North Andover, Mass.—Watts Water Technologies celebrated its 150-year anniversary in style this past week as nearly 300 past and current employees, trade press and local dignitaries gathered to celebrate the long-continued success of the company. Keynotes from Chris Jameison, Senior Vice President and General Manager, and Bob Pagano, CEO, and a special presentation from Tim Read more

Watts Water Technologies

Bob Pagano, CEO, Watts

North Andover, Mass.—Watts Water Technologies celebrated its 150-year anniversary in style this past week as nearly 300 past and current employees, trade press and local dignitaries gathered to celebrate the long-continued success of the company. Keynotes from Chris Jameison, Senior Vice President and General Manager, and Bob Pagano, CEO, and a special presentation from Tim Horne, Director Emeritus, Watts Water Technologies kicked off the event.

The goal for Watts moving forward—to paraphrase Jameison— is to “improve comfort, safety and quality of life” for its customers. Pagano echoed that sentiment emphasizing safety, water conservation and energy efficiency as key tenets for the company.

Tim Horne

Horne regaled the audience of stories of his great grandfather breaking ground, mock home explosions and company growth. What started as a $15,000 investment with the purchase of the company from Joseph E. Watts, a machinist who emigrated to Lawrence, Mass., by Burchard Everett “B.E.” Horne, the company grew exponentially over the years due to expansion through acquisitions, and innovations such as the introduction of the T&P relief valve and entering the backflow market among others, for example. The company stayed in the Horne family for three generations where it is now in good hands, run capably by current CEO Pagano. The company is now worth more than $2+ Billion. Yes, that’s with a B. “Anniversaries are actually more about the future than the past,” says Horne.

The trade media experienced cutting-edge technologies with access to six stations manned by Watts/Bradley experts in what was called the 2024 New Innovations Tour.

Phil Jagelski, Senior Technical Instructor and Instructional Designer, Bradley/Watts gives a tour of the Bradvan, while showing Bradley’s Eyewash Station, wash basin, and an impenetrable storage locker, for example.

Oh, before all of that, media members were granted an exclusive tour of one of the “Bradvans,” one of six of Bradley Corp.’s mobile units that traverses the United States. Backstory, Watts acquired Bradley—a veteran manufacturer of commercial washroom and emergency safety solutions, serving the commercial and industrial end markets for more than 100 years—in 2023.

Three vans feature Bradley commercial, more architectural products, while the other three vans feature Bradley’s Safety Industrial Solutions such as the Halo Swing Activated Faucet Eyewash.

Stop 1 saw the future for Watts technology in its Nexa intelligent water management system. Coming very soon, this sensing technology empowers building owners and operators with unmatched insight and control, improving system efficiency, mitigating the risk of water damage, and conserving water and energy to provide the best occupant experience possible.

Stop 2 on the Innovation Tour featured Watts’ Smart Strainer, which prevents suspended particles and debris from damaging downstream equipment. Integrated differential pressure monitoring proactively alerts users to pressure drops, helping to prevent system damage, avoid downtime, and ensure consistent flow.

Nate Kogler talk about Bradley’s Commercial Washroom and Emergency Safety and Industrial Solutions.

Stop 3 was the inclusion of Bradley products, which featured The Elvari™ Collection of washroom accessories seamlessly blends style and substance for a modern, commercial washroom experience. The Halo™ Swing Activated Faucet Eyewash space-saving design combines best-in-class critical safety equipment for swift emergency response. Elegance meets efficiency with the Verge® with WashBar® WB2 1-Station, providing a touchless, all-in-one solution for washing, rinsing, and drying hands.

The Verge with touchless WashBar WB2 1-Station is so slick, and it just makes sense—clean, rinse and dry your hands all in one place.

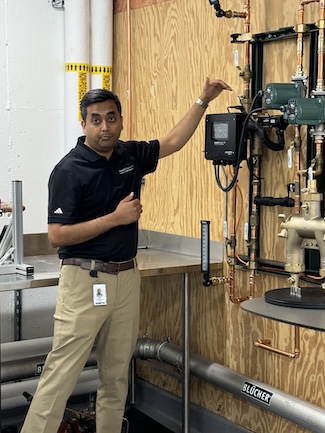

Shashwat Nath demos the Intellidation 2.

