Being informed on the safety of drain cleaning and the dangers of it is very important when out in the field. Whether it be knowing what drain cleaning tools should be used for the job, what safety gear to wear and proper care for your equipment. In this blog post, we will discuss the dangers Read more

PPE

Being informed on the safety of drain cleaning and the dangers of it is very important when out in the field. Whether it be knowing what drain cleaning tools should be used for the job, what safety gear to wear and proper care for your equipment. In this blog post, we will discuss the dangers and safety measures that plumbers should be aware of.

Dangers in drain cleaning

Dangers in drain cleaning

Dangers can be incurred if you use the wrong tool for the job. For example, if you have too small of a cable in too large of a drain or too large of a cable in too small of a drain, you can get the cable caught and you can cause damage to the equipment.

Also, if this should happen and you aren’t using a power feed with a guide tube on it to separate the user from the cable, there is the possibility that you can get a kink in the cable and it can grab the user by the hand or the arm—which can hurt!

Operating drain cleaning equipment should be more like using a drill than a hammer. The user should leverage the rotation of the cable and the cutter to eat its way through the obstruction, applying gentle, forward pressure. Using the right drain cleaning machine can significantly reduce the risks associated with drain cleaning.

Finally, because you are using electricity in the vicinity of water flow, make sure your electrical source is grounded with a properly functioning GFCI to protect from the possibility of an electrical shock.

PPE

Two-ply, leather gloves are highly recommended when using hand tools or drain cleaning equipment, but any kind of gloves that are specifically made for drain cleaning will work. Do not use rubber or cloth gloves, as you run the risk of getting them caught in the coils of the cable. If you must wear rubber gloves, wear them underneath the recommended leather gloves. Protective eyewear is also recommended for obvious reasons. You really don’t need anything else; it’s not necessary to garb up in a hazmat suit for drain cleaning.

Emergency response plan

We like to preach that preventative maintenance is always better than an emergency response plan.

Preventative maintenance would be a plan to regularly snake out drains because you know that if you don’t, they will have the propensity to back up.

The buildup of grease is particularly a problem in multifamily units and food service facilities, which causes emergency situations. For drains that are commonly affected by grease, we strongly recommend that companies invest in small, high-pressure water jetters, which are the right tools for the job.

Grease is not a job for a drum-style cable machine—it will poke a hole in the grease, but it will not remove the grease clog. We recommend preventative maintenance, using a high-pressure water jetter in at-risk pipes on a regular basis as opposed to waiting for them to overflow and creating an emergency. Handling clogged drains, especially when dealing with tough clogs like grease and sludge, requires the right equipment. Preventative maintenance is always easier, cheaper and more time efficient than emergency management.

When investing in basic drain cleaning equipment, companies don’t have to wait for a drain cleaning contractor to come out and do the job. Facility managers can include drain cleaning equipment into their long-term preventative maintenance programs. They will often find additional ways to put the equipment to use that they hadn’t thought of before.

Safely and correctly operating and cleaning equipment and drains

The actual care and preventative maintenance of the drain cleaning equipment should not be overlooked. Every time the machine is used, we recommend that you clean it off and let the water drain out of it. Once the water has been completely drained, we recommend applying snake oil or lubrication to the cables. If you’re using a jetter, you should also clean out the hose and take proper care of the pumps.

Every 200 hours, perform routine maintenance on your equipment—check oil levels, seals, cables and drums. Five minutes of post-job maintenance on equipment will go a long way to preserving your equipment, sometimes for 10 years or more. Maintaining drain cleaning cables and tools is crucial for the longevity of your drain cleaning equipment.

Regular maintenance of your cleaning tools, from a simple sink cleaning hand tool to complex sewer cleaning equipment, ensures longevity and peak performance. Always check for debris that might have been left behind, clean out the drum, and ensure that water is properly drained after each use. Regular upkeep reduces the chances of blockages in your cleaning machine and guarantees that you’re always ready to handle even the toughest clogs.

Here at General Pipe Cleaners, safety is a top priority, which is why it’s important to understand the dangers of drain cleaning and how to perform the job safely.

Questions? Call the Drain Brains at 800-245-6200

Business is all about consistency, longevity, and getting the right results. I’m order to achieve these three things, your company must have everything running in fine order. You’ll do this by adopting the best strategies and recruiting the right people. Failure to do this kind of thing will result in much worse outcomes. Anyone looking Read more

Business is all about consistency, longevity, and getting the right results. I’m order to achieve these three things, your company must have everything running in fine order. You’ll do this by adopting the best strategies and recruiting the right people. Failure to do this kind of thing will result in much worse outcomes. Anyone looking to create a more competitive business will know the standards that should be set.

