Whether installing a new boiler or maintaining an existing one, it’s important to consider the inherent issues that can befall a hydronic system and impact the performance of its components. Anticipating these pitfalls and planning accordingly will result in a smarter installation. By choosing your boiler accessories wisely, you can extend the life of your Read more

Webstone

Whether installing a new boiler or maintaining an existing one, it’s important to consider the inherent issues that can befall a hydronic system and impact the performance of its components. Anticipating these pitfalls and planning accordingly will result in a smarter installation. By choosing your boiler accessories wisely, you can extend the life of your boiler and maintain its efficiency while guarding against potential problems down the road.

One of the most common issues comes in the form of ferrous debris, a result of normal metal pipe wear that, when left unchecked, can cause major problems. Over time, rust particles and other debris in the heating loop build up, creating an iron sludge that reduces boiler efficiency or even stops it altogether from working. The resulting damage can require expensive repairs, increase heating costs, and reduce the overall lifespan of the boiler.

One of the most common issues comes in the form of ferrous debris, a result of normal metal pipe wear that, when left unchecked, can cause major problems. Over time, rust particles and other debris in the heating loop build up, creating an iron sludge that reduces boiler efficiency or even stops it altogether from working. The resulting damage can require expensive repairs, increase heating costs, and reduce the overall lifespan of the boiler.

To combat the accumulated sludge in the pipes, a system flush may be required. Depending on the severity of the issue, this could be a costly and time-consuming process. Moreover, doing so will not reverse any damage that’s already been done to the boiler. By the same token, boiler manufacturers are becoming more stringent about their warranty claim requirements. Installing a boiler accessory as a precautionary measure is the most consistent way to ensure due diligence is being done. The best protection from iron sludge is to prevent it from ever reaching the appliance.

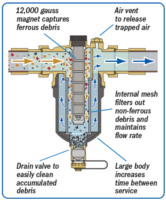

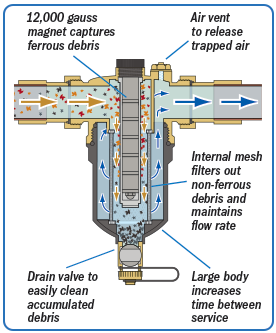

To protect the boiler, consider the Magnetic Boiler Filter (MBF) from Webstone®, a brand of NIBCO. It captures ferrous and non-ferrous debris before it can reach the boiler using a high-powered 12,000 Gauss magnet. Its internal filter knocks out sediment as it enters the unit, breaking down the sludge and maintaining optimal flow rate. The build-up is captured in the body, which has a large storage capacity to increase time between service. The strapped cap is also used to actuate the integrated drain valve, making it simple to remove accumulation when needed, and a service tool is included to help remove the filter housing with ease.

The MBF bodies feature G-thread ends for connection to your choice of MIP, FIP, sweat, or press union fittings. Unions and bodies can be purchased as an installation kit or as separate components depending on the installer’s preference. Optional lead-free dezincification-resistant brass isolation valves are also available to simplify future service. When installed in conjunction with a circulator pump, the flanged ball valve saves space, labor, and leak paths compared to the off-the-shelf assemblies that would normally be required to connect the two appliances. It also mitigates the risk of electrolysis and galvanic corrosion, while allowing virtually no air into the system upon pump replacement. For more simple isolation needs, Webstone offers straight and angled G-union ball valves with reversible handles.

For smaller systems, the ¾” and 1” models feature a universal diverter that allows the MBF to be used in both horizontal and vertical piping orientations on the system return line. For horizontal installations on the system run, the Magnetic Boiler Filter XL model is now available in sizes 1¼” or 1½”. Introduced in 2021, the patent-pending MBF XL is ideal for larger residential and light commercial boiler applications, with a robust 2-layer metal mesh filter and manual air vent.

Webstone offers a wide array of system performance products designed to support efficient operations and protect components. To learn more about how you can work smarter, visit Webstone Valves.

When selecting your next Y-strainer, consider upgrading to the new Pro-Pal® Ball Drain Strainer™ from Webstone, a brand of NIBCO®. Designed to protect the system against debris in the pipes, this patent-pending valve combines a Y-strainer, ball valve, and hi-flow hose drain. Its forged brass construction takes the place of eight individual components; eliminating assemblies Read more

When selecting your next Y-strainer, consider upgrading to the new Pro-Pal® Ball Drain Strainer™ from Webstone, a brand of NIBCO®. Designed to protect the system against debris in the pipes, this patent-pending valve combines a Y-strainer, ball valve, and hi-flow hose drain. Its forged brass construction takes the place of eight individual components; eliminating assemblies needed to isolate, drain, and separate loose particles from the flow. Its flexible design can be installed in a vertical or horizontal orientation, depending on your system’s needs.

