Birmingham, Ala., rolls out the crimson red carpet for Plumbing-Heating-Cooling Contractors Association (PHCC) and its attendees. “The Magic City” played host to the annual PHCC CONNECT show and the city pulled out all the stops. With mild October temperatures, it was the perfect setting to connect with fellow attendees and soak in the vibrant culture Read more

Featured Articles

Birmingham, Ala., rolls out the crimson red carpet for Plumbing-Heating-Cooling Contractors Association (PHCC) and its attendees.

“The Magic City” played host to the annual PHCC CONNECT show and the city pulled out all the stops. With mild October temperatures, it was the perfect setting to connect with fellow attendees and soak in the vibrant culture of Birmingham.

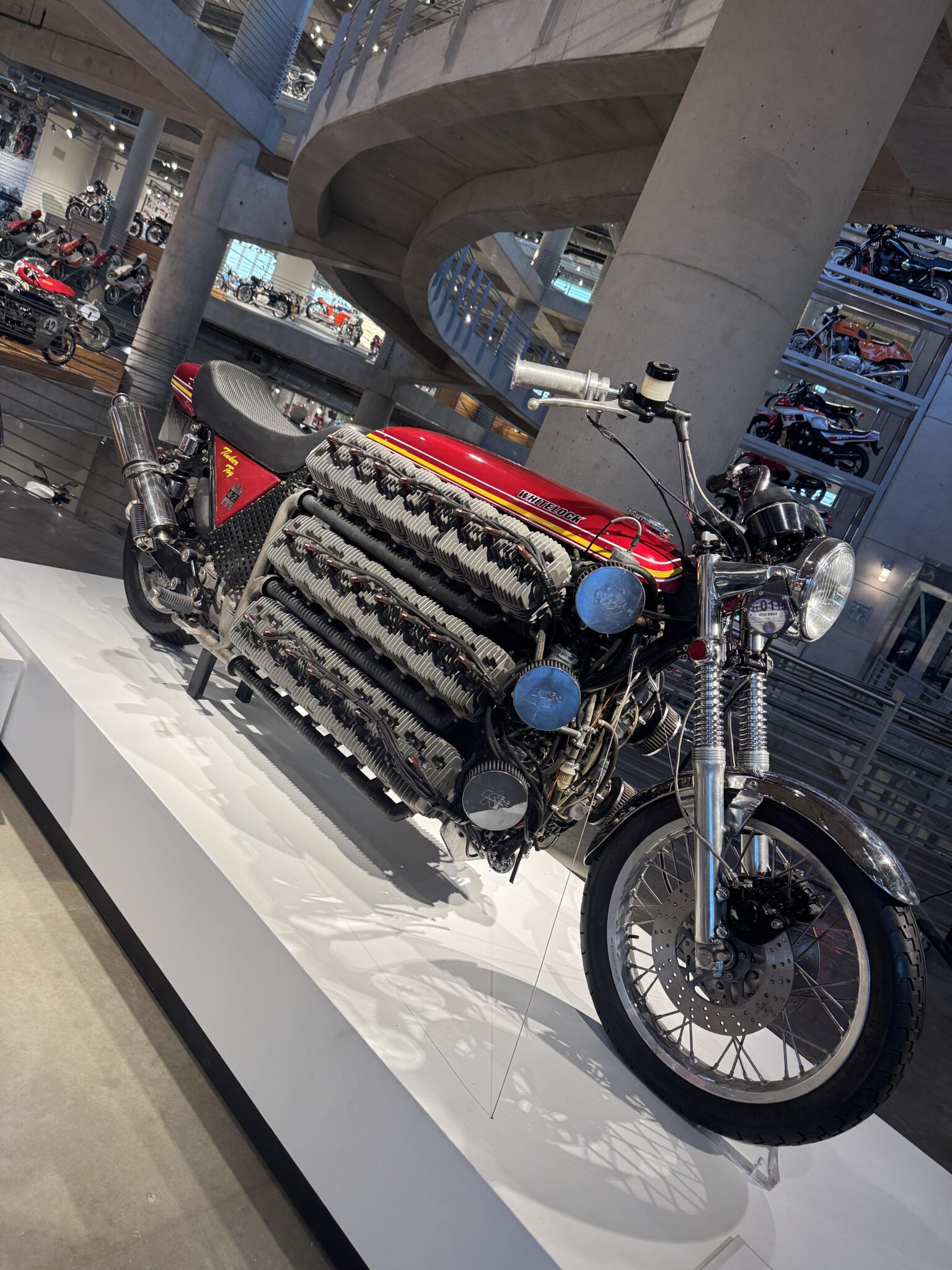

The CONNECT show began with an opening reception at the Barber Vintage Motorsports Museum—recognized by the Guinness World Records as the world’s largest motorcycle collection and home to other rare cars—and ended with an Alabama Tailgate Party at Birmingham Citywalk, where visitors could enjoy an array of food trucks serving local delicacies and engage in fun games.

