It’s been quite the start to 2022 for Ryan Bickerton, owner/operator of Bickerton Plumbing and Heating LLC, Boston. Recently recovered from COVID, his phone hasn’t stopped ringing. He’s been busy, and that’s a good thing. Mostly specializing in high-end renovations, old houses in the historic areas of Boston and high-efficiency boilers, Bickerton has run his Read more

hydronics

It’s been quite the start to 2022 for Ryan Bickerton, owner/operator of Bickerton Plumbing and Heating LLC, Boston. Recently recovered from COVID, his phone hasn’t stopped ringing. He’s been busy, and that’s a good thing.

Mostly specializing in high-end renovations, old houses in the historic areas of Boston and high-efficiency boilers, Bickerton has run his own company since 2014. At the age of 18, Bickerton started into plumbing, working for a larger residential company doing large multi-unit buildings where he worked for 2 1/2 years before moving to a smaller company doing mainly commercial work.

The itch started for Bickerton when he started in construction over the summers during high school, working for a roofing company and a general contractor, basically doing whatever was needed on a job site. “I tried helping whoever needed to be helped on the site—plumbers, electricians, carpenters—cleaning up, making coffee runs, etc. I remember those summers working for the GC and I enjoyed helping the plumbers more than anything else. I realized I was falling in love with the industry, and the rest is history,” says Bickerton.

Nevertheless, Bickerton was encouraged to make an attempt at college even though he didn’t really want to; he gave it a shot anyway. He lasted less than a year and decided that was it. “For me, it was a waste of time and money,” says Bickerton. “My parents were okay with me leaving after giving it a valiant effort, but my father said ‘pick a trade because you’re not going to be sitting around here all day.’”

Nevertheless, Bickerton was encouraged to make an attempt at college even though he didn’t really want to; he gave it a shot anyway. He lasted less than a year and decided that was it. “For me, it was a waste of time and money,” says Bickerton. “My parents were okay with me leaving after giving it a valiant effort, but my father said ‘pick a trade because you’re not going to be sitting around here all day.’”

Bickerton recalls speaking to his father, and a few other people he knew who worked in the trades, and was pushed in the direction of electrical or plumbing mainly because, “you’ll never be looking for work.”

After obtaining his Journeyman Plumbing and Gas Fitting License in 2008, Bickerton completely shifted gears and joined the United States Marine Corps where he was deployed to Afghanistan. It was a difficult decision but joining the military was something Ryan had always wanted to do. In 2008, it was the right time. After six years of service with the Marines, Bickerton returned to plumbing and got his Master Plumbing and Gas Fitting License. “I started doing more and more side work until I landed a few bigger jobs that motivated me to leap into owning my own company. I haven’t look back since,” says Bickerton.

Part of that drive came from his biggest role model, his father, who worked most of his life in a power plant in South Boston as a general mechanic—he could pretty much fix anything and everything that needed fixing. “My father is the hardest working person I know. I remember as a young kid not seeing him for days at a time because he was getting home late and leaving early before we were awake. I knew he was out working hard taking overtime to provide for us. He could and would fix most things around the house. I remember one year our water heater went out on Thanksgiving and he took care of it by himself. I thought that was pretty cool, and still do,” says Bickerton.

As for Ryan, he never considered himself a role model, but he tries to conduct himself that way. Any chance he gets, he’ll speak highly of the trades. “If any young kids ask me about the trades, I do my best to steer them in the right direction and let them know it’s a very viable option. It’s a rewarding career choice, and college and white-collar work doesn’t have to be for everyone,” says Bickerton.

Bickerton does rough-ins to beautiful renovations.

Bickerton’s trade role model was his first foreman, Mike Sheehan, a plumber for 30+ years, his body broken from years of moving massive boilers and extra heavy cast-iron pipe. “But he still loved the trade. He taught me a lot of my early skills, and he would say that this trade has all the potential to do anything you want with it, which has really stuck with me to this day,” says Bickerton.

Bickerton’s go-to tool has been the ProPress/MegaPress. “Don’t get me wrong, I loved to solder and took great pride in having clean joints, and still think it’s a necessary skill to have, but the press system is a complete game changer.”

