Today’s homes are becoming smarter and more efficient, thanks to the advancement of eco-friendly technologies and appliances—from tankless water heaters, low-flow toilets, to self-regulating thermostats. Homeowner Michael Craig, a huge proponent of this technological tide sweeping the country, wanted to upgrade his own 30-year-old residence in Lake Forest, Calif. “My wife and I are always Read more

tankless

Today’s homes are becoming smarter and more efficient, thanks to the advancement of eco-friendly technologies and appliances—from tankless water heaters, low-flow toilets, to self-regulating thermostats. Homeowner Michael Craig, a huge proponent of this technological tide sweeping the country, wanted to upgrade his own 30-year-old residence in Lake Forest, Calif.

“My wife and I are always looking for ways to incorporate advanced technology into our lives,” says Craig, himself a tech expert and owner of Bytelaunch, a digital marketing agency based in Orange County.

In particular, Craig zeroed in on replacing his storage tank water heater with something smarter and more efficient. “We had been considering installing a tankless water heater for a long time and kept the storage tank only because it had been brand new when we moved into our home,” recalls Craig. “After a few years, we were ready to pull the trigger.”

In the spring of 2017, he learned that Noritz had a tankless solution exceeding his expectations.

An EZ Solution

Craig decided to install the ENERGY STAR-certified EZ98-DV high-efficiency, condensing tankless water heater, designed to replace 50-gallon, storage-tank models directly. His installer, Jay Baril of Swift Water Heater, happened to be beta testing the unit for Noritz. The 0.97 energy factor of the EZ98 convinced him this was a green device he wanted in his home. “Unlike our old storage-tank water heater, which burned energy heating unused water, the EZ98 promised to fire only when we needed hot water,” explains Craig.

In addition to yielding energy savings, the EZ98 would bring Craig’s water heating system into the 21st century with its WiFi capability. By downloading the Noritz Connect app, he could take advantage of various remote functions, such as controlling the unit’s temperature and viewing error codes. “The mobile app was a big incentive for us because of our interest in the latest ‘internet of things’ innovations and smart-home trends,” says Craig.

Finally, the EZ98 unit’s direct-replacement design is intended to streamline hookup for installers swapping it in for a storage-tank unit:

- Unlike traditional tankless models, which offer only bottom-mount water-supply connections, the EZ98 unit’s connections are top-mounted—just like on the storage-tank unit being replaced. This eliminates the need to run additional plumbing lines, saving time and labor on the water connections.

- Venting options are also flexible, ranging from dual- or single-pipe (made of PVC or CPVC), to 2-inch Flex, which can be fed through the existing B-Vent.

Installer Baril opted for the 2-inch Flex for venting. He was also able to utilize the same half-inch gas line as the storage tank being replaced, avoiding the hassles and expenses of upsizing. The five-year industry veteran confirms that its configuration creates the potential for time savings.

“The engineers designing this unit put a lot of thought into streamlining the installation, which is always what plumbers look for in evaluating a new solution,” says Baril, who commonly works with storage tank heaters but was impressed with the tankless unit’s ease-of-installation. “The mounting bracket makes the unit easy to position, eliminating the need for a second installer. The top-mount connections are super easy and look very professional. The defining benefit for me, though, was the ability to use the existing B-Vent, not only in terms of saving time, but also because it means I never have to turn down an installation for lack of venting options.”

Comfort and Savings

Immediately after the installation, Craig reported low water pressure, which was later tied to a problem in the piping system and repaired. For its part, the EZ98 began heating the 1,800-square-foot home without issue, supplying hot water for three full bathrooms, a laundry room and a kitchen.

“The water pressure is now perfect, and the heat feels much more consistent across all our fixtures than previously,” says Craig, discussing the improved comfort he and his wife enjoy. “There are no more worries about running out of hot water in the middle of a shower, and the remote control with the wireless app is super-convenient, fitting right into our smart-home goals.”

The wall-hung unit also delivered one other key benefit: “The tankless water heater uses up much less real estate,” notes Craig. “We keep a washer and dryer in the same room, and now there’s more space to maneuver around these appliances.”

Last, but far from least, the switch to tankless is having a positive impact on Craig’s pocketbook. Since the EZ98 fires only on demand, the gas savings began to accrue from Day One. In 2016, with the storage tank heater, Craig’s monthly gas bill totaled an average of $17.19. In 2017, with the tankless water heater in place, the average monthly bill has decreased to $14.14. Estimates Craig, “We are saving an average of 17.7 percent on our monthly gas bill, largely due to tankless.”

