer, CPI Plumbing & Heating, has chosen to invest heavily in developing the tech skills of local high school grads, working with various vendors and suppliers to create a 2,500-sq.-ft. learning facility from scratch. The headlines tell the story with increasing urgency: The shortage of skilled Read more

BY JOHN O’REILLY

35-year industry veteran discusses why his employer, CPI Plumbing & Heating, has chosen to invest heavily in developing the tech skills of local high school grads, working with various vendors and suppliers to create a 2,500-sq.-ft. learning facility from scratch.

The headlines tell the story with increasing urgency: The shortage of skilled workers in the trades hampers our economy. Work takes longer to complete and costs more because of inevitable delays and fierce competition. This list of reasons why this shortage has reached critical mass is as long as your arm. What isn’t as clear is what to do to correct it.

The headlines tell the story with increasing urgency: The shortage of skilled workers in the trades hampers our economy. Work takes longer to complete and costs more because of inevitable delays and fierce competition. This list of reasons why this shortage has reached critical mass is as long as your arm. What isn’t as clear is what to do to correct it.

That is, unless you’re Steve Murray, a 35-year veteran of the PHCP industry and currently HVAC Division Manager at CPI Plumbing & Heating, a full-service contractor based in Mt. Vernon, Washington, a 60-mile drive north of Seattle on Interstate 5. For Murray and CPI owners Brad Tully and Michael (Oly) Olsen, developing a team of properly trained plumbing and HVAC service technicians is a task just as important as—if not prerequisite to—successfully managing the day-to-day operations of this fast-growing company.

The key to the company’s training effort lies in its recently completed “Training Lab” where young apprentices get to practice the skills taught in the company’s classroom. To outfit the 2,500-square-foot space with the plumbing, hydronic and forced-air HVAC systems the company installs and services, CPI went to the vendors that they rely on every day.

Among the most critical was Uponor North America, because its PEX-a piping and fittings offering are at the core of the company’s plumbing and heating disciplines. Uponor responded in a big way: donating nearly $5,000 of Wirsbo hePEX plus pipe for radiant and hydronic heating applications, as well as fittings, manifolds and controls. Also included was nearly 200 linear feet of Quik Trak plywood panels, used mainly for retrofitting a residential space with radiant heating.

“The CPI Training Lab has been a significant investment for us,” says Murray. “We spent $25,000 to $30,000 outfitting the space. Thanks to Uponor and our other vendor partners, we’ve been able to get much of the material donated. But it is a serious expense, for sure—yet one that we think will pay off, long term.”

In the following interview, Murray tells how CPI ensures it has access to a ready and reliably stable of service technicians, as well as how his background positioned him to lead this important initiative for CPI.

Question (Q): How did the idea for the training room develop?

Steve Murray: The closest training center to Mt. Vernon is 50 miles away, and it isn’t practical to ask guys who have already worked a full day to drive 90 minutes in rush-hour traffic to get to a training class. While there are a few local colleges with some HVAC classes, there is nothing in plumbing. Nor did the available curriculum offer any hands-on learning, which we believed essential.

We started by expanding an existing classroom and outfitting it with all the newest audio/visual equipment for online learning. Next, in 2018, we began to transform a junk space every contractor’s shop has into a hands-on lab where apprentices could actually practice what was taught in the classroom. We can now accommodate up to 30 students at one time. Our top techs, Coady Pike and Jake Petterson, help with the training and the curriculum planning as well.

We started by expanding an existing classroom and outfitting it with all the newest audio/visual equipment for online learning. Next, in 2018, we began to transform a junk space every contractor’s shop has into a hands-on lab where apprentices could actually practice what was taught in the classroom. We can now accommodate up to 30 students at one time. Our top techs, Coady Pike and Jake Petterson, help with the training and the curriculum planning as well.

To create an authentic environment, we framed a floor above existing plumbing connections for waste and water connections. The renovated space now has full plumbing facilities: a working bathroom, urinal and kitchen. We also have all the mechanical systems our techs work on in a home: two combi-boilers, two furnaces and air handlers, an electric furnace and, with Uponor’s help, radiant heating on the wall. We also have all kinds of water heaters, tank and tankless.