Stop 4 featured the The IntelliStation® 2 loT-enabled Digital Mixing Valve, which offers significantly improved performance over traditional thermostatic mixing valves, ensuring consistent water temperatures in low and high-demand situations. IntelliStation 2 seamlessly integrates with Nexa for enhanced system insight and control and comes available in pre-piped

configurations for unique installations.

Stop 5 a highly unique investment of Ultra High-Purity Piping (UHP), which offers clean room piping for ROID, manufacturing, and cooling processes. Molded from highly-durable Kynar® PVDF resin, all piping is made-to-order in North America, ensuring short lead times for faster system build-outs.

Stop 6, the last stop on the Innovation Tour, featured Leak Defense’s BuildAlert™ product, which provides 24/7 job site leak protection, providing protection against flooding even when you’re offsite. With remote monitoring and control, you can prevent costly water damage claims and avoid project delays.

According to the EPA, residential leaks—not including commercial water leakage in this country—wastes nearly 1 trillion gallons of water annually. It’s a widespread problem. Not long ago, Washington Post journalists wrote about a guy, Sam, who went to his rural vacation home south of Chicago. Following a long winter, he found the entire basement flooded with Read more

According to the EPA, residential leaks—not including commercial water leakage in this country—wastes nearly 1 trillion gallons of water annually.

It’s a widespread problem. Not long ago, Washington Post journalists wrote about a guy, Sam, who went to his rural vacation home south of Chicago. Following a long winter, he found the entire basement flooded with eight feet of water. It sat there for weeks because of a burst pipe. In such an instance—especially if the leak happened in the summer—the risk of mold, including the toxic Stachybotrys chartarum (black mold), is substantial.

Post reporters also wrote about a woman who lives on the 35th floor of a condo building. While she was out one day, the water to her drinking water filter broke. Half a day and many gallons of water later, she was able to stop the leak, but a lot damage had already been done: the water had cascaded down through several floors of the building, causing significant damage.

This combination of Sentinel Hydrosolutions Leak Defense System technology guards a penthouse mechanical room in a condo facility, including automatic shutoff valves connected to point-of-leak detectors protecting all water sources, including storage tank, water lines and booster pumps. Two large 6″ valves control all water in the building. Remote control emergency water shutoff is controlled a concierge desk. All images courtesy of Watts.

The ravages of water from hidden leaks can be devastating, expensive. Even permanent.

The good news is that today’s wireless technology can either alert you instantly that there’s a problem, or even shut off the water main automatically or remotely. Some of these devices sense water and send an audible alarm along with a text or email alert so whether you are home or away, you get the alert.

According to Kenneth Fox, VP of Sales and Business Development for Escondido, Calif.-based Leak Defense, a Watts Brand, there are a wide variety of solutions, some being far more durable and effective than others.

Says Fox, the best technologies, including the Leak Defense system, continuously monitor properties for hidden leaks and—if one is detected—automatically shuts off the water and alerts homeowners, property managers or plumbing professionals.

“We’ve found that an on-site control, or mobile app, are the best, easiest way to control water flow,” he added. “With multiple ways to monitor, you’ll always feel protected against potential loss, expense and hassle from water damage. Our full line of accessories allows Leak Defense to work with any type of residential or commercial plumbing system.”

In Atlanta, a facility’s entire water service piping is leak-protected.

For commercial systems, leaks can very easily cause frustration among tenants and legal liabilities and lead to remediation hassles and great expense.

At the very least, not being protected from the risk of water damage from hidden leaks can be stressful. According to Fox, Leak Defense has helped thousands of commercial and multi-family building owners and facility managers easily monitor and protect their properties.

“With modern systems, the status of all leak detection components—from smart controls to sensors—should populate information on a convenient, user-friendly dashboard,” said Fox. “The technology should be capable of catching all types of leaks, including those hidden in under slabs, behind walls and in ceilings.”

Like a security system with ability to shut the door!