In addition to the tankless water heater, Craig is gradually adding other smart, energy-efficient products to his lifestyle. He drives an electric car; has installed a thermostat that “learns” a user’s habits and adjusts accordingly; and has even considered adding solar energy to his home.

“Where others see a 30-year-old home, my wife and I see an opportunity to evolve into something greater and more sustainable,” explains Craig. “Who knows what we’ll upgrade next?”

Tankless water heaters can provide a virtually constant, uniform hot water temperature on demand, unlike their traditional, storage tank-based counterparts. Consumers can typically save up to 40 percent in annual energy costs versus tank-type water heaters. To enjoy the full benefits of tankless water heaters, the system must receive routine maintenance, as it’s a key Read more

Tankless water heaters can provide a virtually constant, uniform hot water temperature on demand, unlike their traditional, storage tank-based counterparts. Consumers can typically save up to 40 percent in annual energy costs versus tank-type water heaters. To enjoy the full benefits of tankless water heaters, the system must receive routine maintenance, as it’s a key component for a long service life and high performance.

Maintenance Service Checks

By conducting proper recommended maintenance, tankless units are expected to last far longer than tank-type units. While a conventional water heater typically requires replacement every seven to 10 years, the tankless model could last up to 20 years with recommended annual maintenance. Before servicing any tankless water heater unit, always shut off the electrical power supply, manual gas valve and water valves. Annual maintenance includes inspecting the venting system, combustion chamber, burner, pressure relief, water filter and condensate trap. Maintenance also includes descaling the heat exchanger yearly and cleaning the fin coils of the heat exchanger bi-annually (every two years). Examine the water heater and its components for wear or fatigue and immediately repair all faults to avoid damage to the system.

Know the Water Quality

Water quality can have an impact on appliance longevity and may void the manufacturer’s warranty, as well. For water analysis data call your local water department, or if on a well, have well water analyzed periodically. If the tankless water heater is operating in applications where the outlet temperature exceeds 140°F, a water softening system is strongly recommended. The higher the set temperature is on the appliance, the greater the risk for scale/mineral deposits.

Minimize Scale Buildup

In areas where the water supply has a high mineral content, the heat exchanger should be flushed with a descaling solution. Scale buildup will shorten the life of the water heater and damage resulting from scale may not be covered under the manufacturer’s warranty. A water softener is required if the water hardness exceeds 6 grains/gal (180 mg/l) calcium carbonate. In the Bosch Greentherm 9000 series, the unit’s lifespan is aided by a primary copper heat exchanger and a secondary stainless steel heat exchanger to minimize scale buildup.

Winterize Your Unit

In addition to routine maintenance, tankless water heaters should also be winterized for seasonal use. If the unit must be installed in a location where it may be exposed to freezing temperatures, all the water needs to be drained from the heater. For full details on maintenance and winterizing tankless water heaters, always consult the manufacturer’s installation and maintenance instructions.

Like check-ups at the doctor and car inspections at the auto shop, routine maintenance on tankless water heaters helps address any repair issues early and ultimately extends the life of the unit.

Craig Porter, Bosch Thermotechnology

Somewhere 37,000 feet above the Pacific Ocean, Eric Silva texted me that he had embarked on a journey of a lifetime. Chosen among a select group of contractors to accompany Navien execs to the company’s headquarters and production facilities in South Korea, Silva was excited, yet humbled, to visit the global HQ, take in some Read more

Somewhere 37,000 feet above the Pacific Ocean, Eric Silva texted me that he had embarked on a journey of a lifetime. Chosen among a select group of contractors to accompany Navien execs to the company’s headquarters and production facilities in South Korea, Silva was excited, yet humbled, to visit the global HQ, take in some sights and attend the 2018 Winter Olympics. “Who would have ever thought plumbing would take you to something like this?” asked Silva. “Why me? This is a very unique and humbling opportunity.”

Somewhere 37,000 feet above the Pacific Ocean, Eric Silva texted me that he had embarked on a journey of a lifetime. Chosen among a select group of contractors to accompany Navien execs to the company’s headquarters and production facilities in South Korea, Silva was excited, yet humbled, to visit the global HQ, take in some sights and attend the 2018 Winter Olympics. “Who would have ever thought plumbing would take you to something like this?” asked Silva. “Why me? This is a very unique and humbling opportunity.”

