TotalFit™ is the professional-grade, engineered polymer (EP), push-to-connect fitting solution that provides greater value for residential projects with the same versatility and speed as brass push-to-connect fittings. Ideal for residential repair, maintenance, or remodels for potable hot-water and cold-water distribution piping systems in single-family homes, townhomes, apartments, and condominiums, TotalFit is designed for use with Read more

CPVC

TotalFit™ is the professional-grade, engineered polymer (EP), push-to-connect fitting solution that provides greater value for residential projects with the same versatility and speed as brass push-to-connect fittings.

Ideal for residential repair, maintenance, or remodels for potable hot-water and cold-water distribution piping systems in single-family homes, townhomes, apartments, and condominiums, TotalFit is designed for use with PEX, PE-RT, CPVC, and copper piping systems.

The innovation features patent-pending technology to provide a strong, lasting connection professionals can depend on, and TotalFit is one of the only full-featured, EP, push-to-connect fittings on the market.

Available in sizes from ½” to 1″, the TotalFit solution offers about a 30% savings over brass push-to-connect fittings, and it meets or exceeds all performance requirements of the PEX system performance standard, ASTM F877, as well as the push-fitting performance standard, ASSE 1061.

The complete offering is approved by the Uniform Plumbing Code (UPC) and International Plumbing Code (IPC) for direct burial in soil or concrete (with 4 to 6 mil poly wrap) as well as behind walls without access panels. Additionally, the offering is solidly backed by a 25-year product warranty for added peace of mind.

Get more with Uponor TotalFit for residential plumbing repairs, maintenance, and remodels.

New Technical Document and Details Proper Steps for Use A new technical document that addresses techniques for the safe and proper use of spray polyurethane foam insulation on and around plastic pressure pipe materials has been published by the Plastics Pipe Institute, Inc. (PPI) with input from the Spray Polyurethane Foam Alliance (SPFA). Prepared by Read more

New Technical Document and Details Proper Steps for Use

A new technical document that addresses techniques for the safe and proper use of spray polyurethane foam insulation on and around plastic pressure pipe materials has been published by the Plastics Pipe Institute, Inc. (PPI) with input from the Spray Polyurethane Foam Alliance (SPFA).

Prepared by PPI’s Building & Construction Division, PPI TN-69 Recommendations when Applying Spray Polyurethane Foam Insulation on and around Plastic Pressure Pipes & Fittings discusses the proper application of spray polyurethane foam insulation to avoid damage due to heat generated by the foam. Pipe and fitting materials include CPVC, PEX, PEX/AL/PEX, PE-RT, PP-R, PP-RCT, PSU, PPS, PPSU, and PVDF.

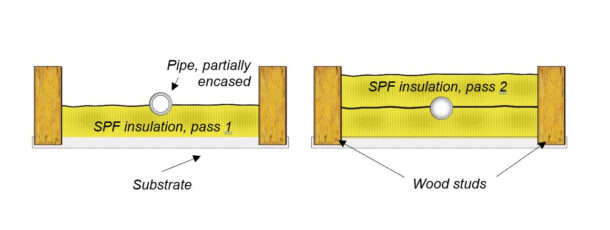

Figure 1: The first layer of SPF insulation is stopped when it reaches the pipe (left), just barely touching or encasing it. After sufficient cooling time, the second layer of SFP insulation is sprayed over the pipe to the required thickness (right).

PPI and SPFA recommend that when there are plastic pipes and fittings in a wall, ceiling, or floor cavity, the SPF installer should apply one layer of foam until it touches the pipe but does not encase the pipe. SPF installers should let the first layer of foam cure for a sufficient amount of time while heat is released from the foam and the pipe remains partially exposed before installing the second layer of foam. These procedures are described in detail within PPI TN-69.

Plastic pressure pipes and fittings are commonly used in applications such as hot- and cold-water plumbing, fire protection, and hydronic heating and cooling systems, including radiant distribution systems. In certain instances, pipes and fittings are installed inside areas that must be insulated, such as within a ceiling or wall cavity. In other installations, the pipes and fittings themselves must be insulated to reduce the transfer of heat through the pipe wall.

According to the SPFA, Spray Polyurethane Foam, or SPF, is a high-performance insulation material commonly used in homes and buildings of all types, and has been used as insulation for decades.

“The spray polyurethane foam curing reaction is exothermic,” explained Richard Duncan, Ph.D., P.E., executive director of SPFA, “which means that heat is generated during the foam reaction. The heat of reaction is highly dependent on the SPF formulation and is also based upon the overall intended application or lift (i.e., layer) thickness installed. Peak temperature within the layer of foam typically occurs within 5 to 15 minutes of application, followed by gradual cooling.”

According to SPFA documents, the chemical reaction that takes place during the application and curing of SPF will generate exothermic temperatures above the 120°F – 130°F setpoint temperatures of the proportioner and hoses. Peak temperatures at the mid-thickness of a pass can exceed 200°F for several minutes and reach peak temperatures 250°F – 275°F for a minute or two, especially for closed-cell SPF, when applied at the maximum pass thickness.

