A recent Gallup poll found that 63% of Americans are worried about the safety of their drinking water. Except in extreme cases, these concerns are mostly unfounded as America’s drinking water is among the safest in the World. However, these concerns are understandable considering that the quality of our water is subject to threats old Read more

Featured Articles

A recent Gallup poll found that 63% of Americans are worried about the safety of their drinking water. Except in extreme cases, these concerns are mostly unfounded as America’s drinking water is among the safest in the World. However, these concerns are understandable considering that the quality of our water is subject to threats old, like millions of lead pipes, and new chemical contamination from things like PFAS.

Protecting North America’s water safety requires a three-step approach: understanding and recognizing modern water quality threats, specifying safe materials, and following correct installation procedure.

Water Quality Threats

Water quality threats are still abundant. A 2018 study identified 163 different substances that have the potential to leach from common piping materials. These substances range from alcohols to hydrocarbons, ketones, esters, metals, peroxides, phthalates, alkyl phenols, organotins, halogenated compounds and vinyl compounds, including some known or suspected as environmental contaminants or carcinogens. Of these, water quality standards only exist for 89 of them. The other 74 are not currently regulated or understood, leaving a gray area on what effects they may have on our water quality and health.

Replacing lead water pipes with copper piping between the street and homes in Flint, Michigan October 28, 2016. (John M. Galloway)

While additional research may help determine the total effect on water quality and health, these substances are a concern and should be taken into consideration when selecting a piping material.

Specifying with Copper

A reliable way to avoid these threats is to select copper, a time-tested, durable, proven piping material. Copper is safe; it won’t release potentially harmful chemicals into the water, it won’t give off toxic fumes in a fire, and it won’t allow harmful chemicals to permeate through the pipe wall. It is natural—made of 99.9% pure copper—and is accepted by all plumbing codes.

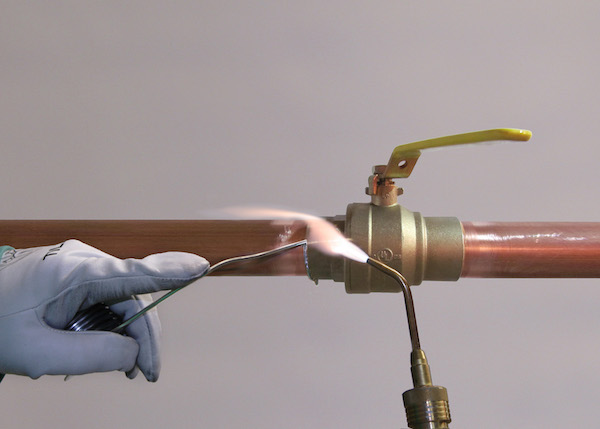

Below, is a brief, step-by-step guide for strong, leak-free solder joints—one of the most common joining methods for copper drinking water systems, provided by the Copper Development Association (CDA). CDA has been instrumental in developing the soldering procedures that are now standard in the copper and plumbing industry, and has since taught these procedures to hundreds of thousands of installers across the country and throughout the world.

Proper soldering technique when working with copper pipe.

To assist contractors and installers, CDA has produced several do-it-yourself videos to its “Do it Proper with Copper” YouTube video series. Additionally, the Copper Tube Handbook, available on www.copper.org, provides additional step-by-step installation guides for all copper joining methods. CDA recommends the following four steps for properly soldering joints:

Step One: Preheat the Tube

First, heat the interior surfaces of the fitting/component with heat from the tube surface. The preheating of the tube should be undertaken with the appropriately sized torch tip directing the flame perpendicular to the tube, about the same distance from the fitting cup as the length of tube that is inserted into the solder cup (i.e. if the fitting cup is 1-inch deep, preheat the tube approximately 1-inch beyond the face of the joint). While there is no definitive time limit on preheating, the tube should be preheated until the flux at the face of the joint begins to become active (begin showing signs of cleaning the tube/fitting surfaces).

Step Two: Preheat the Fitting/Component

Once the appropriate preheat has been applied to the tube, the flame should be moved back onto the fitting/component surface to the base of the fitting cup. Preheating of the fitting is most effective if the torch is directed from the back of the fitting cup to the face of the solder cup. This torch position directs the greatest amount of heat from the back of the fitting cup towards the face, where the solder will be applied. This allows for the primary flame of the torch to concentrate heat into the fitting/component while allowing the secondary flame to keep the tube surface at temperature.

