https://vimeo.com/1029812860 On this Mechanical Hub weekly update, we’re on the road in Elkhart, Indiana to celebrate NIBCO Inc.’s 120 years in business, and another huge surprise from that event. I’ll update you on our latest podcasts, and a partnership worth sharing Read more

Featured Articles

On this Mechanical Hub weekly update, we’re on the road in Elkhart, Indiana to celebrate NIBCO Inc.’s 120 years in business, and another huge surprise from that event. I’ll update you on our latest podcasts, and a partnership worth sharing.

Elkhart, Indiana-based NIBCO Inc. celebrated in style this week as esteemed guests were invited to dinner, drinks and dancing in what was a wedding reception-like ceremony that included a multi-piece band. The following day, invitees were treated the ribbon cutting of the new Rex Martin NIBCO Interactive Museum, and took the tour. The museum offers Read more

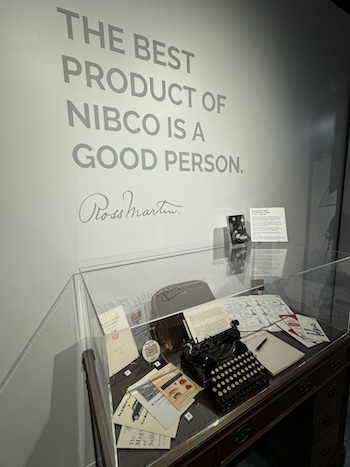

Elkhart, Indiana-based NIBCO Inc. celebrated in style this week as esteemed guests were invited to dinner, drinks and dancing in what was a wedding reception-like ceremony that included a multi-piece band. The following day, invitees were treated the ribbon cutting of the new Rex Martin NIBCO Interactive Museum, and took the tour.

The museum offers a unique and enriching experience from a historical perspective, interactive learning, inspiration, community impact, and career opportunities. Not just a place to learn about the past, it’s a place to get excited about the future of plumbing and the opportunities it holds.

“Our decision to build the NIBCO Interactive Museum and name it after my father is a tribute to his remarkable contributions to the plumbing industry and a continuation of a legacy that began with my great-great-grandfather in 1904,” said NIBCO’s President and CEO Ashley Martin. “This ambitious project was something I wanted to complete and dedicate on NIBCO’s 120th anniversary to make it extra special. The museum is not just about preserving our history; it’s about showcasing the profound impact we’ve had on the evolution of plumbing and our philanthropic efforts within the community.”

“Our decision to build the NIBCO Interactive Museum and name it after my father is a tribute to his remarkable contributions to the plumbing industry and a continuation of a legacy that began with my great-great-grandfather in 1904,” said NIBCO’s President and CEO Ashley Martin. “This ambitious project was something I wanted to complete and dedicate on NIBCO’s 120th anniversary to make it extra special. The museum is not just about preserving our history; it’s about showcasing the profound impact we’ve had on the evolution of plumbing and our philanthropic efforts within the community.”

Martin continued, “I want our NIBCO associated, our customers, local school kids to be able to come here and use this so it needed to be interactive. We also highlighted plumbing: where our products go, how they bring water to you, take waste away, but it also highlights our four manufacturing processes—plastics, copper, bronze and iron.”

Martin continued, “I want our NIBCO associated, our customers, local school kids to be able to come here and use this so it needed to be interactive. We also highlighted plumbing: where our products go, how they bring water to you, take waste away, but it also highlights our four manufacturing processes—plastics, copper, bronze and iron.”

The museum offers a unique and enriching experience from a historical perspective, interactive learning, inspiration, community impact, and career opportunities. Not just a place to learn about the past, it’s a place to get excited about the future of plumbing and the opportunities it holds.

