Monumental concerns in the industry—from supply chain issues and inflation concerns to electrification and decarbonization—challenge contractors and manufacturers alike to be ready to rise above the fray. On September 28, Hurricane Ian, a Category 4 storm, hit the Florida coast, leaving a trail of destruction, loss of life, and people without power, and a place Read more

HVAC

Monumental concerns in the industry—from supply chain issues and inflation concerns to electrification and decarbonization—challenge contractors and manufacturers alike to be ready to rise above the fray.

On September 28, Hurricane Ian, a Category 4 storm, hit the Florida coast, leaving a trail of destruction, loss of life, and people without power, and a place to live. The following week, after the residual rains moved through the South Atlantic states, PHCC CONNECT attendees, exhibitors and staff were fortunate to convene in Charlotte, N.C. for the annual show.

One of the many bright spots during CONNECT was the annual Industry Perspective panel—back by popular demand—which featured some of the industry’s finest: Elisabeth Sutton, Director—Marketing, Professional Channel, Kitchen and Bath Americas, Kohler; Bruce Carnevale, President and CEO, Bradford White Corporation; Randy Roberts, Vice President of Sales and Marketing, Rheem; Scott Teson, Senior Vice President of Skilled Trades, Milwaukee Tool; Jeff Fetters, Chairman, Federated Insurance Companies.

As I prepared for the panel, I would have been remiss if I didn’t mention those people still struggling in the Sunshine State. And the more I thought about what was happening in Florida, the more I could draw some symmetry of what has been plaguing our nation the past few years.

Things like supply chain. Are the right people getting what they need in Florida? Labor shortage. Do we have the manpower to provide assistance? Or, do we have the proper infrastructure in place? What about electrification? I mean, I had just seen a meme that said something like, “2.8 million people without power, time to fire up the Teslas.” Now that could be perceived as a bit naïve, but when you look at California, for instance—declaring no new gas cars sold in the state by 2035—concerns about adequate infrastructure are real.

It’s a good thing we had the right people on the panel to address such concerns. I learned that Federated Insurance sent “catastrophic teams” to Florida to help. “We needed to have boots on the ground as quickly as we could,” said Fetters. “Businesses need to have high expectations for employees to remain safe. Disasters can strike at any time. A risk management culture has to perpetuate through every single employee,” said Fetters.

As a side note, how can contractors prepare for such an event? “Make sure you sit down with an agent to see what it would cost to replace your business, and any personal property in the event of any potential catastrophe,” said Fetters.

Supply Chain Woes

Nonetheless, supply chain issues dominate conversation almost daily among working contractors. “We are still challenged by supply chain issues, and it has forced us as a company to better manage our supply chain. We do things differently now,” said Carnevale.

As a manufacturer, you’re never getting what you need from plastic resins overseas, nickel component slowing lines down to component issue challenges,” said Roberts. “This makes us be creative on managing supply chain.”

According to Sutton, “We see that luxury side of remodeling is still high. The thing impacting supply chain is that distributors are receiving more products, managing inventory for distributors.”

Investments in People/Training

Milwaukee Tool has made an $400 million investment in domestic manufacturing. “We want to control our own destiny,” said Teson. Yet, Teson pointed out that with more commercial construction projects on the books, how do we find the right people to support those jobs? “We need skilled tradesmen and women to support those efforts,” said Teson.

Sutton suggests that technology in products is a viable avenue to attract the younger generation. C’mon, who doesn’t like the way an impact driver or press tool feels in their hands?

Elisabeth Sutton

“We also need to attract people to the industry to show them how wonderful it is, and that should not be specific to one type of person,” said Sutton. “We need more diversity, not just one profile,” continued Sutton.

“This is a fantastic industry, and once people are a part of it, they stay,” said Roberts.

Yet, once in the building, how do we get people to stay? Training. “It has always been a critical part of what we do. We have been very flexible with our training—we will take it to customers and also bring them into our facility,” said Carnevale.

How do employees continue to get better year after year? The panel agreed that it’s about establishing a culture of training in your office. This gives employers a competitive advantage in keeping people and attracting people because they will be seen as investing in them.

