Homeowner’s Mid-January Crisis Resolved by New Jersey Contractor Surprisingly warm temperatures greeted residents of Mid-Atlantic states In the middle of January. For people living in the area who typically face freezing temperatures, severe nor’easter snowstorms, and perilous ice storms, temperatures ranging from the mid-30s to low-40s without precipitation was almost a best-case scenario for the Read more

Featured Articles

Homeowner’s Mid-January Crisis Resolved by New Jersey Contractor

Surprisingly warm temperatures greeted residents of Mid-Atlantic states In the middle of January. For people living in the area who typically face freezing temperatures, severe nor’easter snowstorms, and perilous ice storms, temperatures ranging from the mid-30s to low-40s without precipitation was almost a best-case scenario for the residents’ safety – and thermal comfort.

Despite the mild atmospheric conditions that occurred last January, homeowners who have a malfunctioning boiler, even in tranquil weather, may unexpectedly find themselves in a catastrophe at home. This was the situation a homeowner from New Jersey faced when the heating unit of a century-old home stopped working, causing the residents to shiver as evening temperatures approached the freezing point.

Ezzy Travis, a plumbing and heating contractor and solo proprietor of E. Travis Mechanical installed a HTP ELU 150K BTU boiler to substitute the feeble and inefficient one. Four days without heat or water might not seem like a lot, but can seem like an eternity for people living in the house.

“The boiler was only about 12 years old, but was not properly serviced,’’ Travis said. “With the amount of time it would’ve required to repair the boiler, it didn’t make sense. It also wasn’t piped 100 percent correctly.”

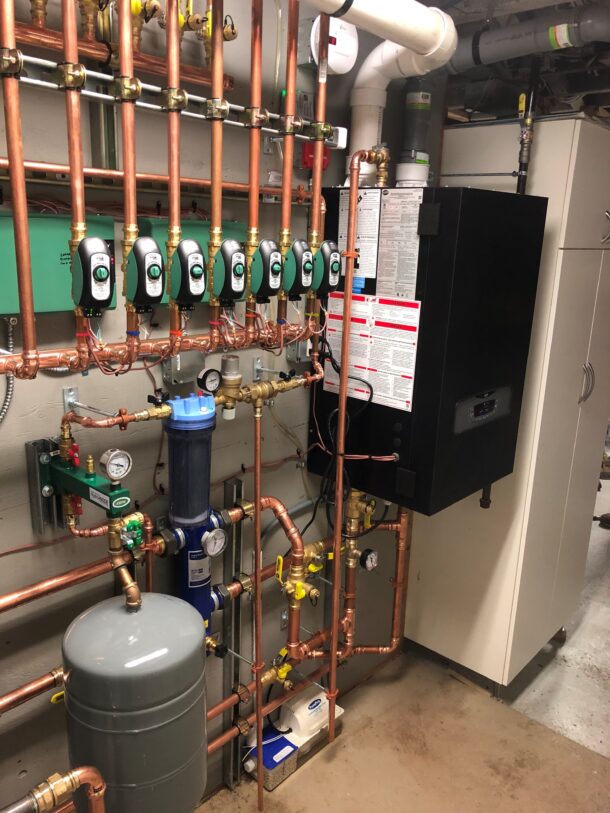

Workers from E. Travis Mechanical replaced the heating system in a century-old New Jersey home when the existing system failed during January, one of the coldest months of the year in the Garden State.

A Fresh Start

Prior to arriving at the home in the New Jersey neighborhood of Glen Rock, Travis had already fixed other home heating emergencies. Upon assessing the situation, he recognized the project required extensive repairs, rather than a short-term solution.

“A wholesaler referred this project to me,’’ Travis said. “I knew right away we’d have to replace the boiler and all the piping. Things weren’t done 100 percent correctly, and I have a standard way of doing things. All the piping in the mechanical room and the boiler had to be ripped out. The only thing that was salvageable was the indirect tank. It had been installed in August, so there was no reason to rip it out.”

Constructed in 1916, the traditional house features four bedrooms and three baths, in a 3,200 square feet area. Despite the house being quite expansive, the mechanical room’s workspace did not have the same luxury.

“That was probably the biggest challenge we faced,’’ he said. “It wasn’t a deep mechanical room. There just wasn’t a lot of room for two of us. I needed another set of hands for this one. We had to ask each other to move out of the way when we had to move within the room. It was a pretty tight squeeze with some significant space constraints.”