The trade show floor was buzzing with latest in products and technology. New this year—although one needed to be a member to gain full access to the entire CONNECT experience—the Products & Technology Showcase floor was open free of charge to local walk-ins. This indeed brought in dozens more from the greater Birmingham area.

“This is the best place to do all of the networking,” says Erica Barnes, president, General Plumbing & Air Conditioning, Inc., Lake Worth, Fla. “I love getting new ideas form the floor and seeing what’s developing over time, such as artificial intelligence (AI) or seeing what new tools are coming out.”

A cool moment during PHCC president Joe Cornetta’s CONNECT opener, 94-year-old James Lindsey of Lindsey Brothers Plumbing and Heating in Norfolk, Va., was recognized for his contributions to PHCC and the industry. Starting his plumbing career at 16, he founded his own business, which will celebrate its 60th anniversary in 2026.

A cool moment during PHCC president Joe Cornetta’s CONNECT opener, 94-year-old James Lindsey of Lindsey Brothers Plumbing and Heating in Norfolk, Va., was recognized for his contributions to PHCC and the industry. Starting his plumbing career at 16, he founded his own business, which will celebrate its 60th anniversary in 2026.

The annual CONNECT Show opens with an opening breakfast emceed by Bruce Carnevale, CEO, Bradford White, a staunch supporter of the association and the skilled trades. Carnevale gave an update on the company and talked about the impending NAECA 4 regulations coming down the pike in 2029, with the eventual movement away from atmospheric venting to all condensing. The Department of Energy (DOE) says the standards will require minor updates to gas-fired storage water heaters, while electric storage water heaters more than 35 gallons will require heat pump technology.

A yearly staple at the CONNECT show is the PHCC Educational Foundation’s National Plumbing and HVACR apprentice contests where plumbing apprentices roughed-in a bathroom—including the drain, waste and vent lines, a toilet, a sink and shower. HVACR apprentices demonstrated their knowledge with a written test, and put their hands-on skills to the test with brazing, pressure testing, refrigerant recovery, and diagnosing and repairing a package unit system. This year, Logan Cunningham with John J. Maurer Inc., Cataumet, Mass., took top prize for plumbing, while Dane Gonser with Emcor Services Fagan, Kansas City, Kansas, was the winner of the HVAC portion.

This year’s theme, “Authentic Connections,” highlighted the importance of building trust and fostering relationships within the industry. From the daily keynotes featuring best-selling author and Navy commander Mary Kelly, who uncovered the key factors behind leadership success and failure to Jeff Butler, who with the help of the three “Cs”—cadence, collaboration and communication—explored actionable strategies to effectively manage cross-generational challenges and leverage the diversity of your multi-generational workforce as a competitive advantage.

Another highly informative and interactive session featured some of the industry’s most recognizable social media personalities who gave advice in a session aptly named, “What the Hell Is an Influencer?” In addition to friends George DeJesus, George’s Drains LLC, Morris County, N.J., and Mike Prencavage Jr., The Family Plumber, Los Alamitos, Calif., last-minute, heavy-hitter fill-ins, Dustin Van Orman, Any Hour Services, Orem Utah, and Roger Wakefield, Richardson, Tex., stepped in to inform attendees how to use social media in an effective way, for business of course.

The final keynote on reverse mentoring, moderated by yours truly, featured Erica Barnes, president, General Plumbing & Air Conditioning; Daniel Birmingham, project manager, JRC Mechanical, Chesapeake, Va.; Chris Johnson, owner, Charles Chester Plumbing & Heating, Elko, Nev.; Chase Johnson, general manager, Charles Chester Plumbing & Heating; and Tyler Arndt, Arndt & Sons Plumbing, Brooklyn, Wis., as they shared their experiences and how their ideas and contributions could help their companies thrive in the future.