Contemporary leak detection and prevention systems should also be effective at turning off water automatically if flow settings are exceeded, or shut off water to selected zones or the entire building. They should also allow manual stopping of water via control or app, and provide round-the-clock monitoring and alarming of all devices—much like contemporary security systems, but with the added capability of shutting the shut the door to deny entry.

To have this remarkable capability, a Leak Defense valve must be installed on the main water line and downstream of the primary shut-off valve, pressure regulator, irrigation line and fire sprinkler line. All components “talk to each other,” with set parameters that allow total system shutoff if conditions warrant it.

Protective measures taken at a national salon franchise with a Sentinel Hydrosolutions Leak Defense System shutoff valve.

According to Fox, the Leak Defense Point of Leak Detector (POLD) is an excellent solution, when coupled with Leak Defense flow sensors, for residential homes or commercial locations to simply and easily protect a property from catastrophic water damage. These multi-point electronic leak detectors can be placed anywhere there’s a high risk for plumbing leaks, typically near appliances and fixtures; they will close the water supply valve and send an alarm if moisture is detected.

“Leak Defense products are available through our over 2,000 nationwide installers, wholesalers and rep firms,” said Fox. “Installer and facility manager training is conducted nationwide.”

Luxury Condo Puts a Stop to Leakage

Sunset Pointe near St. Petersburg, Florida, is a luxury condominium complex on a barrier island off the Florida coast. Since 2017, three of four six-story buildings have been built and occupied, with a fourth one now under construction.

Today, all 130 occupied units, each exceeding $1 million in value, contain a Leak Defense system. Their technologies were installed after three leakage incidents—all within a six- month period in 2018—created more than $150,000 in damage to many individual units, common areas and an elevator system.

“We haven’t had a single loss or insurance claim after completion of the [Leak Defense] products,” said Vince Pusateri, board president of the Sunset Pointe Condo Association.

Three separate incidents

Pusateri, an early resident of Building 1, was the building president at the time the incidents occurred. The first was in a laundry room, when a hose connecting to a washer sprung a leak.

Emergency water shutoff with set schedules protect a facility in Atlanta, Ga.

The second occurred in the middle of the night. A water softener system in a utility closet sprung a leak, and the condo owners awoke to find themselves wading in six inches of water. The water also spread to the two units next door, into the walls of units below, and into the elevator area.

“In a condo complex where there are common walls and floors, a leak in one unit affects not only the people there, but also the people around them,” said Pusateri. “In addition to structural problems, there can be damage to rugs and furnishings—and, potentially, black mold if things aren’t taken care of quickly.”

Installing leak defense

Following a third incident when a hot water tank line sprung a leak in a pantry, a building maintenance engineer suggested several leak detection solutions to the Building Governance Committee. Ultimately, the committee (chaired by Pusateri) chose to install Leak Defense.

The system is comprised of several components. The first is a proprietary valve installed on the incoming waterline to each condo unit; once installed, the automatic water shut-off control valve monitors water flow 24/7/365.

The second is a wireless touchscreen control in each living unit, allowing residents to set the system to fit their family’s lifestyle needs. For example, if high-volume overnight water use would be unusual, the control can send an audible alert; it can also shut off the water intake. The control could also be connected to a third-party monitoring company to make sure an alert is attended to even if the owners are away.

Point-of-leak detectors can be placed at any potential trouble spots to detect leaks, such as in the laundry room or under a bathroom or kitchen sink. Finally, a mobile app allows easy, remote monitoring.

“We liked the sturdy unit [control panel] and the company’s good track record,” Pusateri said. He also pointed to other features, such as being able to set the system for how long water could run before activating an audible alarm, and ease of operation.

Condo owners in Building 1 agreed to the installations, as did the owners later in Buildings 2 and 3. Pusateri said that most condo owners have 6-10 sensors in their home; locations are up to each owner.

“What I also liked is that sensors can detect a change in water pressure, even behind a wall,” said Pusateri.

He added that for reliability in a storm, the system is backed up with an uninterruptible power supply (UPS), which plugs into a wall. “In Florida, we have a lot of lightning strikes and power surges,” Pusateri noted, “but with UPS battery backups, we’re covered.”

