Are your customers requesting bathroom updates that will be stylish and functional for years to come? More homeowners than ever are renovating, using universal design principles that allow these spaces to serve people of varying ages and abilities. Universal design provides numerous important benefits to home and building owners, including higher levels of safety and Read more

Oatey

Are your customers requesting bathroom updates that will be stylish and functional for years to come? More homeowners than ever are renovating, using universal design principles that allow these spaces to serve people of varying ages and abilities. Universal design provides numerous important benefits to home and building owners, including higher levels of safety and increased property value.

Universal design basics

Universal design creates an environment that is accessible to all people to the greatest extent possible. That means a bathroom will function as well for a child as it does for a senior. Basic principles of universal design focus on functionality. In the bathroom that might mean adding strategic lighting, slip-resistant flooring and features like grab bars.

Your customers don’t have to sacrifice aesthetics to achieve the functional goals of universal design. More options than ever are available for enhancing the bathroom’s safety and functionality while adding luxurious upgrades that are as useful as they are eye-catching.

When function and fashion blend like this in home improvements, it can add significant value to properties.

Curbless shower features

Consider one of the year’s top bathroom design trends: curbless showers with linear drains. This creates a barrier-free experience that is visually appealing, making it ideal for the universal design home.

A curbless walk-in shower eliminates hazards like curbs or thresholds that can cause people to slip or trip. It’s easier to use, whether you walk or utilize a device for assistance, such as a shower wheelchair. Curbless showers also provide an open feel, which makes the space feel larger because visual lines are not disrupted.

Curbless showers are enhanced by linear drains that are installed flush to the flooring, further reducing trip hazards while adding a sleek appearance to the space. With no barrier to cross, the floor more easily accommodates a freestanding bench, a walker or other mobility aids.

An added benefit is that linear drains generally avoid looking institutional, like some wheelchair-friendly bathrooms can. An excellent example of this counter-institutional trend is QuickDrain’s WallDrain, in which the drain literally disappears into the wall, offering an ultra-clean and contemporary look.

A curbless shower is achievable with various drainage points, therefore offering versatility in terms of design. A curbless shower also provides flexibility regarding its location, since you are not tied to placing the drain in a specific spot.

Deciding on shower doors is another important aspect of universal design. Glass doors work well for curbless walk-in showers because they open the space and let in light.

Another option is to design the space to be completely open as a wet room. Glass dividers are a hybrid option that provide a partition without a door, but can be easily removed if your customer might want to open the space in the future.

Shower bench

A shower bench can greatly enhance the look and functionality of a shower. It can serve as a necessary place to sit, a retreat to relaxation, or simply a place to store hygiene products, while also offering accessibility and style.

The QuickDrain BenchSeat offers three PET (polyethylene terephthalate) bench configurations to meet differing needs, depending on bench placement and overall shower size. These multiple configurations are suitable for newly constructed or renovated tile showers. Not only do these shower benches meet the ADA standard guidelines for height, but they also exceed the weight requirement, promoting a universal design for all.

Grab bars

Grab bars will offer added stability and convenience to your shower and bathroom. Contrary to popular belief, grab bars aren’t just meant for healthcare or senior living facilities. They can also increase safety and convenience in your home for children, pregnant women, and anyone dealing with health issues or recovering from an injury.

Dearborn Grab Bars are ADA-compliant and available in 1-1/4″ and 1-1/2″ diameters with concealed or open flanges. Available in peened or satin finishes, these grab bars can be ordered in whatever length is needed.

Universal design is important in bathrooms because these spaces are used every day. Whether your customer’s goal is to age in place or to make home improvements to improve property value, bathrooms with stylish universal design will help you meet those goals.

About the Author: Marlee Gannon is Director, Wholesale Product and Channel, at Oatey Co. With a robust background in sales, product development and marketing, Marlee’s comprehensive knowledge of the plumbing industry, its products and people, has helped propel her career over the past 7+ years. She is highly engaged with the chain of distribution, from end-users to Oatey’s wholesaler-partners.

About the Author: Marlee Gannon is Director, Wholesale Product and Channel, at Oatey Co. With a robust background in sales, product development and marketing, Marlee’s comprehensive knowledge of the plumbing industry, its products and people, has helped propel her career over the past 7+ years. She is highly engaged with the chain of distribution, from end-users to Oatey’s wholesaler-partners.

