There seems to be some confusion in the HVAC/R industry right now about press fittings. So RLS – manufacturer of the original RLS (Rapid Locking System) press fittings that were first sold under the ZoomLock brand name – wants to set the record straight. While you can’t always trust what you hear, you can always Read more

HVACR

There seems to be some confusion in the HVAC/R industry right now about press fittings. So RLS – manufacturer of the original RLS (Rapid Locking System) press fittings that were first sold under the ZoomLock brand name – wants to set the record straight.

While you can’t always trust what you hear, you can always trust the facts. And here are some undisputed facts about HVAC/R press fittings:

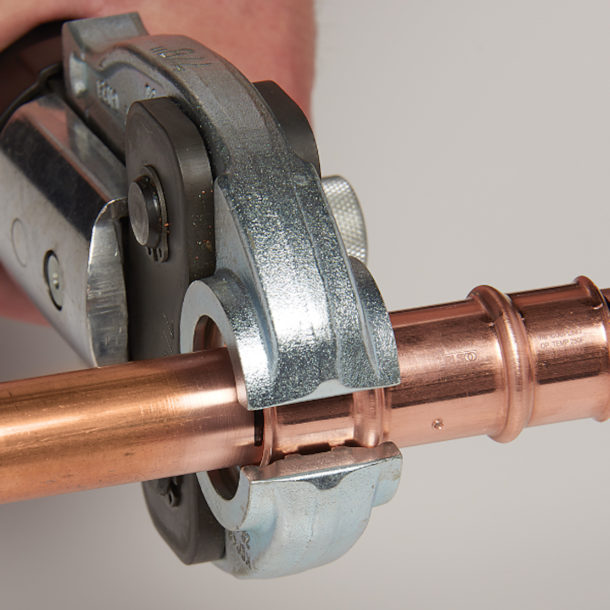

FACT: RLS is the inventor, patent holder and manufacturer of the original HVAC/R press fittings, which were introduced under the ZoomLock brand in 2015, through an exclusive agreement with Parker Hannifin Corporation’s Sporlan division. The fittings were designed and engineered – and continue to be made – in America.

FACT: The exclusive agreement ended in late 2019, and RLS stopped supplying fittings for ZoomLock in August of 2020. (See the official announcement here)

FACT: In August of 2020, Parker began selling press fittings manufactured in Europe by Conex Banninger (the Conex B MaxiPro line) under the “ZoomLock Max” name.

FACT: RLS now sells the exact same fittings, tools and jaws that were originally sold as ZoomLock under their own RLS brand name. That is why the original ZoomLock tools and jaws still work perfectly with RLS fittings – and always will.

FACT: Any rumors being circulated about RLS/ZoomLock jaws needing to be “traded in” or replaced are simply not true.

FACT: RLS fittings and jaws use a patented double circular press, with 360˚ metal-to-metal connections. ZoomLock Max/Conex B MaxiPro fittings and jaws use a hexagonal press similar to what is used in plumbing.

FACT: RLS fittings have a 6+ year proven track record of success worldwide. Conex Banninger introduced the new B MaxiPro design sometime after June of 2019.

FACT: The only difference between the original ZoomLock fittings and the current RLS fittings is the name. The product is identical – and made in the same American factory.

Want more facts? You can get them from the source by visiting rapidlockingsystem.com or emailing sales@rapidlockingsystem.com.

Original dates of January 25-27, 2021 have been officially postponed; March 15-17, 2021 continues to be considered with a final decision expected by October 15, 2020 AHR Expo Show Management today announced the postponement of the original planned Show dates of January 25-27 for the 2021 AHR Expo in Chicago. Both McCormick Place and Choose Read more

Original dates of January 25-27, 2021 have been officially postponed; March 15-17, 2021 continues to be considered with a final decision expected by October 15, 2020

AHR Expo Show Management today announced the postponement of the original planned Show dates of January 25-27 for the 2021 AHR Expo in Chicago. Both McCormick Place and Choose Chicago , an organization dedicated to bringing visitors to Chicago, recognize how vital the Show is to the city and have offered Show Management the dates of March 15-17, 2021 to host the HVACR industry. In a survey conducted by AHR Expo, the proposed move to March is preferred by nearly 80% of exhibitors and attendees. The decision to postpone the original planned January dates was difficult, however, the AHR Expo, ASHRAE and AHRI are encouraged about hosting a live event in March and continue to explore feasibility. A final decision will be announced no later than October 15, 2020.

