Viega adds MegaPress® 316 Spring Check Valves in 1⁄2” to 2” sizes, MegaPress® Ball Valves in 1⁄2”-4” sizes and ProPress ECO Tubing 316 and Manual Balancing Valves for Potable Water Broomfield, Colo. — Viega announces the availability of new products in its MegaPress® and ProPress® product lines. The expanded line of ball valves completes the Read more

Viega ProPress

Viega adds MegaPress® 316 Spring Check Valves in 1⁄2” to 2” sizes, MegaPress® Ball Valves in 1⁄2”-4” sizes and ProPress ECO Tubing 316 and Manual Balancing Valves for Potable Water

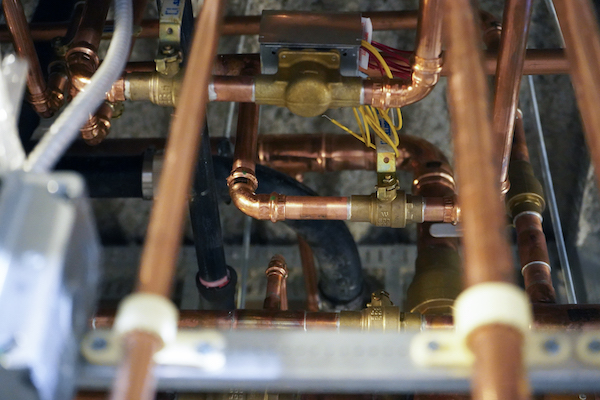

Broomfield, Colo. — Viega announces the availability of new products in its MegaPress® and ProPress® product lines. The expanded line of ball valves completes the MegaPress system and is ideal for commercial and industrial applications, including gas applications. All the valves have Viega’s SmartConnect® technology, which helps installers easily identify unpressed connections during a pressure test. The new products being added to the line of MegaPress ball valves are:

- – MegaPress Ball Valve 1⁄2” to 2” (EPDM Sealing Element) – a full port valve featuring a carbon steel body, double-stem seal, stainless steel ball, and a lockable handle.

- – MegaPress FKM Ball Valve 1⁄2” to 2” (FKM Sealing Element) – this valve has the same carbon steel body, double-stem seal, stainless steel ball, and lockable handle, yet features an FKM sealing element which is designed for use in higher-temperature applications. The 2-1⁄2” to 4” valves feature a carbon steel body, chrome-plated ball and an SST lockable handle.

- – MegaPress 304 FKM Ball Valve 1⁄2” to 4” (FKM Sealing Element) – this valve features a 304 stainless steel body, double-stem seal, stainless steel ball, and lockable handle. The combination of the FKM sealing element and the 304 stainless steel makes this option ideal for harsh environments that require higher operating temperatures.

- – MegaPress 316 Ball Valve 1⁄2” to 4” (EPDM Sealing Element) – this valve works in a variety of harsh environments, including cleaning agents, acid, and potable water. It is made of a 316 stainless steel body featuring a double-stem seal, a stainless steel ball, and lockable handle.

- – MegaPressG Ball Valve 2 1⁄2” to 4” (HNBR Sealing Element) – now available in large diameters, the valves feature an HNBR sealing element at the press-ends which is compatible with fuel and gas applications.

- – MegaPress 316 Check Valve (EPDM Sealing Element) – the check valve helps create directional flow of fluid in one direction while preventing fluid from flowing back. It is ideal for industrial applications, including potable water, rainwater, chilled and hydronic water.

“After 10 years of success, it’s exciting to have the MegaPress portfolio grow with maintenance-free MegaPress ball valves that enable fast, safe and efficient installation from 1⁄2” to 4″. MegaPress 316 spring check valves are a useful addition to the MegaPress 316 portfolio and carry an NSF®-61-372 listing,” said Christian Becker, Product Manager, Valves, of Viega LLC.