Dearborn®, a part of the Oatey family of companies, today announced that its True Blue® Bath Waste Kits are now available in Brass material, further expanding its already extensive offering of bath-waste kits. Designed with the plumber in mind, the True Blue line is made with integrated locking features that reduce the number of tools Read more

Dearborn®, a part of the Oatey family of companies, today announced that its True Blue® Bath Waste Kits are now available in Brass material, further expanding its already extensive offering of bath-waste kits.

Dearborn®, a part of the Oatey family of companies, today announced that its True Blue® Bath Waste Kits are now available in Brass material, further expanding its already extensive offering of bath-waste kits.

Designed with the plumber in mind, the True Blue line is made with integrated locking features that reduce the number of tools needed for installation, saving time and eliminating frustration.

Dearborn® True Blue® Brass is ideal for markets where brass installations are required for commercial and residential applications. It is suitable for standard tub depths up to 16” and whirlpool depths up to 24”.

Dearborn® True Blue® Brass is available in rough and full kits with solder and slip joint connections. The full kit includes a test kit, chrome trim kit, overflow assembly, waste shoe assembly and a solder, or slip joint tee.

Constructed of brass, the True Blue Drain Spud is built for durability and longevity. Featuring two heavy-duty crossbars, it provides a greater flow rate than standard, four-crossbar designs. The Drain Spud can accept the trim veneer for easy finish change and replacement, and is compatible with all existing True Blue components.

True Blue Bath Waste is available in full, half, rough and trim kits with options for ABS or PVC and touch toe, uni-lift and push n’ pull stopper choices. The trim kits come in designer finishes, including Matte Black, Chrome, White, Brushed Nickel, Oil Rubbed Bronze and Brushed Gold. Brass options are available with a standard slip-joint tee, NY tee, solder tee, and female outlet tee.

To learn more, visit oatey.com or your local wholesaler-distributor.

Oatey Co., a leading manufacturer in the plumbing industry since 1916, recently named J&K Sales the top-performing manufacturer representative for its Wholesale Business Unit in 2021, recognizing the agency’s exceptional partnership and accomplishments in support of Oatey Co. and its companies. In addition, Oatey named Chase Freeman, Vice President, Spirit Group, the inaugural winner of Read more

Oatey Co., a leading manufacturer in the plumbing industry since 1916, recently named J&K Sales the top-performing manufacturer representative for its Wholesale Business Unit in 2021, recognizing the agency’s exceptional partnership and accomplishments in support of Oatey Co. and its companies. In addition, Oatey named Chase Freeman, Vice President, Spirit Group, the inaugural winner of its Bob Bender Legacy Award.

J&K Sales, whose partnership with Oatey spans nearly 20 years, earned the title of Wholesale Manufacturer Representative of the Year because of their exceptional work, perseverance and passion throughout 2021. They delivered exceptional sales results for the year, across budget targets, new-product sales and more. In addition, through consistent investments in their business – such as training, associate development and team growth – J&K has positioned themselves for ongoing success.

“Oatey’s manufacturer representatives are an extension of our team, and we are extremely grateful for their hard work and dedication,” said Patrick Aquino, Vice President, Wholesale Sales at Oatey Co. “J&K Sales has built a phenomenal team in the New England states. They are strong in all segments, and I see them only getting stronger. Congratulations to them on this well-deserved honor.”

Oatey also recognized Chase Freeman of Spirit Group as the inaugural winner of the Bob Bender Legacy Award. Prior to his death in 2018, Bender spent his 42-year career in sales at Oatey, during which time he forged indelible relationships with customers and industry partners. His legacy and contributions will continue to serve as an example and inspiration to Oatey team members and partners for years to come.

Freeman was selected for the Bob Bender Legacy Award because of his passion, creative energy and willingness to go above and beyond for Oatey in both the rough-plumbing and waterworks markets. His ability to think outside the box enables him to drive impressive sales results, and he consistently demonstrates perseverance in support of Oatey and its brand.

“Congratulations to Chase on being the well-deserved winner of the Bob Bender Legacy Award,” said Aquino. “His dedication, no-quit attitude and enthusiasm for this industry are a true reflection of Bob’s legacy, and I know Bob would be proud to see Chase receive this recognition. We are so appreciative of his contributions.”

L.R. Brands is comprised of QuickDrain and the newly launched 1916 Collection Oatey Co., a leading plumbing manufacturer since 1916, has announced the launch of L.R. Brands, the latest innovation from the brand that has been the top choice of professional plumbers for more than a century. From elegantly engineered total shower and bath solutions Read more

L.R. Brands is comprised of QuickDrain and the newly launched 1916 Collection

Oatey Co., a leading plumbing manufacturer since 1916, has announced the launch of L.R. Brands, the latest innovation from the brand that has been the top choice of professional plumbers for more than a century. From elegantly engineered total shower and bath solutions to freestanding tub drains, L.R. Brands is the home for design-minded individuals. Built on Oatey’s heritage of quality and named after L.R. Oatey, who founded Oatey Co. in 1916, L.R. Brands is meant to be the one thing that contractors, designers and customers will all agree upon.

