Taco Comfort Solutions is pleased to announce the appointment of Tony Furst as its newest Commercial Trainer. With over 40 years of distinguished experience in mechanical engineering and a comprehensive background in overseeing multimillion-dollar projects, Tony brings a wealth of knowledge and expertise to the Taco team. Tony’s career spans significant roles across renowned organizations Read more

hydronics

Taco Comfort Solutions is pleased to announce the appointment of Tony Furst as its newest Commercial Trainer. With over 40 years of distinguished experience in mechanical engineering and a comprehensive background in overseeing multimillion-dollar projects, Tony brings a wealth of knowledge and expertise to the Taco team.

Taco Comfort Solutions is pleased to announce the appointment of Tony Furst as its newest Commercial Trainer. With over 40 years of distinguished experience in mechanical engineering and a comprehensive background in overseeing multimillion-dollar projects, Tony brings a wealth of knowledge and expertise to the Taco team.

Tony’s career spans significant roles across renowned organizations within the HVAC industry, including Armstrong Fluid Technology, where he served as the US Director of Application Engineering. His responsibilities included providing extensive application engineering support and developing technical education content for commercial HVAC systems. Tony’s commitment to excellence and innovation has consistently resulted in the successful completion of projects on time and within budget.

“We are thrilled to welcome Tony to Taco Comfort Solutions,” said Cheryl Merchant, CEO of Taco Family of Companies. “His deep understanding of mechanical systems and his passion for educating others will be invaluable as we continue to enhance our training programs for the commercial sector,” added Merchant.

Tony holds a BS in Mechanical Engineering from the University of Dayton and an MS in Education from Michigan State University. He is certified in Plumbing Design by the American Society of Plumbing Engineering (ASPE) and is a LEED Accredited Professional with the US Green Building Council. Throughout his career, Tony has been a dedicated member of ASPE and ASHRAE, contributing significantly to technical education committees and serving as a speaker at various industry events.

“I truly enjoy sharing knowledge with others to make modern hydronic systems better,” said Furst. His commitment to advancing industry standards aligns perfectly with Taco Comfort Solutions’ mission to provide innovative and efficient solutions for HVAC systems.

In his new role at Taco, Tony will join a team of esteemed trainers, including Brett Zerba and Rich Medairos, enhancing the company’s capability to deliver comprehensive training programs tailored to the needs of commercial clients.

“It’s rare when you get the opportunity to add someone with Tony’s background, experience, and knowledge to your team,” said John Barba, Director of Training at Taco Comfort Solutions. “Adding Tony to our commercial training team is like having three Hall of Famers in your outfield. I’m looking forward to seeing Tony, Brett, and Rich share their wit, wisdom, and knowledge with our industry,” concluded Barba.

Furst’s appointment marks a significant addition to Taco Comfort Solutions, reinforcing its commitment to excellence in commercial HVAC training and education.

Finding the perfect mix of glycol and water in a hydronic system doesn’t have to be hard. Guest presenter John Panasewicz will discuss the best ways to specify and maintain water-glycol blends in boilers, chillers and other heat transfer applications. This pre-heating-season webinar will clear up the confusing aspects of antifreeze for designers and installers Read more

Finding the perfect mix of glycol and water in a hydronic system doesn’t have to be hard. Guest presenter John Panasewicz will discuss the best ways to specify and maintain water-glycol blends in boilers, chillers and other heat transfer applications. This pre-heating-season webinar will clear up the confusing aspects of antifreeze for designers and installers.

→ How do you know what percentage of glycol is best for your project?

→ What is the best way to maintain system fluid?

→ What is the difference between freeze and burst?

→ How can recovered glycol be reused?

→ How do air and dirt separation affect system fluids?

John was a founding member of the ASTM D15.30 Subcommittee on Heat Transfer Fluids and will provide both technical and practical insights on this topic. He is the Director of Technology at G2 Solutions in Denver, Colorado.