Artifacts, representing various aspects of the history of plumbing, as well as the history of NIBCO, are exhibited throughout the museum, including:

- Early foundry tools

- Original crown jewels of NIBCO

- Original early fittings including the first fitting from 1927 and early valves

- Original product blueprints from the 1930s

- Items from Lee Martin’s collection

- Original printings of Ross Martin’s collection of booklets

- Philanthropic contributions

- Collectibles and promotions

The 8,845-square-foot building was completely renovated beginning in 2023. The museum portion of the space is 3,254 square feet, and additional space in the building will be used as a training area for customers, distributors, and NIBCO associates.

https://vimeo.com/1027108697 On this update, we’ll talk PFAS, our podcasts where on the Make Trades Great Again, Eric and Andy shift from shop talk to van talk, and on the Appetite for Construction podcast, Tim and John talk with Ryan Shikhman about Trades Over College, and we update you on what’s trending on social media the Read more

On this update, we’ll talk PFAS, our podcasts where on the Make Trades Great Again, Eric and Andy shift from shop talk to van talk, and on the Appetite for Construction podcast, Tim and John talk with Ryan Shikhman about Trades Over College, and we update you on what’s trending on social media the past few weeks.

Back in May, I attended the Emerging Water Technology Symposium in Scottsdale, Ariz. Some of the brightest minds in the industry met to discuss water, water efficiency, and what new technology can be used to help conserve this precious resource. On of the many topics that stood out was conversation regarding PFAS. What the heck Read more

Back in May, I attended the Emerging Water Technology Symposium in Scottsdale, Ariz. Some of the brightest minds in the industry met to discuss water, water efficiency, and what new technology can be used to help conserve this precious resource. On of the many topics that stood out was conversation regarding PFAS. What the heck is that, you ask? Well, not necessarily new, it could be considered today’s Flint/lead in piping. I recently caught up with one of those PFAS experts, Eric Yeggy, Director of Technical Affairs, Water Quality Association, who spoke back in the desert on the subject.

MH: For those unaware, what is PFAS?

YEGGY: Per- and polyfluoroalkyl substances, or PFAS, are a group of man-made chemicals that are used in many industries. They have unique chemical properties which make them ideal for use in non-stick coatings, water-resistant fabrics, fire-fighting foams, and many other products. People often refer to PFAS as “forever chemicals” because they do not break down naturally in the environment.

There are thousands of different types of PFAS in use. Some estimate that there are as many as 15,000 different PFAS in use, many of which are considered proprietary chemicals. The exact chemical structure of these proprietary chemicals is not disclosed, which makes it very difficult to test for these chemicals. We know the most about two specific PFAS, PFOA and PFOS, which were voluntarily phased out of production in the U.S. by 2015. We know that PFOA and PFOS have found their way into our food supplies and into our drinking water, and we know that there are serious health concerns associated with these chemicals. Unfortunately, we know the least about the many other PFAS currently in use, including the next-generation PFAS chemicals that the industry switched to when they phased out PFOA and PFOS.

MH: Why is it so important for our audience to know about this?

YEGGY: Once PFAS are released into the environment, they are going to persist until we remove them. Once they reach a water source, such as a stream, lake, or underground aquifer, they can travel many miles. This persistence and mobility is why they are showing up in our food and drinking water. Studies have shown that the majority of people tested for PFAS have detectable levels in their blood.

Ingestion of PFAS through food or drinking water can lead to serious health issues including: reproductive effects such as decreased fertility; developmental effects in children such as low birth weight; behavioral changes in children; interference with hormones; interference with the body’s immune system; decreased effectiveness of vaccines; increased risk of some cancers including prostate, kidney and testicular cancers; increased cholesterol levels and obesity.

MH: How can one be exposed to PFAS, or is it all around us?

YEGGY: PFAS are all around us. We all use products on a daily basis that were made with PFAS. Beyond our food and water, common examples include cookware, carpet; upholstery, clothing, makeup, shampoo, dentil floss, paper straws, paper towels, product packaging, and even food packaging.

MH: Are children more susceptible to it?

