RLS Will Now Supply Its Patented Press Fittings Exclusively Under Its Own Brand RLS® LLC (“RLS”) will no longer supply its patented press fittings to Parker Hannifin Corporation (“Parker”) for the ZoomLock™ brand. RLS is making this announcement to help avoid confusion in the marketplace as to the source and quality of fittings sold under Read more

Refrigerant Press Fittings

RLS Will Now Supply Its Patented Press Fittings Exclusively Under Its Own Brand

RLS® LLC (“RLS”) will no longer supply its patented press fittings to Parker Hannifin Corporation (“Parker”) for the ZoomLock™ brand. RLS is making this announcement to help avoid confusion in the marketplace as to the source and quality of fittings sold under the ZoomLock brand going forward.

RLS is a subsidiary of Marmon Holdings, Inc., a Berkshire Hathaway company. RLS designs, develops, and proudly manufactures in America its patented fittings engineered for high- pressure connections in the air conditioning and refrigeration industries. By replacing the time-consuming and demanding conventional practice of manually brazing copper joints, RLS’s fittings allow for faster, more consistent connections that reduce total installed cost while enhancing safety.

RLS introduced its patented fittings in 2015 and partnered exclusively with Parker at that time. RLS has since manufactured and supplied millions of fittings for Parker’s Sporlan Division to sell under the ZoomLock brand.

However, RLS recently decided not to renew its exclusive partnership with Parker. This decision was made, in part, because RLS believes discounted pricing provided to Parker was not passed along to customers as intended. Paul Schubert, President of RLS LLC, said Parker has paid back most of the discounts at issue and RLS expects to fully recover the remaining funds.

RLS has also learned Parker plans to source fittings for its ZoomLock brand from Conex Universal Limited (“Conex”) in the United Kingdom.

RLS previously filed patent lawsuits against Conex in the United States and the United Kingdom alleging Conex infringed claims of RLS’s patents. RLS and Conex agreed to settle the lawsuits as reported here. As part of the settlement, Conex agreed, without admitting liability or infringement, that it would stop selling the design of its fitting that RLS accused of infringement in the lawsuits.

Today, RLS’s patented fittings remain the only complete range of refrigerant press fittings and are featured in the Copper Tube Handbook. They are also backed by a 10-year limited warranty and proven by millions of fittings installed.

“To be clear, RLS will no longer supply its patented, proven, and made in America product line to Parker to sell under the ZoomLock brand,” Schubert said. “To ensure end users are equipped with the high-quality product they need and have come to expect, look for RLS’s fittings under its own branding going forward. The RLS brand is your assurance of the same quality connection.”

Visit RLS’s website at www.rapidlockingsystem.com for more information on where to find and purchase RLS’s patented fittings.

RLS is the manufacturer of the original, patented, proven press-to-connect fittings for high-pressure HVAC and refrigeration applications. These are the same reliable fittings that have been in widespread use – and fully registered and listed to UL207 for pressures up to 700 PSI – since 2015. Faster and Easier Using an RLS-approved battery-powered tool and Read more

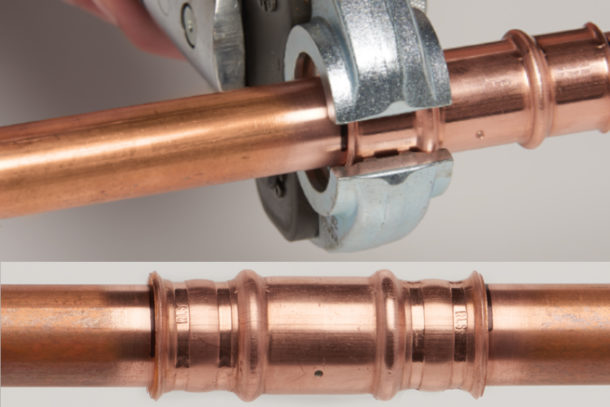

RLS is the manufacturer of the original, patented, proven press-to-connect fittings for high-pressure HVAC and refrigeration applications. These are the same reliable fittings that have been in widespread use – and fully registered and listed to UL207 for pressures up to 700 PSI – since 2015.

Faster and Easier

Using an RLS-approved battery-powered tool and jaws, copper tube connections can be made in less than 10 seconds, resulting in jobs being completed up to 60% faster compared to conventional brazing. So RLS fittings help you get the job done sooner, get to the next job faster and get more jobs done. Plus, no brazing means no hauling brazing equipment and materials from jobsite to jobsite.

Safer

By eliminating the flame from the workplace, RLS press fittings create a safer work environment, removing all the dangers and precautions that come with brazing, as well as eliminating costs:

- No flammable gas

- No fire hazards

- No fire spotters

- No hot work permits

- No nitrogen purging

Reliable

The RLS patented design uses a double circular crimp that work hardens the copper to create a permanent mechanical joint that seals off the O-ring from outside air. The circular crimp also maintains the circular shape of the tube and results in a smooth ID. More than 8 million RLS fittings have been installed worldwide since 2015, so they have a proven track record of dependability. They are also backed by a 10-year limited warranty.

Full Product Line

RLS offers all the products you need to get the job done… couplings, tees, long-

radius elbows, reducers, caps and much more. Current sizes range from ¼” to 1-3/8”, with the “RLS XL” line of 1-5/8" and 2-1/8" press fittings coming later in 2020.

Check with your local distributor for RLS press fittings or visit

www.rapidlockingsystem.com for more information.