… what is the level of scale in your water? Hard to say, I’d imagine. But, over time, believe me, you’ll know. Scale, also known as limescale, refers to mineral buildup—primarily magnesium and calcium—that creates a white, chalky-like substance that can accumulate on the plumbing system’s internal components, including water heaters, pipes, and fixtures, says Read more

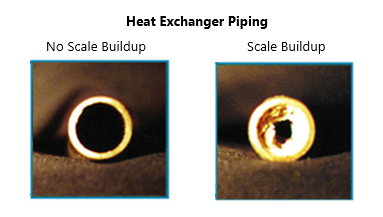

… what is the level of scale in your water? Hard to say, I’d imagine. But, over time, believe me, you’ll know. Scale, also known as limescale, refers to mineral buildup—primarily magnesium and calcium—that creates a white, chalky-like substance that can accumulate on the plumbing system’s internal components, including water heaters, pipes, and fixtures, says Randall Oshiro, Lead Engineer, Noritz America.

In other words, “Common in household water, especially in areas with hard water, scale is essentially the crusty stuff you sometimes see on old pipes or the heating element of an old kettle,” says Ben Tate, National Sales Manager—Water Treatment, Navien, Inc. “When water is heated, these minerals crystallize and stick to surfaces such as the interiors of pipes, boilers, and heaters, forming a hard, insulating layer. It’s a natural process, but not exactly a welcome one, as it hampers the efficiency of any appliance it settles in.”

Scale’s Geography

Scale’s prevalence comes down to the geological makeup of the land through which your water travels. Water is a universal solvent, and as it moves through soil and rock, it picks up minerals like calcium and magnesium. In areas rich in limestone and other calcareous rocks, which are composed mainly of calcium carbonate, water tends to carry a higher load of these minerals. Consequently, regions with such geological features—think of areas like Texas and Florida—often struggle more with hard water and, by extension, scale.

Calcium and magnesium are naturally occurring minerals, says Oshiro. Depending on where the water is drawn from, water flowing through ground sources that contain high concentrations of these minerals will absorb some of the minerals. For example, water drawn from an aquifer with a high concentration of limestone will inevitably have a high concentration of lime (calcium). Like the previous example, areas where water is drawn from underground are often where the highest concentration of hard water exists.

A Water Heater’s Nemesis

Yet the “damage” scale can bring can’t be overstated, says Dan Giosia, Assistant Product Manager, Bradford White Corporation, “The accumulation of scale in a water heating system diminishes the overall performance, efficiency, and lifespan of the water heater unless preventative maintenance measures are implemented.”

Scale poses a triple threat to water heating systems, says Tate. First, it’s an insulator. In a domain where efficient heat transfer is key, scale is a formidable barrier that keeps heat from doing its job effectively, which can drive up energy costs as your system struggles to keep up. Second, scale buildup increases the pressure in water lines and heating chambers, which can lead to leaks or mechanical failures. Lastly, the more energy and repairs a system requires, the more its lifespan diminishes. That’s why preventing scale isn’t just about maintaining water flow; it’s about saving money and extending the life of your equipment.

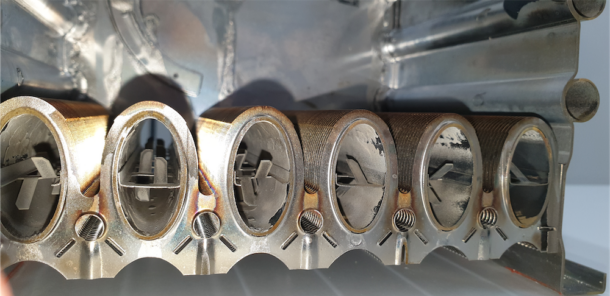

According to Oshiro, the primary danger of this scale formation is that it can accumulate inside the water heater (on the heat exchanger of tankless water heaters, along electrical heating elements, or along the internal flue of gas storage water heaters). This scale formation acts as an insulator in large amounts, preventing the proper heat exchange between the water and the heating source. “When this happens, the temperature will increase—as heat is not being drawn away at the designed rate—leading to increased thermal stress and decreased longevity of the internal components. Additionally, this buildup can reduce the surface area of piping, which can reduce the flow performance of the fixtures as well,” says Oshiro.

Tankless Magnified

Scale impacts both tank-type and tankless water heaters, though it manifests differently in each system, says Tate. In tank-type heaters, scale settles at the bottom of the tank, reducing heat transfer efficiency and leading to increased energy consumption and potential corrosion. Over time, this can significantly shorten the lifespan of the heater. Conversely, tankless models, which heat water directly, experience scale buildup directly on their heat exchangers. This can decrease heating efficiency and disrupt water flow, though it does not necessarily indicate a greater susceptibility to scale than tank-type heaters.