While respecting these two men’s work ethic, Bickerton knows that balancing work and family life is important. It’s probably his most difficult task, says Bickerton. “I’m usually out the door by 5 am and home around 5 pm, and the kids go to bed between 7:30-8 pm and then most nights I have to do estimates or invoices when they’re in bed so I don’t have as much ‘leisure time’ as I’d like. I try to make every second I’m home count.”

And the weekends are for family. Bickerton used to work every Saturday and even some Sundays. Lately, however, Ryan doesn’t work Sunday unless it’s a catastrophic emergency, and on Saturdays he tries to be done by 12 or sometimes not at all. “Like I said before, I love plumbing and working but I don’t think I’ll ever regret not working more and spending less time with my family so I try to best divide my time in the fairest manner possible.”

It’s clear that family time is most important. “In my spare time, more than anything, I enjoy hanging out with my wife and our children. My wife Micayla and I have been married for six years and our three kids are growing up fast. If I’m not working, I’m with them. They are starting to get into different activities, hockey, baseball, football, swimming, horseback riding, and I just enjoy every second of that. Even if it’s just hanging out and watching a movie, it’s never wasted time for me,” says Bickerton.

It’s clear that family time is most important. “In my spare time, more than anything, I enjoy hanging out with my wife and our children. My wife Micayla and I have been married for six years and our three kids are growing up fast. If I’m not working, I’m with them. They are starting to get into different activities, hockey, baseball, football, swimming, horseback riding, and I just enjoy every second of that. Even if it’s just hanging out and watching a movie, it’s never wasted time for me,” says Bickerton.

Perhaps family means a bit more to Bickerton because his daughter, Mallory, was diagnosed with a rare genetic disorder called Rubenstein Taybi Syndrome (RTS). In 2017, Ryan and Micayla, along with some close friends, started a non-profit organization called Mals Pals Foundation. “We have been very fortunate with Mallory. We live in the epicenter for healthcare; she has had an inclusive educational opportunity here in Boston and it helps that we are able to pay for anything and everything she has needed in order to thrive,” says Bickerton.

Mal’s Pals Foundation aims to ease the burden of other families who maybe are not as fortunate. The Bickertons raise awareness for rare diseases like RTS, and they help educate newly diagnosed families. “We are trying to make difference in other people’s lives even if it’s just a small one. You can check us out at malspalsfoundation.org.”

Mal’s Pals Foundation aims to ease the burden of other families who maybe are not as fortunate. The Bickertons raise awareness for rare diseases like RTS, and they help educate newly diagnosed families. “We are trying to make difference in other people’s lives even if it’s just a small one. You can check us out at malspalsfoundation.org.”

Mallory is now seven-years-old and doing well. “Initially, there were concerns, but honestly, I wouldn’t have it any other way,” says Bickerton.

Bickerton looks forward to going to work every day. “But the most rewarding to me is being able to sit back at the end of the day or at the end of a job and look at what I’ve done,” says Bickerton. “I like having something tangible, that I can look at and touch and say I did that, or I fixed that or I created that. Whether it’s fixing a leaking faucet, creating a bathroom where there wasn’t one before, plumbing a 5-unit building completely from scratch or providing someone with heat and hot water for the next 20-30 years. That’s pretty cool.”

In the end, Ryan really loves plumbing, even if he’s stressed out and jobs are behind, or he’s behind on paperwork, or he’s made a mistake and or redo something. “I still consider myself lucky to be doing what I love every day. And on those harder work days, I still get to come home to three beautiful children and a wife who loves me. Every time I walk in the door and they scream ‘DAD!’ all that stress lifts off instantly, and it’s all worth it.”

In the end, Ryan really loves plumbing, even if he’s stressed out and jobs are behind, or he’s behind on paperwork, or he’s made a mistake and or redo something. “I still consider myself lucky to be doing what I love every day. And on those harder work days, I still get to come home to three beautiful children and a wife who loves me. Every time I walk in the door and they scream ‘DAD!’ all that stress lifts off instantly, and it’s all worth it.”