When Building 4 is completed in 2023, Leak Defense systems will be installed to protect those units in the condo complex. “We’re happy with Leak Defense,” Pusateri said. “It has the best track record; it’s rugged, and we don’t want any further damage.”

The latest of the Watts Works Learning Centers, now with 200+ employees, has opened in Ft. Worth, Texas. The 250,000-sq.-ft. facility—customized for broad training purposes, administration, and manufacturing—joins several other Watts Works Learning Centers across North America. https://youtu.be/T74E2QHfnDc In addition to a working mechanical room with pressurized water lab, the facility includes a 3,600-sq-ft. Learning Read more

The latest of the Watts Works Learning Centers, now with 200+ employees, has opened in Ft. Worth, Texas. The 250,000-sq.-ft. facility—customized for broad training purposes, administration, and manufacturing—joins several other Watts Works Learning Centers across North America.

In addition to a working mechanical room with pressurized water lab, the facility includes a 3,600-sq-ft. Learning Center, office areas and a wide range of product manufacturing and assembly, including robotic welding and cutting, metal passivation, sheet metal rolling, precision laser metal cutting, CNC machining, and ASME testing.

At the facility, employees produce PVI water heaters, BLÜCHER stainless-steel trench and HygienicPro® drains, and Ames and Watts in-building risers. The products that are manufactured in Ft. Worth, TX are used worldwide in various commercial applications. Many Watts technologies play a role in supporting energy efficiency, safety and regulation, and water conservation.

Through innovative training, the Watts’ training offerings help customers and employees improve their knowledge of Watts products, services, and solutions to enhance their professional skills.

Other North American-based Watts Works Learning Centers are located at North Andover, Mass.; Blauvelt, N.Y.; St. Pauls, N.C.; Burlington, Ontario; and Woodland, Calif.

For more information, visit https://www.watts.com/resources/training/learn-from-the-experts.

Way back in 1987, ASHRAE experts developed the BACnet protocol as a communications standard for Building Automation Systems (BAS). BACnet has since earned the respect of specifying engineers, facility managers, controls experts and service technicians worldwide as it’s now the leading technology in building automation. BACnet offers an open architecture and the ability to control Read more

Way back in 1987, ASHRAE experts developed the BACnet protocol as a communications standard for Building Automation Systems (BAS). BACnet has since earned the respect of specifying engineers, facility managers, controls experts and service technicians worldwide as it’s now the leading technology in building automation.

BACnet offers an open architecture and the ability to control and monitor any building automation process—from water sourced heat pumps and chillers to boilers and volume water heaters.

At North Andover, Mass.-based Watts, one of the largest and most diverse manufacturers in the plumbing and mechanical and HVAC market, BACnet has been incorporated into several of its brands’ technologies, most notably through its HVAC and snow-melting controls brand, tekmar; “IntelliStation” digital mixing stations for commercial domestic water control and tempering by their brand, Powers; and for Benchmark boilers and Innovation water heaters (via their “EDGE” controller), offered by the company’s brand, AERCO.

“For us, BACnet is so useful because it’s a standardized communication protocol that interconnects and ‘talks to’ all other BAS-connected technologies throughout an entire facility, and also facilitates remote monitoring and control,” said Amar Dhore, AERCO Software Engineering Supervisor. “When fully integrated, all communications can work through one BACnet device. That’s the advantage of standardization, and what it enables.”

New York-based AERCO is one of the nation’s leading suppliers of commercial condensing boilers and water heaters for a variety of industries. Several years ago two of AERCO’s brands—Benchmark boilers, andInnovation water heaters—adopted the use of BACnet to offer sophisticated communications through their EDGE controller and ProtoNode gateway, the key interfaces to BAS for legacy system communications.

AERCO offers a multi-protocol, communications gateway to support integration with customers’ building automation (BAS) and energy management systems (EMS). The plug-n-play package supports build in integration with BACnet/IP, BACnet MS/TP, Modbus RTU, Modbus MSTP. AERCO also has a ProtoNode Gateway to support legacy products like Benchmark standard, Modulex EXT boilers; Innovation and SmartPlate water heaters.

