Transitioning from working for an employer to starting your own business is a big decision. It should be made with seriousness, as there are a lot of factors to consider. But if you’re passionate about plumbing and ready to be your own boss, then starting your own plumbing business may be the right move for Read more

Plumbing

Transitioning from working for an employer to starting your own business is a big decision. It should be made with seriousness, as there are a lot of factors to consider. But if you’re passionate about plumbing and ready to be your own boss, then starting your own plumbing business may be the right move for you. Here’s what you need to know to transition from employee to entrepreneur.

Do Your Market Research

The first step in starting any business is to do your market research. This is especially important for a plumbing business, as you need to ensure enough demand for your services in your area. Talk to other plumbers in your area to see how busy they are and what areas of town they service. You can also talk to potential customers to see if they would be interested in using your services. This market research will give you a good idea of whether or not starting your own plumbing business is a viable option.

Plan Your Finances

Financial planning is crucial if you start your own business. First, you’ll need to have enough money to cover your living expenses for at least six months and the start-up costs for your business. These start-up costs can include anything from licenses and permits to office space and marketing materials. Once you clearly understand your financial situation, you can begin to create a business plan.

Choose Your Business Structure

There are several different business structures you can choose from when starting your own plumbing business, including sole proprietorship, partnership, limited liability company (LLC), and corporation. Each option has its pros and cons, so it’s essential to research and select the structure that makes the most sense for your unique business.

Get Licensed and Insured

To operate legally, all businesses must have the proper licenses and insurance. Plumbing business licenses and insurance requirements vary from state to state, so check with your local government offices for more information. Once you have the necessary permits and insurance, you’ll be ready to start marketing your business!

Offer A Unique Service

One of the best ways to make your plumbing business stand out from the competition is to offer a unique service they don’t have. This could be anything from drain cleaning to septic tank maintenance. By providing a service that other plumbers in your area don’t, you’ll be able to attract more customers and grow your business more quickly.

Market Your Business

Several ways to market a plumbing business include online marketing, print advertising, direct mail campaigns, and more. When developing your marketing strategy, focus on targeting your ideal customer base. For example, if you want to attract residential customers, then online ads targeting homeowners in your area would be an excellent place to start.

Transitioning from working for someone else to starting your own plumbing business is a big decision—but it can also be gratifying. By following these steps and doing your research ahead of time, you’ll be well on your way to making your entrepreneurial dreams a reality!

Milwaukee Valve has announced the retirement of President and CEO Rick Giannini, effective January 20, 2023. John Labellarte, the company’s current COO, will succeed Giannini in leading the commercial, industrial and marine valve manufacturer. Giannini joined Milwaukee Valve in 1998 and successfully guided the business through challenging market conditions. His leadership transformed Milwaukee Valve into Read more

John Lebellarte

Milwaukee Valve has announced the retirement of President and CEO Rick Giannini, effective January 20, 2023. John Labellarte, the company’s current COO, will succeed Giannini in leading the commercial, industrial and marine valve manufacturer.

Giannini joined Milwaukee Valve in 1998 and successfully guided the business through challenging market conditions. His leadership transformed Milwaukee Valve into a service leader and global manufacturer. He guided the transformation of the sales organization, reinvested in manufacturing processes and equipment, and assembled the company’s overseas manufacturing operations. Giannini greatly expanded the development and growth of Milwaukee Valve’s product offering and presence in the Navy Marine market.

Giannini also developed and maintained the management team which will continue to lead the company. He dedicated time and energy to industry-leading organizations, serving as Chairman of the Aircraft Carrier Industrial Base Coalition (ACIBC) since its inception in 2004. He also sat on The American Supply Association’s (ASA) Industrial Piping Division Steering Committee and served on ASA’s Board of Directors.

New president and COO John Labellarte started with Milwaukee Valve in 1999 as General Manager. He was promoted to Vice President and COO in 2006. During his tenure, Labellarte has been instrumental in driving the company’s global manufacturing initiatives, strategic planning, product development and operational performance. His focus on continual improvement and the utilization and development of new technologies will continue to build brand value and value proposition for the company. Prior to joining Milwaukee Valve, Labellarte worked for 12 years with the Marpac & McCANNA Valve companies, serving in operations and management roles. He is extremely qualified to lead Milwaukee Valve, with 35 years of executive and operations management experience in the valve industry.

In its 121st year of business, Milwaukee Valve Company is internationally recognized for state-of-the-art manufacturing facilities and innovative new products covering a wide range of commercial and industrial applications.