“Plastic pipes and fittings in both residential and commercial plumbing, residential fire protection, and most hydronic applications are typically required to have pressure ratings at 180°F (82°C) operating temperature,” explained Lance MacNevin, P. Eng., director of engineering for PPI’s Building & Construction Division.

MacNevin continued, “The plastic pipes and fittings referenced in PPI TN-69 will withstand short-term exposure to temperatures above 180°F. However, exposure to temperatures above the rated operating temperature of each material, which may occur if pipes are encased in a thick pass of closed-cell SPF, are likely to have negative effects on these materials, potentially leading to premature failure. It is important that SPF insulation is installed correctly to prevent overheating of pipes and fittings.”

Access the full content of PPI TN-69 at https://plasticpipe.org/common/Uploaded%20files/Technical/TN-69/PPI%20TN-69.pdf or by scanning:

Additional information and data about pressure pipe materials used for plumbing and mechanical systems are available from the PPI Building & Construction Division at www.plasticpipe.org/buildingconstruction

Additional information and data about pressure pipe materials used for plumbing and mechanical systems are available from the PPI Building & Construction Division at www.plasticpipe.org/buildingconstruction

Uponor TotalFit™ is the professional-grade, engineered polymer (EP), push-to-connect fitting system that provides greater value for residential projects with the same versatility and speed as brass push-to-connect fittings. Designed for use with copper, CPVC, PE-RT, and PEX piping systems, TotalFit is ideal for service repair, maintenance, remodels, and retrofits for hot and cold potable-water piping Read more

Uponor TotalFit™ is the professional-grade, engineered polymer (EP), push-to-connect fitting system that provides greater value for residential projects with the same versatility and speed as brass push-to-connect fittings.

Designed for use with copper, CPVC, PE-RT, and PEX piping systems, TotalFit is ideal for service repair, maintenance, remodels, and retrofits for hot and cold potable-water piping systems in single-family homes, townhomes, apartments, condominiums, dormitories, and more.

With an innovative design for a strong, long-lasting, trusted connection, a 25-year product warranty, and durable EP materials that offer an average of 30% savings over brass push-to-connect fittings, TotalFit is fit for a pro.

The complete offering includes 33 of the highest-volume push-to-connect fittings in sizes from ½” to 1″ to meet the greatest market need. TotalFit also meets or exceeds all performance requirements for ASTM F877 and ASSE 1061 and is approved by the IPC and UPC for direct burial in soil or concrete (with 4 to 6 mil poly wrap) as well as behind walls without access panels.

SharkBite Max fittings build on the brand’s trusted push-to-connect technology with key improvements for stronger, faster and better connections. Reliance Worldwide Corporation (RWC), a leading manufacturer of premium plumbing products, launched its new SharkBite Max push-to-connect fittings — re-engineered to deliver the same reliability as its 1st generation fittings but with new product enhancements that Read more

SharkBite Max fittings build on the brand’s trusted push-to-connect technology with key improvements for stronger, faster and better connections.

Reliance Worldwide Corporation (RWC), a leading manufacturer of premium plumbing products, launched its new SharkBite Max push-to-connect fittings — re-engineered to deliver the same reliability as its 1st generation fittings but with new product enhancements that provide more strength and an easier installation.

“RWC continues to drive innovation in the plumbing industry by creating products that make installations smoother, quicker and long-lasting,” said Will Kilpatrick, EVP and President of RWC Americas. “SharkBite Max fittings allow plumbers to complete their projects with the confidence of knowing that the fittings they’re using will provide their customers with a high-quality and reliable connection.”

SharkBite Max fittings offer plumbers several new benefits:

- Stronger. The original brass body now has a reinforced stainless-steel collar for added strength, allowing the fitting to handle up to double the burst pressure compared to the SharkBite (1st Generation) fitting.

- Easier to install. Plumbing projects often involve working in tight spaces, and the new design makes it even easier to make a connection. SharkBite Max fittings require half the insertion effort as the original fitting, allowing for seamless installations and quicker emergency repairs in wet lines.

- Fast and versatile. Ideal for faster pipe transitions and repairs, SharkBite Max fittings are compatible with PEX, copper, CPVC, PE-RT and HDPE pipe. Plus, they no longer require a tube liner for PEX connections.

Building off the first generation SharkBite technology, the new patented SharkBite Max fittings will continue giving plumbers the peace of mind of knowing that they won’t receive callbacks, improving overall customer satisfaction and maintaining their strong reputation.

Explore SharkBite Max fittings further here.

By Jonathan Simon In plumbing, like many trades, knowledge is often shared plumber-to-plumber in the field. That allows experience to get passed from one generation to the next. But sometimes the information shared doesn’t keep up with new developments or, like a childhood game of “telephone,” gets distorted over time and becomes inaccurate. The result Read more

By Jonathan Simon

In plumbing, like many trades, knowledge is often shared plumber-to-plumber in the field. That allows experience to get passed from one generation to the next. But sometimes the information shared doesn’t keep up with new developments or, like a childhood game of “telephone,” gets distorted over time and becomes inaccurate. The result is the proliferation of “myths” that are accepted as true by some but are provably false. Here are five myths related to CPVC plumbing systems that the FlowGuard Gold® CPVC team has encountered in the field–and the truth behind the myth.

