Last week, the Mechanical Hub Team was onsite to visit the Iowa Build My Future event, where 5,500 kids from across the state were bussed to experience the hands-on trade job fair. Here is a video that accurately describes the event. https://youtu.be/rWG8JLM07k4 Read more

Featured Articles

Last week, the Mechanical Hub Team was onsite to visit the Iowa Build My Future event, where 5,500 kids from across the state were bussed to experience the hands-on trade job fair. Here is a video that accurately describes the event.

Way back in 1987, ASHRAE experts developed the BACnet protocol as a communications standard for Building Automation Systems (BAS). BACnet has since earned the respect of specifying engineers, facility managers, controls experts and service technicians worldwide as it’s now the leading technology in building automation. BACnet offers an open architecture and the ability to control Read more

Way back in 1987, ASHRAE experts developed the BACnet protocol as a communications standard for Building Automation Systems (BAS). BACnet has since earned the respect of specifying engineers, facility managers, controls experts and service technicians worldwide as it’s now the leading technology in building automation.

BACnet offers an open architecture and the ability to control and monitor any building automation process—from water sourced heat pumps and chillers to boilers and volume water heaters.

At North Andover, Mass.-based Watts, one of the largest and most diverse manufacturers in the plumbing and mechanical and HVAC market, BACnet has been incorporated into several of its brands’ technologies, most notably through its HVAC and snow-melting controls brand, tekmar; “IntelliStation” digital mixing stations for commercial domestic water control and tempering by their brand, Powers; and for Benchmark boilers and Innovation water heaters (via their “EDGE” controller), offered by the company’s brand, AERCO.

“For us, BACnet is so useful because it’s a standardized communication protocol that interconnects and ‘talks to’ all other BAS-connected technologies throughout an entire facility, and also facilitates remote monitoring and control,” said Amar Dhore, AERCO Software Engineering Supervisor. “When fully integrated, all communications can work through one BACnet device. That’s the advantage of standardization, and what it enables.”

New York-based AERCO is one of the nation’s leading suppliers of commercial condensing boilers and water heaters for a variety of industries. Several years ago two of AERCO’s brands—Benchmark boilers, andInnovation water heaters—adopted the use of BACnet to offer sophisticated communications through their EDGE controller and ProtoNode gateway, the key interfaces to BAS for legacy system communications.

AERCO offers a multi-protocol, communications gateway to support integration with customers’ building automation (BAS) and energy management systems (EMS). The plug-n-play package supports build in integration with BACnet/IP, BACnet MS/TP, Modbus RTU, Modbus MSTP. AERCO also has a ProtoNode Gateway to support legacy products like Benchmark standard, Modulex EXT boilers; Innovation and SmartPlate water heaters.

AERCO offers a multi-protocol, communications gateway to support integration with customers’ building automation (BAS) and energy management systems (EMS). The plug-n-play package supports build in integration with BACnet/IP, BACnet MS/TP, Modbus RTU, Modbus MSTP. AERCO also has a ProtoNode Gateway to support legacy products like Benchmark standard, Modulex EXT boilers; Innovation and SmartPlate water heaters.

AERCO’s EDGE features built-in translation for BACnet/IP, BACnet MS/ TP, Modbus RTU and Modbus TCP protocols; these communications are selectable and configurable via touch screen (No DIP switch needed). With this easy access to data, customers have ready access to more data. They can also choose and map BAS points of his interest to access, control and monitor devices.

In fact, the company’s Benchmark Platinum boilers can be managed effectively with an app that connects with the EDGE controller. With the app, a service technician or facility manager can monitor or balance hydronic system flow, perform a wide variety of system diagnostics, or combustion analysis and calibration.

For building owners, the EDGE permits trouble-free management of all boiler/water heaters functions—whether one unit or up to 16 units, connected in a cascade.

The EDGE controller also permits flow balancing—a function that allows elimination of balancing valves and also reduces commissioning costs, one of many operations enabled through the built-in communications via BACnet IP, BACnet MS/TP, Modbus IP or Modbus RTU.

Start-up and maintenance functions are also simplified. Boilers +/or water heaters can be calibrated through assisted or manual operations, a big time-savings advantage. The assisted options offers guided steps that automatically adjust precise air/fuel ratios for optimal performance.

