A broad range of allied trade professionals are invited to join a leading panel of experts – beginning Tuesday, Nov. 3 at 10 am ET – during six weekly panel discussions as they address healthcare design and water safety. Online attendees will be able to connect with their peers in a highly-interactive environment that encourages Read more

Legionnaire’s Disease

![]() A broad range of allied trade professionals are invited to join a leading panel of experts – beginning Tuesday, Nov. 3 at 10 am ET – during six weekly panel discussions as they address healthcare design and water safety.

A broad range of allied trade professionals are invited to join a leading panel of experts – beginning Tuesday, Nov. 3 at 10 am ET – during six weekly panel discussions as they address healthcare design and water safety.

Online attendees will be able to connect with their peers in a highly-interactive environment that encourages facility managers, engineers, contractors, and infection control professionals to discuss challenges and opportunities in healthcare design.

Each week, Watts will host a 1.5-hour event starting with a brief presentation, followed by an interactive panel discussion.

Events and topics include:

- Nov 3 – What is WICRA and Why You Need One? Janet Stout, Special Pathogens Laboratory, President

- Nov 10 – Preventing Waterborne Infections During COVID-19 Kristen VanderElzen, University of Michigan, Infection Prevention and Epidemiology Project Manager

- Nov 17 – Lessons Learned in Ice Storage Richie Stever CLSS-HC, CHFM, University of Maryland Medical Center, Director of Operations and Maintenance

- Dec 1 – Next Gen Facilities in a Post-COVID Health Environment Michael Roughan, AIA, ACHA – HDR, Health Principal

- Dec 8 – Healthcare Design from a Facility Manager’s Perspective John N. Ellis, MBA, CHFM – Intermountain Healthcare, System Director of Facilities Management

- Dec 15 – Consequences of Poor Design Christoph Lohr, Healthcare Design Expert

Weekly giveaways to registrants include an Apple Watch Series 5, Air Pods Pro, a virtual reality headset.

Interested professionals can register at: https://www.watts.com/WHS

Mokena, Ill. — The International Association of Plumbing and Mechanical Officials (IAPMO), in conjunction with Special Pathogens Laboratory (SPL), is offering an ASSE 12080 LegionellaWater Safety and Management Specialist Certification Training program, Aug. 17-19. SPL President Janet Stout, Ph.D., a clinical and environmental biologist with more than 30 years of pioneering research in Legionella, will teach Read more

Mokena, Ill. — The International Association of Plumbing and Mechanical Officials (IAPMO), in conjunction with Special Pathogens Laboratory (SPL), is offering an ASSE 12080 LegionellaWater Safety and Management Specialist Certification Training program, Aug. 17-19.

SPL President Janet Stout, Ph.D., a clinical and environmental biologist with more than 30 years of pioneering research in Legionella, will teach the three-day course. The speakers will include David Pierre, vice president of SPL Consulting Services, and Michael Castro, MPH, SPL’s director of Healthcare Services.

“This training provides the critical knowledge that industry professionals need to prevent this life-threatening disease,” Stout said. “At completion, attendees meet the knowledge requirements for the very first Legionella professional qualifications standard [ASSE 12080]. IAPMO’s expertise in education and training, together with Special Pathogens Laboratory, provides participants with the knowledge they need to become an ASSE certified professional for Legionella water safety and management, getting us closer to ending Legionnaires’ disease!”

Attendees will gain the requisite knowledge, understanding, and competency to serve as a member of a facilities water safety team to help protect against Legionella outbreaks and react to one appropriately should it occur. The program will focus on the development of a risk assessment analysis, and water management and sampling plan, for protection from Legionella and other waterborne pathogens. The training will also cover the codes, and the resources, understanding, and skills needed to conduct a facility risk assessment and implement a water safety and management program to reduce the risk of infections due to Legionella.

“By partnering with Special Pathogens Laboratory, both organizations have been able to complement each other’s strengths in order to create a much-needed training and certification program,” said Tony Marcello, IAPMO’s vice president of Training and Credential Services. “We are very excited about the difference this program can make in protecting the health and safety of building occupants as well as helping those who own and manage facilities lower their liability risks.”