AERCO offers a multi-protocol, communications gateway to support integration with customers’ building automation (BAS) and energy management systems (EMS). The plug-n-play package supports build in integration with BACnet/IP, BACnet MS/TP, Modbus RTU, Modbus MSTP. AERCO also has a ProtoNode Gateway to support legacy products like Benchmark standard, Modulex EXT boilers; Innovation and SmartPlate water heaters.

AERCO’s EDGE features built-in translation for BACnet/IP, BACnet MS/ TP, Modbus RTU and Modbus TCP protocols; these communications are selectable and configurable via touch screen (No DIP switch needed). With this easy access to data, customers have ready access to more data. They can also choose and map BAS points of his interest to access, control and monitor devices.

In fact, the company’s Benchmark Platinum boilers can be managed effectively with an app that connects with the EDGE controller. With the app, a service technician or facility manager can monitor or balance hydronic system flow, perform a wide variety of system diagnostics, or combustion analysis and calibration.

For building owners, the EDGE permits trouble-free management of all boiler/water heaters functions—whether one unit or up to 16 units, connected in a cascade.

The EDGE controller also permits flow balancing—a function that allows elimination of balancing valves and also reduces commissioning costs, one of many operations enabled through the built-in communications via BACnet IP, BACnet MS/TP, Modbus IP or Modbus RTU.

Start-up and maintenance functions are also simplified. Boilers +/or water heaters can be calibrated through assisted or manual operations, a big time-savings advantage. The assisted options offers guided steps that automatically adjust precise air/fuel ratios for optimal performance.

AERCO access and control security:

AERCO managers understand the importance of security and have taken steps to make BAS communication secure. EDGE offers built in security using IP and MAC address. Once the security is enabled, user needs to enter front end BAS MAC and IP address. Once done, Edge will only accept the communication from the BAS with specified MAC and IP address.

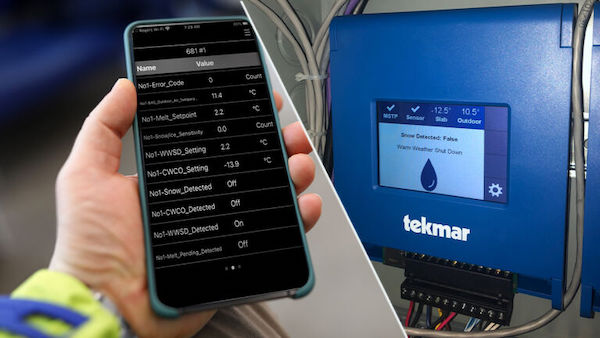

tekmar’s 680, 681 + 284

Vernon, BC-based tekmar Control Systems, a Watts brand, is a world class integrated engineering and manufacturing company that provides solutions for the HVAC industry. For the past 38 years, tekmar has earned a reputation as the leader in complete control solutions for hydronic radiant floor and baseboard heating systems, multi-stage boilers plants, and automatic snow melting controls.

tekmar provides energy-saving control solutions for a broad range of hydronic systems—whether within a building, or outside (for snowmelt or turf-warming)—while assuring no-compromise comfort control, system efficiency and durability.

The company’s technologies provide:

- Setpoint controls—offering precise temperature control for domestic water storage tanks, pools and hot tubs.

- Boiler + domestic water controls—These technologies are designed to control temperature and operation of multiple boilers or volume water heaters. Multi-staging controls provide significant energy savings while also enhancing system reliability.

- Heating controls—Here, tekmar offers controls to provide zoning solutions for heating systems; specific models are designed for use in hydronic heating, radiant heating, HVAC systems, and baseboard or “hydro-air” applications.

- tekmarNet 4 zoning controls—These technologies connect to thermostats to control operation of heating system zone valves or heat pumps for precise delivery of heat.

- Snowmelt control and sensors—Snowmelt control systems measure and control road, driveway or walkway surface temperatures to provide safe, snow- and ice-free surfaces, and at the lowest operating cost. Controls may connect to electric or hydronic systems as the source of warmth. Fully automatic controls, or manual controls can be chosen.