Step Three: Apply Heat and Solder

The copper tube has excellent thermal conductivity so as it is heated, it will conduct heat throughout the tube length inside the fitting space. In addition, as the tube expands into the fitting cup, it will maintain a small capillary space between the two and help to heat the fitting cup from the inside. On horizontal joints, preheating should focus on the bottom two-thirds of the tube. Heat it until the tube is very close to soldering temperature, as indicated by the soldering flux beginning to bubble and clean the surface.

Copper Tube Handbook

Next, move the heat to the base of the fitting cup to bring it up to soldering temperature. Point the torch tip from the face of the fitting cup out towards the tube so the cooler part of the flame continues to keep the tube at soldering temperature. Then apply the heat to the base of the fitting cup. On horizontal joints, that should be somewhere off center near the bottom of the joint, before solder is added. If the solder doesn’t begin to melt, continue to preheat. Once the solder begins to melt, the torch should be moved along with the solder, keeping the heat only slightly ahead of where solder is being applied.

Step Four: Cooling and Cleaning

The completed soldered joint should be allowed to cool slowly and naturally. The new, no-lead alloys may not reject heat as quickly as their predecessors due to their lower thermal conductivity. By controlling the amount of heat applied, an individual can ensure the bare minimum required to facilitate full solder melting and flow is used. This allows the solder to solidify and cool to the joint quickly after the heat is removed.

If the proper soldering procedures are followed, particularly in the preheating and heating process, consistent, high-quality solder joints can be achieved between copper tube and fittings/components.

Durable, Reliable Piping Systems

Compared to copper pipes, no other material has the long history of reliable, leak-free installation in a wide variety of systems and settings, protects the water system from contamination, and does so with proven value. Plus, when copper’s long life cycle finally comes to an end, its high recyclability allows it to be reformed into new products with zero loss of performance. The choice is obvious, the choice is copper.

To learn more about copper piping and installation best practices, visit www.copper.org.

Andrew G. Kireta Jr. is vice president of the Copper Development Association Inc. (CDA). Kireta is responsible for the use of copper and copper alloy systems and products in building construction applications, including plumbing, mechanical and architectural systems.

Since its formation in 1926, IAPMO has been known for its progressive focus on the future. One might believe sanitation and the use of resources have reached a peak; this sort of thinking, however, is not within the realm of IAPMO’s culture. IAPMO Codes and Standards excels in recognizing technology that improve the lives of Read more

Since its formation in 1926, IAPMO has been known for its progressive focus on the future. One might believe sanitation and the use of resources have reached a peak; this sort of thinking, however, is not within the realm of IAPMO’s culture. IAPMO Codes and Standards excels in recognizing technology that improve the lives of Americans and elsewhere. Over time, IAPMO has proven to be the leader in bringing innovation to the industry while, at the same time, protecting the public health and welfare.

Non-Sewered Sanitation Systems

Since the early 1900s, technologies from flight to telephones have advanced with tremendous progress. We have gone from a simple 12 horsepower engine propelling an aircraft to jets that can break the sound barrier. Telephones have gone from rotary dial and cords to smart phones that have far more computing power than all the computers used to send the first man to the moon in 1969.

But what about wastewater management? It has not really advanced much. Yes, the sanitation is far safer than it was in the early 1900s, but the concept is the same. Not to mentioned that more than 2.3 billion people across the world lack access to basic sanitation services.

Water-leak-detection technology listed to the IAPMO standards has the capability of letting the homeowner know if there is a water leak with the use of a smartphone.

Now there is technology that is attempting to take sanitation to another level. It is technology that has already benefited areas where resources are scarce. Any country that adopts this technology has taken a leap into the future of sanitation. This technology is the Non-Sewered Sanitation System (NSSS) and it is covered by the ISO 30500 standard.

ISO 30500, Non-sewered sanitation systems—Prefabricated integrated treatment units—General safety and performance requirements for design and testing, seeks to provide general safety and performance requirements for the product design and performance testing of these non-sewered sanitation systems. It applies to integrated sanitation systems that are not attached to a sewer.