The ASSE 12080 certification exam will be administered at the end. Attendees who pass the exam will become certified as Legionella Water Safety and Management Specialists.

The training program is scheduled for 8 a.m.-5 p.m. Aug. 17-19 at the UA Local 130 Training Center, 1400 W. Washington Blvd., Chicago. The registration fee includes the ASSE exam, the SPL workbook Puzzled by Legionella? A Guide to Understanding Detection, Prevention, and Water Management, and lunch. To register, visit https://www.iapmolearn.org/topclass/searchCatalog.do?catId=129117.

For information about the ASSE 12080 standard, visit https://bit.ly/31dzNoQ.

The COVID-19 pandemic is causing commercial buildings such as day care facilities, hotels, schools and health clubs to remain closed for abnormally long periods. When the coast is clear to begin reopening, ensuring safe and sanitary plumbing water will be of utmost importance. Plumbing systems left idle can be susceptible to harmful bacteria such as Read more

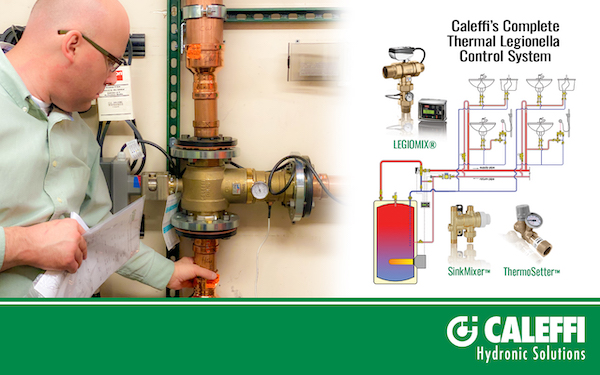

The COVID-19 pandemic is causing commercial buildings such as day care facilities, hotels, schools and health clubs to remain closed for abnormally long periods. When the coast is clear to begin reopening, ensuring safe and sanitary plumbing water will be of utmost importance. Plumbing systems left idle can be susceptible to harmful bacteria such as Legionella which can proliferate to dangerous concentrations.

Experienced water maintenance managers know susceptible systems should be flushed before reusing. Important considerations should not be overlooked such as ensuring all service lines are purged and dead legs drained.

Several factors determine if the system equipment requires treatment such as how long a system is left idle, the temperature of the stagnated water and condition of the internal surfaces. This is so bacteria that are resistant to simple purging/draining and have become resident in biofilm can be addressed. Common methods include thermal treatment or treating with chemicals such as chlorine, chlorinated gas and chlorine dioxide.

A significant benefit of thermal treatment is that it’s a proven, cost-effective method for bacteria management on an ongoing basis in the hot side of the plumbing system. The cold side doesn’t typically require ongoing treatment unless water remains stagnated for extended periods within the temperature range that Legionella grows which is 68°F to 122°F.

Thermal treatment requires little additional maintenance compared to chemical treatment. Also, common plumbing equipment such as seals, gaskets and polymer components are not exposed to potentially incompatible life-shortening chemicals.

Residual chemicals in the water can also be a human health concern if acceptable concentration values are exceeded. In contrast, most common plumbing materials can withstand, without effect, thermal shock temperatures such as 160°F.

Thermal treatment consists of periodically circulating elevated water temperature such as 160°F through the entire system for a specific and measured period of time, thereby killing harmful bacteria and restoring the water to a safe and usable condition. During this period it is important to ensure all point-of-use fixtures are either disabled for access or equipped with anti-scald devices. An example is the Caleffi scald-protection valve SinkMixerTM — an innovative, easy to install valve for under-sink applications.

Often the most difficult portions of the hot water side to circulate sufficiently through is the recirculation return risers. This because they are sized and balanced to a relatively low flow rate such as 0.5 GPM. The Caleffi ThermoSetterTM thermal balancing valve automatically responds when it senses high temperature water by fully opening an internal by-pass, thereby allowing a sufficient return riser flushing during treatment. It then automatically returns to standard operation state when water temperature decreases to normal.