By Jonathan Simon In plumbing, like many trades, knowledge is often shared plumber-to-plumber in the field. That allows experience to get passed from one generation to the next. But sometimes the information shared doesn’t keep up with new developments or, like a childhood game of “telephone,” gets distorted over time and becomes inaccurate. The result Read more

By Jonathan Simon

In plumbing, like many trades, knowledge is often shared plumber-to-plumber in the field. That allows experience to get passed from one generation to the next. But sometimes the information shared doesn’t keep up with new developments or, like a childhood game of “telephone,” gets distorted over time and becomes inaccurate. The result is the proliferation of “myths” that are accepted as true by some but are provably false. Here are five myths related to CPVC plumbing systems that the FlowGuard Gold® CPVC team has encountered in the field–and the truth behind the myth.

Myth 1: CPVC should be replaced when it shows signs of discoloration

It’s easy to see how some myths get started. A plumber may think that discoloration is an indication of structural weakness, decides the pipe needs to be replaced and passes that “tip” onto a younger plumber.

But older CPVC pipes that show signs of discoloration do not need to be replaced. CPVC naturally becomes more rigid as it ages and may discolor, but these factors do not increase the risk of failure in a properly installed and serviced system. In fact, the pressure-bearing capability of CPVC pipes improves with age, so, by that measure, an older CPVC pipe is actually stronger than it was when first installed.

It is recommended that plumbers use C-style cutters, a wheel cutter, or a fine-tooth saw when servicing older CPVC pipes, but there is no reason to remove the pipe from service due to discoloration. One of CPVC’s strengths is the material’s long service life—some of the first CPVC pipes ever installed back in the 1960s are still in service today–and discoloration is not a reason to shorten that service life.

Myth 2: CPVC is difficult or slow to install

Some myths are rooted in misperceptions and false assumptions while others can be traced to competitors seeking to gain traction in a competitive market. The myth that CPVC is difficult to install falls into the second category.

CPVC plumbing systems are similar to copper in their design. Both are rigid systems that use socket-style fittings in which the pipe fits into the fitting. But CPVC is easier to work with than copper and the solvent welding process used to bond CPVC pipes and fittings is simple, easy to learn and does not require any special tools. CPVC plumbing systems install faster than copper and have installation times that compare favorably to PEX systems.

Independent research studies that measured installation times for CPVC and PEX systems found that CPVC trunk-and-branch systems install up to 17% faster than comparable PEX trunk-and-branch systems. A PEX mini-manifold system installed 10% faster than a CPVC trunk-and-branch system but used 21% more pipe and the added material costs outweighed the time savings. Most plumbers with experience using both materials have reported no noticeable speed difference between CPVC and PEX plumbing systems.

Myth 3: CPVC can’t handle higher pressures and temperatures

A review of material specifications will quickly dispel this myth. Plumbing codes require that domestic water plumbing systems be capable of handling at least 100 psi of pressure at 180°F without ballooning or bursting. FlowGuard Gold pipes and fittings not only meet this requirement but are pressure rated to 400 psi at room temperature and above 200 psi at all temperatures up to 140°F. When subjected to extreme quick-burst testing, a solvent-welded FlowGuard Gold CPVC plumbing system will not typically fail until the system reaches pressures of 1200 psi or higher.

In addition, CPVC isn’t subject to additional temperature and pressure limitations imposed by chlorinated water on other plastic plumbing systems (140° F and 80 psi). That makes CPVC ideal for higher temperature applications such as hot water lines. It can even support legionella mitigation strategies that store water above 140°F. In multi-story buildings, CPVC’s excellent pressure rating enables use of gravity-fed distribution systems and booster pumps that can introduce risks to other plastic plumbing systems.

Myth 4 CPVC is not as sustainable as other plumbing systems

You might expect a plastic piping system like CPVC to be less sustainable than a metal system like copper, but CPVC has excellent sustainability credentials.

FlowGuard Gold CPVC requires less energy to manufacture and produces fewer greenhouse gases over its service life than PEX and copper systems. The material’s long service life, enabled by its chlorine immunity, means less material is ultimately required to support the application. Plus, CPVC is recyclable through proper centers.

FlowGuard Gold CPVC is also the only residential plumbing system certified by Home Innovation Labs National Green Building Standard (NGBS) and has a lifecycle assessment to contribute to LEED certification.

