Uponor North America (Uponor) announced Anna Picchetti as the new Vice President of Marketing & Strategy, effective May 8, 2023. In her role, Anna will oversee Channel Marketing, Portfolio, Analytics, Sustainability, Segment, Engagement, Brand, and Communications. She will report to Uponor North America President Andres Caballero and be a key member of the company’s Senior Management Committee. Anna joins Read more

Uponor

Uponor North America (Uponor) announced Anna Picchetti as the new Vice President of Marketing & Strategy, effective May 8, 2023. In her role, Anna will oversee Channel Marketing, Portfolio, Analytics, Sustainability, Segment, Engagement, Brand, and Communications. She will report to Uponor North America President Andres Caballero and be a key member of the company’s Senior Management Committee.

Anna joins Uponor with 20 years of experience in Marketing and Operations across industrial, technology, and medical device industries. She brings a wealth of experience developing forward-thinking strategies with a strong track record of execution at industry-leading brands such as Tennant, SPS Commerce, and Honeywell. She has worked at the forefront of innovations like autonomous vehicles and renewable energy, managed high-growth SaaS products and positioning, and transformed customer experiences.

“To help us move our business and aggressive growth goals forward, it was important we found a senior leader who can lead market disruption and drive innovation and segment growth initiatives all while guiding channel development, portfolio management, and go-to-market strategies,” says Caballero. “I’m confident Anna’s approachable leadership style will be a good cultural fit, as she has a proven track record of engaging teams by intentionally listening, learning, and setting clear expectations and outcomes.”

Anna earned a Master of Business Administration degree from the Carlson School of Management at the University of Minnesota. She is a member of the Women United Committee for the Greater Twin Cities United Way chapter and is also a member of Chief, a network for women in the C-Suite as well as senior executives and vice presidents. In addition, she is a USA Hockey-certified coach with a local youth hockey program.

For information about Uponor products, systems, services, and solutions, visit uponor.com.

Uponor North America (Uponor) recently announced Jon Sillerud, Vice President, Operations, has agreed to accept the additional responsibilities of leading the Supply Chain function for the company, effective immediately. He has been filling the Supply Chain leadership role on an interim basis for several months, proving his experience and extensive knowledge make him the ideal Read more

Uponor North America (Uponor) recently announced Jon Sillerud, Vice President, Operations, has agreed to accept the additional responsibilities of leading the Supply Chain function for the company, effective immediately. He has been filling the Supply Chain leadership role on an interim basis for several months, proving his experience and extensive knowledge make him the ideal person to lead both functions. His new title is Vice President, Integrated Supply Chain, Uponor North America.

Since 2017, Sillerud has led North American Operations, a critical function that includes manufacturing, maintenance, quality, process engineering, real estate, security, and safety. In his newly expanded role, he will also guide the Supply Chain strategy and team, building partnerships with suppliers and leading continuous improvement initiatives that cover supply planning, production scheduling, distribution, transportation, and inventory.

Since 2017, Sillerud has led North American Operations, a critical function that includes manufacturing, maintenance, quality, process engineering, real estate, security, and safety. In his newly expanded role, he will also guide the Supply Chain strategy and team, building partnerships with suppliers and leading continuous improvement initiatives that cover supply planning, production scheduling, distribution, transportation, and inventory.

“Under Jon’s leadership, our business will accelerate its lean manufacturing journey and ensure we continue to drive our growth trajectory under the priorities of safety, quality, delivery, productivity, and continuous improvement,” says Andres Caballero, President, Uponor North America. “I am thrilled to have Jon expand his leadership role and look forward to the success he will bring for the Integrated Supply Chain functions in North America.”

For information about Uponor products, systems, services, and solutions, visit uponor.com.

The popularity of PEX in residential and commercial construction has produced an influx of engineered polymer (EP) F1960 expansion fittings claiming to be “just the same as Uponor ProPEX®”. However, these lower-quality F1960 fittings are putting systems and contractors at significant risk for leaks or poor performance. Uponor ProPEX fittings are certified by a third-party Read more

The popularity of PEX in residential and commercial construction has produced an influx of engineered polymer (EP) F1960 expansion fittings claiming to be “just the same as Uponor ProPEX®”. However, these lower-quality F1960 fittings are putting systems and contractors at significant risk for leaks or poor performance.

Uponor ProPEX fittings are certified by a third-party agency, NSF International, to prove the product is designed and manufactured to the ASTM F1960 standard. In addition, ProPEX fittings also include additional internal quality testing that extends beyond ASTM F1960 standard requirements to provide a higher-quality product.

Some suppliers claim their fittings are compliant to F1960, which means, in their opinion, they meet the standard. However, there is no third-party agency to confirm that compliance. This confusion between certification and compliance is resulting in PEX piping installations with lower-quality connections that are putting systems at risk for failure and jeopardizing installers’ reputations.