Regardless of the system type, the key to mitigating scale effects lies in regular maintenance. Both tank-type and tankless water heaters benefit from routine descaling and the proactive use of water treatment solutions like water softeners or scale inhibitors. Properly maintained, both systems can handle scale effectively, ensuring efficient operation and extending the lifespan of the heater. Thus, neither system is disadvantaged by scale when properly cared for, allowing users to choose based on their specific needs and preferences.

The reality is the mechanism/issue is about the same for both types of technology. “However, it will present itself much sooner/more apparently with a tankless type water heater than a tank-type water heater. The reason for this is basically that the pipes are smaller. Imagine a ¾” pipe and 24” round storage vessel. The smaller pipe, with a ¼” of scale buildup, loses significantly more of its surface area in comparison. This means that issues like reduced flow will become more apparent sooner,” says Oshiro.

However, it should be noted, continues Oshiro, that this same amount of scale will have the same actual effect on the systems (reduced efficiency, higher thermal stress). As a result, a tankless water heater may show signs of decreased performance sooner; however, this also allows the customer to preemptively conduct maintenance to ensure that the product will last many times longer than a storage tank-type water heater.

The storage tank-type water heater often continues to build up this scale over time, resulting in lower efficiencies (meaning higher operating costs) and eventual failure sooner. This scale formation is one of the primary mechanisms by which water heaters will fail. 1

According to Bradford White’s Giosia, scale does pose a greater issue for tankless water heaters compared to tank-type water heaters due to their compact heat exchanger design. With a limited surface area and brief heating period, tankless heaters must rapidly elevate water temperatures, requiring high temperatures within the heat exchanger. As a result, scale tends to accumulate on this surface. If scale buildup becomes excessive, it can restrict water flow through the heat exchanger to the point of causing component or unit failure so it’s important for homeowners to contact their plumbing professional for regular maintenance.

In comparison to gas tank-type water heaters, electric tank-type heaters are generally more susceptible to scale buildup. This is primarily due to the very hot surfaces of electric heating elements, which have a small area and are prone to accumulating limescale within the tank. However, the impact of scale buildup is limited by the fact that electric heating elements are relatively inexpensive to replace, especially when compared to the cost of replacing a tankless gas heat exchanger or complete unit.

Gas tank-type water heaters may vary in susceptibility to scale buildup depending on their design. Units with a burner located outside the tank are typically less affected by scale compared to those with an internal heat exchanger where scale can accumulate.

Action Plan

What can contractors/homeowners do to “combat” scale? “The first step is to know your water supply,” says Oshiro. “Almost every municipal water supply company will annually publish a water quality report that will include data about the hardness of your water supply. This rating will often be rated on a scale of grains per gallon (gpg), parts per million (ppm), or milligrams per liter (mg/L). These ratings tell the density of mineral hardness (calcium) present in the water supply. The USGS[1] has a relative hardness indicator, where 61-120 mg/L (3.6-6 gpg) would be considered somewhat hard water.”

The best way to reduce scale is to treat the cause. This means using water treatment devices to prevent the calcium from building up in your water heater and piping. However, this isn’t always possible, so maintenance can be conducted by a descale flush: running a deliming agent (ex., vinegar or a specialized deliming agent) solution through piping the water heater to neutralize the calcium. As calcium is a basic material (pH >7), the acidic deliming agent will neutralize the calcium and remove buildup.

It’s also essential to adhere to the manufacturer’s recommendations for preventative maintenance, including specific procedures and frequency, for their product, advises Giosia.

Regular descaling of the water heater is often recommended to minimize scale buildup on the heat exchanger of a tankless water heater. The frequency of preventative maintenance typically depends on the characteristics of the water supply in your area, such as whether it is heating hard or soft water.

Installing a water softener can help reduce the hardness of the incoming water into both tankless and tank-type water heaters. However, it’s important to consult with a plumbing professional to ensure compatibility and to follow their recommendations.