Q: What is your background and how did you gravitate to training?

Murray: After high school, I joined the Coast Guard. The trade skill in that branch of the military is called “damage control.” On a ship, damage control involves everything from firefighting, to taking care of plumbing systems, to welding and carpentry. That’s where I learned how to maintain plumbing and hydronic systems.

After five years, I left the service and got a job working for a maintenance/property management company, maintaining large apartment buildings in the older part of Seattle. From there, I worked for various contractors, becoming a journeyman plumber and HVAC service technician. Eventually, I opened my own shop for a time.

The one constant at every company, including my own, was a need for trained personnel. Most applicants lacked the necessary skills; or, worse, they had really bad habits. So, I started devising in-house training programs.

At the same time, I taught the plumbing apprenticeship track at a local trade organization called the Construction Industry Training Council. Working two jobs and commuting two hours each way for work eventually became too much. So, in 2016, I joined CPI, which is just 10 minutes from my house.

The owners wanted to grow their HVAC business, and I took on the role of HVAC Division Manager. We’re still working to grow it, and it has been a challenge, mainly because we just don’t get a lot of already properly trained candidates. That’s really what it boils down to.

Q: Who are the students and how do you find them?

Murray: Most are high school grads who CPI has hired. The average age of our apprentice crew is 20, although the average apprentice nationwide is 27, so we’re significantly below that.

Recruitment isn’t easy. Our marketing person participates in all the Chamber of Commerce meetings and all the local contractor trade groups. Last year, we started an outreach program to the local high schools, hosting meet-and-greets at the schools with graduating seniors, talking to them about the opportunities in the trades. We also host monthly open houses for interested kids and their parents. They tour the CPI Career Center and talk about what it’s like to work in the trades. That is really our best opportunity.

There is no perfect system to find the right people, and it is pretty easy to get disillusioned. So many high school guidance counselors still think every student needs to go to college to have a meaningful life. It makes no sense to me. Kids need to hear the message that the trades are a real career option that can provide a good living, post-apprenticeship training.

Q: How many young people are a part of the CPI apprenticeship program right now? What is the curriculum they follow?

Murray: Pre-COVID 19, our classes had 8 to 10 students, now it’s 3 to 5 students per session, so we can spread out.

We have done a couple of things to create the curriculum. We’ve pulled pieces together from Skill Mill (Interplay online for task-based learning), the National Center for Construction Education and Research, NATE [HVAC Courses], as well as content from the Illustrated Plumbing Manuals. I am in the classroom and can monitor what each student is learning online and can supplement that with real-world instruction on what we encounter in the field. Half a day is spent on online lessons; the other half, we’re going to the training lab to practice those skills, hands-on.

Right now, the curriculum is based on a three-month, eight-hours-a-day learning. We call it “boot camp.” Once a student graduates boot camp, he or she works in the field, side-by-side with a journeyman-level technician. Six months to a year down the road, we bring each apprentice back in for a refresher and a hands-on evaluation. There are performance tests each must pass before working independently with a customer.

Q: Do most students pick one track or another, plumbing or HVAC?

Murray: Some do both. From our perspective, it would be great if everyone did. But some lack the interest; others lack the proper skill set. Michael Olson and I are fully licensed journeyman plumbers and fully licensed HVAC technicians. We have the advantage of being able to model that opportunity for students who want to do both.

Q: What’s the advantage to CPI in developing its own young talent?

Murray: We have the confidence that the people we train know how to do things correctly. So much of what goes on in the trades is learning, one person to another. That system relies 100 percent on the person doing the training, teaching the right way to do the work. Without standardized curriculum, that is a crapshoot. The Training Lab allows us to make sure, before we send anyone into the field, they are trained to do work correctly — the way we want it done.

Q: Cynics say: Why spend the money on training, knowing that a trainee may leave and take the skills and all that investment to a competitor?

Murray: We hold ourselves to a very high standard. We want to be the best at turning out quality people. Better to train someone and run the risk of losing them, than not train them and run the risk that they will stay.