Contractors often encounter working areas that are cramped like a sardine can. “It’s weird because many times when you need space, you don’t have it,’’ Travis said. “Other times we’ll install something that is relatively small, and we have all the space in the world. A lot of my jobs are in areas where everybody wants to utilize every square inch of the basement. I’ll have to spend time putting down protective material for the carpet and wall, which makes it take longer. I don’t want to do any damage to the house.”

Navigating tight staircases with burdensome boilers is a risk that contractors frequently experience. When setting up the new boiler to replace the faulty one, Travis and his helper maneuvered carefully as they removed the old unit and installed the new one.

The project included the installation of an HTP ELU 150K boiler, which was selected for its durability and 11:1 turndown ratio.

Turning Up the Heat

Finding the appropriate boiler is key for a project in an old home with many rooms and floors. Contractors must consider that houses with compromised insulation and large square feet make the selection even more important.

“I had to factor in the heat loss of the house,’’ Travis said. “In this part of New Jersey, we see a lot of houses like that. In a hydronic system, you need to do thorough heat loss analysis. I wanted to make sure that the unit we installed was able to overcome any heat loss within the house.”

The high BTU output the HTP boiler provides was the deciding factor in Travis’ choice. “I also liked the fact that it had a 11:1 turndown ratio,’’ Travis said. “I like the simplicity of it. It’s not a complicated boiler. Because of the age of the house, I was also concerned about heat loss. I wanted to make sure we had enough BTUs to heat the entire house.”

In nearly all residential heating systems, the 11:1 ratio is a significant factor to consider. Whenever a boiler or burner finishes a cycle, it uses a substantial amount of energy. Reducing the amount of complete on and off cycles by utilizing a higher turndown ratio can minimize inefficiencies, resulting in lower maintenance costs. Additionally, high turndown burners are capable of responding more rapidly to changes in demand.

The HTP units – offered in sizes from 85K BTU input and all the way up to 199K BTU input – feature high-quality stainless-steel heat exchangers that guarantees the highest quality at the boiler’s core with corrosion resistance. The amplification in water flow provided by the heat exchanger results in increased turbulence that helps scrub the internal walls, thus reducing the accumulation of hazardous deposits.

“I liked the simplicity of this boiler,’’ Travis said. “There are not a lot of moving parts and it’s pretty uncomplicated.”

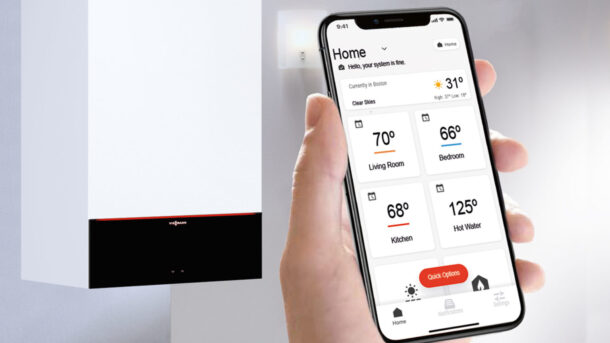

The HTP ELU boiler includes a Wi-Fi solution that enables remote monitoring and notifies personnel when faults occur in the system.

Linked Together

With the help of HTP link technology, the HTP ELU boiler offers a Wi-Fi solution for remote observation and alerts staff in the instance of a system fault. The boiler’s settings can also be conveniently adjusted on location without getting up from the chair.

During his 20-plus years in the industry, Travis has suggested HTP units for several projects. “I like their efficiency, durability and simplicity,’’ he said. “I get a lot of support when I’m installing them. They’ve been a good product for me over the years.”

Despite primarily being a one-man team, Travis takes pride in resolving significant or minor issues for all his clients. “I don’t feel like I’m doing anything special,’’ he said. “I’m just doing what I do. Fortunately, we were able to come up with a good solution for this rather quickly. It’s never a good thing for a homeowner to be without heat in the middle of winter.”

Brian Giardina writes on building, construction, engineering and other trade industry topics for publications throughout the United States.

Businesses that entrust their data storage to the state-of-the art Novva data center outside of Salt Lake City will benefit from a location chosen for its many data center-friendly attributes. The area offers outstanding connectivity, low power costs, and a central-western site with easy access to a major international airport. In addition, the site’s climate Read more

Businesses that entrust their data storage to the state-of-the art Novva data center outside of Salt Lake City will benefit from a location chosen for its many data center-friendly attributes. The area offers outstanding connectivity, low power costs, and a central-western site with easy access to a major international airport. In addition, the site’s climate and 5,000-ft. altitude allow for many hours of free cooling annually.