Myth 5: CPVC is more expensive than other plastic plumbing systems

Plumbers who haven’t compared material costs can be forgiven for believing CPVC is one of the more expensive plumbing systems. After all, FlowGuard Gold CPVC is the only material in the industry that offers a warranty that isn’t voided by exposure to chlorinated water, putting it in a class by itself. It doesn’t make sense that it should be less expensive, but it is. According to a cost study done by a leading PEX manufacturer, CPVC material costs were half the cost of their own PEX system.

These savings come from two key areas: fittings and pipe sizing. While a PEX system contains about 30% fewer fittings than a CPVC system, those fittings (and the crimp, cinch or expansion rings that go with them) typically cost 3-5 times more than the comparable CPVC fitting. In addition, because those insert fittings introduce significant pressure drop at ½” diameters, PEX systems are typically upsized to use more 1” and ¾” pipe than required with a CPVC system, saving even more money. You can verify this yourself by comparing PEX and CPVC costs on your next job.

Better Information Leads to Better Service

Plumbers looking to deliver the best service to their customers and grow their business should be careful not to take everything they hear at face value. There are resources available that provide reliable information about plumbing systems, including manufacturer websites. To get more information on CPVC, visit the plumber’s resource center on the FlowGuard Gold website.

While he’s not busy with his day job working on hydronic heating systems, commercial and residential plumbing, backflow prevention and gas work, Chris Massaro (@nwo_plumber) loves playing guitar and recording music. Admiring the recent tattoo to commemorate his daughter’s birth, “I was in a bunch of bands throughout high school and recorded an album once Read more

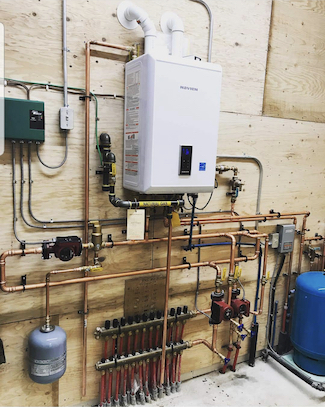

While he’s not busy with his day job working on hydronic heating systems, commercial and residential plumbing, backflow prevention and gas work, Chris Massaro (@nwo_plumber) loves playing guitar and recording music. Admiring the recent tattoo to commemorate his daughter’s birth, “I was in a bunch of bands throughout high school and recorded an album once. I don’t get around to it as much as I used to or like to, but I’m definitely making more time for that now,” says Massaro, owner/lead tech at Aqua North Plumbing and Heating Ltd., Thunder Bay, Ontario, Canada.

While he’s not busy with his day job working on hydronic heating systems, commercial and residential plumbing, backflow prevention and gas work, Chris Massaro (@nwo_plumber) loves playing guitar and recording music. Admiring the recent tattoo to commemorate his daughter’s birth, “I was in a bunch of bands throughout high school and recorded an album once. I don’t get around to it as much as I used to or like to, but I’m definitely making more time for that now,” says Massaro, owner/lead tech at Aqua North Plumbing and Heating Ltd., Thunder Bay, Ontario, Canada.

I take that back. Massaro also enjoys hanging out with friends and family, golfing and mountain biking. And, he definitely needs to get that grill time in—grill, smoke, BBQ. “Sometimes in that order, in one cook. Most of the time I do use the smoker though. I’ve been on a pulled pork kick lately. My favorite is some nice pork shoulders on the Traeger. It’s the ultimate dad activity, in my opinion,” says Massaro.

The work\life balance has been a struggle for Massaro; he realized one day that when you are running your own small business sometimes there isn’t a balance. You have to make the time and prioritize it. “Do what’s important to you and make time for the people and activities you love. And most importantly, take care of yourself! Because you’re worth it. Time stands still for no one so spend it wisely,” says Massaro.

And that’s why staying physically fit and active is important to Massaro. “I’m always lifting, bending, up and down the stairs all day so it’s helpful to have a training regimen that supports that. And, it really helps to keep me in mental shape as well,” say Massaro.

And that’s why staying physically fit and active is important to Massaro. “I’m always lifting, bending, up and down the stairs all day so it’s helpful to have a training regimen that supports that. And, it really helps to keep me in mental shape as well,” say Massaro.

Even more important is eating right, says Massaro. “We use a lot of energy in a day in the trades so we have to keep that fire fed. All of this allows me to stay energized all day and still have plenty of gas in the tank when I get home for family time,” continues Massaro.