Electrification is the Buzzword

According to Carnevale, topics surrounding electrification loom large. For example, will the infrastructure be in place to support the new products? How will the infrastructure build out in a very short time? This puts the consumer in a bad position and puts our national security at risk—i.e., supply chain issues and the country’s fragile relationship with China.

“Electrification and decarbonization, whether we like it or not, we need to be prepared. We have the products available,” said Roberts.

Government Regulations

Carnevale noted that he receives email relating to a regulatory issue almost daily. “The DoE is extremely active, and there’s a requirement that is in the foundational law that once the DOE sets a new minimum efficiency standard, it cannot go backward.”

The panel consisted of (from l to r): John Mesenbrink, moderator; Elisabeth Sutton, Kohler; Bruce Carnevale, Bradford White; Randy Roberts, Rheem; Scott Teson, Milwaukee Tool; Jeff Fetters, Federated Insurance.

According to Rheem’s Roberts, there is an “Install Date Standard for Air Conditioning Systems” looming and, “Contractors will be breaking the law if they install an AC system not rated to the new standard come January, 1 2023.” Efficiency standards dictate that sell through of existing systems will be allowed in the northern states if the product was manufactured prior to January 1, 2023. This is not the case in the South and Southwest. AC systems must comply with the 2023 federal minimums to be installed after January 1, 2023. Current Heat Pump systems can continue to be installed in all regions as long as they were manufactured before January 1.

And who is enforcing this, you may ask? “Contractors and distributors will be self-policing installations to make sure they meet the new standard. In addition, manufacturers cannot ship products that don’t meet the new standards or allow them to be registered for warranties if installed after January 1. A standard based on install date will ultimately create inventory challenges for everyone in the industry,” said Roberts.

That Dreaded ‘R’ Word

There are whispers of the “R” word and I don’t think it means that “relief” is on the way anytime soon. From inflation to fuel prices, contractors have faced economic hardships that may continue to linger into 2023, and beyond. “We’ve been bearish on the economy longer than the financial press has been,” says Carnevale. “It is pretty clear that we are in a recession. There have been some positive signs, the fed is getting aggressive, and we will see significant drop in housing market.”

Carnevale continued that he is concerned about the macro economy, even though there are some good signs. “Labor shortages continue to be a vexing problem, and we need to focus on the labor participation rate compared to pre-pandemic, meaning there are a lot of people who are choosing not to work,” said Carnevale.

Teson said that interest rates are the real threat. “We’re watching it very closely and trying to make decisions that will make us come out stronger than our competitors.”

Carnevale added that there is a very distinct demand for discretionary vs. non-discretionary products. In the end, “As the demand starts to soften, we are subject to the laws of supply and demand. It is not going got back to where it is pre-pandemic, but will see some softening on pricing.”

Roberts says that overall, we should see a correction. “How do you position yourself to come out stronger than you go into it?” That’s the question.

For more info, visit PHCC.

Let’s face it: no one can work forever. After years of building and managing your HVAC business, you will have to pass the baton to a successor at some point. As the baby boomers generation ages, it’s a cold hard fact that many contractors can no longer keep up with the ever-changing demands of the Read more

Let’s face it: no one can work forever. After years of building and managing your HVAC business, you will have to pass the baton to a successor at some point.

As the baby boomers generation ages, it’s a cold hard fact that many contractors can no longer keep up with the ever-changing demands of the heating and cooling industry. Today, owners of HVAC and other contracting businesses are retiring in droves to move on to the next chapter of their lives. Couple that with record-breaking levels of merger and acquisition (“M&A”) activity in the HVAC sector, and owners have many considerations and opportunities to consider when succession planning.

How prepared are you for that big day in your future?

In today’s dynamic business environment, managing risks associated with planned and unplanned departures is a business imperative that contractors can no longer afford to ignore. Decades-old, highly successful and well-established HVAC businesses, in particular, need proactive succession planning to ensure continued business growth.

Succession planning, however, can be a complex undertaking. It involves identifying and training your successor to ensure your retirement does not disrupt operations. Additionally, it requires creating a robust strategy to maximize the business’s economic value during the ownership transition and manage any taxation and compliance implications. Succession planning also includes considering M&A options for your business.