At the age of 17, Silva initially got into plumbing by digging basements for his uncle, who was a union residential contractor. A few months later—at the age of 18—Silva decided to apply to the local plumber’s union, at which he was initially rejected for what he says as being too “high profile.” Silva, outspoken on many topics in the trade, and rightfully so, indicated that union officials weren’t too elated with his “cockiness” when he responded, “in one of your chairs” when asked where he saw himself in 10 years.

Yet, Silva was just being forthright in his response. To be fair, Silva saw big picture: he also wanted his journeyman’s card and he wanted to own his own business one day. Realistically, Silva was confident and measured in his approach, and he was being honest, traits that he has carried with him to this day.

In 2000, Silva ultimately was accepted into the UA Local 98 Plumbers & Pipefitters, Madison Heights, Mich., to which he is eternally grateful for the education he received there. By 2005, Silva was running neighborhood service north of Detroit as a foreman for a large residential contractor, focusing on residential water heaters and boilers, hydronic and gas piping.

Fast forward to 2010—during the country’s economic downturn, Silva decided to go on his own to start Silva Mechanical LLC, Walled Lake, Mich., a one-man shop that specializes in tankless water heaters, hydronic heating, on-demand boilers and backflow testing. A difficult decision for sure, but one Silva may have been forced to make.

“When the economy went down, much like a lot of other guys, you didn’t have anything to fall back on but plumbing,” says Silva. “It was a sink- or swim-type deal. You never know what you are able to accomplish until your back is pushed up against the wall. We are all faced with adversity everyday; life obviously gives us a number of decisions,” says Silva.

Fortunately, in 2011, there was a resurgence in new residential construction, which gave him enough work to propel him forward, and Silva has not looked back since. “As workplaces continue to shrink, more and more people are starting on their own,” says Silva. “For those just getting into the trade, you have the ability to make it what you want it to be.”

A self-proclaimed enthusiast and believer in everything he sets out to do, Silva puts his best foot forward in servicing on-demand water heaters and boilers. In fact, a recent customer review of his work said, “We chose Silva Mechanical and its Navien package because of the company’s product knowledge, enthusiasm, and peace of mind knowing that the installer is the master plumber and mechanical contractor who’s doing the install, and it’s the most inclusive installation package.”

That is saying something, especially in a time when the plumbing industry faces a number of obstacles: DIYers, big box store renegades, bad installs and guys competing for work against those less experienced, or those not even licensed. According to Silva, bad installs and installers are the death sentence of the trade. In Michigan, says Silva, only one member of a plumbing shop needs to be licensed. “Wrong installations are killing the trades.” The concern then becomes underqualified workers overcharging customers. “I’m not going to sell you a high-dollar product and hope that it works,” says Silva. “Some companies are motivated by sales; I sell product lines at an affordable price.”

Everyday Silva crosses paths with somebody who knows someone who has had what Silva calls a “junk unit,” and his goal it to take that skeptic and make them a believer. “Every company believes they deserve the highest premium because of their ‘extensive training,’ yet we’re providing customers the highest quality materials, and still matching or beating our competitor’s price with a more inclusive package,” says Silva.

Everyday Silva crosses paths with somebody who knows someone who has had what Silva calls a “junk unit,” and his goal it to take that skeptic and make them a believer. “Every company believes they deserve the highest premium because of their ‘extensive training,’ yet we’re providing customers the highest quality materials, and still matching or beating our competitor’s price with a more inclusive package,” says Silva.

In a day and age when contractors look to diversify their business to increase income streams, Silva is doing just the opposite. As a licensed and insured master plumber and mechanical contractor, Silva has relied on his core competencies. “I’ve been installing on-demand water heaters for 12 years and never thought I could make it 100% a staple of my business, and realized that maybe I was too diverse,” says Silva.

In the end, it’s still comes down to relationships. For Silva, it’s the relationships he’s built, not only with Navien, but Rinnai, Nortiz, A.O. Smith and Triangle Tube that has allowed Silva Mechanical to stay ahead of the pack. In fact, the company is the first company in the U.S. as A.O. Smith approved for tankless products, says Silva.