AERCO access and control security:

AERCO managers understand the importance of security and have taken steps to make BAS communication secure. EDGE offers built in security using IP and MAC address. Once the security is enabled, user needs to enter front end BAS MAC and IP address. Once done, Edge will only accept the communication from the BAS with specified MAC and IP address.

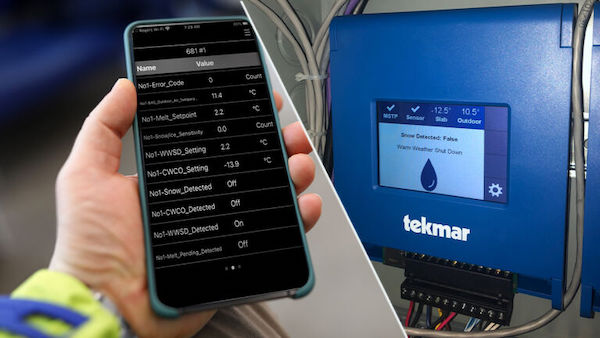

tekmar’s 680, 681 + 284

Vernon, BC-based tekmar Control Systems, a Watts brand, is a world class integrated engineering and manufacturing company that provides solutions for the HVAC industry. For the past 38 years, tekmar has earned a reputation as the leader in complete control solutions for hydronic radiant floor and baseboard heating systems, multi-stage boilers plants, and automatic snow melting controls.

tekmar provides energy-saving control solutions for a broad range of hydronic systems—whether within a building, or outside (for snowmelt or turf-warming)—while assuring no-compromise comfort control, system efficiency and durability.

The company’s technologies provide:

- Setpoint controls—offering precise temperature control for domestic water storage tanks, pools and hot tubs.

- Boiler + domestic water controls—These technologies are designed to control temperature and operation of multiple boilers or volume water heaters. Multi-staging controls provide significant energy savings while also enhancing system reliability.

- Heating controls—Here, tekmar offers controls to provide zoning solutions for heating systems; specific models are designed for use in hydronic heating, radiant heating, HVAC systems, and baseboard or “hydro-air” applications.

- tekmarNet 4 zoning controls—These technologies connect to thermostats to control operation of heating system zone valves or heat pumps for precise delivery of heat.

- Snowmelt control and sensors—Snowmelt control systems measure and control road, driveway or walkway surface temperatures to provide safe, snow- and ice-free surfaces, and at the lowest operating cost. Controls may connect to electric or hydronic systems as the source of warmth. Fully automatic controls, or manual controls can be chosen.

“Our specialties are boiler and snowmelt system controls,” explained tekmar’s Cleber Alves. “One of our unique products is the new BACnet snow/ice sensor interface 681—designed to measure the presence of snow or ice and interfaces with the BAS to activate or deactivate electric or hydronic snow melting systems.”

According to Alves, the 681 uses tekmar sensor technology to automatically detect precipitation, then communicates with the BAS through BACnet MS/TP. This operation allows the BAS to automatically turn the heat source and distribution system on, or off, and provide operational status for all snow-melt functions. The 681 is ideally suited for commercial applications such as hospitals, schools, airports, ski resorts, business entrances, driveways, loading docks, and shopping malls.

According to Alves, the 681 uses tekmar sensor technology to automatically detect precipitation, then communicates with the BAS through BACnet MS/TP. This operation allows the BAS to automatically turn the heat source and distribution system on, or off, and provide operational status for all snow-melt functions. The 681 is ideally suited for commercial applications such as hospitals, schools, airports, ski resorts, business entrances, driveways, loading docks, and shopping malls.

The 681’s features include slab target temperature, automatic snow and ice detection, error codes, warm weather shut-down, melt pending function, cold weather shutdown, and supports both in-slab and retrofit aerial sensors—all with BACnet MS/TP communication.

IntelliStation digital water control

Public safety relies chiefly on the availability of clean water. As it can affect water quality, the condition of premise (building-specific) plumbing systems have a direct impact on the safety of those within the facility. The ability to remotely monitor and control water temperature, flow, and other parameters in a quick and precise way is vital to delivering healthy, safe water in an efficient manner.

Patents held by Powers, a Watts brand, function as the backbone for many products in commercial and industrial water temperature control markets. The company develops and manufactures thermostatic and digital mixing solutions to bring safety and comfort to modern plumbing systems.