Myth 1: CPVC should be replaced when it shows signs of discoloration

It’s easy to see how some myths get started. A plumber may think that discoloration is an indication of structural weakness, decides the pipe needs to be replaced and passes that “tip” onto a younger plumber.

But older CPVC pipes that show signs of discoloration do not need to be replaced. CPVC naturally becomes more rigid as it ages and may discolor, but these factors do not increase the risk of failure in a properly installed and serviced system. In fact, the pressure-bearing capability of CPVC pipes improves with age, so, by that measure, an older CPVC pipe is actually stronger than it was when first installed.

It is recommended that plumbers use C-style cutters, a wheel cutter, or a fine-tooth saw when servicing older CPVC pipes, but there is no reason to remove the pipe from service due to discoloration. One of CPVC’s strengths is the material’s long service life—some of the first CPVC pipes ever installed back in the 1960s are still in service today–and discoloration is not a reason to shorten that service life.

Myth 2: CPVC is difficult or slow to install

Some myths are rooted in misperceptions and false assumptions while others can be traced to competitors seeking to gain traction in a competitive market. The myth that CPVC is difficult to install falls into the second category.

CPVC plumbing systems are similar to copper in their design. Both are rigid systems that use socket-style fittings in which the pipe fits into the fitting. But CPVC is easier to work with than copper and the solvent welding process used to bond CPVC pipes and fittings is simple, easy to learn and does not require any special tools. CPVC plumbing systems install faster than copper and have installation times that compare favorably to PEX systems.

Independent research studies that measured installation times for CPVC and PEX systems found that CPVC trunk-and-branch systems install up to 17% faster than comparable PEX trunk-and-branch systems. A PEX mini-manifold system installed 10% faster than a CPVC trunk-and-branch system but used 21% more pipe and the added material costs outweighed the time savings. Most plumbers with experience using both materials have reported no noticeable speed difference between CPVC and PEX plumbing systems.

Myth 3: CPVC can’t handle higher pressures and temperatures

A review of material specifications will quickly dispel this myth. Plumbing codes require that domestic water plumbing systems be capable of handling at least 100 psi of pressure at 180°F without ballooning or bursting. FlowGuard Gold pipes and fittings not only meet this requirement but are pressure rated to 400 psi at room temperature and above 200 psi at all temperatures up to 140°F. When subjected to extreme quick-burst testing, a solvent-welded FlowGuard Gold CPVC plumbing system will not typically fail until the system reaches pressures of 1200 psi or higher.

In addition, CPVC isn’t subject to additional temperature and pressure limitations imposed by chlorinated water on other plastic plumbing systems (140° F and 80 psi). That makes CPVC ideal for higher temperature applications such as hot water lines. It can even support legionella mitigation strategies that store water above 140°F. In multi-story buildings, CPVC’s excellent pressure rating enables use of gravity-fed distribution systems and booster pumps that can introduce risks to other plastic plumbing systems.

Myth 4 CPVC is not as sustainable as other plumbing systems

You might expect a plastic piping system like CPVC to be less sustainable than a metal system like copper, but CPVC has excellent sustainability credentials.

FlowGuard Gold CPVC requires less energy to manufacture and produces fewer greenhouse gases over its service life than PEX and copper systems. The material’s long service life, enabled by its chlorine immunity, means less material is ultimately required to support the application. Plus, CPVC is recyclable through proper centers.

FlowGuard Gold CPVC is also the only residential plumbing system certified by Home Innovation Labs National Green Building Standard (NGBS) and has a lifecycle assessment to contribute to LEED certification.

Myth 5: CPVC is more expensive than other plastic plumbing systems

Plumbers who haven’t compared material costs can be forgiven for believing CPVC is one of the more expensive plumbing systems. After all, FlowGuard Gold CPVC is the only material in the industry that offers a warranty that isn’t voided by exposure to chlorinated water, putting it in a class by itself. It doesn’t make sense that it should be less expensive, but it is. According to a cost study done by a leading PEX manufacturer, CPVC material costs were half the cost of their own PEX system.

These savings come from two key areas: fittings and pipe sizing. While a PEX system contains about 30% fewer fittings than a CPVC system, those fittings (and the crimp, cinch or expansion rings that go with them) typically cost 3-5 times more than the comparable CPVC fitting. In addition, because those insert fittings introduce significant pressure drop at ½” diameters, PEX systems are typically upsized to use more 1” and ¾” pipe than required with a CPVC system, saving even more money. You can verify this yourself by comparing PEX and CPVC costs on your next job.

Better Information Leads to Better Service

Plumbers looking to deliver the best service to their customers and grow their business should be careful not to take everything they hear at face value. There are resources available that provide reliable information about plumbing systems, including manufacturer websites. To get more information on CPVC, visit the plumber’s resource center on the FlowGuard Gold website.