L.R. Brands is comprised of two brands with a shared commitment to craftsmanship – QuickDrain and 1916 Collection. A premier manufacturer of curbed and curbless shower solutions, QuickDrain pushes the boundaries of bathroom design with custom-feeling shower solutions, including WallDrain, ShowerLine, ProLine, SquareDrain and BenchSeat. The newly established 1916 Collection is a portfolio of thoughtfully designed, exceptionally engineered bath accessories, including its recently launched Freestanding Tub Drain, that enhance both of the form and function of every bath experience.

“At Oatey, we are craftsmen at heart,” says Katherine Lehtinen, Senior Vice President, Brand and Digital Marketing. “We pay attention to the finer details – it’s who we are, and it’s what our customers expect. That’s the inspiration behind L.R. Brands. We’re building on our heritage brands, known for their quality behind the wall, to bring new bathroom solutions to the table that help you elevate the design you had in mind.”

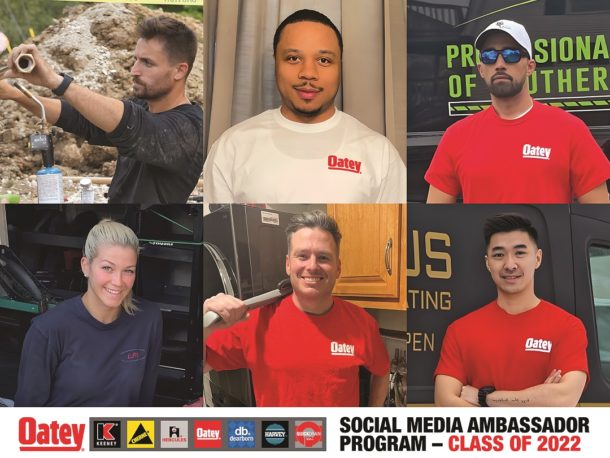

The program has now doubled in size since its launch last year, expanding its impact on the brand’s robust social media community and digital footprint. Oatey Co., a leading manufacturer in the plumbing industry since 1916, today announced the addition of six new plumbing and building professionals to its Social Media Ambassador Program. Through its Read more

The program has now doubled in size since its launch last year, expanding its impact on the brand’s robust social media community and digital footprint.

Oatey Co., a leading manufacturer in the plumbing industry since 1916, today announced the addition of six new plumbing and building professionals to its Social Media Ambassador Program. Through its Ambassador program, which launched in June 2021,The program is an extension of the brand’s robust, highly engaged social media community, through which Oatey connects with its end users, provides helpful resources, answers questions and builds relationships with tradespeople around the world.

The 2022 class of Oatey Ambassadors includes experienced licensed plumbers Chris Sbrocco, Germaine Nelson, Robert Broccolo, Laura Giudice, Thomas Young, and Darryl Wong, collectively representing a diverse range of plumbing and building expertise from across North America. The new Ambassadors join existing Oatey Ambassadors Danielle Browne, Trey Young, Alex Goin and Omar Harris.

As Ambassadors for Oatey in the field, program participants champion the Oatey family of brands (including Oatey, Dearborn, Hercules, Cherne and more), creating unique multimedia content to be shared across social media and other digital platforms. Each Ambassador receives curated kits of Oatey branded gear, including Ambassador-exclusive swag. They are provided with a range of products to support their day-to-day work, are among the first to know about new product launches and have the chance to try new products firsthand. Ambassadors also have the opportunity to travel to Oatey’s headquarters in Cleveland, Ohio, for a two-day Ambassador event.

“Over the past year, Oatey’s Social Media Ambassador Program has been such a rewarding opportunity for us to connect with some of the most talented tradespeople in our network and amplify their unique perspectives and exceptional work,” said Katherine Lehtinen, Senior Vice President, Brand and Digital Marketing at Oatey. “Now, we are honored to welcome our second class of world-class Ambassadors, whose talent and expertise will certainly speak for itself as they champion Oatey’s products in the field and online.”

A new class of Ambassadors will be selected each year. Individuals interested in becoming a future Oatey Ambassador can submit their information on the Oatey website for consideration.

For additional information about Oatey’s Social Media Ambassador Program, visit oatey.com.