“IntelliStation and IntelliStation Jr. [a smaller version] digital water mixing systems are designed to deliver tempered hot water throughout a recirculation loop in commercial and institutional facilities,” explains Sr. Product Manager Bruce Fathers. “Our digital solutions can be integrated into a BAS to allow facilities managers to remotely monitor and control water temperatures.

“We offer most of the common protocols, with gateways to others if need be,” added Fathers. “Modbus and BACnet are native to our controller, so it’s integrated into our IntelliStation products with no additional cost. Most of our competitors do require an additional module at an added cost to facilitate BACnet. So, it’s become a competitive edge for us, one our customers have come to appreciate.”

According to Fathers, BAS is used to seamlessly monitor and control important facets of system operation—such as mixed outlet temperature, pressure, flow, and inlet temperature. The sensors all require connection/input points.

“For commercial domestic water systems, mixed outlet temperature is most important,” explained Fathers. “It’s typically set at 120°F, or 140°F—to either render [biogens/pathogens] unable to reproduce, or to outright kill them [point-of-use mixing valves are then used at showers and faucets to protect users. Facility managers have remote visibility to all critical datapoints.

Fast, responsive digital technology enables the collection of a large amount of data which can be stored and communicated through a building automation system (BAS) or locally at the controller, providing intelligence at the foundation of the entire plumbing system.

Internet of Water

Control of the water recirculation loop ensures safe, precise, and consistent water temperatures (+/- 2oF), supports energy conservation, and reduces energy costs. BACnet IP, BACnet MSTP, and Modbus protocols are supported.

Technology helps to fulfill these needs with digital mixing and connected components like sensors and cloud-based monitoring.

The extent to which COVID-19 has impacted public health and the increased prevalence of Legionella bacteria have highlighted the need for:

- Visibility of water temperature, flow, and quality even when off-site

- A way to remotely control water temperatures

- Automated monitoring and reporting of premise plumbing water parameters and facility management activity

- Connected products that help increase safety and efficiency

- Reliable ways to reduce the risk of Legionella and other harmful bacteria

BAS empowers facility managers and engineers to proactively prevent issues before they arise, rather than having to react to or attempt to mitigate issues once they’ve occurred,” added Fathers.

There are three main technology-driven components in a digital mixing solution:

- Sensors, serving as eyes and ears

- The controller’s algorithm (the “mind”)

- Electronic, high-speed actuated valve, continually responds to sensor inputs, to maintain set point

“Our digital mixing controller algorithm processes data from the mixed temperature outlet sensor and signals the actuator to make adjustments to maintain set-points in real time,” continued Fathers. “Sensors relay key system data for pressure, temperature and flow for troubleshooting and optimization.”

Building automation systems give facility managers the ability to see vital data, quickly make informed decisions, and act, even remotely. Digital water mixing controls hot water delivery through a programmable valve or system that processes temperature, flow, and pressure data.

Serious risks, such as Legionella growth, scalding, and thermal shock are associated with mismanaged water temperature. Legionella bacteria are destroyed almost instantly at water temperatures above 160°F, but at temperatures between 70°F and 115°F, their growth is abundant. The Catch 22 is that uncontrolled and unmonitored water distribution systems can create high-temperature scalding hazards in bathtubs, sinks, and showers.

A proactive monitoring program can help reduce risks, predict trends, and improve operational efficiency. Proactive monitoring enables three key control measures that help address modern-day public safety risks:

- Allows for quick decisions based on real data

- Allows facility managers to more easily manager their systems

- Generates automatic reports showing trends and performance

Fortunately, there’s no Catch 22 to the use of BACnet technology. It facilitates fast, reliable communications between all facets of the network it operates in. Watts and its brands rely on BACnet for many operational uses, successfully, and with no compromise.

