Dearborn®, a part of the Oatey family of brands, today announced that its True Blue® Bath Waste Kits are now available in a fashion-forward Brushed Gold finish, adding to its already robust line of designer finishes. Innovative, flexible and designed with the plumber in mind, the True Blue Bath Waste line is made with integrated Read more

Oatey

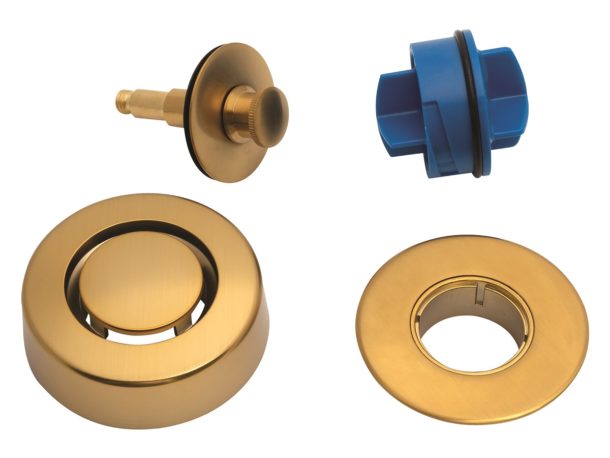

Dearborn®, a part of the Oatey family of brands, today announced that its True Blue® Bath Waste Kits are now available in a fashion-forward Brushed Gold finish, adding to its already robust line of designer finishes.

Innovative, flexible and designed with the plumber in mind, the True Blue Bath Waste line is made with integrated locking features that reduce the number of tools needed for installation, saving time and frustration. The new Brushed Gold finish enhances the existing portfolio of the True Blue line, which also includes bath-waste kits in Matte Black, Chrome, White, Brushed Nickel and Oil Rubbed Bronze. Constructed of brass, the True Blue Drain Spud is built for durability and longevity. Featuring two heavy-duty crossbars, it provides a greater flow rate than standard four crossbar designs. The Drain Spud can accept the trim veneer for easy finish change and replacement and is compatible with all existing True Blue components.

True Blue Bath Waste is available in full, half and trim kits with options for ABS or PVC and touch toe, uni-lift and push n’ pull stopper options. The trim kits in designer finishes are also compatible with True Blue FLEX, made with flexible PVC tubing to overcome jobsite obstructions. To learn more, visit oatey.com or your local distributor.

The website is designed to best support customer needs, optimizing user-experience and convenience Cherne Industries (Cherne), the industry-leading manufacturer of pipe plugs and testing equipment and part of the Oatey Co. family of companies, has launched its new website, CherneInd.com — a robust, easy-to-use hub for Cherne product information, customer support and helpful application resources Read more

The website is designed to best support customer needs, optimizing user-experience and convenience

Cherne Industries (Cherne), the industry-leading manufacturer of pipe plugs and testing equipment and part of the Oatey Co. family of companies, has launched its new website, CherneInd.com — a robust, easy-to-use hub for Cherne product information, customer support and helpful application resources.

The new website houses the brand’s full product catalog, allowing customers to search more than 700 Cherne products, including each product’s specifications, key features, FAQs and safety/instruction manuals. In addition to this technical information, as well as case studies and blogs, the website hosts online training opportunities and detailed, how-to videos.

The Cherne website is mobile-friendly and includes sophisticated navigation with enhanced functionality, making it simple for users to find the specific product they need across both the Waterworks and Plumbing categories. Visitors seeking additional help or information can also communicate in-real-time with a Cherne expert using the “Ask a Tech” functionality, conveniently located at the yellow question mark icon in the bottom right corner of each webpage.

“We’re thrilled to debut the new Cherne website,” says Katherine Lehtinen, Senior Vice President of Brand and Digital Marketing at Oatey. “Not only does it allow us to better serve and connect with the waterworks and plumbing contractors who rely on our products, but it also gives us an opportunity to share our story and reinforce a mission that’s so important to us — developing the best pipe plugs and testing tools to ensure safety and efficiency at jobsites across the globe.”