Viega also released two new products for the ProPress system – the ProPress Manual Balancing Valve and ProPress 316 ECO Tubing. The ProPress 316 ECO Tubing is a stainless-steel alternative to copper. It’s engineered for commercial potable systems where the piping may come into contact with corrosive cleaning liquids. It is compatible with ProPress 316 fittings and is a great option for potable water, air, acidic and cleaning solution applications.

Viega also released two new products for the ProPress system – the ProPress Manual Balancing Valve and ProPress 316 ECO Tubing. The ProPress 316 ECO Tubing is a stainless-steel alternative to copper. It’s engineered for commercial potable systems where the piping may come into contact with corrosive cleaning liquids. It is compatible with ProPress 316 fittings and is a great option for potable water, air, acidic and cleaning solution applications.The Viega ProPress Manual Balancing Valve features an adjustable handle with an integral scale visible on the side used to increase or decrease the flow rate. The two pressure-test ports are used to measure the differential pressure across the seat of the valve, which can be used to calculate the flow rate. The ProPress Manual Balancing Valve is suitable for commercial applications, including potable and hydronic systems.

“Our customers now have more options to use press technology for a larger number of applications,” said Luke Paulo, Manager, Product Portfolio Development of Viega LLC. “The new ProPress 316 ECO tubing is a natural extension to our existing ProPress 316 line. It carries an NSF®-61-372 listing, which means our ProPress 316 system can be used in potable water systems.”

When millions of gallons of water are traveling through your piping system every month, it’s bound to put wear and tear on the system. The folks at Model Linen Service in Ogden, Utah, realized that huge volumes of water were doing a number on their copper; so in a new laundry facility building, they incorporated Read more

When millions of gallons of water are traveling through your piping system every month, it’s bound to put wear and tear on the system. The folks at Model Linen Service in Ogden, Utah, realized that huge volumes of water were doing a number on their copper; so in a new laundry facility building, they incorporated stainless pipe instead.

Then, in looking at options for connecting the 3” and 4” pipe, they discovered Viega’s ProPress Stainless fittings and thought it could be a better option than threading.

“ProPress made the day!” said Ryan Thon, Chief Engineer at Model Linen. “I’ve been using copper over the years and just found that I wasn’t getting the life out of it. We get so much water volume through the pipes that it wears out the copper. So we decided to go with the Schedule 40 stainless.”

Model Linen services about 700,000 pounds of linen a week. Their main business in the facility where the ProPress fittings are located is restaurant service items like bar towels and floor mats. Running at capacity, Model Linen needed to expand, so they built a 19,000-square-foot facility bordering the original main plant.

When Thon and his crew started on the building in April 2018, circumstances beyond his control meant they had to start threading instead. He said the first quarter of the building was threaded.

“There’s so much time and effort involved with threading Schedule 40 pipe,” he said. “Then [when circumstances changed], I was able to get the press tool and jaws. And I’d say it probably took me the same amount of time to press the other three-quarters of the building with Viega as it did to thread the first quarter!

“It’s a big facility and it took months of time—but pressing made it so much easier. I’d probably still be threading right now!” Thon said with a laugh.

In the building, there is a 4” water main that brings in the cold water. It’s softened and goes into an exchanger. Thon explained that old, dirty water coming from the washers is recycled and feeds through the exchanger to work as a heater. It raises the city water up to about 95 degrees without any heating elements.

“It’s hot water. Why let it go straight into the sewer?” Thon said. “All we’re using is the radiator and pumps to pump it, but we re-water to get our tempered water.”

From there, half of the tempered water goes into the washers and the other half goes through a heater to make hotter, 165-degree-water.

Model Linen does a good job in saving as much water and energy as possible. In addition to using the reclaimed hot water to heat the incoming water supply, the washer’s final-rinse hot water is also reused.

“At that point with the last rinse, the soap is out and it’s clean, so that water drops into its own trench and recirculates to be used in the first part of the wash cycle with the detergent,” he explained. “It’s a pretty cool process instead of using more clean city water.”