The Magnetic Boiler Filter XL is designed to protect larger residential boilers from iron sludge that can accumulate in a hydronic system. Commonly installed on the system run, it captures ferrous and non-ferrous debris before it can reach the boiler using a high-powered 12,000 Gauss magnet and plastic filter. https://youtu.be/pmZaip09_kA The drain makes it simple Read more

The Magnetic Boiler Filter XL is designed to protect larger residential boilers from iron sludge that can accumulate in a hydronic system. Commonly installed on the system run, it captures ferrous and non-ferrous debris before it can reach the boiler using a high-powered 12,000 Gauss magnet and plastic filter.

The Magnetic Boiler Filter XL is designed to protect larger residential boilers from iron sludge that can accumulate in a hydronic system. Commonly installed on the system run, it captures ferrous and non-ferrous debris before it can reach the boiler using a high-powered 12,000 Gauss magnet and plastic filter.

The drain makes it simple to remove accumulation, with a strapped cap that can be used to actuate the drain valve and a large filter body that increases time between service. A service tool is also included to help install and maintain the filter with ease. G-threads make it simple to swap out your choice of press, MIP, FIP, or sweat G-union end connections in sizes 1¼” or 1½”. The MBF XL can withstand 250°F and 145 PSI CWP.

All plumbing systems should be designed with future servicing in mind. In a typical closed-loop system, maintenance usually involves a four-step process: draining the existing fluid, flushing with a descaling/cleaning solution, rinsing out the solution, and refilling with new fluid. During installation, contractors will designate a purging station and a filling station in anticipation of Read more