As far back as he can remember, Derek Zeolla, general manager and licensed plumber at Zeolla Plumbing & Heating Corp., was running plumbing jobs with his father in downtown Boston as early as seven years old. Derek’s dad was a Boston service plumber that ran a 1- to 2-man shop. “It’s not like this was Read more

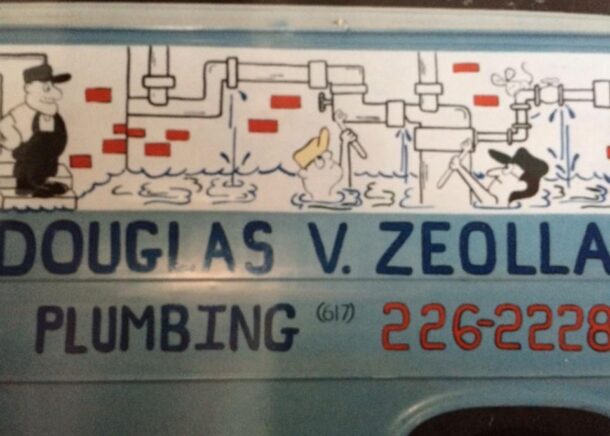

As far back as he can remember, Derek Zeolla, general manager and licensed plumber at Zeolla Plumbing & Heating Corp., was running plumbing jobs with his father in downtown Boston as early as seven years old. Derek’s dad was a Boston service plumber that ran a 1- to 2-man shop. “It’s not like this was common, I was just growing up around it,” says Zeolla (@zeollaplumbing).

Derek Zeolla and his wife Arlene

Derek’s father eventually stopped working as a plumber in the late ’90s. Around this time, while still a teenager, Derek dropped out of school had a baby at the age of 18. Moving forward, “My brother, Doug, and I convinced our dad—also named Doug—to get back into the trade, but before we worked as a family, he sent us off to get experience elsewhere,” recalls Zeolla.

Derek’s father’s company in the ’90s

According to Zeolla, they worked all over the city and jumped around recklessly from company to company, some jobs together, some not. “We always found a way of getting together with a new employer, one of us would talk up the other,” says Zeolla. “It’s funny looking back on that thinking how little we knew back then. My parents were coming off of a divorce and my father was starting to take on some service stuff in our new town Stoughton, Mass. where we grew up and went to high school. Eventually, he had enough work for both of us and we stayed pretty busy,” says Zeolla.

And that’s how Zeolla Plumbing & Heating Corp.—residential service plumbing, drain cleaning, heating, and boiler installation—came to be. “We have built a solid reputation in our area through more than a decade of answering the phone and showing up. Man, we have come a long way since then,” says Zeolla.

The Family Dynamic

Working with his father, brother and one of his cousins most of the time were the best memories in the field for Zeolla. “I can’t explain it, but something about sharing the bond of working together, figuring out problems together, feeling the pride was the best, and I hope to share that with my two boys one day,” says Zeolla.

Derek with his father Doug a few years ago.

But with life, things change. “As many know, my brother passed away. This was tough, and even before that, my father took a step back from the business and went to Florida (but still flies back to Boston from time to time to help out). Add to that, my cousin and I haven’t talked in years so it’s not the same out here anymore,” says Zeolla.

Zeolla says he is blessed that his wife Arlene has filled a void. “She is the savior in the office, and I have a great team.”

Derek also hired his younger cousin Justin last year and he has been phenomenal. “I was out with him today clearing drains on a Sunday and it brought back that feeling again of working with family. Working with a Zeolla,” says Derek nostalgically.

And while Derek puts his father center on the Mount Rushmore of mentors, there were some other people outside the family that were strong influences on Derek. For Zeolla, one of the best was a Greek guy named Alex, who, when Derek was looking for work, took him on for a couple of years. “He taught me how to get shit done; he taught me how to move.”

Derek working with his cousin Justin

Alex was a great mentor yet has since passed away. “Which brings me to, am I a role model? I don’t know, but Alex has two sons. One has come to me looking for mentorship, and it’s just so crazy how things come full circle because now he works with me and he is already just like his father when it comes to plumbing skill.”

Zeolla hopes to be a good role model for him, including and all his younger guys he works with. “I will never steer them in the wrong direction, that’s for sure. This is too important to me,” says Zeolla.

Challenges/Rewards

One of my biggest challenges isn’t the pipes, says Zeolla, it’s the people. “I say this phrase a lot, and I love people in general, and I love my customers, but sometimes when it comes to understanding what we are doing in their homes, it can be challenging. It’s very important to explain things and make sure they feel comfortable. It’s a delicate balance between taking control of a situation and saying, ‘hey, look, I’m the professional here I need you to trust me,’” says Zeolla.

Again, the pipes are the easy part! “I’m lucky that I have great customers. The rewarding part is helping people out, getting someone’s heat back on, clearing a main drain, getting the hot water back, or being told that you are appreciated is probably the best. That ride home to then seeing your family after you helped another family, that’s the reward.”