“Our specialties are boiler and snowmelt system controls,” explained tekmar’s Cleber Alves. “One of our unique products is the new BACnet snow/ice sensor interface 681—designed to measure the presence of snow or ice and interfaces with the BAS to activate or deactivate electric or hydronic snow melting systems.”

According to Alves, the 681 uses tekmar sensor technology to automatically detect precipitation, then communicates with the BAS through BACnet MS/TP. This operation allows the BAS to automatically turn the heat source and distribution system on, or off, and provide operational status for all snow-melt functions. The 681 is ideally suited for commercial applications such as hospitals, schools, airports, ski resorts, business entrances, driveways, loading docks, and shopping malls.

According to Alves, the 681 uses tekmar sensor technology to automatically detect precipitation, then communicates with the BAS through BACnet MS/TP. This operation allows the BAS to automatically turn the heat source and distribution system on, or off, and provide operational status for all snow-melt functions. The 681 is ideally suited for commercial applications such as hospitals, schools, airports, ski resorts, business entrances, driveways, loading docks, and shopping malls.

The 681’s features include slab target temperature, automatic snow and ice detection, error codes, warm weather shut-down, melt pending function, cold weather shutdown, and supports both in-slab and retrofit aerial sensors—all with BACnet MS/TP communication.

IntelliStation digital water control

Public safety relies chiefly on the availability of clean water. As it can affect water quality, the condition of premise (building-specific) plumbing systems have a direct impact on the safety of those within the facility. The ability to remotely monitor and control water temperature, flow, and other parameters in a quick and precise way is vital to delivering healthy, safe water in an efficient manner.

Patents held by Powers, a Watts brand, function as the backbone for many products in commercial and industrial water temperature control markets. The company develops and manufactures thermostatic and digital mixing solutions to bring safety and comfort to modern plumbing systems.

“IntelliStation and IntelliStation Jr. [a smaller version] digital water mixing systems are designed to deliver tempered hot water throughout a recirculation loop in commercial and institutional facilities,” explains Sr. Product Manager Bruce Fathers. “Our digital solutions can be integrated into a BAS to allow facilities managers to remotely monitor and control water temperatures.

“We offer most of the common protocols, with gateways to others if need be,” added Fathers. “Modbus and BACnet are native to our controller, so it’s integrated into our IntelliStation products with no additional cost. Most of our competitors do require an additional module at an added cost to facilitate BACnet. So, it’s become a competitive edge for us, one our customers have come to appreciate.”

According to Fathers, BAS is used to seamlessly monitor and control important facets of system operation—such as mixed outlet temperature, pressure, flow, and inlet temperature. The sensors all require connection/input points.

“For commercial domestic water systems, mixed outlet temperature is most important,” explained Fathers. “It’s typically set at 120°F, or 140°F—to either render [biogens/pathogens] unable to reproduce, or to outright kill them [point-of-use mixing valves are then used at showers and faucets to protect users. Facility managers have remote visibility to all critical datapoints.

Fast, responsive digital technology enables the collection of a large amount of data which can be stored and communicated through a building automation system (BAS) or locally at the controller, providing intelligence at the foundation of the entire plumbing system.

Internet of Water

Control of the water recirculation loop ensures safe, precise, and consistent water temperatures (+/- 2oF), supports energy conservation, and reduces energy costs. BACnet IP, BACnet MSTP, and Modbus protocols are supported.

Technology helps to fulfill these needs with digital mixing and connected components like sensors and cloud-based monitoring.

The extent to which COVID-19 has impacted public health and the increased prevalence of Legionella bacteria have highlighted the need for:

- Visibility of water temperature, flow, and quality even when off-site

- A way to remotely control water temperatures

- Automated monitoring and reporting of premise plumbing water parameters and facility management activity

- Connected products that help increase safety and efficiency

- Reliable ways to reduce the risk of Legionella and other harmful bacteria

BAS empowers facility managers and engineers to proactively prevent issues before they arise, rather than having to react to or attempt to mitigate issues once they’ve occurred,” added Fathers.