To explore Cherne’s new website and product catalog, go to CherneInd.com.

ABOUT CHERNE INDUSTRIES

Part of the Oatey Co. family of companies, Cherne Industries (Cherne®) is the industry-leading manufacturer of test plugs and testing equipment for residential, commercial, industrial and municipal piping systems. Based out of its state-of-the-art headquarters in Shakopee, Minn., Cherne’s products are manufactured with an unwavering commitment to safety and quality.

Available via Oatey Co.’s distribution network throughout North America and through partner distribution on every continent, Cherne products are relied upon by residential and commercial contractors, as well as industrial and municipal engineers, worldwide.

For more information, visit www.CherneInd.com, call 1-800-843-7584 or follow Cherne on LinkedIn.

ABOUT OATEY CO.

Since 1916, Oatey has provided reliable, high-quality products for the residential and commercial plumbing industries, with a commitment to delivering quality, building trust and improving lives. Today, Oatey operates a comprehensive manufacturing and distribution network to supply thousands of products for professional builders, contractors, engineers and do-it-yourself consumers around the world.

Oatey is based in Cleveland, Ohio, and has locations in the United States, Canada, Mexico and China. For more information, visit www.oatey.com, call (800) 321-9532 or follow Oatey on Facebook, Twitter, LinkedIn or Instagram

Cherne Industries, part of the Oatey Co. family of brands, recently completed a historic move of its headquarters and manufacturing operations — its first in more than 60 years — to a newly constructed, 130,000-square-foot facility located in Shakopee, MN, situated 25 miles southwest of downtown Minneapolis. Opened in March, the manufacturing portion of the Read more

Cherne Industries, part of the Oatey Co. family of brands, recently completed a historic move of its headquarters and manufacturing operations — its first in more than 60 years — to a newly constructed, 130,000-square-foot facility located in Shakopee, MN, situated 25 miles southwest of downtown Minneapolis.

Opened in March, the manufacturing portion of the new, state-of-the-art headquarters was built to Cherne’s exacting specifications by the OPUS Group, as management sought to more fully integrate all its operations under one roof. Shakopee combines automated robotic manufacturing pneumatic pipe plugs, mechanical pipe plugs and testing equipment with a new research and development laboratory for product testing, extensive customer training facilities, and an in-house machine shop for making all the needed tooling on premises, rather than depending upon outside sources.

In addition, the new building contains ample storage space for raw materials and finished product, so that Cherne no longer relies on outside warehousing for storage and shipping. The resulting, more efficient material flows have already cut lead times and increased operating efficiencies since the move.

“Cherne has been growing at a double-digit pace for the past seven years,” says General Manager and seven-year company veteran David Biron, explaining why the former, 66,000-square-foot facility in nearby Edina was no longer suitable. “We had acquired some robotic equipment and other automation components in recent years, but as the business grew, we simply ran out of space.

“The R&D and testing operations demonstrate Cherne’s newly fortified capabilities as we maintain world class, industry-leading new-product development that provide the safest, most productive value-added solutions for our end users,” Biron continues. Cherne can now test its entire production on premises, instead of relying on outside facilities, as had sometimes been the case in the past.

“The old building did not offer a setting large enough — and therefore safe enough — to test larger plugs and testing equipment, which expand up to 120 inches,” says Biron. “No other plug maker can offer as comprehensive or as safe a testing facility as what we’ve built in Shakopee.”

Robotics = safer, longer-lasting plugs: The most impactful upgrade with the new Shakopee operation is the inclusion of a pair of automated robots for producing Cherne’s industry-first and industry-leading offering of pneumatic plugs. The robotic technology creates a mechanical bond to more securely join the plug’s aluminum end plate to its premium natural-rubber core.

The result is more precise and consistent fabrication, from plug to plug, minimizing field failures sometimes found with the manual, chemical-bonding connection process long used by other manufacturers. Cherne’s robotic-made plugs are a significant industry advancement, offering best-in-class safety, durability, and premium performance.