In total, nearly 100 Viega fittings were used in Model Linen’s new building, ranging in size from 1¼ ” adapters to 4” fittings in various configurations.

Thon said he’s confident the ProPress Stainless fittings will hold up well to the demands of Model Linen’s system. He said there are not many chemicals that run through the pipes, just a mild softener.

One of the concerns in piping a laundry facility are issues with water hammer, Thon said.

“If the washer has a 3” valve open, that’s a lot of water going in quickly; and if it shuts off too quickly, then it shakes the whole system,” he said. “Luckily we have good equipment dialed in well so that they close slowly. There has been no movement with the pipes at all—I was impressed.”

Thon was so pleased with Viega fittings that they’ll be appearing in Model Linen’s other building a few miles down the road, where all of their hotel linens are serviced. He said he purchased a “whole stack of 3” ProPress Stainless” and was getting ready to tear out all the old copper and put in stainless piping at that facility, too.

“Pressing these fittings down saved the day,” he said simply. “I’ve been pretty impressed with the whole thing.”

Classes to be held in Colorado and New Hampshire Broomfield, Colo. — Viega, LLC has announced its Winter 2019-20 lineup of courses at its seminar centers in Broomfield, Colo., and Nashua, N.H. The offerings include topics from commercial piping solution to radiant design and LoopCAD. With two fully equipped state- of-the-art seminar centers, Viega is Read more

Classes to be held in Colorado and New Hampshire

Broomfield, Colo. — Viega, LLC has announced its Winter 2019-20 lineup of courses at its seminar centers in Broomfield, Colo., and Nashua, N.H.

The offerings include topics from commercial piping solution to radiant design and LoopCAD. With two fully equipped state- of-the-art seminar centers, Viega is an industry leader in supporting the trades and helping contractors become more versatile, skilled and efficient. To date, more than 40,000 people, from self-employed contractors to employees of large firms, have taken courses at the centers.

The classes are taught by experts with years of experience in the field and offer ample hands-on experience. Attendees leave with skills and knowledge that will show immediate benefits on the job.

Training seminars are listed below:

Radiant Design, Piping and Controls

Jan. 27-29, Nashua, N.H.; March 3-5, Broomfield, Colo.

Covers design theory and practice, piping arrangements and control strategies. Includes hybrid systems, multiple temperature piping arrangements and system component placement.

LoopCAD

Feb. 11-12, Nashua; Jan. 22-23, Broomfield

How to use LoopCAD software for radiant design and layouts. Covers heat loss, drawing layout, material selection and snow melt.

Commercial Piping Solutions

Dec. 3-4 and March 18-19, Nashua; March 3-4, Broomfield

Covers Viega systems and products and their appropriate uses. Includes PureFlow, ProPress and MegaPress; hybrid systems; installation techniques; project savings; hands-on installation and competitive information.

Hydronics 101 & Radiant Systems

March 3-4, Nashua; Jan. 16-17, Broomfield

Provides a basic understanding of how hydronic systems work. Topics include methods of heat transfer, piping materials and components, control strategies and installation methods.

Carbon Steel Press Technology

Jan. 13, Nashua

Covers the use of carbon steel press systems for residential, commercial and industrial piping applications.

Stainless Steel Press Technology

Feb. 20, Nashua

Covers the use of stainless steel press systems for commercial and industrial plumbing, heating and piping applications. Properties and chemical compatibility of 304 and 316 stainless steel will be covered.

Press Technology for Fuel Gas Piping

Feb. 3, Broomfield

Covers the use of carbon steel press systems for fuel gas piping in residential, commercial and industrial applications. Fuel types such as natural gas, LP gas, diesel, fuel oil and kerosene and their implications in NFPA 54 will be covered.

NFPA 13D Fire Sprinkler

Covers NFPA 13D requirements, system design, installation concerns and energy code compliance.

For more information and to register, click here.