In the end, it’s still comes down to relationships. For Silva, it’s the relationships he’s built, not only with Navien, but Rinnai, Nortiz, A.O. Smith and Triangle Tube that has allowed Silva Mechanical to stay ahead of the pack. In fact, the company is the first company in the U.S. as A.O. Smith approved for tankless products, says Silva.

Meanwhile, while other companies claim to be experts, Silva continues to accumulate the accolades. The local area rep, says Silva, coined the company as one of the “premier installers of our state.” A Navien engineer refers to Silva Mechanical as “premium installation, premium service,” and a Navien senior tech nominated him for the contractor of the year in 2017. “An expert is someone that excels in what they know. The only thing the folks in metro Detroit need to know is, ‘Silva Knows Tankless,’” says a confident Silva.

So to answer the original question, “Why Silva?” I have to believe it’s excelling at his job, confident and measured in his everyday approach to the trade, and being a loyal Navien enthusiast who promotes a good product at an affordable price. It’s also the dedication to the product line by continuing education and attending intensive training courses.

So to answer the original question, “Why Silva?” I have to believe it’s excelling at his job, confident and measured in his everyday approach to the trade, and being a loyal Navien enthusiast who promotes a good product at an affordable price. It’s also the dedication to the product line by continuing education and attending intensive training courses.

Ultimately, it is being damn good at what you do, would be my answer. Yet, perhaps it’s in the simplicity of Silva’s overall message to service contracting, “Give the customer a greater service than what they originally had.”

For more information on Silva Mechanical, www.silvamechanical.com.

Navien tankless water heaters have been in the US market for quite some time, I recently installed the latest model in my own home. I live in central Minnesota, in a rural area where until this summer I had not had access to Natural Gas. Two Navien NPE-240A condensing tankless water heaters have now replaced Read more

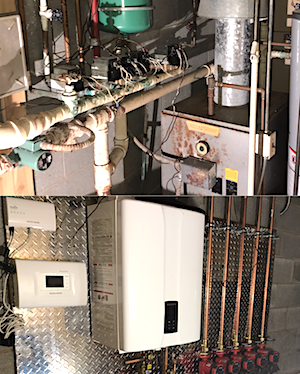

Navien tankless water heaters have been in the US market for quite some time, I recently installed the latest model in my own home. I live in central Minnesota, in a rural area where until this summer I had not had access to Natural Gas. Two Navien NPE-240A condensing tankless water heaters have now replaced existing, 13 year old, tank water heaters. Here’s my take on the build, installation and overall performance.

First off, as with all tankless water heaters careful consideration must be taken to calculate needed performance values such as total flow rate needed, gas supply available, venting options, recirculation requirements and water temperature delta-t.