“No other North American manufacturer is building plugs with one robot, let alone two,” says Biron. “Other producers still assemble them by hand, as they have been for decades. This entire facility demonstrates the enduring strength of the Cherne brand and why a customer can be comfortable buying and installing plugs and related piping products from us.”

Rapid turnaround: Until this past March, every plug sold by Cherne over the past five decades and more had been made in the company’s former Edina facility, erected by founder Lloyd Cherne in 1970. (Oatey Co. bought Cherne in 1990.) So, it may seem surprising that the relocation to Shakopee required only seven days, as Biron reports, with the new plant successfully running 70 percent of the company’s catalog by the end of that first week.

Biron expects to employ 130 personnel, a gain of approximately 20 over Edina. Among the reasons Cherne chose to move to Shakopee was to tap its “wide cross-section of qualified workers” to fill the diversified roster of skilled technical positions needed to operate and maintain Cherne’s large, automated equipment at a high level.

“We drew it all up on a napkin two years ago,” recalls Biron, “and spent another 18 months meticulously planning the move down to the smallest detail. It was unbelievable how our team came together, and it could not have gone any more smoothly — even with all of our large pieces of equipment and despite the pandemic. In a year when everything seemed to go wrong, this move and its aftermath have gone exceptionally right.”

Some key partners that were critical to making the move go as well as it did were Cullinan Rigging and Erecting, OlympiaTech Electric, Voson Plumbing and Allen Mechanical. “Without their attention to detail and customer focus,” says Biron, “this move wouldn’t have been successful.”

To learn more about careers and opportunities available at Cherne Industries, visit oatey.com/careers.

Resource-rich website offers intelligent, user-centric product selector tool, allowing installers to customize QuickDrain shower-drain products to their particular specifications QuickDrain USA has unveiled a new and completely reimagined website, quickdrain.com, designed to offer the ultimate user-friendly experience to design professionals and their clients. Providing intuitive design, improved navigation and functionality, the new website allows visitors Read more

Resource-rich website offers intelligent, user-centric product selector tool, allowing installers to customize QuickDrain shower-drain products to their particular specifications

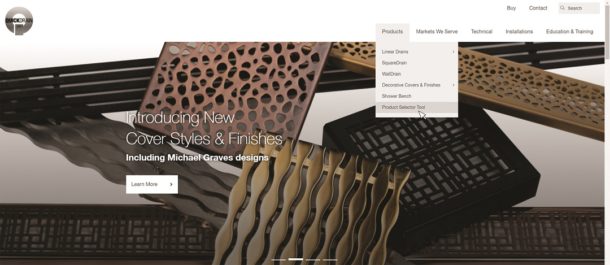

QuickDrain USA has unveiled a new and completely reimagined website, quickdrain.com, designed to offer the ultimate user-friendly experience to design professionals and their clients. Providing intuitive design, improved navigation and functionality, the new website allows visitors to immerse themselves in the full QuickDrain portfolio and to customize those products through a new and innovative product selector tool.

The new website affirms QuickDrain’s brand promise; an elegant blend of design, versatility, and functionality. With high-quality, visually appealing, in-use imagery and clear calls to action, the website delivers to designers, architects, installers, and showroom consultants not only a service, but also an experience, offering an abundance of bath-design inspiration, helpful tools and resources.

The site incorporates the following enhancements:

- Product Selector Tool: The new selector tool (located under the Products tab in the navigation menu) allows installers to customize QuickDrain products to meet the needs of their particular application. Designers and their clientele can now configure a QuickDrain shower solution themselves by responding to a series of questions: Curb or curbless? Linear or center point drain? The selector tool also requests details on drain placement, outlet orientation and enclosure dimensions, while offering customers a visual interface where they can change various attributes (drain cover finish, material, parts, etc.). The payoff is a fully customized PDF-outline of the QuickDrain system designed to their specifications.

- Where to Buy: Quotes and information on where to purchase QuickDrain products are now easily requested through an online form that speeds and streamlines the process. Once the form has been submitted, a member of the QuickDrain Customer Champion Team will contact the customer to walk them through the purchasing and installation process.