“We continue to exhaust all possibilities that will allow us to host a safe and successful event for all industry stakeholders,” said Mark Stevens, Show Manager. “But we have to take into account that there are barriers for allowances within the state of Illinois and the city of Chicago that we cannot control. We remain cautiously optimistic that we can meet together in Chicago in March.”

In consideration of the significant planning and preparation required to participate in the Show, AHR Expo Show Management, along with co-sponsors ASHRAE and AHRI, will make the final determination and announcement on or before October 15th. While six months remain between now and March, a decision to make a final call well in advance will allow both exhibitors and attendees to more easily plan.

Throughout the spring and summer, countless meetings have been held to explore all possible avenues in order to produce a safe and successful Show in Chicago. In partnership with Show co-sponsors and the advisory committee, Show Management has been in close contact with McCormick Place, the city of Chicago, Show vendors, and other officials to provide the best guidance to host the event. These meetings will continue throughout the month as all options are considered.

“All of us in the industry understand the vital role HVACR plays in the world. We at AHR Expo know the importance of the Show in providing a unique environment where members of the HVACR community can congregate to learn, share, and grow as professionals while experiencing all that’s new in the industry,” continued Stevens. “I think we all understand the challenges this year has presented thus far, and while HVACR has emerged as a primary player in how we can hope to combat COVID-19 and other pandemic threats of the future, there are safety, governmental, and practical considerations that have to be taken into account.”

Show Management will continue to follow updates within the state of Illinois, the Governor’s office, as well as the CDC and other advisory councils.

Medical offices are complex spaces with unique requirements, and often have older, inefficient design and systems that need upgrading. Retrofits are necessary to ensure patient comfort and care, but as medical offices can’t simply shut down, it can be challenging to complete an update. A recent example of a successful medical office HVAC retrofit is Read more

Medical offices are complex spaces with unique requirements, and often have older, inefficient design and systems that need upgrading. Retrofits are necessary to ensure patient comfort and care, but as medical offices can’t simply shut down, it can be challenging to complete an update.

A recent example of a successful medical office HVAC retrofit is a project in Kentville, Nova Scotia. Through a collaborative effort the stakeholders were able to effectively schedule the overhaul of all the interior zones in the medical building to bring it up to current standards and fit the requirements of the office. The owners wanted an energy-efficient heating and cooling system that was easy to use and would allow for independent control in each space as well as savings on future energy bills.

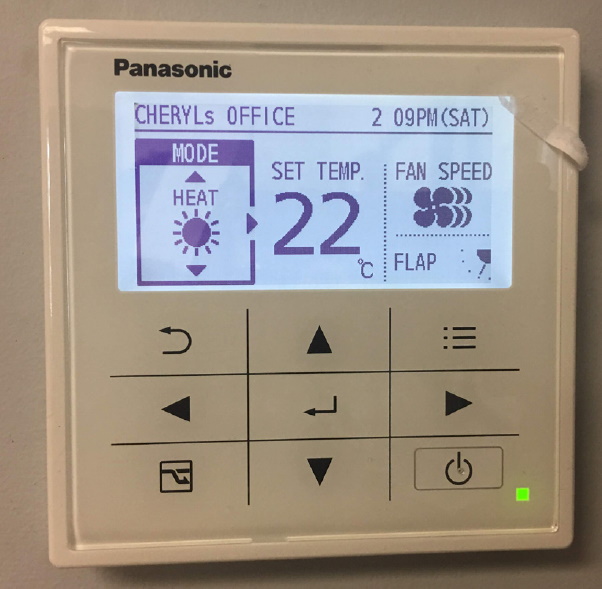

Given that the renovations needed to be done while the offices conducted regular business, the challenge was to work with minimal disruption. Additionally, work had to be completed outside of the medical office’s regular hours of operation, meaning there was a small time frame during which work could be done each day. Panasonic also had to work with limited space for the heating and cooling units and that had to be concealed as much as possible.

PANASONIC SOLUTION

Due to the space and installation restrictions as well as the features the client wanted, a new three-way Panasonic (heat recovery) Variable Refrigerant Flow (VRF) system with a combination of multiport and individual heat recovery boxes was designed. The advantages of this state-of-the-art system include individual and precise control of heating and cooling needs in different areas rather than a single temperature setting for the whole building. This allows everyone to enjoy a comfortable indoor environment, conserving energy and generating cost-savings on energy bills. Plus, installing a VRF system allows owners/operators to optimize the lifecycle cost of the project and realize long-term savings thanks to its energy efficient technology.