Throughout the years, we’ve seen how the lack of a well-thought-out succession plan has led to severe financial damages for many HVAC companies. With this in mind, businesses must develop long-term strategies to mitigate risks and ensure a successful transition.

The Importance of Succession Planning for Your HVAC Business

Whether you have no plans of retiring anytime soon, the future is unpredictable. Having a solid, documented succession plan is crucial to your business’s health and fate.

Succession planning allows you to:

- Ensure your management team is aligned with your plans and goals for the company’s future.

- Stay focused on a long-term, bigger-picture vision for the business.

- Protect the business in the event of a sudden major life-changing event.

- Assess parts of your business that may need special attention for your succession plan to be effective.

No matter the size or structure of your contracting business, having a defined succession plan is critical to selecting and developing the best leaders. Extending tenures may prevent the impending headwind, but there is no substitute for a viable long-term succession strategy. After all, business leaders, irrespective of their stature, would inevitably need to make way for the younger generation.

3 Insightful and Actionable Succession Planning Steps

Every business situation requires a different exit strategy. Some existing business owners may want to step out of their position for good. While some would prefer to stay minimally involved to ensure the company’s future success.

Whether you plan to pass your company on to one of your children or trusted employees or sell it to an outside party, succession planning is paramount.

Here are three important things to consider as you plan for your HVAC business succession:

-

Decide Who Will Take Over

Identify who will take the reins when you retire, and give them the opportunity to develop their skills and experience to successfully replace you in the future. Every aspect of business operations should be clearly defined, including detailed role definitions for key decision-makers at various levels. This is especially true for family-owned businesses.

With any luck, you’ve had capable family members or employees who have established themselves in the specific roles they will eventually assume.

If your business is family-owned and operated, it is important to talk to your family members before making succession choices. Ask them if they are interested in taking over the business, and determine if they have the capability to effectively run the company.

Starting your succession plan sooner rather than later gives you more time to hone the knowledge and skills they will need to take over.

On the other hand, if you’ve been anticipating that one of your employees will buy out your business, make sure they have the financial capacity to give you market value for your business along with the skills to sustain its success. Internal transfers are often structured where the owners are paid over time through the profits of the business, so it is important to really assess if your successor has the skills to run the company profitably without you going forward. Otherwise, you’re giving your business to someone who can put your long-term financial security at risk if they cannot execute successfully. This is why many business owners look to third-party M&A to transition their business.

As retirement looms, you must also train them to do the jobs well to ensure that a steady hand will lead from the top down.

-

Determine When the Transition Will Happen

You can’t just flip a switch and hand over the job to your successor with little notice. Think long-term and set a date for your last day in the company. The ownership transition should begin before your last day to give your successor enough time to get accustomed to their new role.

As the existing business owner, you must also invest in the professional development of your succession choice to help them gain valuable experience and boost their soft skills. Let them assume different responsibilities to assess where they might need some additional training and development.

If you’re in a position where you don’t have a qualified candidate to take over, then you need to craft a broader succession plan that enlists a third party to purchase the business. Make sure to find a buyer who values your business the way you do, has the ability to demonstrate consistent earnings and will continue its legacy when you are no longer there.

-

Consider a merger and acquisition (M&A)

When one entity buys another entity and folds it into their organization, that is referred to as an acquisition. In a merger, two equal companies join to form another entity or co-branded company. The timing has never been more perfect for HVAC businesses to consider M&A. More investors are looking for lower-middle-market organizations for M&A activity, and the benefits to you, as a small business owner, are immense.

Rewarding financial returns are one of the reasons business owners turn to M&A. During an M&A, you’ll be able to enhance the price you receive for your company, allowing you to cash in on your hard-earned success and retire with ease. There are also opportunities to create generational wealth by selling portions of your business to a private equity firm. In this scenario, you are able to continue investing, you stay involved in running your company, and you work with the majority owner to generate increased value for your business. Eventually, you’ll be able to liquidate your equity at a larger amount in this second sale of the business.

If you are interested in M&A, it’s never too early to start planning. Price isn’t the only thing to focus on. From determining timing, better understanding your customer relationships and determining what to do with your team, there are seven things to consider when selling your company.