“Our primary goal during the redesign process was to create a more valuable, user-centric, and responsive resource for QuickDrain customers,” says Chris Oatey, General Manager of QuickDrain USA. “Specifically, we wanted to focus on delivering our brand’s promise of luxury, while making it easier for users to learn and locate valuable information about our linear and SquareDrain solutions for their particular application or building type.”

The new website features five key navigation channels: Products, Markets, and Installation, plus Education and Training. Besides accessing product and application information, including case studies, visitors can use these channels to access technical documents (submittals, BIM Revit, Code Approvals, etc.) and explore how-to videos and online training opportunities.

The new site at https://www.quickdrain.com/ can be fully accessed through all the major browsers, especially the latest versions of Google Chrome, Microsoft Edge, and Firefox.

ABOUT QUICKDRAIN USA AND OATEY CO.

Part of the Oatey family of brands, QuickDrain USA is a premier manufacturer of curbless and curbed shower solutions for showers and wet areas. Balancing elegant design with exceptional performance and universal design, QuickDrain’s shower solutions offer best-in-class accessibility, flexibility and ease of installation, making them the ideal choice for healthcare, hospitality and residential renovations and new builds alike. For more information, visit www.quickdrain.com or follow QuickDrain on Facebook, LinkedIn or Instagram.

Since 1916, Oatey has provided reliable, high-quality products for the residential and commercial plumbing industries, with a commitment to delivering quality, building trust and improving lives. Today, Oatey operates a comprehensive manufacturing and distribution network to supply thousands of products for professional builders, contractors, engineers and do-it-yourself consumers around the world.

Oatey is based in Cleveland, Ohio, and has locations in the United States, Canada, Mexico and China. For more information, visit www.oatey.com, call (800) 321-9532 or follow Oatey on Facebook, Twitter, LinkedIn or Instagram.

Program builds upon Oatey’s robust social media community to build connections with Oatey’s end users Oatey Co., a leading manufacturer in the plumbing industry since 1916, today launched its Social Media Ambassador Program, partnering with influential plumbing professionals and Oatey brand loyalists to promote Oatey’s products across social media platforms. As Ambassadors for Oatey in Read more

Program builds upon Oatey’s robust social media community to build connections with Oatey’s end users

Oatey Co., a leading manufacturer in the plumbing industry since 1916, today launched its Social Media Ambassador Program, partnering with influential plumbing professionals and Oatey brand loyalists to promote Oatey’s products across social media platforms.

As Ambassadors for Oatey in the field, program participants will champion the Oatey family of brands (including Oatey, Dearborn, Hercules, Cherne and more), creating unique multimedia content to be shared across social media and other digital platforms. Each Ambassador will receive a curated kit of Oatey-branded gear, including Ambassador-exclusive swag. They will be provided with a range of products to support their day-to-day work, will be among the first to know about new-product launches, and will have the chance to try new products firsthand. Ambassadors will also have the opportunity to travel to Oatey’s headquarters in Cleveland, Ohio, for a two-day Ambassador event.

Danielle ‘Twig’ Browne

By amplifying the Oatey brand across the Ambassadors’ social media platforms, the Ambassador program will build upon Oatey’s robust, highly engaged social media community. The 2021 class of Oatey Ambassadors includes experienced licensed plumbers Danielle Browne, Trey Young, Alex Gouin, Omar Harris and Bobby Drescher, collectively representing a diverse range of plumbing backgrounds and years of unique application expertise from across North America.

“Oatey’s social media community is a special place, and our Ambassador program provides an opportunity for us to further expand our footprint and grow our relationships in that space,” says Katherine Lehtinen, Senior Vice President, Brand and Digital Marketing. “We’re honored to partner with five, exceptionally talented individuals in our inaugural class of Ambassadors, and we’re looking forward to seeing them represent Oatey through their unique perspectives and experiences.”

A new class of Ambassadors will be selected each year. Individuals interested in becoming a future Oatey Ambassador can submit their information on the Oatey website for consideration.

For additional information about Oatey’s Social Media Ambassador Program, visit www.oatey.com.