Navien’s Tate says contractors and homeowners in these regions should adopt a proactive approach to water treatment. Installing a water softener is one effective strategy; it replaces hardness ions like calcium and magnesium with sodium or potassium, preventing them from forming scale. Additionally, I’d recommend considering scale prevention systems, which are designed to transform hardness minerals into harmless crystals that won’t stick to surfaces. Regular maintenance checks are also vital—they help ensure that any potential scale buildup is managed before it becomes a serious issue.

If you know that your water source is hard water, Oshiro suggests that you can take action to alleviate the risks.

- Develop a routine maintenance plan: This can be done by “descaling,” or flushing, your water heater regularly, depending on usage and quality. Asking your water heater manufacturer or installer for recommendations on frequency is a great first step.

- Treat the water: There are ways to eliminate (sequester or remove) hard-water minerals from the water source. These include items like water softeners, which use an ion-exchange process to physically remove free calcium from the water, or products that use a polyphosphate media to sequester the calcium to prevent it from coming out of the solution when heated.

Technology Tips

Is there newer technology that could make the equipment more scale-resistant? “Indeed,” says Tate. “One of the latest advancements in this area is Template Assisted Crystallization (TAC), which is a highly effective technology for preventing scale without the use of chemicals or salt. TAC systems work by transforming the calcium and magnesium minerals in hard water into stable, harmless crystal particles. These particles then flow through the system without sticking to surfaces, effectively preventing scale buildup. This technology is particularly useful for protecting high-efficiency tankless water heaters from scale, ensuring they operate at optimal efficiency while extending their lifespan.”

To some degree, says Oshiro, the selection of materials, design of the heat transfer surface, and the temperature in which the system operates, all have roles to play in controlling the amount of scale formation.

- Materials with less surface roughness provide less chance for scale particles to attach.

- Systems with lower temperature rises can also slightly reduce the formation rate of scale.

There is constant research into reducing the harmful effects of scale formation in water heating products, but at its core, it is a challenging situation to avoid entirely.

According to Giosia, some tankless water heater models incorporate technology aimed at enhancing scale resistance, such as scale reduction technology and replacement filtration cartridges. Moreover, water softeners can serve a similar purpose in mitigating scale buildup.

However, despite these advancements, maintenance remains essential for all tankless water heaters to prevent excessive scale accumulation. Regular upkeep is necessary to ensure optimal performance and longevity of the unit.

In conclusion, the timeline for significant damage can vary widely depending on the water’s hardness and the frequency of system maintenance. In regions with very hard water and minimal preventive measures, says Tate, significant scale buildup can occur within just a few months, leading to efficiency losses and potential system failures. Conversely, with proper management and regular maintenance, scale-related damage can often be staved off for years, preserving the efficiency and extending the life of the system.

1

https://www.usgs.gov/special-topics/water-science-school/science/hardness-water#:~:text=Measures%20of%20water%20hardness&text=General%20guidelines%20for%20classification%20of,mg%2FL%20as%20very%20hard

Providence, R.I. – The first annual John Hazen White III Memorial Tribute was held under sunny skies on Saturday, April 27, at Narragansett Brewery. It was a memorable day filled with unity and celebration. Participants included Taco employees, cherished family members, dear friends, and valued partners at Community Preparatory School. The event began with a Read more

Providence, R.I. – The first annual John Hazen White III Memorial Tribute was held under sunny skies on Saturday, April 27, at Narragansett Brewery. It was a memorable day filled with unity and celebration. Participants included Taco employees, cherished family members, dear friends, and valued partners at Community Preparatory School.

The event began with a meaningful one-mile walk/run, symbolizing the shared commitment to our community and its well-being. The slogan, “Come Walk or Run in Memory of Maddie’s Daddy,” provided an extra special, heartfelt incentive.

Following the walk/run, the festivities continued at the brewery, where attendees enjoyed live music, delicious food, and the joyous camaraderie of being together. It was a time to reflect on the impact of John Hazen White III’s legacy and to honor his vision of making a positive difference in the lives of others.

“Seeing everyone here today means so much to us,” said Kate White, Corporate Social Responsibility Partner at Taco. “This is exactly the type of event that John would have loved—an opportunity to spend time together with family and friends for such a wonderful cause. We wish he was still here, but we know he lives on in all of us,” Kate mused.