Massaro’s foray into the trades started when he starting working for the family business as a plumbing apprentice at the age of 13. “Made best friends with my shovel and we went to work. Thankfully, I graduated from digging trenches and went on to start really learning about the ins and outs of the trade,” recalls Massaro.

Over the next few years, Massaro spent most days plumbing residential systems with a few commercial jobs sprinkled in here and there while working for my father. “It was nice to be doing a bit of everything and not just strictly one area of the trade, which I felt was important to be a well-rounded tech.

Once Massaro had a few years under his belt, he did a lot of remote northern work for fly-in communities. “Those big jobs we did up there really sharpened my time and material management skills,” says Massaro.

In addition, the high school Massaro attended offered a cooperative education program where he was able to gain work experience hours toward his apprenticeship if he chose to stick with plumbing. “I would go to regular classes for the morning periods then co-op at Aqua North in the afternoon,” says Massaro.

In addition, the high school Massaro attended offered a cooperative education program where he was able to gain work experience hours toward his apprenticeship if he chose to stick with plumbing. “I would go to regular classes for the morning periods then co-op at Aqua North in the afternoon,” says Massaro.

As a side note, Massaro says that if your local high school offers a cooperative education program, he highly recommends getting involved. “It’s a really pressure-free way to get your feet wet in whatever trades the school offers,” says Massaro. “I always try to take on one co-op student per year and leave them with a positive experience in the trade. I feel that’s the best way for kids to feel out what they want to do. And, don’t be afraid to ask questions!”

Next, after getting all of his trade school and work hours complete, Massaro then wrote his exam for his certificate of qualification in plumbing. Shortly thereafter, Massaro bought the family business, and the rest is history.

As fourth-generation plumber, Massaro has had some great mentors in his career, with plenty of help and guidance from his father and grandfather in learning new and old ways of plumbing. “If my great grandfather was around then I’m sure he would have some real old school stuff to show me.”

As fourth-generation plumber, Massaro has had some great mentors in his career, with plenty of help and guidance from his father and grandfather in learning new and old ways of plumbing. “If my great grandfather was around then I’m sure he would have some real old school stuff to show me.”

And while Massaro doesn’t consider himself a role model, he’s always willing and ready to help others to do their best at work, and life in general. “I’ve learned a lot over the years and sharing the experiences and knowledge with up-and-coming tradespeople is paramount,” says Massaro.

For Massaro, he loves building something from nothing and executing the job. “Sometimes just sitting back after the job is done and being like ‘damn we really did that.’”

Perception Change

The perception of the industry needs to change, says Massaro. “I think the wheels are turning on that as we speak but we’ve got a long way to go.”

Social media is that vehicle for the instrument of change as it’s an easy way to showcase contractor work, and connect with other professionals. “There’s a solid amount of tradespeople out there doing an amazing job. If we can show people that there’s more to plumbing than just plunging toilets, fixing leaks, and back-breaking work, then I think that’s a win,” says Massaro.

Social media is that vehicle for the instrument of change as it’s an easy way to showcase contractor work, and connect with other professionals. “There’s a solid amount of tradespeople out there doing an amazing job. If we can show people that there’s more to plumbing than just plunging toilets, fixing leaks, and back-breaking work, then I think that’s a win,” says Massaro.

Whether it’s new and better tools, techniques, business knowledge, etc., Massaro has learned so much on social media. “It’s awesome that we can connect with people and have such a great community sharing tricks of the trade, meet-ups or even debate if it’s tape then dope—which it is—or dope then tape,” says Massaro.

In the end, as Massaro sets his sights on his career and further enriching his life, a good bucket list item to check off would be getting a recreational pilot’s license. “Always wanted to get into aviation in some way.”

The sky’s the limit.

While endorsements and referrals are used in the early process to narrow down selections, homeowners look at logistical considerations before making their final hiring decision. And, according to Lowe’s State of the Pro report, price is almost always a top factor for homeowners, with availability to start and final written bid coming in close behind Read more

While endorsements and referrals are used in the early process to narrow down selections, homeowners look at logistical considerations before making their final hiring decision. And, according to Lowe’s State of the Pro report, price is almost always a top factor for homeowners, with availability to start and final written bid coming in close behind. Learn more about homeowners’ expectations and how to meet them here.

While endorsements and referrals are used in the early process to narrow down selections, homeowners look at logistical considerations before making their final hiring decision. And, according to Lowe’s State of the Pro report, price is almost always a top factor for homeowners, with availability to start and final written bid coming in close behind. Learn more about homeowners’ expectations and how to meet them here.