Leisure Time

Derek and his wife love to travel, and they take their kids literally everywhere they go. AHR Atlanta was their second time leaving them overnight in five years. But basically, there is no leisure time without the phone ringing and Derek coordinating with his six guys, and customers. “My wife and I are like running a telethon while ‘trying’ to be on a vacation. We love it and we are good at it, but she knows I can’t be away from the field long. It’s my therapy and I get depressed if I’m not turning wrenches,” says Zeolla, a self-described workaholic.

As far as spare time close to home, Zeolla enjoys fishing, hiking and hanging out at his cabin nestled in the White Mountains of New Hampshire. “Summer weekends there with my boys are what I work toward every week. When my brother passed, I wanted to find a place to escape, and I found something special,” says Zeolla.

As far as spare time close to home, Zeolla enjoys fishing, hiking and hanging out at his cabin nestled in the White Mountains of New Hampshire. “Summer weekends there with my boys are what I work toward every week. When my brother passed, I wanted to find a place to escape, and I found something special,” says Zeolla.

The Skilled Trades

According to Zeolla, “We” need to push our way into middle schools and high schools to get “our” message heard. Kids need to know that they have options at a younger age, says Zeolla.

“Listen, school isn’t for everyone. You might be told you aren’t good enough, or your attention span is too short, or you can’t listen to lectures all day, but put that kid in front of something hands-on, something he or she can feel—and feel the pride of building something—the sky is the limit. Once you get that feeling of being productive and important, you will open doors you didn’t even know were there,” says Zeolla.

The past few years have been good for contracting businesses, barring component availability and skilled labor woes. For anyone in the trades, operating a plumbing and mechanical company profitably looks different today than it did 20 years ago, but there are still plenty of similarities. Joe Tull, 36, founded Straight Plumbing, LLC seven years ago Read more

The past few years have been good for contracting businesses, barring component availability and skilled labor woes. For anyone in the trades, operating a plumbing and mechanical company profitably looks different today than it did 20 years ago, but there are still plenty of similarities.

Joe Tull, 36, founded Straight Plumbing, LLC seven years ago, and feels as though he’s settled into a sweet spot. Right now, that includes running two trucks and focusing on Maryland’s Hartford County and northern Baltimore County. The company used to be bigger, but not necessarily better, according to Tull.

Roughly 30 percent of Straight Plumbing & Heating’s work is hydronic heat. The rest is residential and commercial plumbing service.

“I’ve always preferred quality over quantity,” he explained. “When I had more employees, I spent a lot of time going behind them and fixing their mistakes or shortcuts. Right now I have a fantastic apprentice, Robert Howard, who’s been with me four years. He’s always respected me and done things my way, which simply means not cutting corners. I’d hire 20 like him, if I could find them.”

Joe grew up working for his father’s plumbing company, but after a while, the two Tulls couldn’t see eye to eye. So Joe left and spent several years on the plumbing service crew for a large company before hanging out his own shingle in Jarrettsville, Md.

Specialization

“Specialization gives the people . . . the opportunity to go further in any direction of study than any other human has gone before.” – Ryan North

“Service is what I knew best, and what I could build a reputation on most rapidly,” said Tull. “Service work also provides the greatest opportunity to solve people’s problems. The new construction side of the business is more volatile. So I specialized in plumbing service, and as soon as I was up and running, I dug into hydronics to expand our offering.”

Joe Tull founded Straight Plumbing, LLC in 2016, after working for his family’s company and several other plumbing firms in the area.

Today, 30 percent of Straight P&H’s work is hydronic heat. The rest is plumbing service, both residential and commercial. Due to the rural nature of his territory and the presence of hard and harsh water, many of their service calls involve well pumps and water conditioning. A deep understanding of water quality has infinity improved Tull’s hydronic and plumbing work.

Forging relationships

“Technology does not run an enterprise, relationships do.” – Patricia Fripp

Tull learned early in his career that relationships are critical to the success of a business. In addition to learning from his father, he had mentors at supply houses, rep firms and within his social circle.

“I had a lot to learn when I first started installing boilers” said Tull. “Jim Bull, at Thomas Somerville became a mentor. He has a wide range of heating knowledge and was always generous with that information. He’d even stop at my jobs in the evening and set me straight if I was in a bind.”