The final keynote on reverse mentoring, moderated by yours truly, featured Erica Barnes, president, General Plumbing & Air Conditioning; Daniel Birmingham, project manager, JRC Mechanical, Chesapeake, Va.; Chris Johnson, owner, Charles Chester Plumbing & Heating, Elko, Nev.; Chase Johnson, general manager, Charles Chester Plumbing & Heating; and Tyler Arndt, Arndt & Sons Plumbing, Brooklyn, Wis., as they shared their experiences and how their ideas and contributions could help their companies thrive in the future.

Also new this year to CONNECT was live podcasting from the tradeshow floor. The magic of spontaneous discussions, solutions, and insights came alive with some of the industry’s top podcasters. These media personalities hosted high-profile guests as they shared their particular insights to the industry.

Oh, and why is Birmingham called the Magic City, you may ask? Including other names such as “The Iron City” or “The Pittsburgh of the South,” Birmingham is referenced as the Magic City because its soil contained the three necessary elements to produce steel: limestone, coal and iron ore.

Next year’s CONNECT will take place in Grand Rapids, Mich.

https://vimeo.com/1022947522 This week we talk ASPE, which just took place this week actually. Tim Ward gives an update from the show floor and we visit with our friends from Uponor. We have a new Contractor Spotlight on the site. We talk American Plumber Stories Season 5, Episode 2. And, of course, we’ll talk podcasts Read more

This week we talk ASPE, which just took place this week actually. Tim Ward gives an update from the show floor and we visit with our friends from Uponor. We have a new Contractor Spotlight on the site. We talk American Plumber Stories Season 5, Episode 2. And, of course, we’ll talk podcasts.

Still crushing it 40+ years into the plumbing trade, Susan Jacobs-Marshalsea, Ms. Fix It Plumbing LLC, Foxborough, Mass. (@plumbersue on Instagram) says it’s that love of plumbing that still motivates her to this day. And there are really no plans of slowing down as of yet, “It’s probably the adrenaline that kicks in so the Read more

Still crushing it 40+ years into the plumbing trade, Susan Jacobs-Marshalsea, Ms. Fix It Plumbing LLC, Foxborough, Mass. (@plumbersue on Instagram) says it’s that love of plumbing that still motivates her to this day. And there are really no plans of slowing down as of yet, “It’s probably the adrenaline that kicks in so the physical aspect of plumbing sometimes gets ignored by my body because my brain just tells me to do it. Customers with emergencies and/or plumbing issues still excite me. I will plumb as long as I can physically,” says Jacobs-Marshalsea.

And that’s a good thing. You see, Jacobs-Marshalsea has been a staunch advocate for women in the trades. “Did you know that only 3.5% of plumbers are women. Did you also know that only 2.2% of electricians are women, only 3% of tile/carpet installers are women and less than 2% of carpenters are women? I don’t know why the percentage is so low,” says Jacobs-Marshalsea. “This is why I have become overly obnoxious in my Facebook and Instagram posts. Hopefully, other women seeing me plumb may encourage/entice them to think about a trade as a career.”

When asked about what we can do as an industry to help bring women into the trades, “Exactly what you did with asking me these questions,” she says. “We women need to put ourselves out there and promote ourselves and by having news interviews, publication interviews, promote workshops/trade shows and speak at local middle/high school career fairs—anything that helps get the word out that women can be in this trade, and that we are very good at it for various reasons.”

Jacobs-Marshalsea says she really doesn’t “fight” any stigma today as far as being a woman in the trades. “I did 40+ years ago in the late 1970s, early ’80s. There weren’t many female tradeswomen back then, especially in the private sector. I’ve made a name for myself and have a great customer base and get referred often so I feel I have proved myself decades ago. Now I’m just the pink plumber lady, locally.”

Jacobs-Marshalsea says she really doesn’t “fight” any stigma today as far as being a woman in the trades. “I did 40+ years ago in the late 1970s, early ’80s. There weren’t many female tradeswomen back then, especially in the private sector. I’ve made a name for myself and have a great customer base and get referred often so I feel I have proved myself decades ago. Now I’m just the pink plumber lady, locally.”

But does Jacobs-Marshalsea consider herself a mentor? She’d love to mentor but very few women/girls are interested in plumbing, she says. “I think it’s the poop thing. And we all know that unless you are a drain cleaner, plumbers only come across ‘poop’ maybe 3-5 a month.”

Jacobs-Marshalsea teaches Plumbing 101 workshops to condo/homeowners, real estate agents, youth groups, parent/child, married couples, etc. so that she will have something to do, and a form of income, during retirement. “I started teaching because of the shortage of tradespeople—just little plumbing knowledge and repairs,” says Jacobs-Marshalsea.