The advantages of the system include easy installation and minimum intrusion to the envelope of the building, as copper pipes that contain refrigerant are being used instead of extensive and costly ductwork. Customers also benefit from pre-installation training and technical support, which is essential for successful operation of the unit.

CUSTOMER EXPERIENCE

The project was a great success, with the units operating smoothly to keep the office temperature comfortable while saving energy. The overall feedback from users has been that they appreciate being able to have independent control of the heating and cooling in their area, and that temperatures are well maintained throughout the building. The system is simple, user-friendly and efficient, and the indoor units blend in nicely with the interior and are aesthetically pleasing.

Chuck Hazel, the senior mechanical contractor from C.Tech Refrigeration, a division of the Baxter Group of Companies was very happy with the outcome.

“We got a lot of support from Panasonic – from pre-installation to installation and post-installation. The Panasonic VRF system was easy to install and has been seamless for the client. Panasonic delivered on their promise of a top-quality system and I would recommend and work with them on future projects.”

PROJECT SYNOPSIS

CHALLENGES: Medical offices are complex spaces with unique requirements, and often have older, inefficient design and HVAC systems that need upgrading. Retrofits are necessary to ensure patient comfort and care, but as medical offices can’t simply shut down, it can be challenging to complete an update. The building was looking for a solution to replace their existing HVAC solution that was flexible with their requirements and could be completed with minimal disruption outside of regular business hours.

SOLUTIONS: Due to the space and installation restrictions as well as the features the client wanted, a new three-way Panasonic heat recovery Variable Refrigerant Flow (VRF) system with a combination of multiport and individual heat recovery boxes was designed.

RESULTS: The project was a great success, with the units operating smoothly to keep the office temperature comfortable while saving energy. The overall feedback from users has been that they appreciate being able to have independent control of the heating and cooling in their area, and that temperatures are well maintained throughout the building.

To learn more visit www.panasonic.com/ca/vrf

One of the things that keeps contractors up at night is worrying about where their next qualified hire is going to come from. The shortage of skilled workers in the trades is severe and getting worse. Seventy percent of construction companies nationwide are having trouble finding qualified workers, according to the Associated General Contractors of Read more

One of the things that keeps contractors up at night is worrying about where their next qualified hire is going to come from.

One of the things that keeps contractors up at night is worrying about where their next qualified hire is going to come from.

The shortage of skilled workers in the trades is severe and getting worse. Seventy percent of construction companies nationwide are having trouble finding qualified workers, according to the Associated General Contractors of America.

And if Congress ever does approve a much-needed infrastructure package, the need will be even greater.

We in the trades can hope parents will stop pushing the necessity of a four-year degree to every child, regardless of interest or qualifications, but there are more practical measures we can take in the meantime.

Last year, Viega LLC launched the Viega Trades Education Network (VTEN) to boost the ranks and skills of students studying the design, installation and function of plumbing and hydronic systems. Viega is partnering with trade schools, community colleges and the UA in the United States and Canada to subsidize and provide training on mechanical systems.

VTEN is about providing a better education for those already enrolled and supporting the schools and instructors that are training the next generation of workers. Like all educational institutions, these schools don’t have the budgets and resources to deliver everything they’d like to give their students.

As members of VTEN, schools get comprehensive curriculum modules that easily integrate into existing programs. The modules include Hydronics 101, Piping & Controls, Radiant Design, Trades Math, Blueprint Reading, CAD and BIM, and more. In addition, Viega provides functional demonstration units supported by lesson plans and projects and a complete tooling package.

Educators receive admission to an annual VTEN conference in Colorado or New Hampshire, including hotel, airfare, food and admission; Viega and direct vendor support of BlueVolt® eLearning platform; hands-on tool demonstrations and LoopCAD® license options and instructor training.

The LoopCAD package includes on-site orientation to the network and a Zoning Demonstration Board and Mixing Demonstration Board to give students hands-on experience in troubleshooting systems.

And, of course, VTEN offers credentialed classes for Viega products, including ProPress® and MegaPress®.

But the program doesn’t stop there. Schools also receive a RIDGID® RP-340 tool or Milwaukee M18® Force Logic Press Tool with a set of jaws for metal and PEX, as well as samples of various types of pipe and couplings for each student.

The first students in VTEN will graduate soon and we welcome them to the ranks of the trades. We invite other companies to follow suit and join us in building the workforce of the future.

Lino Santoro is Viega Trades Education Network (VTEN) Manager.

Lino Santoro is Viega Trades Education Network (VTEN) Manager.