If a building is equipped with a Caleffi LEGIOMIX digital mixing valve, it will enjoy highly accurate mixed water temperature 24/7. The LEGIOMIX has industry-unique, calendar- based automatic thermal disinfection programs. For thermal monitoring, it has data logging capabilities and can connect to a building automation system for remote monitoring and access.

LEGIOMIX combined with SinkMixer anti-scald valves and ThermoSetter recirculation balancing valves offer an innovative total thermal solution for control of safe and sanitary domestic hot water.

NSF Health Sciences and Urban Sustainability Directors Network report recommends electronic cooling tower registry to help public health investigators quickly pinpoint the source of outbreaks. Ann Arbor, Mich. — A new policy report, Electronic Registration Systems for Cooling Towers – Improving Public Health and Sustainability Outcomes, published by the Urban Sustainability Directors Network (USDN) proposes a Read more

NSF Health Sciences and Urban Sustainability Directors Network report recommends electronic cooling tower registry to help public health investigators quickly pinpoint the source of outbreaks.

Ann Arbor, Mich. — A new policy report, Electronic Registration Systems for Cooling Towers – Improving Public Health and Sustainability Outcomes, published by the Urban Sustainability Directors Network (USDN) proposes a standardized yet flexible template for cooling tower registries that are designed to improve health outcomes, address disparity in affected populations, and increase water and energy efficiency.

NSF Health Sciences LLC, an NSF International company, and GroveWare Technologies developed the report for USDN with workshop input from more than 20 federal, state, provincial, city health, environmental, sustainability, water and/or building agencies.

Cooling towers are the point where heat extracted from a building is dissipated to the atmosphere through an evaporative process. As such, they are a critical component of many cooling systems in commercial, industrial, health care, hospitality and residential facilities. There are more than 2 million cooling towers in the United States, making them more common than elevators, yet much less regulated, according to the report.

Poorly maintained cooling towers can disperse Legionella through contaminated water droplets that are created as part of the cooling process. Once inhaled, the bacteria can cause Legionnaires’ disease, an acute form of pneumonia, and the less severe Pontiac fever. According to a study published in April 2018 in Current Environmental Health Reports, cooling towers were implicated or suspected in the majority of Legionnaires’ disease outbreak-associated deaths examined during the study period between 2006-2017.

With Legionnaires’ disease at a record high, the report argues that cities, states and water utilities should create electronic cooling tower registration systems to improve surveillance and response to cases, as well as to prevent exposure to Legionella bacteria by encouraging proper maintenance of cooling towers.

Additionally, since poor energy conservation practices increase water demand on buildings, registries are an important sustainability tool that can help evaluate the effectiveness of maintenance plans and identify areas for improved efficiency, the report highlights.

The U.S. Centers for Disease Control and Prevention (CDC) reported a record number of 9,933 Legionnaires’ cases in 2018, a more than eightfold increase since 2000. The National Academies of Sciences, Engineering, and Medicine (NASEM) in a 2019 report estimated as many as 70,000 people per year in the United States alone may suffer from the disease, and recommended adoption of cooling tower registries to help prevent or to rapidly respond to outbreaks. Response time is critical in an outbreak and proactively knowing the locations of cooling towers can help public health investigators pinpoint the source for remediation.

According to the CDC, one in 10 cases is fatal, and 90% of the outbreaks are preventable.

“Establishing a cooling tower registry is the crucial first step to dramatically improve the ability to meet public health and sustainability goals. This touch-stone document provides the scientific basis for creating cooling tower registries and the road map to ensure their successful implementation,” said Chris Boyd, General Manager of Building Water Health at NSF Health Sciences.

Most North American cities do not track the location of cooling towers and are “forced to rely on imprecise methodologies during public health emergencies,” the report says, adding that there is a “continued tolerance of widely divergent maintenance practices by building owners.”

“Cooling tower registries are a demonstrably effective and proactive tool for improving public health and fulfilling water efficiency goals,” said Patrick Ryan, M.Sc., P.Eng., Chief Building Official from Vancouver (Canada), a key participant city in the new report.