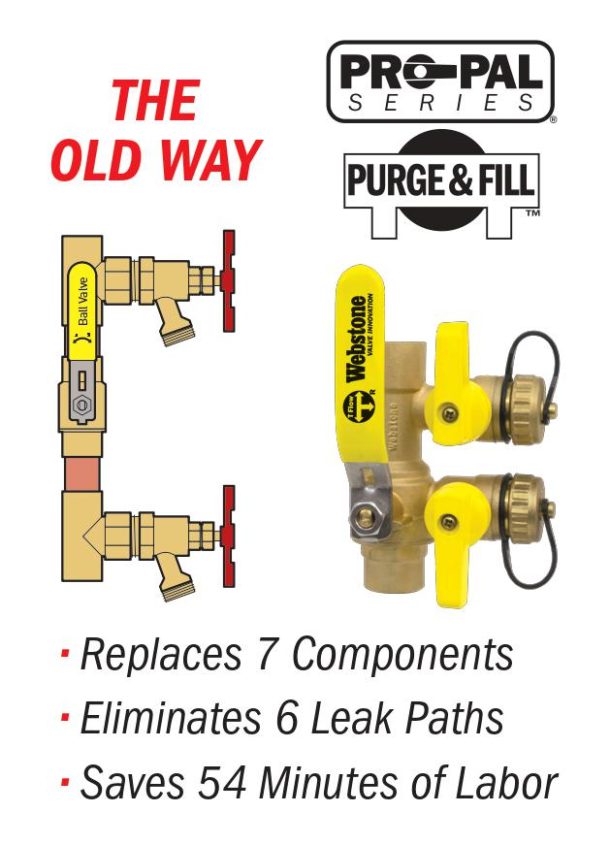

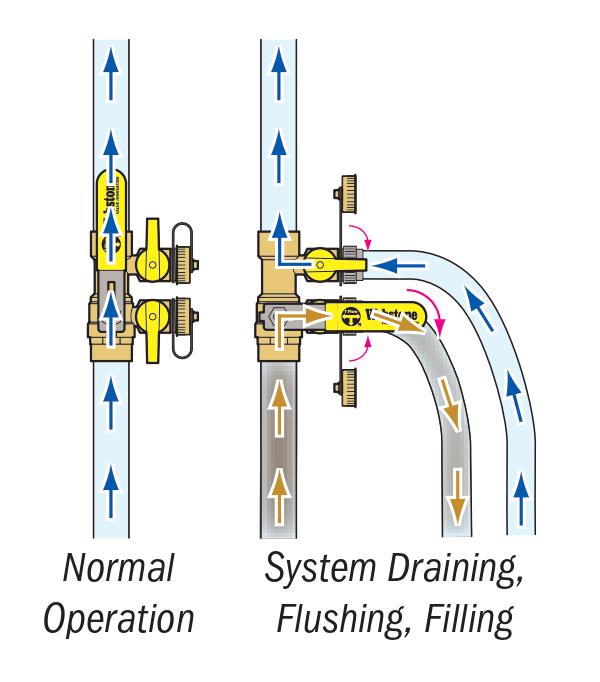

All plumbing systems should be designed with future servicing in mind. In a typical closed-loop system, maintenance usually involves a four-step process: draining the existing fluid, flushing with a descaling/cleaning solution, rinsing out the solution, and refilling with new fluid. During installation, contractors will designate a purging station and a filling station in anticipation of such a process. Each station would consist of a hose drain to purge or fill, and a ball valve to isolate it from the rest of the system.

To consolidate components and to avoid draining the system completely, contractors began fabricating combined purging and filling stations. A pair of assemblies each consisting of a boiler drain, tee, and close nipple would be installed, with a central ball valve placed in between the two stations for isolation. By opening the drain valves and closing the ball valve in the middle, the system loop would open. Then, when new fluid was introduced via the filling station, the flow would displace old fluid through the system and out the decoupled purging station on the other side of the ball valve. Through some clever fabrication, what was once a four step process was now just one step.

Though this assembly does its job to simplify the process, it’s not without its drawbacks. Field fabrications, though functional, are an inelegant solution. Contractors need to take into account the bulkiness of such an assembly when designing the system layout, which can be a challenge when space is limited. Aside from the lengthy footprint, this assembly also introduces three valves and four fittings into the system, increasing labor and leak paths with each component used. These disadvantages have long been accepted by contractors as a necessary evil in designing a system that expedites the purging and filling process.

Enter the Webstone Purge & Fill. An all-in-one forged brass valve alternative, it eliminates 6 leak paths and saves the installer nearly one hour of labor. Its patented design not only streamlines installation, but it also employs the same principals explained above to facilitate future servicing of the closed loop. The three-way ball quickly isolates the flow between the two hose connections, allowing new fluid to enter the system through the top fill drain. The fluid will then flow through the system, forcing out the old fluid until it completes the circuit through the bottom purge drain. By displacing the old fluid with the new, contractors can avoid the timely process of draining and filling the system between each step of the maintenance process.

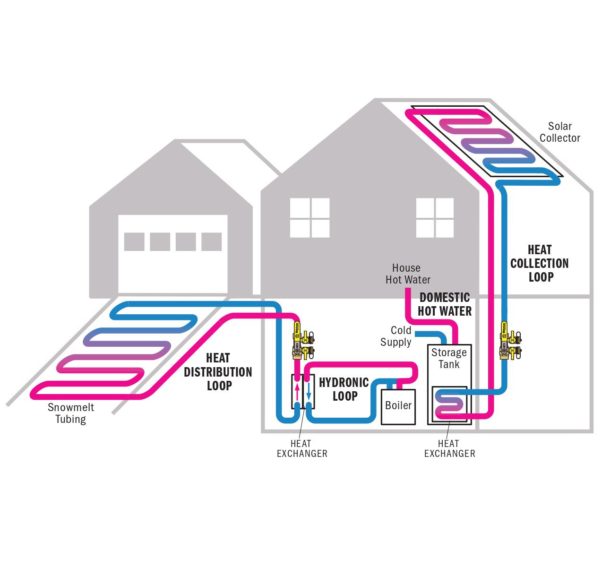

The Purge & Fill was designed for use anywhere that requires routine maintenance of the fluids within a closed-loop. In applications where piping systems are exposed to the elements, a heat transfer fluid like propylene glycol is added to the water to prevent freezing. This fluid mixture will run through the loop, utilizing a heat exchanger to prevent direct contact with any potable water distribution. Over time, this fluid must be replaced, and the piping system should be cleaned or descaled if needed. This is an ideal application for the Purge & Fill because it allows the loop to maintain normal operating conditions as it is simultaneously purged and filled during servicing.