There are three main technology-driven components in a digital mixing solution:

- Sensors, serving as eyes and ears

- The controller’s algorithm (the “mind”)

- Electronic, high-speed actuated valve, continually responds to sensor inputs, to maintain set point

“Our digital mixing controller algorithm processes data from the mixed temperature outlet sensor and signals the actuator to make adjustments to maintain set-points in real time,” continued Fathers. “Sensors relay key system data for pressure, temperature and flow for troubleshooting and optimization.”

Building automation systems give facility managers the ability to see vital data, quickly make informed decisions, and act, even remotely. Digital water mixing controls hot water delivery through a programmable valve or system that processes temperature, flow, and pressure data.

Serious risks, such as Legionella growth, scalding, and thermal shock are associated with mismanaged water temperature. Legionella bacteria are destroyed almost instantly at water temperatures above 160°F, but at temperatures between 70°F and 115°F, their growth is abundant. The Catch 22 is that uncontrolled and unmonitored water distribution systems can create high-temperature scalding hazards in bathtubs, sinks, and showers.

A proactive monitoring program can help reduce risks, predict trends, and improve operational efficiency. Proactive monitoring enables three key control measures that help address modern-day public safety risks:

- Allows for quick decisions based on real data

- Allows facility managers to more easily manager their systems

- Generates automatic reports showing trends and performance

Fortunately, there’s no Catch 22 to the use of BACnet technology. It facilitates fast, reliable communications between all facets of the network it operates in. Watts and its brands rely on BACnet for many operational uses, successfully, and with no compromise.

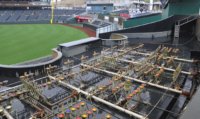

CUSTOMER: Kansas City Royals’ Kauffman Stadium SCOPE: Upgrade 130 existing ductile iron control valves in the stadium fountain with new Watts stainless steel automatic control valves CHALLENGE: Original control valves became completely rusted due to continuous submersion and needed replacement SOLUTION: Approximately 130 Watts stainless steel automatic control valves (ACVs) – ranging from two to Read more

CUSTOMER: Kansas City Royals’ Kauffman Stadium

SCOPE: Upgrade 130 existing ductile iron control valves in the stadium fountain with new Watts stainless steel automatic control valves

CHALLENGE: Original control valves became completely rusted due to continuous submersion and needed replacement

SOLUTION: Approximately 130 Watts stainless steel automatic control valves (ACVs) – ranging from two to six inches

RESULTS: Fountain’s stainless steel ACVs modulate, open, and close for reliable and trouble-free operation, providing an eye-catching display of vibrant colors for spectators. The entire operation is controlled via a remote programmable logic controller.

Kauffman Stadium is home to two-time World Series winning KC Royals—a central division Major League Baseball team founded in 1969.

The park’s best-known feature is the “Water Spectacular”—a massive fountain and waterfall display behind the right field fence. Built in the 90s, the fountain is now a focal point for ballpark fans.

The park’s best-known feature is the “Water Spectacular”—a massive fountain and waterfall display behind the right field fence. Built in the 90s, the fountain is now a focal point for ballpark fans.

At 322 feet in length, it’s the largest privately funded fountain in the world. Half a million gallons of water surge through fountain pipes before and after games and between innings; the waterfalls flow continuously. The impressive display changes colors often and—on occasion—serves as an off-limits swimming pool for overenthusiastic Royals fans, or rivals.

Over a period of time, the control valves—fully submerged under water—became corroded and were completely rusted through. Needing a better solution, ballpark owners chose to replace the original ductile iron control valves for the fountain in 2017, replacing them with approximately 130 stainless steel Watts automatic control valves. They worked with Watts’ local representative Mack McClain & Associates on the project.

Over a period of time, the control valves—fully submerged under water—became corroded and were completely rusted through. Needing a better solution, ballpark owners chose to replace the original ductile iron control valves for the fountain in 2017, replacing them with approximately 130 stainless steel Watts automatic control valves. They worked with Watts’ local representative Mack McClain & Associates on the project.

The fountain now has valves that modulate easily, assuring park owners that fans will enjoy the dramatic water feature for years to come.