Just as important to Novva’s clients, the new data center has a low disaster risk. The area is not prone to earthquakes, floods, or adverse weather events such as hurricanes.

And finally, for the additional peace-of-mind that makes this data center truly start-of-the-art, the cooling system for the computer servers boasts Aquatherm PP-RCT piping that will provide virtually leak-free service for decades to come. The Aquatherm piping will never scale or corrode, and the cooling water flow will remain unchanged throughout the anticipated 50-year lifespan of the pipe. All of this data adds up to a win for Novva and its clients.

The “hyperscale” data center in Salt Lake City will be Novva’s flagship data center. The 100-acre Utah campus is planned to ultimately include more than 1.5 million square feet of data center space and will accommodate 250kW to 30 MW clients. The construction is taking place in four phases. The first phase, which includes a 300,000-sq.-ft. data center, a 120MW substation and an 80,000 sq ft headquarters office building for Novva, was completed in December 2021.

Beating the Heat

Reliable cooling systems are an essential component of modern data centers. Computer servers are notorious for generating heat—and heat is notorious for being an enemy of computer servers.

The decision to install Aquatherm pipe as part of the new data center’s cooling system was driven by Steven Boyce, vice-president of infrastructure and design at Novva Data Centers. Boyce has been involved in the IT and data center space for more than 20 years, and has worked on multiple successful startups during that time.

When I first learned about Aquatherm, it was a no-brainer,” Boyce said. “I had been using steel pipes in my builds, which would corrode and rust, and in turn, fill my equipment with sediment and pieces of rust. Efficiencies would be diminished, and the pipes would eventually have to be replaced. Aquatherm’s total installed costs are lower, and their warranty is something that no steel vendor could match.”

Once the decision was made to trust the cooling system’s performance to Aquatherm pipe, Novva turned to the Salt Lake City branch of Harris Mechanical for the installation.

Harris had experience installing Aquatherm pipe, although the Novva data center represented the company’s largest data center Aquatherm installation to date. To handle the first phase of the Novva system, Harris installed a BASX custom chiller package (which included the pumps and controls), the Aquatherm pipe for computer system cooling, and the comfort system piping and plumbing. The piping work for phase 1 began in mid-May 2021 and was completed in October 2021. The system was commissioned and turned over to the owner in December 2021.

Fast and Furious

Jeff Reading, operations manager, construction, Harris Mechanical, explained that the Novva data center started out as a core and shell project, with the office built first and the data hall scheduled to be built out later. However, as anyone in construction work knows, it’s always best to expect the unexpected.

“We finished the core and shell construction in May 2021, and the data hall was right on its heels as a change order to the original project. So it came at us fast and furious,” Reading said. “The original plan was to complete the entire chilled water loop, which runs underneath the floor on both sides of the building. However, it was decided to install the piping in stages as the facility is built out. So far we have installed about half of the piping that will ultimately go in there.”

The installation to date has included 4,418 ft of Aquatherm Blue Pipe SDR 17.6. The main system piping is 10-in., and the takeoffs are 4-in.

Training Professionals

To handle such a large project. Harris Mechanical sent several installers to Aquatherm’s U.S. headquarters in nearby Lindon, Utah, for training.

Having Aquatherm-trained technicians opens up new opportunities for HVAC and plumbing companies. The company gains differentiation in the market, and enjoys the time- and labor-savings associated with installing polypropylene pipe.

Aquatherm training is the most intensive, comprehensive training in the polypropylene piping industry. Attendees receive both classroom training and hands-on training with multiple fusion machines, and must pass a rigorous test using all the fusion tools correctly.

After the training, Harris completed the installation using McElroy fusion tools and a combination of socket fusion for the 4-in. pipe and butt fusion for the 10-in. pipe. The system runs at a low pressure (35 to 45 psi); the cooling system supply water runs at 55°F and returns to the chiller at about 60°F.

According to Reading, Harris Mechanical had a good experience with Aquatherm piping at the Novva data center, and the ease of installation compared to steel pipe helped Harris stay ahead of the project’s tight schedule.