The Ball Drain Strainer allows you to isolate the strainer from upstream flow, simplifying the servicing of the strainer port without the need for additional assemblies. During normal operation, the main valve is open to create a straight flow path which allows debris to fall into the plugged blow down port. To remove accumulation, simply close the valve to restrict the flow from the port, unscrew the strainer cap, and clean the debris from the screen. The exclusive multi-function flow path is also ideal for diverting fluid into the drain from either side of the ball. With a turn of the handle, you can choose between a variety of applications including draining before or after the ball, flushing the valve with fresh water, or flushing with reverse flow from the system.

The Ball Drain Strainer is available in sizes ½” to 1¼” in press or FIP connections. It features lead-free dezincification resistant forged brass construction, replaceable 20 mesh screens, and O-ring sealed and plugged strainer port for easy removal of the filter and installation of the drain valve.

Pro-Pal® 3-way ball valves from Webstone®, a brand of NIBCO, are designed to divert, select, or mix fluids based on your application needs. Flow options include a 90° handle operation to divert or select, or a 180° handle operation to divert, select, or mix. A dual stem seal incorporates both an O-ring and PTFE packing Read more

Pro-Pal® 3-way ball valves from Webstone®, a brand of NIBCO, are designed to divert, select, or mix fluids based on your application needs. Flow options include a 90° handle operation to divert or select, or a 180° handle operation to divert, select, or mix. A dual stem seal incorporates both an O-ring and PTFE packing with an adjustable packing gland for extra leak protection. Products are forged from lead-free dezincification-resistant brass and can withstand up to 250 PSI CWP and 200°F. Available in ½” to 2” end connections that are compatible with popular press tools. Work smarter and save time, labor, and leak paths.

- Divert, select, or mix fluids based on your application needs

- Dual stem seal design incorporates both an O-ring and PTFE packing with adjustable packing gland for extra leak protection

- Compatible with popular press tools

Learn more at www.webstonevalves.com/propal.

In recent years, PP-R pipe has become an increasingly popular choice in plumbing and hydronic heating systems. Introduced over 30 years ago, this copolymer made from Polypropylene-Random has been a top choice among plastic piping options. Suitable for both hot and cold pipe, it’s known as a naturally insulating option that allows the installer to Read more

In recent years, PP-R pipe has become an increasingly popular choice in plumbing and hydronic heating systems. Introduced over 30 years ago, this copolymer made from Polypropylene-Random has been a top choice among plastic piping options. Suitable for both hot and cold pipe, it’s known as a naturally insulating option that allows the installer to make fast connections that are both permanent and leak-free. Using heat fusion technology, the installer can do more than just join two PP-R ends together – they can create a joint that has the same strength as that of the pipe wall. In contrast to other pipe-joining methods, common long-term concerns like corrosion and fatigue damage are eliminated with heat fusion. In fact, fusion connections are touted to be so robust that they will outlast their own piping system.

In the mid 2000’s, a new generation of PP-R pipe was introduced to the market – Polypropylene-Random Crystallinity Temperature – or PP-RCT. Its crystallinity allows the copolymer to resist greater levels of pressure at higher temperatures. The advancement of copolymers in recent years has begun to shift opinions on plastic pipe, leaving behind outdated misconceptions about its dependability.

But the ways of the past are not all gone. Installers may be embracing plastic pipes and fittings, but they have been slower to accept plastic bodied valves. The proven field reliability of brass-bodied construction remains favorable in a time when strong, reliable plastics are still a relatively new concept. As such, manufacturers who work with PP-R and PP-RCT have been trying to figure out how to bridge the gap between the time tested technology and recent innovations.

In order to incorporate brass valves into a PP-R/PP-RCT piping system, installers have historically had few choices. Options for brass valves with fully integrated connections have been somewhat limited. Some piping manufacturers have elected to offer valves that are compatible only with their specific line of piping, so finding a valve that is compatible with all PP-R and PP-RCT piping systems proved increasingly difficult. In absence of a universal solution, installers made use of transitional fittings to connect their brass ends to PP-R/PP-RCT pipe, at the expense of additional leak paths and labor.

