Geothermal heating and cooling is a well-established technology; it’s been around in simplistic forms for more than half a century and has developed at an impressive rate to become a technology that is providing real solutions for decarbonization and grid management. In its years of growth and innovative development, geothermal has taken on many different Read more

heat transfer

Geothermal heating and cooling is a well-established technology; it’s been around in simplistic forms for more than half a century and has developed at an impressive rate to become a technology that is providing real solutions for decarbonization and grid management. In its years of growth and innovative development, geothermal has taken on many different forms and variations, all of which have their own unique benefits.

The Vanderbilt Breakers Mansion saves $36,000 a year with Direct Geothermal Exchange.

The first recorded closed-loop geothermal design installed was a water-free direct exchange geothermal system in 1945. Robert C. Webber (1911-1984) is acknowledged by most to be the inventor of the ground-coupled heat pump system. In fact, according to a September 1948 issue of “The Refrigeration Industry,” Webber was the first to heat his seven-room home in Indianapolis by reversing the cycle on his home freezer. The issue featured Webber as The Refrigeration Industry’s “Man of the Month.” Webber’s “freezer in reverse” was also featured in Ripley’s Believe it or Not in 1948.

Caption: Robert C. Webber (1911-1984)

Direct geothermal exchange (DGX) waterless geothermal systems, also known as direct exchange systems, offer an innovative and sustainable way to heat and cool your home without requiring water in the loop for heat exchange. Unlike many other types of systems, DX uses a closed-loop refrigerant circuit to release heat from under our feet, eliminating the need for water that other systems require. One of the most vital benefits of Direct Exchange Waterless Geothermal is how efficiently it produces year-round temperature control using safe, reliable refrigerants.

There are many pioneers within the sustainable and renewable energy field, one of which is Bill Buschur, President of Total Green Manufacturing. Bill is a recognizable figure within the geothermal industry, and within the niche of waterless geothermal, with a history in the development of the technology used today. For reference, back in 1980, EarthLinked Technologies (ETI) established itself as a research company in the geothermal industry, becoming the original direct exchange manufacturer. It continued to have great success over the years as it carved out a niche in the geothermal industry. ETI partnered with Total Green Mfg. for five years, and Total Green acquired the 38-year-old DGX Manufacturing company.

Total Green Crew installs a DGX system.

A little history

“At around 12 years old, I began to ride along with my father in the service truck and I would run back and forth from the truck to get him tools or the parts he needed to make the repairs,” Buschur shared with us, “As I got a little older, I began building geo ground loops. I remember we had two football practices a day, and I would come home and build loops for the rest of the day. Eventually, I began to go to the job site with other crew members and help with the installation process.”

Young Bill Buschur working on site.

One of the keys to innovation is passion, and Bill Buschur has no issue with showing his passion through actions and incredible results. Bill has grown his business from a hard-working crew of only four people to becoming the largest direct exchange geothermal contracting company in the U.S., installing over 100 DX systems on a yearly basis.

Establishing the Waterless® brand was no small feat for Bill, but after earning a degree in Business Management and a refrigeration certification, topped off by 30 years of experience in geothermal heat pump technology, he’s become the driving force behind the biggest name in Direct Geothermal Exchange nationwide.

Quality is vital in any field, but Bill has ensured that his geothermal direct exchange units are to the highest standard, stating, “Dad always taught us that ‘If you don’t do things right the first time, you’ll end up doing it again’”. So we made sure we didn’t cut any corners when it came to Designing and Installing a geothermal system.”. This has been a key factor in how effectively Total Green has kept up with the latest technology.

At the end of the day, the million-dollar question is, “Are direct exchange waterless geothermal systems as efficient as water-based geothermal systems?” The answer is yes. Past criticisms of DX systems have primarily revolved around the question of environmentally friendly refrigerants. Today modern DX systems use advanced refrigerants that are both environmentally friendly and efficient with heat transfer, which will enhance the performance of the system altogether.

Bill Buschur in his younger years learning the trade (right).

We’re fortunate to have so many diverse options when considering which geothermal system to choose from, accompanied by so many industry pioneers behind each system. As we continue to push for the world to embrace and prioritize sustainability and energy efficiency, minimizing negative environmental impact and using the natural resources given to us, we should make a conscious effort to do so as one piece of that ever-forming puzzle. Any and every geothermal system contributes to a brighter, greener, world-changing future for us and generations to come.

We are on the same team, we are in the same boat, and we are a part of the geothermal heat pump revolution, changing the world for the better.