“It was a smooth process,” he said. “We definitely gained experience and confidence with the pipe throughout the project, and our installers became accustomed to ‘leapfrogging’ and working with more than one [fusion] machine at a time.”

A Smooth Path

The underfloor piping system presented one of the major installation challenges at this project. The floor is raised 5-ft., and all of the facility’s piping, wiring, HVAC ducting, and utilities run through the raised space.

Aquatherm’s building information modeling (BIM) capabilities and Scan-to-Fab service helped ensure that the installation went smoothly by preventing underfloor conflicts and collisions.

“Using 3D BIM and Revit really helped with coordinating this installation,” said Autumn Turner, a fabrication drafter at Aquatherm. “Not only was all the HVAC and plumbing under the floor, there were floor stands every square foot. It took a lot of coordination to avoid all those potential obstacles.”

Turner noted that careful coordination enhanced the already-fast heat-fusion installation of Aquatherm pipe, and that less time and money spent on welders is a major benefit of choosing Aquatherm.

“Aquatherm is just easier work with than steel pipe,” she said. “It takes a lot less time to weld, and when you add in the BIM support and drafting it was easier for the installers to get situated into the floor and navigate the space.”

Turner added that Aquatherm’s BIM and Revit capabilities will ensure the future installation phases of the massive project also go smoothly.

Rhett Coles, Aquatherm’s fabrication drafting/scan-to-fab manager, said that Aquatherm’s Scan-to-Fab service and in-house fabrication makes any piping installation easier and smoother. Spools can be custom made in any size or configuration and shipped to the jobsite ready to install. In addition, any pieces fabricated by Aquatherm are covered by a comprehensive 10-year warranty.

“In the case of the Novva data center, we were in constant communication with Steven Boyce and the owner’s group,” Coles said. “We were not providing a cookie cutter system to them. They would tell us whatever they wanted or needed and we would work directly with them to help them fully accomplish their goals.”

A reliable, leak-free piping system with a long life span, and a smooth installation in any space, including challenging underfloor designs? The data are in: Aquatherm is the right choice for data centers.

Plumbing Champions from across the world gather at ISH 2023 to prefab some bathroom fixtures, which were then donated to a nearby local sport facility in Frankfurt. In what was a first of its kind event at an ISH Frankfurt show, 12 young plumbers/apprentices from eight different countries from around the world gathered at ISH Read more

Plumbing Champions from across the world gather at ISH 2023 to prefab some bathroom fixtures, which were then donated to a nearby local sport facility in Frankfurt.

In what was a first of its kind event at an ISH Frankfurt show, 12 young plumbers/apprentices from eight different countries from around the world gathered at ISH Frankfurt earlier this year to work together for one single goal: prefab Geberit bathroom plumbing systems on the show floor, which would be eventually transferred off site to bathrooms at Niddahalle, part of the Eintracht Frankfurt sports club, west of the city.

“We are working together as a team in a collaborative workshop to produce some new bathrooms for the Eintracht Frankfurt sports club,” said Sean Keárny, Managing Director, for the International Water, Sanitation and Hygiene Foundation (IWSH). “We built them over the first three days of the trade show, and for the final two days of the trade show, we’ll be taking them to the facility and installing them. This is the first time anything like this has ever been done at ISH, and we are excited about that.”

The skilled plumbers assembled pre-wall frame systems and internal plumbing during the first three days of the ISH show. The systems were then transported to, and installed in, bathrooms at Niddahalle, which is undergoing modernization retrofits.

IWSH and the World Plumbing Council (WPC), brought the Plumbing Champions to Frankfurt from the United Association of Journeymen and Apprentices of the Plumbing and Pipefitting Industry of the United States and Canada (UA), the Plumbing Industry Climate Action Centre (Australia), Apprenticeship Training Trust (New Zealand) and the Connect Trade Union (Ireland); all hosted and working together alongside peers from the Frankfurt branch of Innung Sanitär Heizung Klima (SHK), the master craftsperson’s guild for sanitation, heating and air conditioning in the city of Frankfurt am Main, Germany.

The Plumbing Champions consist of: Patrick Howorka, Alexander Tödter and Colin Cubr (Germany); Danny Hoekstra (Australia); Sam Madgin (New Zealand); Veronika Schächle (Liechtenstein); Alex Svetz (United States); Elijah Sommers (Canada); and Jamie Bermingham and James Stenson (Ireland).