Ignite A Big-Picture Mindset

Changes in the HVAC business happen fast. But through effective succession planning and considering M&A options, you can ensure business continuity. Don’t forget to call in the experts for help with your company’s succession planning. Look for a team with many years of experience, diverse business background and a proven track record in the M&A industry.

Need help with your company’s succession planning? The experts at Align BA are happy to advise you on the best way to create a strong leadership pipeline.

About the Author: Dena Jalbert is at the forefront of executive leadership within the M&A industry. She is also an award-winning entrepreneur, a mother and a philanthropist. Dena is an outgoing, high-performing, and deeply analytical leader who is passionate about driving business growth through financial discipline, innovation and creativity. Dena is a proven leader whose distinction interlaces a wider-view of business needs to connect the dots between data and business growth strategy. It is this unique strength that has led to repeated successes throughout her career, enabling a different and fresh perspective in building and leading organizations — utilizing innovative strategies to deliver transformations in operations and business results. As a mother of two young girls, Dena is determined to do what she can to advance the opportunities of young girls and women throughout Central Florida.

About the Author: Dena Jalbert is at the forefront of executive leadership within the M&A industry. She is also an award-winning entrepreneur, a mother and a philanthropist. Dena is an outgoing, high-performing, and deeply analytical leader who is passionate about driving business growth through financial discipline, innovation and creativity. Dena is a proven leader whose distinction interlaces a wider-view of business needs to connect the dots between data and business growth strategy. It is this unique strength that has led to repeated successes throughout her career, enabling a different and fresh perspective in building and leading organizations — utilizing innovative strategies to deliver transformations in operations and business results. As a mother of two young girls, Dena is determined to do what she can to advance the opportunities of young girls and women throughout Central Florida.

The International Association of Plumbing and Mechanical Officials (IAPMO) was pleased to have participated in the Plumbing and Heating event at WorldSkills Competition 2022 Special Edition (WSC2022SE), Nov. 2-4 at GROHE Technikum in Lahr, Germany. The competition showcased national champions from 20 WorldSkills member countries. IAPMO CEO and World Plumbing Council (WPC) Deputy Chair Dave Read more

The International Association of Plumbing and Mechanical Officials (IAPMO) was pleased to have participated in the Plumbing and Heating event at WorldSkills Competition 2022 Special Edition (WSC2022SE), Nov. 2-4 at GROHE Technikum in Lahr, Germany. The competition showcased national champions from 20 WorldSkills member countries.

The International Association of Plumbing and Mechanical Officials (IAPMO) was pleased to have participated in the Plumbing and Heating event at WorldSkills Competition 2022 Special Edition (WSC2022SE), Nov. 2-4 at GROHE Technikum in Lahr, Germany. The competition showcased national champions from 20 WorldSkills member countries.

IAPMO CEO and World Plumbing Council (WPC) Deputy Chair Dave Viola relished the opportunity to present medals to the winning champions, concluding a thrilling three-day competition at the celebratory closing ceremony on Saturday, Nov. 5. Viola was joined by IAPMO Chief Administrative Officer and WPC Secretariat Gaby Davis, as well as IAPMO President David Gans and Vice President Steve Panelli, both experiencing a WorldSkills competition for the first time.

Plumbing and Heating competitor Florian Bliem of Austria captured the gold. Joint silver medals were awarded to Tom Pean of France and Marton Offner of Hungary, and the bronze medal was won by Tai-Yu Chen of Chinese Taipei.

Dave Viola

Indicative of the high standard of this year’s long-awaited, rescheduled competition, six additional entrants were awarded medallions for achieving a final assessment above WorldSkills’ benchmark for excellence: Sangyeop Kim (Korea), Saku Hurtig (Finland), Luca Herzog (Switzerland), Connor Cruden (United Kingdom), Fabian Grün (Germany), and Yuto Itahashi (Japan).

“What we are seeing today at WorldSkills is the best of the best, showcasing their skills and inspiring other people to do their best quality work,” Gans said. “We are looking at the future of plumbing, and plumbers. These are the young men and women who are going to take plumbing to the next level and help change the world.”

The event also showcased a new Plumbing Champions training activity, sponsored by the World Plumbing Council and delivered by the International Water, Sanitation and Hygiene Foundation (IWSH), charitable arm of The IAPMO Group. Three young students, accompanied by one mentor and one interpreter — all from Ukraine — were sponsored to participate in an educational workshop completing the same test project as was tackled in the WorldSkills competition, guided and supported by technical experts from IAPMO and GROHE.