In among all of this, there needs to be a level of safety and steadiness. Without a steady ship, your business might fall to pieces in a matter of weeks. You never know what might go wrong in business, so you must prepare for all sort of eventualities. Serious danger can strike when you least expect it. Here are a few ways you can prevent or stop problems like these from happening:

Identify Hazards With Comprehensive Risk Assessment

Understanding what can happen in any given eventuality will help with preventing issues. A thorough risk assessment is something that any serious business needs to take care of. You’ll be able to identify potential hazards and deal with them accordingly. Faulty equipment and sleepy surfaces are just two examples of what can be taken care of. A regular review will help to update the situation and progress as new risks inevitably emerge. Taking part in something like this is proactive – which is a huge step up from reactive competitors.

Train Employees Robustly

Comprehensive training programs will turn your employees into much more competent individuals. They won’t exactly be useless when it comes to certain issues, but training will only be beneficial in the long run. Emergency procedures and equipment usage should be talked about regularly. There will be changes and things will evolve all of the time, so regular training is paramount.

Possess The Right Emergency Plans For Any Situation

Over the course of your tenure in business, there will be emergency issues from time to time. It’s unheard of that’s a business will be around for years without dealing with something like this. Let your employees know about evacuation routes and assembly points. include protocols for medical emergency and fires.

Maintain And Inspect The Premises Efficiently

Maintenance schedules should be implemented for all equipment and machinery. These inspections will ensure that detections are found earlier. Potential malfunctions in deterioration are very common in many workplaces. For instance, incorporating devices such as aquatrol safety valves in the industrial world makes plenty of sense as they will be able to prevent pressure related accidents from happening.

Communicate Effectively With Everybody In The Workplace

A culture of safety will mean that sensible behavior is a given. If every employee is comfortable with reporting near misses and concerns, you will be in a much safer environment each day. Anonymous reporting mechanisms are agree addition, too. When everybody works together, the entire workplace becomes a much better place to spend time. A collaborative environment, with everybody actively participating in identifying risks, can ensure success happens sooner rather than later.

A century of head protection innovation defines the Bullard CEN10™ Helmet. Designed to provide wearers with the reliability, comfort, and toughness expected from a Bullard industrial hard hat. Sports the distinctive Bullard 3-rib trademark design that is easily recognizable on worksites across the globe. The modern matte finish surface with polished smooth lines design makes Read more

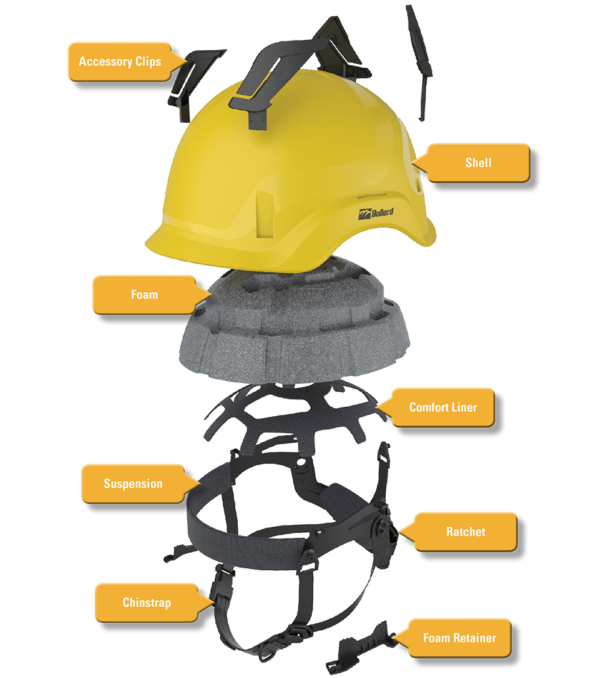

A century of head protection innovation defines the Bullard CEN10™ Helmet. Designed to provide wearers with the reliability, comfort, and toughness expected from a Bullard industrial hard hat.

- Sports the distinctive Bullard 3-rib trademark design that is easily recognizable on worksites across the globe.

- The modern matte finish surface with polished smooth lines design makes the CEN10™ helmet look stylish and unique.