The ISO 30500 standard helps develop new toilet technology that will save millions of lives

Imagine using a toilet where the drainage system has the capability of preserving energy for use in other applications, such as powering lights, and with a recirculation loop for fluid reuse. Imagine a remote location where there is no water supply or a drainage system, yet you can have a fully functional toilet or urinal. The possibilities are endless with the use of the NSSS technology.

IAPMO is leading this effort to bring the NSSS technology to countries such as the United States and Canada. A committee with both U.S and Canadian stakeholders is preparing to bring the ISO 30500 standard to these respective countries as an American National Standard (ANS) and National Standard of Canada (NSC).

States like Hawaii or other areas where the use of cesspools is of concern, or California where droughts are common, can benefit from this technology. Likewise, provinces in Canada can also derive benefit.

Safe sanitation is something that IAPMO takes seriously and IAPMO feels privileged to be selected as the Accredited Standards Developer (ASD) by ANSI to introduce this technology to the U.S. and Canada.

Leak-Detection Systems

As stated, there are areas where resources are scarce. Such scarcity does not only apply to underdeveloped nations but well-established, developed nations, as well. There are areas in the United States where safe and sanitary water is not a basic commodity. From California to New York, and around the globe, water is a resource that must be cherished and protected. A drop of water the size of grain of rice can be easily ignored or overlooked due to its local minimal effect. This miniscule drop multiplied numerous times around the globe now becomes a large body of water. This now becomes something that cannot be overlooked.

IAPMO Codes and Standards is once again at the forefront tackling this issue. IAPMO has long published standards that address water-leaking detection products. Those standards are the IAPMO IGC 115 and IAPMO IGC 349, which are expected to become national standards soon (IAPMO Z1115 and Z1349). These standards are being used for the listing and certification of products designed to detect water leaks. Jurisdictions nationwide are already looking for the IGC 115 and IGC 349 mark for these products.

The water-leak-detection technology listed to the IAPMO standards has the capability of letting the homeowner know if there is a water leak with the use of a smartphone. Aside from preserving resources, a homeowner will save money on their water bill and insurance companies can have peace of mind that water leaks will be detected prior to causing major damage to the structure. Aside from damage to the structure, leaks that are not properly fixed can cause mold to grow.

IAPMO Codes and Standards prides itself as being the go-to-source for new and novel products. There are many plumbing technologies that began as an IAPMO standard and slowly became a normal part of our lives. Many innovators and manufactures have taken advantage of IAPMO’s services to ensure that their novel products find their way into the industry. As technology rapidly improves, IAPMO Codes and Standards is ready to meet the needs of the industry.

Code Development

The IAPMO codes provide consumers with safe and sanitary systems while, at the same time, allowing latitude for innovation and new technologies. The industry looks to IAPMO codes to address innovations or novel products.

The Uniform Plumbing Code (UPC) introduced an appendix that provides a modern way of sizing water supply piping. The newly developed Water Demand Calculator (WDC) recognizes that the world is now utilizing lower flowrate fixtures. In many states, it is law to use low-flow fixtures. Due to the lower water demand, the existing water pipe sizing method used will typically lead to oversizing, which means more volume of water in the piping. The larger volume of water equates to longer waits for the hot water to come out of the shower. This also leads to more water waste. The UPC is the only code that takes all this into account with the Water Demand Calculator (WDC) in Appendix M. The WDC is the first update since Hunter’s 1940 Curves to estimate peak water demand for single and multi-family dwellings using efficient fixtures. It reduces meter and pipe sizes and increases cost savings.

The Uniform Mechanical Code (UMC) was the first national mechanical code to address A2L refrigerants. A major milestone that introduced lower flammability refrigerants such as A2L and B2L. The industry’s concerns to address lower Global Warming Potential (GWP) refrigerants led to the development of these lower flammability refrigerants.

But why stop there? The Uniform Codes also have up-to-date provisions for geothermal, solar thermal energy systems and hydronic energy systems.

IAPMO’s codes based on principle and on a proven consensus process, the ANSI process. It is the only process that has been proven time and time again to employ true consensus. It is a development process that is used internationally for a reason. It is a process that has an oversight from a third-party to assure true consensus.