Uponor has performed a random sampling of these lower-quality F1960 EP fittings and found them to have a reduced internal diameter — up to 50% in some instances. Additionally, Uponor has received claims for failed connections that, after investigation, were found to be different suppliers’ low-quality F1960 fittings.

Many generic F1960 expansion fittings have a thinner sealing barb and weaker tube stops compared to ProPEX fittings. Those differences can result in leaks that cost time and money to repair — and also damage a contractor’s reputation.

It is important to be vigilant when ordering and purchasing F1960 fittings. Ensure you are getting the superior quality of ProPEX that comes with a 25-year transferable limited warranty when used as a system with Uponor PEX-a pipe and ProPEX rings.

To learn more about the differences in ProPEX and how it can impact your business, visit uponor.com/propex.

By Aaron Stotko When a century-old Dallas railroad company headquarters required major renovations to transform into a Homewood Suites by Hilton, initial cost estimates for the hydronic heating system came in too high. That’s when City Wide Mechanical of Dallas looked to alternative piping systems for a solution. They found PEX-a pipe with F1960 expansion Read more

By Aaron Stotko

When a century-old Dallas railroad company headquarters required major renovations to transform into a Homewood Suites by Hilton, initial cost estimates for the hydronic heating system came in too high.

That’s when City Wide Mechanical of Dallas looked to alternative piping systems for a solution. They found PEX-a pipe with F1960 expansion connections to be the ideal system, due to its durability and ease of installation in addition to the job-site productivity, safety and, best of all, profitability potential it provided.

And City Wide Mechanical isn’t alone in their findings. Many mechanical contractors are discovering the benefits of PEX-a pipe and F1960 connections as the preferred alternative to copper, iron, and steel, which have dominated the mechanical piping industry for decades.

Benefits of PEX-a

PEX is an acronym for crosslinked polyethylene. It has been used in North America since the mid-1980s, starting with radiant floor heating systems, then moving into plumbing and, eventually, to hydronic hot-water heating and chilled-water applications.

PEX can be manufactured via three different processes, which create products with varying crosslinking percentages that allow for different characteristics. PEX-a is the most durable, flexible, and resilient with crosslinking around 85%. PEX-b is a stiffer piping product with crosslinking around 65% to 70%, and PEX-c features crosslinking around 70% to 75%.

ASHRAE Headquarters Grand Opening Fall 2021, photos by Devin Abellon

One major benefit of the higher crosslinking in PEX-a is its extreme flexibility along with its thermal and shape memory. The flexibility of PEX-a eliminates most connections in smaller-diameter piping, saving time and money with up to half the connections required in rigid metal piping systems. To make a change in direction, the installer simply bends the pipe instead of having to stop and make a fitting. There are also bend supports available that help hold a bend securely in place.

The thermal memory of PEX-a provides kink repairability with a simple shot of heat from a heat gun. This eliminates the need to add in a coupling if a kink ever occurs in the pipe. (It is important to note that kink repairability is not possible with PEX-b or PEX-c pipe.)

The shape memory of PEX-a allows the pipe to expand and contract back down to its original shape. This makes it extremely resilient in freezing conditions and also provides for the fastest, easiest, most reliable PEX-a fitting system — F1960 expansions.

Expansion fittings require one simple tool to expand the pipe and an expansion ring before inserting a fitting. As the pipe and expansion ring naturally shrink back to their original shape, it creates a strong, durable connection that holds tight and can never be dry-fit. (Note: It is not recommended to expand PEX-b or PEX-c pipe due to microcracking that can occur.)

The innovative expansion fitting method eliminates torches, glues, and solder from a job site for greater worker safety. Plus, the system is extremely easy for installers to learn, helping get new crews up to speed quickly.

Speaking of job-site safety, PEX is also much lighter in weight compared with metal systems. For example, a 300-foot coil of 1/2-inch PEX weighs about 18 pounds, whereas the same amount of copper pipe weighs around 85 pounds. The lighter weight of PEX makes it safer and easier for installers to move around a job site and also eliminates the need for heavy-lifting equipment.

PEX-a also has a long-term advantage over copper when it comes to performance longevity. It is a static system, meaning its internal surfaces — which are three times smoother than copper — will not pit, scale, or corrode. That means its performance will remain the same from day one through decades of use.

Finally, because it is not a traded commodity, PEX-a holds a relatively stable material cost. This makes bidding a project much more consistent and reliable.

Application Details and Installation Tips

PEX-a is regulated by the ASTM F876 standard, which denotes temperature and pressure ratings of 200°F at 80 psi (pounds per square inch), 180°F at 100 psi, and 73.4°F at 160 psi. These values are well within the range of operation for most hydronic systems, including chilled beams, fan coil units, baseboards, radiators, hydronic VAV (variable-air volume) reheat coils, and radiant manifolds.