According to the report, registries provide municipalities with a management tool for maintenance record-keeping and support to building owners to meet regulations.

“The City of Vancouver is a true leader in North America in advancing public health measures in urban water systems. The uptake of this work is incredible to watch, proving the need for resources to support city inventory of cooling towers to prevent Legionella outbreaks. USDN is pleased to have been able to provide support for such an important effort,” said Nils Moe, USDN Executive Director.

New York City was the first U.S. city to create an electronic cooling tower registry system after a large outbreak in 2015 that sickened 138 people and led to 16 deaths. A handful of other cities and states, including Austin, Texas; Hamilton, Canada; Vancouver, Canada; the State of New York; Quebec, Canada; and Victoria, Australia, now require cooling towers to be registered. National registries also exist in the United Kingdom, France, Germany, the Netherlands, Hong Kong and Singapore.

The report details IT specifications to create and rapidly implement an electronic cooling tower registration system.

“Technology plays a key role in nurturing a healthy urban living environment. The USDN workshop provided us the opportunity to share our experience deploying the New York City Registration Portal with participating governments and provided attendees with a roadmap for a successful program implementation,” said Hrair Achkarian, President and CEO of GroveWare Technologies Inc., the software firm that developed New York City’s cooling tower registration system.

Registries can also be a crucial tool to measure key sustainability performance indicators, aiding jurisdictions in evaluating the effectiveness of a building’s water conservation plans and identifying areas for improved energy efficiency.

Cooling towers can be a significant source of water demand for a building, representing 20-50% of total water usage, according to the report, which added that poor management practices result in millions of wasted gallons of water per year in a single cooling tower. In Los Angeles alone, for example, it is estimated that more than two billion gallons of water per year are wasted, according to the report.

The report reflects information collected from participants in webinars on April 15, May 17 and July 16, 2019; as well as a two-day workshop conducted Sept. 9-10, 2019, at the annual Legionella Conference in Los Angeles co-hosted by NSF Health Sciences and the National Environmental Health Association. NSF and GroveWare also conducted interviews with several agencies participating in the USDN project to gain insight into what criteria and factors were critical to their public health and sustainability missions.

NSF Health Sciences is presenting the findings of the report at upcoming events, including the AWWA Sustainability Conference in March 2020 in Minneapolis, AWWA ACE in June 2020 in Orlando and the National Environmental Health Association annual meeting in July 2020 in New York City. Public agencies interested in receiving a training/workshop on cooling tower registration systems, Legionnaires’ disease outbreak response investigations and/or sustainability strategies for cooling tower systems should contact NSF Health Sciences LLC’s building water health team at +1.734.769.8010. Read the report with a full list of participant cities at USDN and NSF.

“They always put up the stop sign at the dangerous intersection after a horrible accident, right?” said an editorial colleague in response to a side conversation regarding a Legionella presentation at the 2nd Healthcare Symposium hosted by Watts Water Technologies. The symposium featured four high-level executives whose expertise centered around a comprehensive approach to mitigating Read more

“They always put up the stop sign at the dangerous intersection after a horrible accident, right?” said an editorial colleague in response to a side conversation regarding a Legionella presentation at the 2nd Healthcare Symposium hosted by Watts Water Technologies. The symposium featured four high-level executives whose expertise centered around a comprehensive approach to mitigating opportunistic waterborne pathogens, especially Legionella.

Image courtesy of Watts Water Technologies

When it comes to Legionella assessment, for example, there is continued debate throughout the industry on cost justification vs. actual risk. What is the cost of not putting a water safety plan in place? Injury, death, lawsuits, negative publicity, etc. Is this not enough to be acting now toward a more proactive approach to mitigation? Although Legionella can’t be completely “eradicated” in plumbing systems, implementing safeguards and following through with proper processes to keep a healthcare facility relatively “safe” from opportunistic pathogens—while it does incur a cost—should be the proper approach, and it is fiscally responsible.