The Adaptive Sports Center in Crested Butte, Colorado, has been helping people with disabilities, as well as veterans, go on therapeutic recreation adventures for 30-plus years. Now the group is finally getting the building—and the space—it deserves so it can amp up its offerings and help even more people. The nonprofit organization, located in the Read more

The Adaptive Sports Center in Crested Butte, Colorado, has been helping people with disabilities, as well as veterans, go on therapeutic recreation adventures for 30-plus years. Now the group is finally getting the building—and the space—it deserves so it can amp up its offerings and help even more people.

The nonprofit organization, located in the Colorado Rocky Mountains, is constructing a new building all its own. For the past decade, the organization knew it was running short on space, but real estate at the base of Crested Butte Mountain Resort is expensive and hard to come by, so it’s taken a while to make dreams reality.

Two years ago, the organization purchased land and began raising funds. Now the 25,000-square-foot building is just months from opening and leaders of the ASC can hardly wait.

“There has been a lot of work into this new building,” said Brian Barker, Marketing Manager for the ASC. “Our community has been hugely supportive, and we’re lucky to have help from a lot of really generous people and organizations that are both local to the Crested Butte area and across the country. We received donations from local individuals to major foundations and organizations—like Viega—who want to help out, because so many people believe in helping people.”

“There has been a lot of work into this new building,” said Brian Barker, Marketing Manager for the ASC. “Our community has been hugely supportive, and we’re lucky to have help from a lot of really generous people and organizations that are both local to the Crested Butte area and across the country. We received donations from local individuals to major foundations and organizations—like Viega—who want to help out, because so many people believe in helping people.”

Viega helped this project by donating ProPress fittings for the plumbing. In total, in-kind donations for the construction efforts totaled more than $1 million, and Viega had a hand in it. Not only does the donation of ProPress fittings help monetarily, but ASC Executive Director Chris Hensley said it also helps by saving the contractors time—which also equals money.

The schedule for construction of the building was only 13 months, so there was no time to waste. During planning, there were lots of conversations about how to save the ASC money, and ProPress was one solid option.

Alpha Mechanical Solutions, LLC, out of Gunnison, Colorado, was hired to plumb the building, and Fred Niederer, a managing member of Alpha Mechanical, was already familiar with Viega and with ProPress.

“Viega’s training facility in Nashua (New Hampshire) made it possible to see the entire product line and made it easy to justify setting up our first ProPress gun seven years ago,” he said. “Our second gun was a matter of necessity, based on how often we use the Viega system.

“ProPress was really great for this project because it had a very tight timeframe and I couldn’t think of a better product to use. The time savings method over standard joining is huge.”

Alpha Mechanical had between 15 and 20 workers on the project to plumb nearly a mile of copper lines. The copper with ProPress fittings is for hot, cold and hot water recirculation lines, as well as hydronic lines, some variable air volume units, some in-floor heating and a little snowmelt.

“This has been press and go. Easy,” Niederer said.

The building is officially named the Kelsey Wright Building. Kelsey was a longtime participant of the ASC, and after she died her parents gave a generous gift to the organization in her honor to help get the fundraising project started. Barker said her family “really believed in what we do and what we did for her,” and they wanted to share it with others.

The four-story building (plus basement) will allow the ASC to double its capacity. Previously the organization only had the ability to offer overnight accommodations for a group of 15-20 people at a time, at a lodge in town. The new building will have housing on the third floor to allow for a second group to be served at the same time.

The facility is ski-in, ski-out, and fully accessible for all participants no matter their ability. Groups of participants come from various hospitals, VA medical centers, Walter Reed National Military Medical Center and more.

There are other activities and amenities within the Kelsey Wright building as well, including an indoor rock climbing wall, programming area and kitchen facilities. Within the basement there will be lockers that can be rented out as an additional revenue stream for the ASC, and there is an area for participants to be fitted with their skis or other apparatuses before they head out.

Adventures through the ASC don’t just happen in the winter… There are activities like canoeing, cycling, hiking and mountain climbing in the summer, or skiing, snowshoeing and ice climbing in the winter.