Relationships are as important to Tull today as they were then, when he was still building his portfolio of experience.

“I try to be an information sponge and do my best to become an asset to the people who add value to my life,” said Tull. “Over the past three years, I’ve worked closely with the reps at ROI Marketing, specifically Dan Byrne, district manager, and Dave Raabe, sales manager. Those guys are never more than a phone call away.”

“I try to be an information sponge and do my best to become an asset to the people who add value to my life,” said Tull. “Over the past three years, I’ve worked closely with the reps at ROI Marketing, specifically Dan Byrne, district manager, and Dave Raabe, sales manager. Those guys are never more than a phone call away.”

Byrne has known Tull for more than 20 years, but has only been his hydronic rep for about three years, after helping Straight P&H sort out some technical issues on a particularly challenging project. Tull installs their line of U.S. Boiler Company condensing and cast iron boilers, ComfortPro PEX, State water heaters and Webstone valves. Some of that equipment comes through Jordan Mitchell, at Northeastern Supply, while some is sourced at other supply houses throughout the area.

Straight Plumbing & Heating used to be a larger company, but Tull intentionally reduced it to two trucks for the sake of quality and consistently.

“Dave and Dan rock,” said Tull. “Their support, and the help I’ve received from the factory tech support at U.S. Boiler has been outstanding. I’ve used other boiler brands with less success and non-existent customer service.”

Byrne and Raabe visit Tull’s jobsites a dozen times or so each year, often on the front end, to provide sizing assistance, system concepts, etc.

“What I observed when I first met Joe was a young guy that wanted to install stuff properly,” said Raabe. “He’s very talented and his work is extremely professional, yet he’s humble and not afraid to ask for help.”

“I wish all our customers were like Joe,” added Byrne. “He takes real pride in his work.”

Referral marketing

“Courteous treatment will make a customer a walking advertisement.”

– James Cash Penney

“I left my previous job because I saw customers being taken advantage of,” Tull said. “I don’t hard-sell anyone. I present their options along with fair pricing and let them decide what they prefer. I want customers for life. If I’m fair and I do the job to the best of my ability, my customers become my salesforce.”

Tull doesn’t just talk the talk. His 38 five-star reviews on Facebook are proof enough. One review states, “Joe came to my house and fixed me up. After I got estimates from other plumbers that were way too expensive, Joe fixed my old water treatment system without pushing me to buy a new one. He simply stated ‘Please think of me when you decide to upgrade.’ And you bet your butt I will.”

Create value

“You don’t get paid for the hour. You get paid for the value you bring to the hour.” – Jim Rohn

Straight Plumbing and Heating creates value as well as anyone in the business. Homeowner Steve Shelley learned this when he first hired Tull to solve some minor plumbing issues. Years later, when it came time to replace the home’s oil-fired boiler, Joe was his first and only call.

“Joe is very responsive, knowledgeable and thorough,” said Shelley. “He doesn’t try to oversell, he’s happy to answer questions, and he’s never in a rush to get things done. I didn’t have to think twice about hiring him to convert our home from oil to propane, which we did mainly for the energy savings.”

The combi boiler system Tull installed heats the home through a hydronic air handler, while also providing more hot water than the homeowner had ever had in the past.

The home is heated by hot water fan coils, and the existing boiler used to provide DHW through a 40-gallon indirect tank. Shelley estimates that the unit burned 800 gallons of oil each year, or roughly $3,200.

Tull buried a large propane tank in the yard, replaced the existing unit with a 200 MBH Alta Combi boiler, and sidewall vented the new unit.

The retrofit took place in June last year, giving Shelley nearly a year to calculate the energy savings that Straight Plumbing and Heating had provided.

“We used 400 gallons of propane over the winter, and I’m sure we’ve consumed a little more through the fall and spring for hot water,” he Shelley. “With LP at $2.00 per gallon, we’re saving somewhere around $2,000 per year.”

Tull replaced an oil-fired boiler with a new Alta condensing combi boiler for an annual savings of $2,000.

Shelley also noted that the family used to run out of DHW quickly. Now they can shower as long as they want and run multiple taps.

“We have all the hot water we need,” Shelley explained. “We can’t smell oil in the basement anymore, and we don’t hear the boiler start up like we used to.”