Mayor of the city of Lahr Markus Ibert paid a special tribute to the Ukrainian group in his closing remarks.

“I would like to thank all participants who made this special event possible, and I wish you all the best for your ongoing life; success, and peace — especially to our guests from Ukraine. To you, to your families and your neighbors, have a good time, in peace, and with benefits, for a good life.”

The biennial WorldSkills international competition returns in September 2024, where it will be hosted in Lyon, France.

For more information about WorldSkills, visit https://worldskills.org/.

While he’s not busy with his day job working on hydronic heating systems, commercial and residential plumbing, backflow prevention and gas work, Chris Massaro (@nwo_plumber) loves playing guitar and recording music. Admiring the recent tattoo to commemorate his daughter’s birth, “I was in a bunch of bands throughout high school and recorded an album once Read more

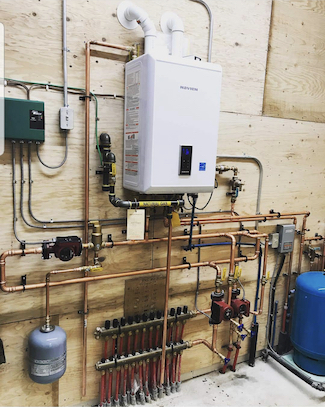

While he’s not busy with his day job working on hydronic heating systems, commercial and residential plumbing, backflow prevention and gas work, Chris Massaro (@nwo_plumber) loves playing guitar and recording music. Admiring the recent tattoo to commemorate his daughter’s birth, “I was in a bunch of bands throughout high school and recorded an album once. I don’t get around to it as much as I used to or like to, but I’m definitely making more time for that now,” says Massaro, owner/lead tech at Aqua North Plumbing and Heating Ltd., Thunder Bay, Ontario, Canada.

While he’s not busy with his day job working on hydronic heating systems, commercial and residential plumbing, backflow prevention and gas work, Chris Massaro (@nwo_plumber) loves playing guitar and recording music. Admiring the recent tattoo to commemorate his daughter’s birth, “I was in a bunch of bands throughout high school and recorded an album once. I don’t get around to it as much as I used to or like to, but I’m definitely making more time for that now,” says Massaro, owner/lead tech at Aqua North Plumbing and Heating Ltd., Thunder Bay, Ontario, Canada.

I take that back. Massaro also enjoys hanging out with friends and family, golfing and mountain biking. And, he definitely needs to get that grill time in—grill, smoke, BBQ. “Sometimes in that order, in one cook. Most of the time I do use the smoker though. I’ve been on a pulled pork kick lately. My favorite is some nice pork shoulders on the Traeger. It’s the ultimate dad activity, in my opinion,” says Massaro.

The work\life balance has been a struggle for Massaro; he realized one day that when you are running your own small business sometimes there isn’t a balance. You have to make the time and prioritize it. “Do what’s important to you and make time for the people and activities you love. And most importantly, take care of yourself! Because you’re worth it. Time stands still for no one so spend it wisely,” says Massaro.

And that’s why staying physically fit and active is important to Massaro. “I’m always lifting, bending, up and down the stairs all day so it’s helpful to have a training regimen that supports that. And, it really helps to keep me in mental shape as well,” say Massaro.

And that’s why staying physically fit and active is important to Massaro. “I’m always lifting, bending, up and down the stairs all day so it’s helpful to have a training regimen that supports that. And, it really helps to keep me in mental shape as well,” say Massaro.

Even more important is eating right, says Massaro. “We use a lot of energy in a day in the trades so we have to keep that fire fed. All of this allows me to stay energized all day and still have plenty of gas in the tank when I get home for family time,” continues Massaro.

Massaro’s foray into the trades started when he starting working for the family business as a plumbing apprentice at the age of 13. “Made best friends with my shovel and we went to work. Thankfully, I graduated from digging trenches and went on to start really learning about the ins and outs of the trade,” recalls Massaro.