The bathrooms in Niddahalle are more than 40 years old, built before today’s high-efficiency plumbing solutions that use less water. “Frankfurt is a water-stressed area. Drought conditions threatened significant economic damage last year when water on the Rhine got so low it impeded barge traffic,” said Dave Viola, CEO of IAPMO and IWSH (IAPMO’s philanthropic arm) and deputy chair of the WPC. “The plumbing industry can alleviate water stress through improved water technology and a skilled workforce. We’re here to demonstrate it in real life.”

The Plumbing Champions initiative showcase retrofit approaches that advance energy efficient goals for the built environment: critical industry requirements set out in modern-day, international agendas such as the European Green Deal. The team will perform tasks including joining and bending hot and cold-water piping systems, installing cisterns and brackets for water closets and basins, and joining HDPE waste pipe. Participants will install plumbing systems designed by Geberit, a European leader in sanitary products working in partnership with the Frankfurt branch of Innung SHK.

“We see value in this program as a recruitment tool, it’s a good humanitarian effort for the community, and we are going to continue to do this at the next ISH two years from now, and we are going to do this in other places in the United States through the World Plumbing Council connections,” says Tom Bigley, Director of Plumbing, UA and chairman, World Plumbing Council.

The latest of the Watts Works Learning Centers, now with 200+ employees, has opened in Ft. Worth, Texas. The 250,000-sq.-ft. facility—customized for broad training purposes, administration, and manufacturing—joins several other Watts Works Learning Centers across North America. https://youtu.be/T74E2QHfnDc In addition to a working mechanical room with pressurized water lab, the facility includes a 3,600-sq-ft. Learning Read more

The latest of the Watts Works Learning Centers, now with 200+ employees, has opened in Ft. Worth, Texas. The 250,000-sq.-ft. facility—customized for broad training purposes, administration, and manufacturing—joins several other Watts Works Learning Centers across North America.

In addition to a working mechanical room with pressurized water lab, the facility includes a 3,600-sq-ft. Learning Center, office areas and a wide range of product manufacturing and assembly, including robotic welding and cutting, metal passivation, sheet metal rolling, precision laser metal cutting, CNC machining, and ASME testing.

At the facility, employees produce PVI water heaters, BLÜCHER stainless-steel trench and HygienicPro® drains, and Ames and Watts in-building risers. The products that are manufactured in Ft. Worth, TX are used worldwide in various commercial applications. Many Watts technologies play a role in supporting energy efficiency, safety and regulation, and water conservation.

Through innovative training, the Watts’ training offerings help customers and employees improve their knowledge of Watts products, services, and solutions to enhance their professional skills.

Other North American-based Watts Works Learning Centers are located at North Andover, Mass.; Blauvelt, N.Y.; St. Pauls, N.C.; Burlington, Ontario; and Woodland, Calif.

For more information, visit https://www.watts.com/resources/training/learn-from-the-experts.

Viessmann and Carrier align; Uponor rebuffs Aliaxis. Are we seeing a renewed “trend” toward consolidation in the PHVAC industy? Inflation, fuel prices, war, supply chain, electrification, and economy woes are all factors for potential wholesale changes. Over the past month, there has been heavy movement in the industry to suggest such a thing. In a Read more

Viessmann and Carrier align; Uponor rebuffs Aliaxis.

Are we seeing a renewed “trend” toward consolidation in the PHVAC industy? Inflation, fuel prices, war, supply chain, electrification, and economy woes are all factors for potential wholesale changes. Over the past month, there has been heavy movement in the industry to suggest such a thing. In a week that saw big movement, we learned recently that two major players in the PHVAC industry have been active in talks.

The first, just officially confirmed, Carrier will acquire Viessmann Climate Solutions, the largest segment of Viessmann Group, in a cash and stock transaction valued at €12 billion, subject to working capital and other adjustments. According to the release, Viessmann Climate Solutions provides Carrier with an iconic, premium brand in the highest growth segment of the global heat pump and energy transition markets. In addition, Carrier announced plans to exit its Fire & Security and Commercial Refrigeration cabinet businesses.

“The acquisition of Viessmann Climate Solutions is a game-changing opportunity,” said Carrier Chairman & CEO David Gitlin. “Climate change, sustainability requirements and geopolitical factors are driving an unprecedented energy transition in Europe. Accelerated by government regulations and incentives, the transition creates a significant, long-term growth opportunity.