“We have about a dozen Alta boilers in the field,” said Tull. “They work very well on LP. Most of the installations in Hartford County are on propane. The Alta is also easy to clean, and access is fantastic because the side panels are removable.”

There’s another reason that Tull installs the Alta. Much like other models in the U.S. Boiler Company lineup, the Alta is available at a variety of local supply houses, including Northeastern Supply, Thomas Somerville and R.E. Michel.

“When it’s cold and a customer needs heat, I can’t come up empty-handed on parts and product,” said Tull. “Having equipment that’s readily available is extremely important.”

Overcoming challenges

“A challenge only becomes an obstacle when you bow to it.” – Ray Davis.

Last heating season, Straight Plumbing and Heating installed 35 boilers. This year, only 20. He suspects the economy has something to do with that, but he’s certain there’s another reason.

According to Tull, many big HVAC companies are pushing homeowners toward inexpensive heat pumps. There are lots of “house flippers” in his territory, as well. Typically, flippers install the cheapest heat pump on the market.

Straight Plumbing & Heating has a dozen Alta boilers in the field, and he’s found them to be reliable and very easy to work.

“I’m not talking about high-efficiency, low-ambient temperature systems,” he said. “I mean the cheap, undersized unitary systems. I’ve had homeowners call me after buying a house with a new heat pump, asking if I can install ‘a real heating system.’ Once winter hits, they’re uncomfortable and their electric bill spikes because the units constantly run on emergency heat.”

It’s hard to sell a premium system against a budget option when the customer doesn’t know the difference before signing the contract.

“I know it will all come full circle,” said Tull. “You only make that mistake once. If I was trying to grow rapidly, I’d be concerned about it, but I’m happy with where the company is. It’ll grow gradually. We’ll continue solving harsh water problems and creating extremely comfortable heating systems. If we do that and remain transparent with our customers, the company will continue to do well.”

Businesses that entrust their data storage to the state-of-the art Novva data center outside of Salt Lake City will benefit from a location chosen for its many data center-friendly attributes. The area offers outstanding connectivity, low power costs, and a central-western site with easy access to a major international airport. In addition, the site’s climate Read more

Businesses that entrust their data storage to the state-of-the art Novva data center outside of Salt Lake City will benefit from a location chosen for its many data center-friendly attributes. The area offers outstanding connectivity, low power costs, and a central-western site with easy access to a major international airport. In addition, the site’s climate and 5,000-ft. altitude allow for many hours of free cooling annually.

Just as important to Novva’s clients, the new data center has a low disaster risk. The area is not prone to earthquakes, floods, or adverse weather events such as hurricanes.

And finally, for the additional peace-of-mind that makes this data center truly start-of-the-art, the cooling system for the computer servers boasts Aquatherm PP-RCT piping that will provide virtually leak-free service for decades to come. The Aquatherm piping will never scale or corrode, and the cooling water flow will remain unchanged throughout the anticipated 50-year lifespan of the pipe. All of this data adds up to a win for Novva and its clients.

The “hyperscale” data center in Salt Lake City will be Novva’s flagship data center. The 100-acre Utah campus is planned to ultimately include more than 1.5 million square feet of data center space and will accommodate 250kW to 30 MW clients. The construction is taking place in four phases. The first phase, which includes a 300,000-sq.-ft. data center, a 120MW substation and an 80,000-sq.-ft. headquarters office building for Novva, was completed in December 2021.

Beating the Heat

Reliable cooling systems are an essential component of modern data centers. Computer servers are notorious for generating heat—and heat is notorious for being an enemy of computer servers.

The decision to install Aquatherm pipe as part of the new data center’s cooling system was driven by Steven Boyce, vice-president of infrastructure and design at Novva Data Centers. Boyce has been involved in the IT and data center space for more than 20 years, and has worked on multiple successful startups during that time.

When I first learned about Aquatherm, it was a no-brainer,” Boyce said. “I had been using steel pipes in my builds, which would corrode and rust, and in turn, fill my equipment with sediment and pieces of rust. Efficiencies would be diminished, and the pipes would eventually have to be replaced. Aquatherm’s total installed costs are lower, and their warranty is something that no steel vendor could match.”

Once the decision was made to trust the cooling system’s performance to Aquatherm pipe, Novva turned to the Salt Lake City branch of Harris Mechanical for the installation.