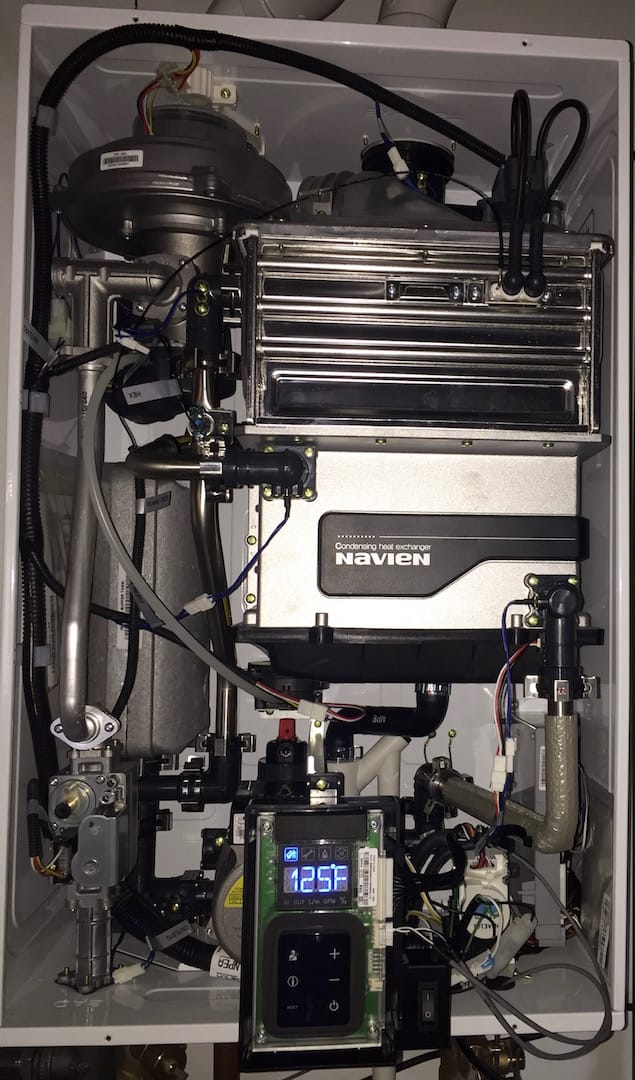

The Navien NPE-240A has a minimum input of 19,900 Btu/h with its maximum topping off at 199K. The negative pressure gas valve and fan with dual venturi operation allows for better adaptability to low gas pressure applications. Operating gas pressures of 3.5” w.c. – 10.5” w.c. are required. The dual stainless steel heat exchangers are an industry exclusive [at time of posting this review].

2” & 3” 2 in or 3 in PVC, CPVC, Polypropylene & Special Gas Vent Type BH (Class II, A/B/C) are listed as optional venting sizes and materials for both the intake and exhaust.

The NPE-A models features the “Comfort Flow” built-in recirculation system that monitor use patterns and closely match the hot water needs of the home or commercial building in an effort to eliminate the “cold water sandwich” that plagued the early tankless installs for so long. A built-in buffer tank and recirc pump are included.

The NPE-240A model has ¾” water, recirculation and gas connections. The unit comes equipped with a standard 120V appliance cord [installed] and operates between 200 and 300 watts (max 3 A with external pump connected).

The typical safety devices included are a flame rod sensor, ignition operation detector, water temp high limit switch, power surge fuse and an exhaust temp high limit sensor.

I have to point out that the overall size of the NPE-240 is rather large when compared to other top brands on the market. To be honest, this is a positive in my opinion. The larger cabinet affords more room inside. Where other tankless models are ultra cramped, this one is slightly less cramped. A little larger cabinet and heat exchanger adds to the total weight, the NPE-240A (w/ hot water circ pump & buffer tank) tips the scale at 82lbs. The cabinet measurements are as follows: 29” tall, 17” wide, 13” deep.

I have been installing and servicing tankless water heaters for a little over fifteen years. In that time dozens of models have came and went, none of them had the built-in features that the NPE has. The ability to operate under such low gas supply pressure, link up to 16 units in one group easily with a simple cable and control configuration. Common venting is a breeze too, though standard individual venting in 2” PVC/CPVC/PP can go as long as 60’. The 0.01 minimum flow rate for the “A” model is outrageously low when compared to the units we were installing as recent as 5 years ago.

In summary:

My family hasn’t noticed any changes since I made the switch to tankless. The installation was extremely simple, more so than other models I have installed in the past. I’m impressed by the easy to read and access front control and just how quiet the NPE model is; it’s nearly silent.

I’ll update this review if any issues arise over the next year. Thanks for your time, I hope you found this useful.

Eric Aune

Aune Plumbing, LLC

A. O. Smith launches the Simplicity Series of concentric venting, non-condensing tankless water heaters — designed to make installations simple and flexible through a new gas convertible combustion system. Alongside the energy-efficient technology built into every A. O. Smith tankless product, this newline will please installers and distributors alike, according to David Chisolm, vice president Read more

A. O. Smith launches the Simplicity Series of concentric venting, non-condensing tankless water heaters — designed to make installations simple and flexible through a new gas convertible combustion system.

Alongside the energy-efficient technology built into every A. O. Smith tankless product, this newline will please installers and distributors alike, according to David Chisolm, vice president of marketing for A. O. Smith.

“These units were built using a concentric vent design, which allows for simpler and more flexible installations with commercially available venting,” said Chisolm.

The Simplicity Series models come in three sizes and are designed to easily convert from naturalgas to propane – with all necessary components already in the box. This new line will assist distributors in managing their inventories by reducing the number of product variations needed,which ensures product availability as well.

“By incorporating a gas convertible combustion system into the design, we’ve eliminated theneed for our distributors to stock all the typical designs to meet field demand, effectively cuttingtheir product variations in half,” said Chisolm.

Available in 140K, 190K and 199K BTU versions and ULN-certified, the Simplicity Seriesscores a 0.82 EF rating. These new models also come equipped with integrated controls that make temperature adjustment and diagnostic review easier.