Whether it is codes or standards, IAPMO is the Standards Development Organization that is bringing innovation to the industry. Jurisdictions everywhere are taking advantage of IAPMO’s proven process because IAPMO codes and standards are developed by the industry for the industry. The Uniform Codes don’t only claim to be ahead of the curve, they are.

Please visit http://www.iapmo.org/standards-development/american-national-standards for more information.

Hugo Aguilar, P.E., is Senior Vice President of Codes and Standards for IAPMO.

Every month Mechanical Hub and the Plumbing Museum will be collaborating to bring you a piece of plumbing history. The American Sanitary Plumbing Museum is dedicated to promoting the contributions of the plumbing industry and its talented craftsmen across the United States. This month’s installment is the Automatic Storage Water Heater by Ruud. Read more

Every month Mechanical Hub and the Plumbing Museum will be collaborating to bring you a piece of plumbing history. The American Sanitary Plumbing Museum is dedicated to promoting the contributions of the plumbing industry and its talented craftsmen across the United States. This month’s installment is the Automatic Storage Water Heater by Ruud.

Every month Mechanical Hub and the Plumbing Museum will be collaborating to bring you a piece of plumbing history. The American Sanitary Plumbing Museum is dedicated to promoting the contributions of the plumbing industry and its talented craftsmen across the United States. This month’s installment is the Automatic Storage Water Heater by Ruud.

This Ruud “Automatic Storage Water Heater” (pictured left at the Plumbing Museum) was introduced by Edwin Ruud in 1889. Hot running water on demand was a luxury unknown to even the most affluent Americans. Other breakthroughs, large and small, followed over the years, as Ruud became a leading pioneer in water heating products for the home as well as for commercial and industrial applications. By the time Ruud departed the scene, his breakthrough innovation had changed the daily hygienic habits of every living American.

This Ruud “Automatic Storage Water Heater” (pictured left at the Plumbing Museum) was introduced by Edwin Ruud in 1889. Hot running water on demand was a luxury unknown to even the most affluent Americans. Other breakthroughs, large and small, followed over the years, as Ruud became a leading pioneer in water heating products for the home as well as for commercial and industrial applications. By the time Ruud departed the scene, his breakthrough innovation had changed the daily hygienic habits of every living American.

Located in a renovated ice house in Watertown, Mass., the American Sanitary Plumbing Museum is dedicated to promoting the contributions of the plumbing industry and its talented craftsmen across the United States. Through its unique mix of industrial history and modern art, it showcases artifacts and exhibits that range from 19th century tubs to modern toilets and a functioning rainwater reclamation system. The museum welcomes nearly a thousand visitors each year for tours and private events, and has been featured in the Wall Street Journal. For more information, visit: www.theplumbingmuseum.org.

When it comes to style trends and technology, kitchen and bath products have kept up in today’s marketplace. In terms of finishes, designers and homeowners alike are looking for statement pieces that will stand out in a space and get noticed. “With a wider array of finishes becoming more popular in the marketplace, and the Read more

When it comes to style trends and technology, kitchen and bath products have kept up in today’s marketplace. In terms of finishes, designers and homeowners alike are looking for statement pieces that will stand out in a space and get noticed. “With a wider array of finishes becoming more popular in the marketplace, and the rising trend of combining different finishes and textures, Moen, for example, has thoughtfully crafted a sophisticated Brushed Gold finish,” says Danielle Radic, product manager, Moen.

When it comes to style trends and technology, kitchen and bath products have kept up in today’s marketplace. In terms of finishes, designers and homeowners alike are looking for statement pieces that will stand out in a space and get noticed. “With a wider array of finishes becoming more popular in the marketplace, and the rising trend of combining different finishes and textures, Moen, for example, has thoughtfully crafted a sophisticated Brushed Gold finish,” says Danielle Radic, product manager, Moen.

Historically, gold fixtures were often associated with traditional design, but now, homeowners are also using this finish as part of a modern aesthetic, says Radic. Moen’s Brushed Gold finish, available on select kitchen and bathroom faucets, allows consumers to add elegance to their space and blends seamlessly with a variety of décor styles. “It also mixes well with other gold accents they may have throughout their space and has been designed to stand the test of time,” says Radic.