Because PEX is oxygen-permeable, it is important to use a pipe with an oxygen barrier that limits oxygen diffusion to levels below DIN 4726. This will protect the metallic components in the mechanical piping system, such as valves, strainers, and pump volutes, from corrosion.

The pipe is manufactured in sizes from 5/16 inch up to 4 inches and features a copper tube size (CTS) outside diameter. This means all the off-the-shelf components used in a copper hydronic piping system — hangers, supports, and insulation — can be the same.

For horizontal piping, the industry offers PEX-a Pipe Support — a galvanized-steel channel that is 9 feet in length and available in PEX pipe sizes from ½ inch to 3½ inches. This solution enables hanger spacing similar to copper pipe and helps control the natural expansion and contraction of the pipe as it heats and cools.

Because PEX-a expands at 1.1 inches per 100 feet per 10°F Delta T (which is 10 times that of copper), installing anchors every 65 feet and using PEX-a Pipe Supports allows PEX-a to function much like a copper system. In fact, different installation methods have a different effect on the overall net expansion rate.

With a strut-and-clamp system, using PEX-a Pipe Supports and anchoring with fixed points reduces the expansion rate of PEX-a to 0.08 inches per 100 feet per 10°F Delta T (a rate less than copper). And a loop-and-clevis system can reduce the rate to 0.12 inches per 100 feet per 10°F Delta T.

If you’d like to learn more about PEX-a piping systems, visit the Plastics Pipe Institute at plasticpipe.org or the Plastic Pipe and Fittings Association at ppfahome.org.

Aaron Stotko is the director of Segment Marketing at Uponor. He can be reached at aaron.stotko@uponor.com.

Aaron Stotko is the director of Segment Marketing at Uponor. He can be reached at aaron.stotko@uponor.com.

Apple Valley, Minn. — Uponor North America (Uponor) held a ceremonial “pipe-cutting event” to mark the opening of its $5.5 million, 25,000-square-foot expansion to the Hutchinson, Minn., facility. This new space will increase the company’s PEX-a pipe extrusion production capacity by more than 10 percent, while growing highly skilled jobs in Hutchinson in the coming Read more

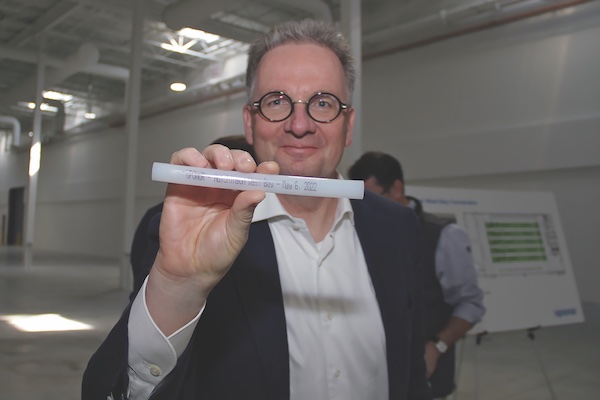

Apple Valley, Minn. — Uponor North America (Uponor) held a ceremonial “pipe-cutting event” to mark the opening of its $5.5 million, 25,000-square-foot expansion to the Hutchinson, Minn., facility. This new space will increase the company’s PEX-a pipe extrusion production capacity by more than 10 percent, while growing highly skilled jobs in Hutchinson in the coming years.

Michael Rauterkus, president and CEO, Uponor Group, (center) joins business leaders as he cuts the ceremonial PEX-a pipe to mark the opening of the company’s $5.5 million, 25,000 sq. ft. expansion in Hutchinson, Minn.

The expansion project broke ground in July 2021 with PCL Construction as the general contractor, Tekton Engineers as the structural engineer, Focal Point Partners as the electrical subcontractor, and Legend Companies as the mechanical subcontractor. The renovated space will allow Uponor to move forward with a major investment in next-generation extrusion technology.

Michael Rauterkus, president and CEO, Uponor Group, took part in the event. This was his first trip to visit Uponor facilities across North America since joining the company in August 2021. He toured the Hutchinson production facility, met with team members, and helped cut the ceremonial pipe.

“Today was a special day for Uponor North America,” Rauterkus said during the event. “Seeing this investment become a reality and knowing what is possible from a manufacturing potential, I am certain Uponor will continue to make positive impacts on the Hutchinson area. I am eager to see what happens next with this team.”

“This expansion reinforces our commitment to Hutchinson and the team members who help us deliver for our customers. I want to thank our construction partners for their efforts in designing and building this space, as well as our global partners across Uponor who saw the potential in what our Hutchinson team could achieve with this major investment,” said Jon Sillerud, vice president, Operations, Uponor North America.