“Seeing everyone here today means so much to us,” said Kate White, Corporate Social Responsibility Partner at Taco. “This is exactly the type of event that John would have loved—an opportunity to spend time together with family and friends for such a wonderful cause. We wish he was still here, but we know he lives on in all of us,” Kate mused.

John H. White, Jr, Executive Chairman and Owner of Taco, reflected on the day. “Today’s event was truly special. Sharing time together with friends, family and the Taco community is the perfect way to celebrate John’s life and the joy he brought to all those who knew him,” said John.

“We are so thankful for everyone joining us here to pay tribute to John,” said Ben White, Program Manager, Business Operations at Taco. “He made us all better people and continues to have a positive impact on our lives. As we have been saying, love is not a big enough word when it comes to John,” concluded Ben.

“We are so thankful for everyone joining us here to pay tribute to John,” said Ben White, Program Manager, Business Operations at Taco. “He made us all better people and continues to have a positive impact on our lives. As we have been saying, love is not a big enough word when it comes to John,” concluded Ben.

We invite you to consider donating to the John Hazen White III Endowed Scholarship fund at Community Preparatory School. Your generous donations will help us continue his legacy of empowering young minds and transforming lives. Details on how to donate can be found at https://bit.ly/44inhTJ.

Training in 2024 is just as important as ever. How do you integrate training, education and continued learning with today’s busy contractor? Power Points, sales pitches and doughnuts. Tried and true methods of training gone by, that’s for sure. But what does today’s training look like, especially in the purview of the younger generation of Read more

Training in 2024 is just as important as ever. How do you integrate training, education and continued learning with today’s busy contractor?

Power Points, sales pitches and doughnuts. Tried and true methods of training gone by, that’s for sure. But what does today’s training look like, especially in the purview of the younger generation of contractors that digests information in 90 seconds or less?

“What was that? Sorry, I was looking at my phone,” jokes Max Rohr, Director, Education and Technical Marketing, Caleffi. “Five years ago, a three-minute-long video was a good option, now it will seem long if it is over that 90-second threshold. Ideally, you get to the point in the first five seconds and work the explanation back from there. Like showing the cake and then going back to bowls of ingredients.”

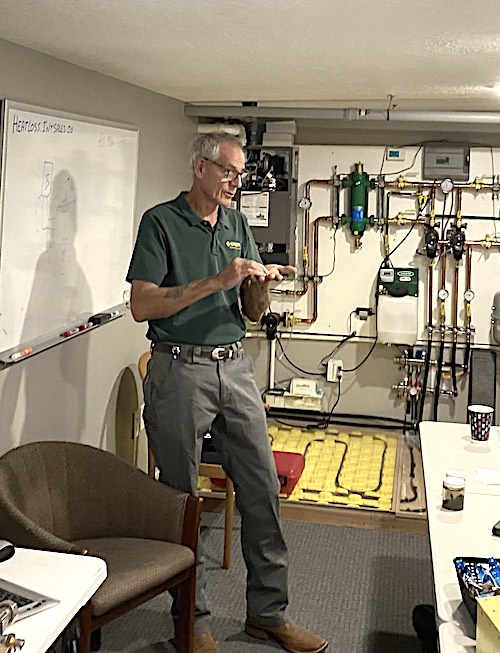

According to, Dave Holdorf, Residential Trainer & Rep Training Manager—Eastern Region, Taco Comfort Solutions, it’s a challenge. “We’ve found that it helps to bring different instructors in for specific segments of the training. Each instructor brings their own perspective; even hearing a different voice in the room makes for a more compelling presentation. Every facet of our training is now geared to maintain the attention of participants. We also make sure to schedule breaks so that the attendees can attend to business, or need at home. By creating the curriculum with attendees in mind, their focus remains with the topic in front of them.”

Nevertheless, the training department at Taco has always looked at training not from a product view but from an application perspective, giving attendees the information they need to do their job better, and to give their customers the comfort they deserve. “We use real world experiences to solve real world problems with personal experiences and a bit of humor—as you know, John, it ain’t worth doing if you’re not having fun as well,” says Holdorf.

Caleffi’s Bob “Hot Rod” Rohr brings his props and his wealth of experience and knowledge to trainings.