In solar heating systems, the valve can be placed within the heat collection loop. Here the fluid mixture will circulate through the solar collectors, gathering heat that is then distributed to the potable water through the heat exchanger.

In snowmelt applications, the valve can be placed within the heat distribution loop, where the fluid mixture will pass through the heat exchanger and distribute heat through a series of tubing under an outdoor surface.

The fluid mixture’s levels within either loop in must be checked and replaced periodically to ensure proper operation and maintenance of the system. With the Purge & Fill installed in each loop, the fluid can easily be inspected, flushed, and refilled as needed.

Available with threaded or sweat connections and in sizes ¾” through 1 ½”, the Purge & Fill is suitable for any closed-loop system. Its single body forged brass construction features heavy duty brass and hi-flow hose drains. The reversible handle is accompanied by an adjustable packing gland and blow-out proof stem that offer versatility and dependability throughout the life of the product.

Inspired by the field fabrication solutions that came before it, the Purge & Fill is part of Webstone’s Pro-Pal series; a line of step-saving valves designed with the professional in mind. The result is a cleaner looking installation, with fewer components and more efficient system operation. Like all Webstone products, the Purge & Fill is guaranteed for life.

Adds Four Hydronic Solutions, Reintroduces Braukmann Product Name to Global Product Offering Resideo Technologies Inc. (NYSE: REZI), a leading global provider of home comfort and security solutions, today announced new hydronic heating components that complement its full water solutions portfolio. Resideo’s world-class hydronic portfolio offers the ultimate in performance, comfort and consistency, and works together seamlessly Read more

Adds Four Hydronic Solutions, Reintroduces Braukmann Product Name to Global Product Offering

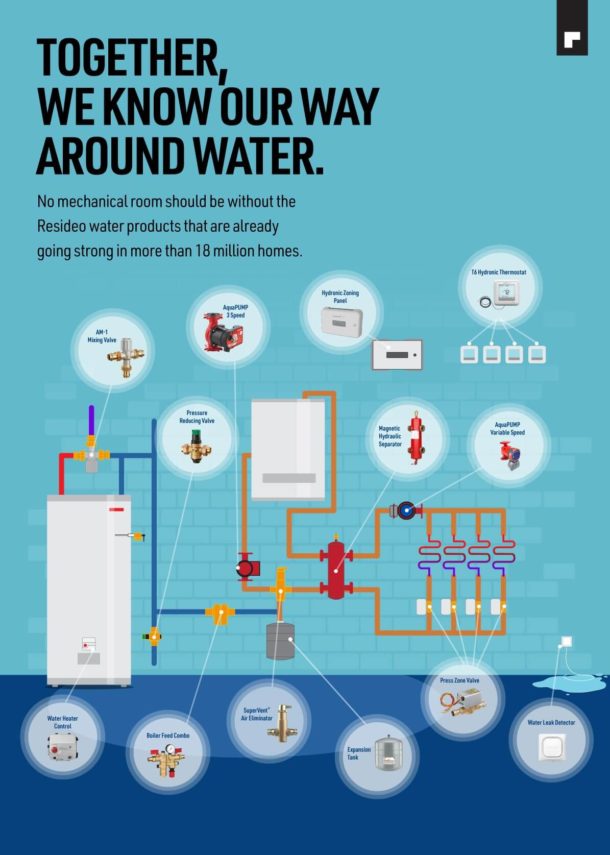

Resideo Technologies Inc. (NYSE: REZI), a leading global provider of home comfort and security solutions, today announced new hydronic heating components that complement its full water solutions portfolio. Resideo’s world-class hydronic portfolio offers the ultimate in performance, comfort and consistency, and works together seamlessly to offer an end-to-end hydronic control system.