The Beginnings

As fifth generation Master Plumber in Massachusetts, it was a no-brainer for Jacobs-Marshalsea. Jacobs Plumbing started in 1895 in Boston and her father was her mentor. “At first, he didn’t think women could plumb—late 1970s—but after a few jobs, he decided that I had the capability to do anything I set my mind to,” says Jacobs- Marshalsea.

After her father became ill and closed his business after 50 years, Susan started her own business in 2015 as S Jacobs Plumbing LLC. Susan rebranded and renamed her business around 2018 and Ms. Fix It Plumbing LLC was born. It’s as strong as ever, even more so during and after pandemic. “I assisted my father for more than 30 years in handling all aspects of his business—up to 15 guys, all the business stuff, running jobs, employees, advertising, fleet maintenance, etc—so when he closed his business I was fully up and running with my own in under a week,” says Jacobs-Marshalsea.

Today, with more than 600 residential/commercial/industrial customers, Susan has never not had her phone ring. She takes pride in still having a live-person, 24-hour answering service that she has used for more than 40 years, which helps people know that she will receive their message. “There is something about a customer calling and actually speaking with a live person, especially with an emergency, that eases their minds,” says Jacobs-Marshalsea.

“I receive that call via email within 10-30 seconds of them hanging up. I then text them within 2-4 hours, depending on the plumbing issue or if they are an existing customer. I then have them send photo(s)/video(s) of their plumbing problem and can diagnose within minutes of what needs to be done.”

“I receive that call via email within 10-30 seconds of them hanging up. I then text them within 2-4 hours, depending on the plumbing issue or if they are an existing customer. I then have them send photo(s)/video(s) of their plumbing problem and can diagnose within minutes of what needs to be done.”

And while Jacobs-Marshalsea admits she loves plumbing and all it entails, surely there must be something she doesn’t care for, no? “Crawl spaces is probably my least favorite, but because I’m a small woman, I can get into most places male plumbers cannot. And, due to the shortage of tradespeople, specifically plumbers, the T&M rates (including flat rate) have been steadily increasing, so when someone asks how much something will be and I give them a guesstimate they are astonished and try to get me to lower my guesstimate, which is the thing I dislike about having a business or being a plumber. We protect the health of the nation and we are licensed and insured and are mandated to go to Continuing Education, so that frustrates me a lot,” says Jacobs-Marshalsea.

The Personal Side

When Jacobs-Marshalsea is not plumbing, she is working elsewhere, whether it’s in her gardens, getting ready for a workshop, volunteering for many non-profits, making improvements on her own home or offering to help someone else. “I find keeping busy keeps my mind sharp and my body flexible,” she says.

“But I’d like to take 30+ days and fly to California and rent a RV van and drive across America back to MA to see the country.”

Susan is finding that her social media is important for a handful of reasons. In addition to being informative, “People love to see me in my ‘yoga positions’ or ‘what to do or not to do’ or ‘helpful hints.’ Posting frequently lightens my day, and other’s as well.”

Finally, when asked when the last time she said, Today is a great day, “Every day is a great day— the sun came up and my feet hit the floor so when I leave somewhere I always say, ‘Have a great day!’”

The staff at Spark by Hilton™ in Redlands, California, turned to A. O. Smith for a water heater capable of providing ample hot water to their hotel. It’s no simple task to supply hot water all day, every day, to a hotel with 85 rooms, a kitchen and multiple commercial laundry facilities. But for A Read more

The staff at Spark by Hilton™ in Redlands, California, turned to A. O. Smith for a water heater capable of providing ample hot water to their hotel. It’s no simple task to supply hot water all day, every day, to a hotel with 85 rooms, a kitchen and multiple commercial laundry facilities. But for A. O. Smith, it was the perfect opportunity to showcase the power of the CHP-120 Fully Integrated Commercial Heat Pump Water Heater (HPWH).

The hotel chose to install four CHP-120 HPWH units—all of which function as part of a single fully integrated water heating system. It was critically important to the specifying engineer that the system be integrated as it makes installation significantly easier and is more cost-effective for the hotel.

“I prefer the CHP-120 model’s integrated system because it makes installation and piping easier than other competitive technologies,” said Peter Yoon, lead specifying engineer and owner of American Power Solutions. “The CHP-120 unit is more compact, which means our team does not have to worry about the typical mechanical room space constraints associated with an average commercial unit. We also do not have to worry about additional space for insulation or the need for a large pipe for the system, which makes my job very simple and easy.”