But what about those PowerPoints and doughnuts? “Every learning style is different, so you have to be adaptable. If you see the audience tuning out a PowerPoint, stop and grab a product to bring to an attendee and talk about a case study that is related instead,” says Rohr.

In addition, everything falls apart for a trainer if the audience gets the impression they are overpromising, adds Rohr. For example, “Honesty is something Hot Rod is specifically good at in contractor training sessions. As a former installer, he always has tips for getting the job done and workarounds that are really tangible,” says Rohr.

The New Normal?

The Covid pandemic saw what we thought was going to be a new normal with virtual training, but what we are now seeing is the importance, and return, of in-person training.

This past year Taco saw a huge jump of in-person training, on the road as well as at Taco HQ in Rhode Island. So much so that the company had to dramatically increase the number of sessions back in Rhode Island to accommodate. “However, that does not mean to diminish the virtual training, Taco Tuesday and Taco After Dark webinars are still posting a large number of attendees that are hungry for information in bite size chunks, not as large as when we all locked down at home, but still popular,” says Holdorf.

Taco’s Holdorf conducts a training at the Cranston, R.I. HQ.

Nonetheless, “when we’re online, we know it’s so easy to stray off to the next shiny thing online, so to keep attendees engaged, we encourage two-way communications. If participants have questions, we want them to ask immediately,” continues Holdorf.

In fact, Holdorf says that people who attend Taco’s webinars typically take it to the next level and seek live training. A combination of both virtual and live training can help attendees dial in on what they want to learn—or perhaps didn’t initially develop a full understanding of what it is they most needed to know. “These options allow them to fine-tune their training experience to make them as good as they want to be. And, ideally, we help them raise the bar. We routinely heard from trade pros who came to us for a better understanding of a single application or concept, and through that experience come away with an energized desire for much more,” says Holdorf.

In 2023, Caleffi performed almost a 50/50 mix of in-person and virtual. Contractors like hands-on training, says Rohr, so it is good to be back on job sites for that type of interaction. And, engineers didn’t all go back to the office after COVID. “Many of the engineering sessions we do are virtual because that firm may be scattered all over the region. You might catch 20 people in a virtual training, where only 10 of them are in the office that day,” says Rohr.

Know-It-Alls

What about those who are stubborn enough to think that they don’t need further education and training? “I love this question and see and hear it often in the industry,” says Ken Midgett, L.M.P, Plumbing, Marketing Director, Interplay Learning, and former Teacher and Apprenticeship Instructor, Lehigh Career & Technical Institute.

Those in skilled trades should embrace the concept of being “lifelong learners,” consistently expanding their knowledge in their current specialty and exploring related disciplines. Whether licensed or not, individuals in skilled trades should assess their goals, career paths and professional growth within their field. It’s common for some to reach a point where they feel adequately skilled and think further education is unnecessary. According to Midgett, this assumption is misleading for several reasons:

• For example, a residential plumber could benefit from learning about commercial plumbing, Med Gas, Backflow, Water Well work, Water Conditioning, HVAC, Electrical, etc. Diversifying skills not only enhances one’s expertise but also increases their marketability across various skill sets, intern boosting income and long-term employability.

• Despite advancements in safety measures within the construction industry, the misconception that skilled trades workers are immune to injuries persists. While the overall safety landscape has improved, life-changing injuries can still occur. In such unfortunate instances, if an individual can only rely on skills specific to their trade and lacks versatility, their career may face irreparable damage. Therefore, investing in ongoing training, education, and professional development becomes crucial for ensuring resilience in the workforce and mitigating the impact of unforeseen challenges. Repurposing skillsets may be challenging when there has been no prior skill or professional development planning before the injury event.

• The industry, codes, tools, and methods to do a task are constantly changing. Skilled trades workers need to educate themselves and stay on top of new developments. This is critical to the success of a technician and company.

In the end, it’s what ends up in the ol’ noggin as useful information that translates to the jobsite. “Students only retain a tiny amount of the information that you present to them, but they will remember their feelings about the trainer for a very long time,” says Rohr. “It is hard to know if a bigger win is when customers retain a piece of information you presented or if they remember that you seem like you know what you are talking about. “If they trust that you did a good job, that memory will stay with them for a career, potentially.”