Shatha Salah

The proactive vs. reactive conversation stemmed as a response to the presentation by Shatha Salah, Environmental Manager, UAB Medicine, the first of four speakers at the symposium. Following a Legionella outbreak at the University Hospital, Salah is now responsible for directing and managing the UAB Medicine Water Safety Plan and serves as a member on the UAB Medicine water safety team. “It’s important to create a team for a water safety plan, which includes plumbers who are the front-line soldiers in the fight against Legionella,” says Salah. “The plumber’s role is important in protecting patients from waterborne illnesses.”

William Rhoads

Through a combination of a supplemental water treatment system and point-of-use filters, UAB gained control of Legionella growth in the building and began developing a comprehensive water safety plan, engaging team members that can take action and influence process change to conduct risk assessments to help mitigate the growth and distribution of waterborne pathogens.

Dr. William Rhoads, EIT, PhD, postdoctoral researcher, Virginia Tech, focused on the importance of proper assessment of engineering controls and understanding water quality with his “Controlling Opportunistic Pathogen Growth in Building Plumbing” presentation.

Rhoads suggests some Engineering Control Strategies:

- Control Water Age—flow conditions

• Limit Nutrients

• Pipe Material Selection

• Secondary Residual Type and Dose—including in-building treatment - Water Heater Set Point— including thermal shock

- Probiotic/Prebiotic

• Upgrade Water Mains

• System Design—hot water recirc, piping strategy

Aaron Bock, Cannon Design

Why the increased incidence of Legionella? Rhoads suggests a few reasons: improved detection and diagnosis; people are spending more time indoors; changing demographics and immunodeficiency status; and the unintended consequences of more sustainable buildings and cities. “Sustainability in buildings may increase water age—the Distribution System Water Age + Precise Plumbing System Water Age—which can lead to more opportunistic pathogens,” says Rhoads.

Piggybacking Rhoads’ points, Aaron Bock, PE, CPD, Plumbing and Fire Protection Discipline Leader, Cannon Design, suggests that some challenges include building codes, standards and guideline; equipment and fixtures; and building piping and design. Items such as low flow and seldomly used fixtures can lead to stagnant water, which encourages bacterial growth, says Bock. Programmable sensor faucets, for instance, should be chosen carefully and limited to high-traffic areas. Other concerns include water system size and age, building location, equipment and appliances and uncirculated piping can all lead to problems.

Bock’s solutions include:

- Plumbing System Design

Selection of Fixtures & Materials

– Laminar Flow or Open Faucet Spouts

– Placement of Fixtures

– Sanitizable Fixtures & Piping Materials

– Hands-Free Faucet Operation

– Sensors in Public Areas Only

Temperature & Flow Maintenance

– Limiting uncirculated water piping accomplishes both

– Recognize devices/piping that create stagnation

– Don’t ignore cold water systems

– Isolation of System Sections

- Chemical/Ion Injection

– Chlorine

– Chlorine Dioxide

– Monochloromine

– Copper-Silver Ionization

- Supplemental Measures

– Elevated Water Temperatures

– Ultrafiltration—Total Building, Hot Water, Point-of-Use

Moreover, Bock suggests implementing Design, Construction and Occupancy Phases, which include fixture selection and future provisions during the design, flushing and disinfecting water lines during construction, and water management plans, monitoring control points and maintenance during occupancy. “It’s important to education building owners during the design phase,” says Bock.

Frank Sidari, Special Pathogens Laboratory

Frank Sidari, Technical Director, Special Pathogens Laboratory, an encore speaker from the Watts’ inaugural Healthcare Symposium, placed continued emphasis on the importance of a water management plan. Sidari focused on a closer inspection on how engineers, facility managers and infection control can work to manage building water systems to reduce the risk associated with opportunistic waterborne pathogens and coordinate efforts with their water safety and management program. Interestingly, he cited a National Academies of Sciences, Engineering, and Medicine (NASEM) report that states, “Stronger policies are needed to protect the public against Legionnaires’ Disease.”

Perhaps building codes and standards can take a more focused look in mandating more stringent building compliance when it comes to mitigation and a tangible action plan. In the meantime the bottom line is this: it is better to be proactive than reactive when considering water safety and pathogen mitigation in healthcare facilities.