“Viessmann Climate Solutions is uniquely positioned to capitalize on this opportunity with its premier brand, highly differentiated distribution channel and innovative product offerings. With 70% of its business consisting of heat pumps and related accessories, solar PV, batteries and services, Viessmann Climate Solutions is a critical leader in Europe’s energy transition. We look forward to welcoming its 11,000 team members to the Carrier family and Max Viessmann, CEO of Viessmann to the Carrier Board of Directors at closing, which is expected around the end of 2023.

But a recent announcement from Viessmann found on LinkedIn read, “the new transatlantic partnership underlines the importance of international, cross-border collaboration in the fight against global climate change. Both companies are fully committed to take more responsibility for a sustainable energy transition in the building sector, focusing on our purposes: Viessmann Group’s purpose is to co-create living spaces for generations to come. Carrier’s vision is to create solutions that matter for people and our planet. We both regard the climate goals in North America and Europe as a once-in-a-century opportunity to make a positive impact, by actively shaping sustainable climate and energy solutions for future generations.

“The Viessmann Group will continue to remain an independent family business in full ownership of the Viessmann entrepreneurial family. Today, the Viessmann Group—excluding its Climate Solutions business area—generates a total revenue of EUR 1 billion in sales—including non-consolidated entities—with around 4,000 employees. Looking ahead, the clear goal and ambition of the Viessmann Group is to grow to a size that is larger than the Climate Solutions business area today, latest by the end of the decade.”

How does this affect contractors? The Hub’s Eric Aune, who is an ardent Viessmann installer, was sent this message: By combining Viessmann Climate Solutions and Carrier, we are co-creating one of the leading climate solutions companies in the world. Through the combination of both companies, we are forming a resilient, fast-growing innovation leader in a highly competitive market environment. All partners and customers of Viessmann Climate Solutions will significantly benefit from this new partnership:

- Viessmann Climate Solutions’ premium integrated offering will be complemented by electrified products and services from Carrier and its sub brands (heat pumps, battery storages, cooling and ventilation solutions as well as after-sales-services, digital and value-added solutions). This will lead to a wider product range for you.

- Viessmann Climate Solutions will get better access to suppliers via the global network of Carrier, especially its subsidiary Toshiba Carrier Corporation in Asia. This will lead to a faster delivery for you, in the long run. Thereby, you can significantly shorten your time to installation completion—a decisive component for the decarbonization of the building stock both in Europe and beyond.

- The iconic brand of Viessmann will be continued. All your respective contact persons at Viessmann will remain in charge. The Climate Solutions Executive Board and leadership team of Viessmann Climate Solutions, led by CEO Thomas Heim will continue to run the business. Viessmann Climate Solutions will become a major driver of Carrier’s growth strategy in Europe. Its headquarters will remain in Allendorf, Germany. The Viessmann Group will become one of the largest shareholders in Carrier. Consequently, Viessmann Group CEO Max Viessmann will become a new member of the Board of Directors of Carrier.

Meanwhile, according to an industry insider close to Mechanical Hub, Putin’s iron grip on the fuel supply in Europe could be a contributing factor to sell now. And, will Viessmann alter its path to market? One observer asked, “Will it be through the DCNE wholesale network?” We will see how things shake out in the next few weeks to months.

PEX Power

On the piping side, there have been tremors of a major shake-up in the PEX world. But all for naught, it turns out. Mechanical Hub has learned that Belgian company Aliaxis, a manufacturer of advanced fluid management solutions—with IPEX already a part of the company—had approached Uponor in its interest to sell. According to information acquired by Mechanical Hub, Aliaxis had announced a non-binding intention to make a tender offer to acquire all shares in Uponor.

Finland’s Uponor said on Wednesday (4/26/23), it rejected an unsolicited offer from Belgian rival Aliaxis, adding that the suggested price of 25 euros per share did not reflect the company’s value and long-term prospects.

According to Reuters and from sources within Uponor, the company’s board unanimously rejected the offer, but said it would consider any further proposals made by Aliaxis or any other party, if it was in the best interest of its shareholders.

Aliaxis last Monday made a $2 billion unsolicited offer to buy Uponor, seeking to form a global water management group, and the following Monday raised its stake in the Finnish company to 10.6%.

Oras Invest, Uponor’s largest shareholder with about 25.7% of the company’s shares, said on the day Aliaxis made its unsolicited offer that it had no intention of accepting it.