“Our professional contractors’ time and energy are precious, so we’re looking forward to offering them a complete, easy-to-install hydronics system from Resideo that is engineered for accuracy, safety and reliability,” said Matthew Robbins, vice president global product management, Comfort & Care. “Our new hydronics solutions are our first Resideo-branded offerings and serve as a true example of what our professionals can expect from Resideo’s behind-the-wall solutions: quality solutions that help save our professionals time, money, labor, and parts.”

Resideo Hydraulic Separator

Resideo’s new hydronic solutions include:

- AquaPUMP Variable Speed Circulating Pumps are offered in both cast iron and stainless-steel models for closed- and open-looped applications. Available in five different modes of operation, the pumps provide versatility to cover the performance of fixed- and variable-speed circulators and utilize pressure responsive control. These quiet and energy-efficient pumps are backed by a five-year warranty.

- Magnetic Hydraulic Separators regulate pressure, reduce flow velocity, minimize audible noises with air elimination and protect the boiler system from ferrous sediment with a standardized magnet. Magnetic Hydraulic Separators are ideal for greater boiler efficiency and protection in various applications from residential homes to multi-family housing. Hydraulic Separator bodies are offered with union connections from one-to two-inch for sweat, threaded, or press fitting. Flanged bodies are available with connections from two to six inches.

- Press PV SuperVent® Air Eliminators easily vent out the air in hydronic systems with the most secure connection offered in the industry. SuperVent® Air Eliminators have debris baffles to control dirt fouling and to prevent failing. The adjustable collar ring allows for easy installation and application flexibility.

- Press Boiler Trim Kits offer a high-quality Press PV SuperVent® Air Eliminator, Press NK300 boiler feed combination and expansion tank with service check valve all in one box. Best-in-class fittings make for a simple, seamless and high-quality installation.

The newly expanded hydronic portfolio is now available in the U.S. and Canada through Resideo’s distribution network.

Resideo Braukmann

Resideo is reintroducing the Braukmann product name to its global potable water products, such as pressure reducing valves and mixing valves. The changes reflect the company’s ongoing opportunity to build and strengthen the Resideo brand and product portfolio.

“Our European and North American customers have known and trusted the Braukmann name for more than 40 years, and we’re honored to bring back the well-known potable water product family,” said Lisa Goldson Armstrong, vice president of global marketing at Resideo. “Reintroducing the Braukmann name acknowledges our proud heritage and gives us an opportunity to take another step in our Resideo brand journey.”

The company acquired Braukmann in 1980 from its founder, and with more than 75 years of experience in the European residential water control market it’s become well-known for demonstrating proven reliability. The water products can be found in more than 18 million households and are trusted by more than 100,000 installers.

Resideo Braukmann solutions are available globally through Resideo’s distribution network.

Taco’s new VR Series high-efficiency ECM cast iron or stainless steel circulators offer a wide range of low, medium or high head options in sizes from 1/3 – to 2-HP. Easy, intuitive settings and operation will appeal to installers for a broad range of uses, including HVAC, hot water recirculation and NSF commercial hot applications Read more

Taco’s new VR Series high-efficiency ECM cast iron or stainless steel circulators offer a wide range of low, medium or high head options in sizes from 1/3 – to 2-HP. Easy, intuitive settings and operation will appeal to installers for a broad range of uses, including HVAC, hot water recirculation and NSF commercial hot applications.

00e VR circulators provide an easy-to-program pump interface with real-time feedback. Modbus, BACnet, 0-10Vdc + pulse width modulation (PWM) are standard. The circulators provide 62 feet max head and up to 320 GPM flow. They are NSF/ANSI 61 + 372 commercial hot certified.

00e VR circulators provide an easy-to-program pump interface with real-time feedback. Modbus, BACnet, 0-10Vdc + pulse width modulation (PWM) are standard. The circulators provide 62 feet max head and up to 320 GPM flow. They are NSF/ANSI 61 + 372 commercial hot certified.

The circulators are also equipped with ASHRAE’s 2019 Software Innovation Award-winning Taco Tags, providing vital product/application information instantly to phones or other mobile devices. Even the molded insulation shell is included.

For more information, visit www.TacoComfort.com