YEGGY: It is still unknown whether children are more sensitive to all of the harmful effects of PFAS, but obviously since they are still developing, they are more susceptible to any chemical like PFAS that can cause detrimental development effects. And because of their behaviors, children might be exposed more than adults. Children play on the floor where they may be more exposed to microparticles of carpet that contain PFAS. Very young children have a habit of putting things in their mouths. Children drink more water, eat more food, and breathe more air per pound of body weight than adults do. All of these factors potentially increase the exposure risk of children.

MH: I feel like PFAS has come up lately more in conversations but I realize that it has been a problem for some time, and it has become the “new lead in drinking water crisis.” Am I oversimplifying this?

YEGGY: No, I think you are correct about that. PFAS have been a problem for many decades. The EPA’s recent actions to regulate PFAS, especially in our drinking water, have brought new media attention to an old problem that the general public wasn’t previously knowledgeable of.

MH: Is there anything that can be done to lower PFAS levels or limit it?

YEGGY: Because PFAS are so persistent in the environment, we will need to get better at preventing that from happening in the first place. Right now we are continuously recycling PFAS back into the environment (see attached graphic). Much of it passes right through wastewater treatment plants, ending up back in the surface water. Some of it is captured in the wastewater treatment sludge, which is then land-applied as fertilizer. The PFAS leaches out of the sludge and is either carried off by stormwater to a nearby stream, or percolates down through the soil into the groundwater. If PFAS-laden waste ends up in a  landfill, you will have PFAS in the landfill leachate solution that is sent to the local wastewater treatment plant, which simply starts the cycle over again. You may also end up with some landfill leachate solution containing PFAS escaping and percolating down into the groundwater. On top of all this continued recycling of PFAS back into the environment, you also have the industry constantly creating more PFAS, which eventually ends up in this cycle.

landfill, you will have PFAS in the landfill leachate solution that is sent to the local wastewater treatment plant, which simply starts the cycle over again. You may also end up with some landfill leachate solution containing PFAS escaping and percolating down into the groundwater. On top of all this continued recycling of PFAS back into the environment, you also have the industry constantly creating more PFAS, which eventually ends up in this cycle.

The good news for consumers is that companies are becoming more sensitive to these concerns and looking for alternatives to PFAS. And there are very simple over-the-counter treatment devices that consumers can use to remove PFAS from their drinking water. For the DIY consumer, there are Filters and Reverse Osmosis systems certified to remove PFAS. Look for a third-party certified seal on the product packaging that indicates the product has been certified to reduce the concentration of PFAS. The three most common third-party seals in the U.S. market are the IAPMO seal, the NSF seal and the WQA seal. I will send you a slide that shows their seals and websites.

Consumers who prefer to have a trained water treatment professional take care of this can use our website to find a qualified water treatment professional in their area who has agreed to abide by WQA’s code of ethics:

Or better yet they can use our more advanced search engine to find a Certified water treatment professional in their area, who has also agreed to abide by WQA’s code of ethics:

https://find.wqa.org/programs-services/resources/find-providers/find-certified-professionals

MH: Where can we find more information on PFAS?

YEGGY: Consumers who have questions about PFAS in drinking water can reach out to WQA (wqa@wqa.org or 630-505-0160).

WQA also has a PFAS guide for the general public:

https://wqa.org/wp-content/uploads/2024/04/PFAS-Consumer.pdf

The EPA also has a good website on PFAS which contains general information, and a link where people can submit questions to the EPA:

https://www.epa.gov/pfas/our-current-understanding-human-health-and-environmental-risks-pfas

https://vimeo.com/1025087361 We hope you all had a great Halloween with plenty of little visitors dressed up in their most creative costumes. This week we’ll talk presidential election, where the race for the White House is certainly heating up. Key battle ground states are still undecided. If you haven’t already, get out and vote. Election day Read more

We hope you all had a great Halloween with plenty of little visitors dressed up in their most creative costumes. This week we’ll talk presidential election, where the race for the White House is certainly heating up. Key battle ground states are still undecided. If you haven’t already, get out and vote. Election day is next Tuesday.