Over the next few years, Massaro spent most days plumbing residential systems with a few commercial jobs sprinkled in here and there while working for my father. “It was nice to be doing a bit of everything and not just strictly one area of the trade, which I felt was important to be a well-rounded tech.

Once Massaro had a few years under his belt, he did a lot of remote northern work for fly-in communities. “Those big jobs we did up there really sharpened my time and material management skills,” says Massaro.

In addition, the high school Massaro attended offered a cooperative education program where he was able to gain work experience hours toward his apprenticeship if he chose to stick with plumbing. “I would go to regular classes for the morning periods then co-op at Aqua North in the afternoon,” says Massaro.

In addition, the high school Massaro attended offered a cooperative education program where he was able to gain work experience hours toward his apprenticeship if he chose to stick with plumbing. “I would go to regular classes for the morning periods then co-op at Aqua North in the afternoon,” says Massaro.

As a side note, Massaro says that if your local high school offers a cooperative education program, he highly recommends getting involved. “It’s a really pressure-free way to get your feet wet in whatever trades the school offers,” says Massaro. “I always try to take on one co-op student per year and leave them with a positive experience in the trade. I feel that’s the best way for kids to feel out what they want to do. And, don’t be afraid to ask questions!”

Next, after getting all of his trade school and work hours complete, Massaro then wrote his exam for his certificate of qualification in plumbing. Shortly thereafter, Massaro bought the family business, and the rest is history.

As fourth-generation plumber, Massaro has had some great mentors in his career, with plenty of help and guidance from his father and grandfather in learning new and old ways of plumbing. “If my great grandfather was around then I’m sure he would have some real old school stuff to show me.”

As fourth-generation plumber, Massaro has had some great mentors in his career, with plenty of help and guidance from his father and grandfather in learning new and old ways of plumbing. “If my great grandfather was around then I’m sure he would have some real old school stuff to show me.”

And while Massaro doesn’t consider himself a role model, he’s always willing and ready to help others to do their best at work, and life in general. “I’ve learned a lot over the years and sharing the experiences and knowledge with up-and-coming tradespeople is paramount,” says Massaro.

For Massaro, he loves building something from nothing and executing the job. “Sometimes just sitting back after the job is done and being like ‘damn we really did that.’”

Perception Change

The perception of the industry needs to change, says Massaro. “I think the wheels are turning on that as we speak but we’ve got a long way to go.”

Social media is that vehicle for the instrument of change as it’s an easy way to showcase contractor work, and connect with other professionals. “There’s a solid amount of tradespeople out there doing an amazing job. If we can show people that there’s more to plumbing than just plunging toilets, fixing leaks, and back-breaking work, then I think that’s a win,” says Massaro.

Social media is that vehicle for the instrument of change as it’s an easy way to showcase contractor work, and connect with other professionals. “There’s a solid amount of tradespeople out there doing an amazing job. If we can show people that there’s more to plumbing than just plunging toilets, fixing leaks, and back-breaking work, then I think that’s a win,” says Massaro.

Whether it’s new and better tools, techniques, business knowledge, etc., Massaro has learned so much on social media. “It’s awesome that we can connect with people and have such a great community sharing tricks of the trade, meet-ups or even debate if it’s tape then dope—which it is—or dope then tape,” says Massaro.

In the end, as Massaro sets his sights on his career and further enriching his life, a good bucket list item to check off would be getting a recreational pilot’s license. “Always wanted to get into aviation in some way.”

The sky’s the limit.

While endorsements and referrals are used in the early process to narrow down selections, homeowners look at logistical considerations before making their final hiring decision. And, according to Lowe’s State of the Pro report, price is almost always a top factor for homeowners, with availability to start and final written bid coming in close behind Read more

While endorsements and referrals are used in the early process to narrow down selections, homeowners look at logistical considerations before making their final hiring decision. And, according to Lowe’s State of the Pro report, price is almost always a top factor for homeowners, with availability to start and final written bid coming in close behind. Learn more about homeowners’ expectations and how to meet them here.

While endorsements and referrals are used in the early process to narrow down selections, homeowners look at logistical considerations before making their final hiring decision. And, according to Lowe’s State of the Pro report, price is almost always a top factor for homeowners, with availability to start and final written bid coming in close behind. Learn more about homeowners’ expectations and how to meet them here.