- This helmet is expertly designed to provide the highest level of protection to workers with a 3-point chinstrap for a secure fit when working at heights.

The CEN10 is a hardhat designed to be modern and comparable to a helmet worn in sporting activities such as rock climbing, kayaking, etc. Unlike traditional Type I hard hats, CEN10 is little to no brim, has a foam insert rather than a suspension, and comes with a built-in chinstrap.

Blaklader’s introduces its new Hi-Vis Softshell Jacket that is wind- and water-resistant for use during shoulder seasons or for layering. It features reflective details and tape on the body and sleeves, adjustable Velcro sleeves, front zipper pockets, adjustable collar, detachable hood, extended back, and adjustable hem with drawstring. CERTIFICATION Not certified according to CSA-Z96 MAIN Read more

Blaklader’s introduces its new Hi-Vis Softshell Jacket that is wind- and water-resistant for use during shoulder seasons or for layering. It features reflective details and tape on the body and sleeves, adjustable Velcro sleeves, front zipper pockets, adjustable collar, detachable hood, extended back, and adjustable hem with drawstring.

CERTIFICATION

Not certified according to CSA-Z96

MAIN MATERIAL

92% polyester, 8% elastane, 3-layer softshell, waterproof, windproof, breathable, stretch, 8 oz

FUNCTIONALITY

Dark color field in high grime-exposure sections, Wind and waterproof material, no taped seams

DETAILS

Shoulder sections in contrasting color

High collar

Removable hood

D-ring

Good surface for transfer

FRONT CLOSURE

Robust one-way plastic zipper

POCKETS

Chest pockets with zipper and D-ring

Front pockets with zipper

FINISH

Extended back, Adjustable hem with drawstring

Adjustable sleeve end with velcro

REFLEX

50 mm wide reflective tape, Reflective details, Reflective tape on body and sleeves

The jacket is available in men’s and women’s cuts. www.blaklader.com

It’s no secret that being a plumber can sometimes be a hazardous occupation. When you conduct any plumbing work, you could potentially injure yourself or other people around you, such as your customers, if things don’t go according to plan. Thankfully, there are some ways you can boost your safety while you’re at a customer’s Read more

It’s no secret that being a plumber can sometimes be a hazardous occupation. When you conduct any plumbing work, you could potentially injure yourself or other people around you, such as your customers, if things don’t go according to plan.

Thankfully, there are some ways you can boost your safety while you’re at a customer’s. Plus, here are a few ideas you can follow to protect your plumbing business from litigation.

Take a look at these examples to see what you can consider for your business:

Check Your Tools Before Each Job

As a plumber, you will undoubtedly use an array of hand and power tools to complete your work satisfactorily. You may also use things like gas torches and even welding equipment, depending on the nature of your work.

It’s crucial that you ensure each tool you use is safe before you commence any work at a customer’s premises. For instance, torches shouldn’t leak gas and potentially cause an explosion.

Get the Right Insurance

You will undoubtedly have some insurance coverage for your plumbing business to protect you against the most common legal threats. For example, one type of cover that all plumbers will have is public liability insurance.

Make sure that your insurance policies provide comprehensive coverage for the type of plumbing work you do. Find out more about what to consider with public liability insurance, especially if you work at industrial premises.

Don’t Take On More Work Than You Can Handle

One of the biggest mistakes that some plumbers make is taking on too much work. For example, some plumbing contractors might attempt to repair unfamiliar equipment or pipework because they don’t want to turn the job down.

The truth is, such decisions are incredibly risky. If you don’t fully know what you’re doing, you could possibly cause a dangerous situation – both for yourself and other people in the vicinity.

You should either turn down the job or sub-contract the unfamiliar elements to suitably experienced plumbers in such situations.

Stock the Parts You Will Likely Need

There’s nothing worse than getting to a job and discovering you don’t have the right parts to complete the work. Such scenarios typically mean plumbers will need to go and purchase those parts and make a return journey to their customer’s premises.

Sadly, some plumbers try to get creative by adapting the parts they have available to them. It might be a concept that can work in certain situations; however, it’s not a recommended option for every case.

Wear the Right PPE

Lastly, you should always make sure that you’re wearing the right PPE (personal protective equipment). Doing so means you have some degree of protection in your work, and you are less likely to cause an injury to yourself or other people.

Safety glasses and gloves are the two most essential PPE items you should always have at your disposal. You may need other things, depending on the types of jobs you usually complete.