Harris had experience installing Aquatherm pipe, although the Novva data center represented the company’s largest data center Aquatherm installation to date. To handle the first phase of the Novva system, Harris installed a BASX custom chiller package (which included the pumps and controls), the Aquatherm pipe for computer system cooling, and the comfort system piping and plumbing. The piping work for phase 1 began in mid-May 2021 and was completed in October 2021. The system was commissioned and turned over to the owner in December 2021.

Fast and Furious

Jeff Reading, operations manager, construction, Harris Mechanical, explained that the Novva data center started out as a core and shell project, with the office built first and the data hall scheduled to be built out later. However, as anyone in construction work knows, it’s always best to expect the unexpected.

“We finished the core and shell construction in May 2021, and the data hall was right on its heels as a change order to the original project. So it came at us fast and furious,” Reading said. “The original plan was to complete the entire chilled water loop, which runs underneath the floor on both sides of the building. However, it was decided to install the piping in stages as the facility is built out. So far we have installed about half of the piping that will ultimately go in there.”

The installation to date has included 4,418 ft of Aquatherm Blue Pipe SDR 17.6. The main system piping is 10-in., and the takeoffs are 4-in.

Training Professionals

To handle such a large project. Harris Mechanical sent several installers to Aquatherm’s U.S. headquarters in nearby Lindon, UT, for training.

Having Aquatherm-trained technicians opens up new opportunities for HVAC and plumbing companies. The company gains differentiation in the market, and enjoys the time- and labor-savings associated with installing polypropylene pipe.

Aquatherm training is the most intensive, comprehensive training in the polypropylene piping industry. Attendees receive both classroom training and hands-on training with multiple fusion machines, and must pass a rigorous test using all the fusion tools correctly.

After the training, Harris completed the installation using McElroy fusion tools and a combination of socket fusion for the 4-in. pipe and butt fusion for the 10-in. pipe. The system runs at a low pressure (35 to 45 psi); the cooling system supply water runs at 55°F and returns to the chiller at about 60°F.

According to Reading, Harris Mechanical had a good experience with Aquatherm piping at the Novva data center, and the ease of installation compared to steel pipe helped Harris stay ahead of the project’s tight schedule.

“It was a smooth process,” he said. “We definitely gained experience and confidence with the pipe throughout the project, and our installers became accustomed to ‘leapfrogging’ and working with more than one [fusion] machine at a time.”

A Smooth Path

The underfloor piping system presented one of the major installation challenges at this project. The floor is raised 5-ft., and all of the facility’s piping, wiring, HVAC ducting, and utilities run through the raised space.

Aquatherm’s building information modeling (BIM) capabilities and Scan-to-Fab service helped ensure that the installation went smoothly by preventing underfloor conflicts and collisions.

“Using 3D BIM and Revit really helped with coordinating this installation,” said Autumn Turner, a fabrication drafter at Aquatherm. “Not only was all the HVAC and plumbing under the floor, there were floor stands every square foot. It took a lot of coordination to avoid all those potential obstacles.”

Turner noted that careful coordination enhanced the already-fast heat-fusion installation of Aquatherm pipe, and that less time and money spent on welders is a major benefit of choosing Aquatherm.

“Aquatherm is just easier work with than steel pipe,” she said. “It takes a lot less time to weld, and when you add in the BIM support and drafting it was easier for the installers to get situated into the floor and navigate the space.”

Turner added that Aquatherm’s BIM and Revit capabilities will ensure the future installation phases of the massive project also go smoothly.

Rhett Coles, Aquatherm’s fabrication drafting/scan-to-fab manager, said that Aquatherm’s Scan-to-Fab service and in-house fabrication makes any piping installation easier and smoother. Spools can be custom made in any size or configuration and shipped to the jobsite ready to install. In addition, any pieces fabricated by Aquatherm are covered by a comprehensive 10-year warranty.

“In the case of the Novva data center, we were in constant communication with Steven Boyce and the owner’s group,” Coles said. “We were not providing a cookie cutter system to them. They would tell us whatever they wanted or needed and we would work directly with them to help them fully accomplish their goals.”

A reliable, leak-free piping system with a long life span, and a smooth installation in any space, including challenging underfloor designs? The data are in: Aquatherm is the right choice for data centers.