Founded in 1987, and originally known as the Physically Challenged Ski Program of Crested Butte, 33 lessons were given during the first winter by an all-volunteer staff. Today, more than 6,000 lessons are provided to more than 700 individuals each year. The team includes 15 board members, 14 full-time staff, more than 25 professional instructors and hundreds of volunteers. The main focus is on the long-term impact of programming on participants, aiming to get—and keep—them more physically active.

Barrel O’ Fun, a snack manufacturer with three locations across the U.S., distributes nationwide to retail stores, food service outlets and private labels. As the company continued to expand its reach, a distribution center was needed for the growing western market, which led them to build a new, multi-million dollar facility in Phoenix. Niemeyer Read more

Barrel O’ Fun, a snack manufacturer with three locations across the U.S., distributes nationwide to retail stores, food service outlets and private labels. As the company continued to expand its reach, a distribution center was needed for the growing western market, which led them to build a new, multi-million dollar facility in Phoenix.

Niemeyer Brothers Plumbing, Inc., also located in Phoenix, did the plumbing work on the new Barrel O’ Fun facility. They knew that stainless steel was the best option for the job because of its quality and performance in washdowns as well as its appealing design for areas where the piping penetrated the ceilings.

Rick Niemeyer, President of Niemeyer Brothers, estimated that the team installed thousands of feet of stainless pipe.

“Viega ProPress was the best choice for this project because of the labor savings and the availability of the products,” he said.

Niemeyer Brothers installed Viega 304 and 316 stainless pipe and fittings, ranging in sizes from ½” to 3″. Applications included nitrogen, process water, compressed air and domestic hot and cold water.

Approved for a variety of applications and available in a vast array of fitting configurations, Viega systems can be installed in multiple applications within the same project. Niemeyer Brothers installed the nitrogen line using Viega 304 stainless, but the potable water system utilizes the 316 stainless because of its NSF rating.

“The entire nitrogen system is all in stainless,” he said. “It worked fantastic. Not only does it look aesthetically pleasing, it’s just the right material for the application.”

As an experienced plumber, Niemeyer wasn’t sure that Viega ProPress would work when he first heard about it, but after installing it in 2008, he experienced the system’s labor savings and trustworthy connections firsthand. Since then, Niemeyer Brothers has continued to install Viega ProPress systems in a greater variety of projects.

As an experienced plumber, Niemeyer wasn’t sure that Viega ProPress would work when he first heard about it, but after installing it in 2008, he experienced the system’s labor savings and trustworthy connections firsthand. Since then, Niemeyer Brothers has continued to install Viega ProPress systems in a greater variety of projects.

“Change is always a little challenging,” Niemeyer said. “But now we install it in more and more projects all the time, especially in hospital and medical work.”

With trustworthy system solutions, Niemeyer Brothers Plumbing, Inc. can count on Viega to help this snack food manufacturer focus on meeting the needs—and taste buds—of its customers.

“It eliminates the welding process, which is definitely slower,” Niemeyer said. “You can press a lot faster than you can weld. The fittings are more expensive, but the installation time you pick up is worth the cost.”

For more information, call 800-976-9819 or visit www.viega.us.

Viega also released two new products for the ProPress system – the ProPress Manual Balancing Valve and ProPress 316 ECO Tubing. The ProPress 316 ECO Tubing is a stainless-steel alternative to copper. It’s engineered for commercial potable systems where the piping may come into contact with corrosive cleaning liquids. It is compatible with ProPress 316 fittings and is a great option for potable water, air, acidic and cleaning solution applications.

Viega also released two new products for the ProPress system – the ProPress Manual Balancing Valve and ProPress 316 ECO Tubing. The ProPress 316 ECO Tubing is a stainless-steel alternative to copper. It’s engineered for commercial potable systems where the piping may come into contact with corrosive cleaning liquids. It is compatible with ProPress 316 fittings and is a great option for potable water, air, acidic and cleaning solution applications.