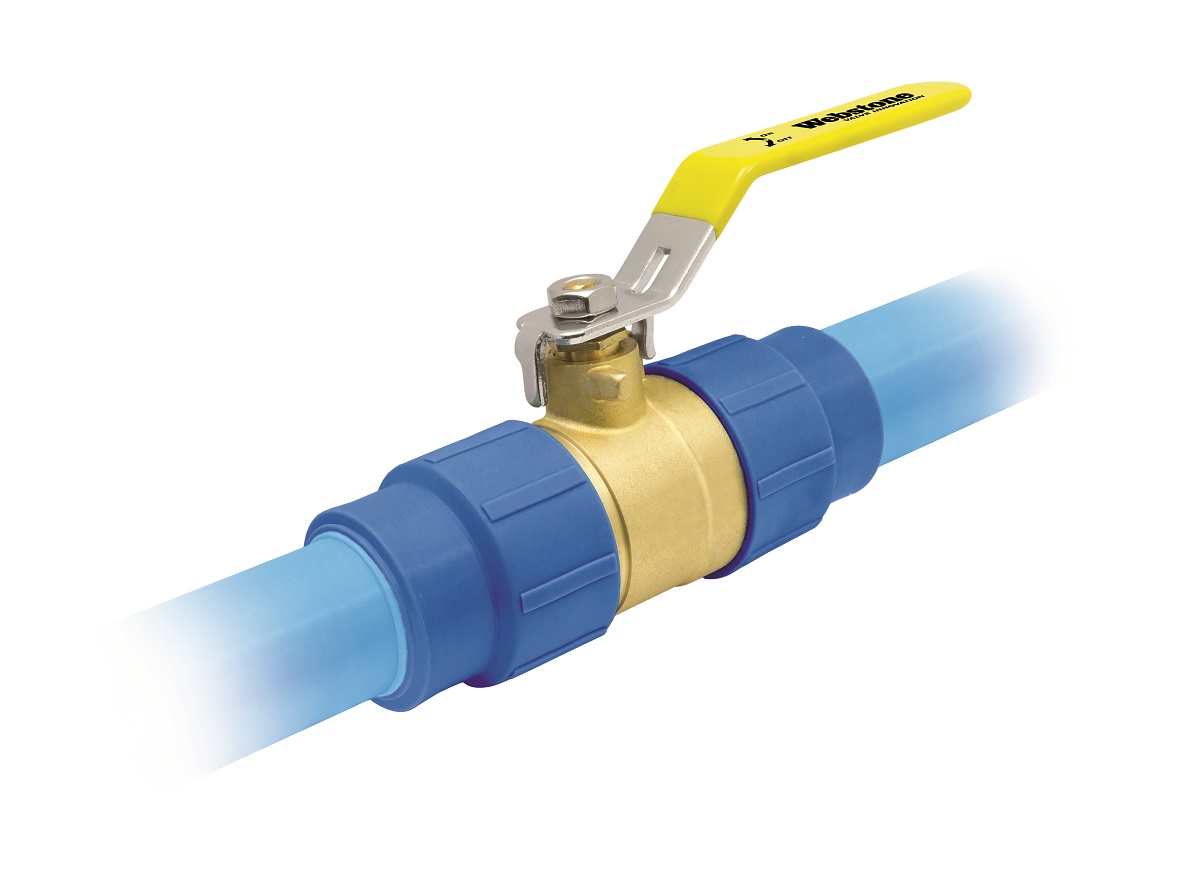

That’s where Webstone comes in. Known for their quality brass valves, Webstone has introduced fully integrated PP-R or PP-RCT ends to their most popular engineered products. The Pro-Connect PP-R Pro line now includes the Isolator with Rotating Flange (a uni-flange ball valve with 360 degrees of motion and optional multi-function hose drain), the Pro-Pal Ball Drain, and ball valves (including PP-R/PP-RCT x FIP ends to transition to or from metal piping).

These products all feature socket style connections, which makes the heat fusion process as quick and simple as possible. Valves come in a variety of sizes and are certified lead free for both residential and commercial use. Additionally, all Webstone products carry a lifetime guarantee against manufacturer’s defects – ensuring peace of mind that no other valve manufacturer in the industry can match. To learn more, visit WebstoneValves.com/PP-R-Pro

Tee and elbow union products from Webstone®, a brand of NIBCO®, eliminate the need for multiple fittings and valve assemblies. This line features ball valves combined with a choice of an integrated tee or elbow union fitting that may be used to change the direction of a line or to install a branch off of Read more

Tee and elbow union products from Webstone®, a brand of NIBCO®, eliminate the need for multiple fittings and valve assemblies. This line features ball valves combined with a choice of an integrated tee or elbow union fitting that may be used to change the direction of a line or to install a branch off of a line.

The T-Union Ball Drain model combines these same features with a hi-flow hose drain, allowing the user to quickly and easily install a drain off of a line. It has an adjustable flow path and a reversible handle to drain from either side of the ball. The integrated union adds versatility and makes installation fast and simple, with the ability to easily disconnect and replace the pipes for future repairs.

The dual stem seal design incorporates both an O-ring and PTFE packing with an adjustable packing gland for extra leak protection. These valves feature press end connections in sizes ½” – 1½”, including reducing options suitable for manifold/zone assemblies. They can save up to one hour of labor, replace 8 components, and eliminate 7 leak paths.

All products are made from lead-free dezincification resistant brass, can withstand up to 250°F and 200 PSI CWP, and are certified to NSF/ANSI 61 and 372.