Mimi (Hannah) Egg is a Social Media Marketing Consultant with a passion for writing and researching. She has overseen the social media accounts for multiple private and corporate organizations and is constantly learning new ways to understand and optimize demographic outreach and form beneficial business connections through social networking for her clients. She can be reached at Mimieggshell@gmail.com

Mimi (Hannah) Egg is a Social Media Marketing Consultant with a passion for writing and researching. She has overseen the social media accounts for multiple private and corporate organizations and is constantly learning new ways to understand and optimize demographic outreach and form beneficial business connections through social networking for her clients. She can be reached at Mimieggshell@gmail.com

In electronics, a heat sink is a passive component that transfers heat generated by an electronic device to a cooler external environment. By absorbing and dissipating heat, heat sinks enable electronic devices to remain within their safe operating temperature limits. Heat sink design Heat sink design is an important aspect of many different types of Read more

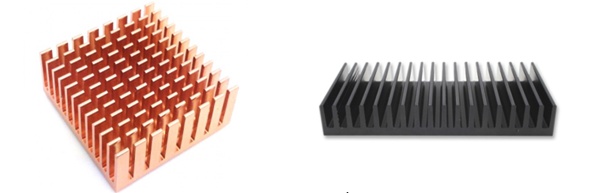

In electronics, a heat sink is a passive component that transfers heat generated by an electronic device to a cooler external environment. By absorbing and dissipating heat, heat sinks enable electronic devices to remain within their safe operating temperature limits.

Heat sink design

Heat sink design is an important aspect of many different types of devices and machinery. Proper heat sink design is critical in ensuring that these devices and components function properly and do not overheat. Overheating can lead to a number of problems, including decreased efficiency, shortened lifespan, and complete failure. Heat sink designs vary depending on the specific application. For example, larger heat sinks are typically used for high-powered lasers, while smaller heat sinks are sufficient for LED lights.

The size, shape, and material of the heat sink must be carefully considered when designing a heat sink for a specific application.

If the heat sink is not properly matched to the device or component it is cooling, it will not be effective and overheating may still occur. In some cases, multiple heat sinks may be used in order to dissipate heat more effectively. For example, a heat sink with a large surface area may be used in conjunction with a heat sink with good heat conductivity in order to cool a particularly heat-generating component.

The material used in the heat sink also varies depending on the application. For example, aluminum is a popular choice for heat sinks due to its good heat conductivity. Copper is another common choice due to its even better heat conductivity. However, copper is more expensive than aluminum and can be difficult to work with, so it is not always the best choice for every application.

It is important to note that heat sinks are not the only way to manage heat in electronic devices and components. In some cases, other methods such as forced air cooling or water cooling may be used instead of, or in addition to, heat sinks.

However, heat sinks remain a popular choice for many applications due to their simplicity and low cost.

Common applications for heat sinks include:

- Regulating the temperature of electronic devices and components

- Cooling high-powered lasers

- Dissipating heat from LED lights

- Managing heat in power amplifiers

All in all, when properly designed and installed, a heat sink can help to keep your devices and components running cooler and perform better for longer.

Types of heat sinks

A heat sink is a device that helps to cool an electronic or mechanical device by absorbing and dissipating heat from it. There are many different types of heat sinks available on the market, each designed for specific applications.

Some common types of heat sinks include:

- Fan-cooled heat sinks: These heat sinks have a fan attached to them which helps to circulate air and dissipate heat more quickly. They are often used in high-power devices such as CPUs and GPUs.

- Liquid-cooled heat sinks: These heat sinks use liquid cooling instead of air to help dissipate heat more quickly. They are often used in high-performance devices such as servers and gaming PCs.

- Passive heat sinks: These heat sinks do not have any fans or other active cooling methods, and instead rely on convection and radiation to dissipate heat. They are often used in low-power devices such as laptops and smartphones.

There are many factors to consider when choosing a heat sink for a particular application, such as the size and power of the device, the environment in which it will be used, and the required cooling performance. The type of heat sink you choose will also depend on your budget and the level of noise you are willing to tolerate.

Advantages of machining a heat sink using a CNC

When looking at heat sink design and manufacture, there are several key factors that come into play in order to create an effective heat sink. One important factor is the method of machining the heat sink. A CNC machine can offer a number of advantages over other methods of machining, making it the ideal choice for heat sink production.

Some of the benefits of using a CNC machine to machine a heat sink include:

Increased accuracy

When heat sinks are produced using a CNC machine, the process is much more accurate than other methods such as hand grinding or milling. This increased accuracy results in a better finished product with less waste.

Greater repeatability

The use of a CNC machine also allows for greater repeatability in the manufacturing process. This means that heat sinks produced using a CNC machine will be more consistent in terms of quality and performance.

Faster production times

The increased accuracy and repeatability of the manufacturing process also results in faster production times. This is particularly beneficial if heat sink demand is high or if deadlines need to be met.

Reduced manpower requirements

As the CNC machine can handle the majority of the machining process, there is less need for manual intervention. This reduces the amount of skilled labor required and can lead to reduced costs.

Overall, there are many advantages to using a CNC machine to machine heat sinks. The benefits of increased accuracy, repeatability, and faster production times can make a significant difference in the quality and performance of the heat sink. When considering heat sink design and manufacture, it is worth considering the use of a CNC machine to ensure the best possible results.