“It takes two days to install the units, with only 10 hours of water shutoff required. After those ten hours of work, your machine will be set to run,” noted Yoon. “There is not much maintenance needed except a filter replacement every year or every other year, so I love it.”

Features & Benefits:

- Industry-leading 4.3 Co-efficient of Performance (COP)

- ENERGY STAR®-certified

- Heat pump technology provides a more energy-efficient way to heat water with electricity

- Integrated 119-gallon tank enables heat pump to operate more frequently, saving money

- Three operating modes (Efficiency, Hybrid, and Electric) maximize efficiency while meeting specific hot water demands

- First-hour delivery exceeds 194 GPH

- Dual 6 kW heating elements provide additional heating capability for periods of high demand

- Maximum water temperature of 150° F in Efficiency and Hybrid modes, and 180° F in Electric mode

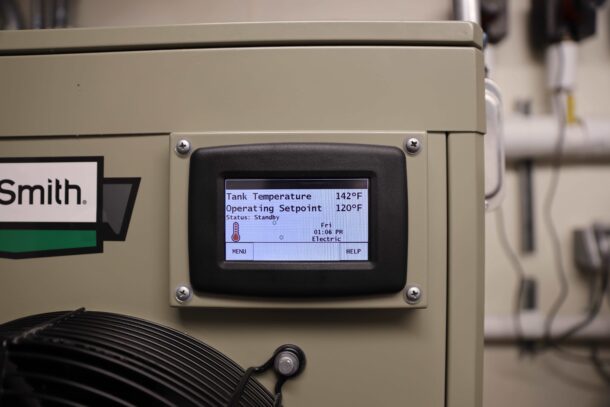

- Large touchscreen LCD display allows for mode selection, provides run information, and includes troubleshooting alerts and detail

Beyond improving the installation process, the CHP-120 HPWH provides the hotel with incredible cost savings on energy. The CHP-120 unit is four times more efficient than a standard electric water heater, saving the hotel up to $3,000 per unit on their annual electric bills. The CHP-120 does this by moving heat from the surrounding air rather than creating heat, allowing it to run at an industry-leading 4.3 Coefficient of Performance (CoP).

The CHP-120 HPWH comes with three different operating modes for maximum efficiency. The three operating modes (Efficiency, Hybrid, and Electric) allow facility managers to adjust as needed to meet the hotel’s varying hot water demands. Facility managers can easily switch between modes due to the CHP-120 unit’s large touchscreen LCD display, which allows for mode selection, and displays run information, including troubleshooting alerts and details. Dual 6 kW heating elements integrated into the unit provide additional heating capability for periods of high demand. This feature ensures that even when the hotel reaches maximum capacity, it can still supply ample hot water to customers, even those staying on the highest floors.

“We used to get customer complaints about not getting hot water on the higher floors of the hotel, but since installing A. O. Smith’s CHP-120 units there have been no customer complaints,” said the hotel manager. “The hot water on the first floor is the same temperature hot water that guests experience on the third floor of the hotel.”

In addition to improving the guest experience, the CHP-120 unit also qualifies for significant utility rebates in the state of California. Payback time on the investment of installing a unit is expected to be just under two years.

“With the current rebate program, it’s almost cost-free to the customer,” said Yoon. “When replacing an old boiler, the investment in new technology is typically the biggest barrier, but with the CHP-120 HPWH we received a big rebate upfront. California has aggressive energy savings goals, so they provide generous rebates on high-efficiency technology like the CHP-120 model. We received $20,000 in rebates for each unit that we installed at the Spark Hotel.”

“Going from a gas-fired water heater to the CHP-120 HPWH, the savings are dramatic. Customers could be wasting thousands of dollars a year by not making the switch,” said Anthony Sun, Delco salesman. “Once the CHP-120 unit is installed, it can run in efficiency mode by using just the compressor, the cool air and the hot air in the room to heat the water, saving the hotel money and energy.”

Find more information about the CHP-120 HPWH and other products at www.hotwater.com.

https://vimeo.com/1020210961 What normally is a “quiet” time of year in terms of traveling for us, we have been on the road the road these last few weeks. In this update, we’ll talk PHCC CONNECT in Birmingham, Ala., ASPE in Columbus, Ohio, our critically-acclaimed weekly podcasts, and, yes, hand washing Read more

What normally is a “quiet” time of year in terms of traveling for us, we have been on the road the road these last few weeks. In this update, we’ll talk PHCC CONNECT in Birmingham, Ala., ASPE in Columbus, Ohio, our critically-acclaimed weekly podcasts, and, yes, hand washing.