Additionally, homeowners continue to incorporate dark finishes into their homes. Moen’s on-trend Matte Black finish, available on a selection of kitchen and bath fixtures, offers a contemporary look that complements a variety of décor choices, while providing consumers with a unique finish that makes a statement.

Additionally, homeowners continue to incorporate dark finishes into their homes. Moen’s on-trend Matte Black finish, available on a selection of kitchen and bath fixtures, offers a contemporary look that complements a variety of décor choices, while providing consumers with a unique finish that makes a statement.

In regards to technology, consumers also are continuing to gravitate towards innovations that make their lives easier, including products that offer the benefit of smart technology. “In 2019, we’re showcasing some updates to the U by Moen shower, which is a cloud-based, app-driven digital shower that offers Wi-Fi mobile connectivity and unmatched personalization, delivering on consumers’ desire to create their perfect shower experience with up to 12 customizable presets,” says Michael Poloha, group manager, IoT, Moen. Consumers can control their shower anyway they like: with their voice, the smartphone app or the in-shower controller.

The product now features enhanced functionality with Amazon Alexa—including compatibility with groups and routines—as well as compatibility with Apple HomeKit™ and Google Assistant™. There’s also a new Matte Black controller finish for additional design customization.

The product now features enhanced functionality with Amazon Alexa—including compatibility with groups and routines—as well as compatibility with Apple HomeKit™ and Google Assistant™. There’s also a new Matte Black controller finish for additional design customization.

“We’re also excited to introduce Flo by Moen, a game-changing smart home water monitoring and leak detection system that enables homeowners to control their home’s water from their smartphones,” says Poloha. It calculates water pressure, flow rate and temperature within the home’s water supply system while using AI to differentiate normal water use from abnormal use. This enables the device to monitor and help detect water leaks and other vulnerabilities, says Poloha.

The Flo by Moen app provides users with real-time information about their home’s water consumption habits and alerts to any abnormalities. Within the app, users can control how the system provides alerts and respond to potential issues. Alerts may be sent to users through push notifications, via email, or by text or phone call. The user also can turn off their water directly from the app.

It’s nearly mid-2019. Another trip around the sun has just begun. How did your business treat you in 2018? How did you treat it? Now’s a good time to look back and see where you can make improvements. If you’re in the service industry, consider the impression your vehicle fleet makes on the members of Read more

It’s nearly mid-2019. Another trip around the sun has just begun. How did your business treat you in 2018? How did you treat it? Now’s a good time to look back and see where you can make improvements. If you’re in the service industry, consider the impression your vehicle fleet makes on the members of your community.

“A high-quality truck wrap is one of the cheapest, most effective forms of marketing available to heating and cooling contractors,” said Gary Nolt, president of Cassel, a Lancaster, Pennsylvania-based sign and vinyl shop with 18 employees. “If you break down the number of impressions a vehicle wrap provides, divided by the cost and lifespan of the wrap, the average cost per one thousand impressions is $.15. Compare that to $5.92 for radio advertising, $11.66 for a quarter-page newspaper ad, or $20.54 for a prime time TV spot.”

A quality truck wrap takes roughly two weeks to complete, and should last for seven to 10 years.

Cassel wraps or letters roughly 500 service vans each year—it makes of 35 percent of their business. The company was founded in 1945, and has progressed from hand-lettering furniture and trucks to become a one-stop-shop branding, design and display company. Custom vinyl vehicle wraps are what they specialize in, from Smart Cars to semi-trailers.

“My father in law started in the family business when he was 15 years old,” said Nolt. “I’ve been here for 22 years. As a matter of fact, my very first project here was the Burnham Racing trailer. That was in the spring of 1996 I purchased the company in 2012, and we recently opened a second location.”

Branding war

During his two decades with the company, one of the biggest changes Cassel has witnessed is the marketing mindset of service contractors. It’s one of the reasons that Cassel has made a strong shift from sign production to vehicle wraps.

Modern truck wraps are made of specialized vinyl, and are typically applied in different panels to avoid stretching.

“Everyone is busy right now, so it would almost make sense to think companies would be trimming their marketing budgets a little,” said Nolt. “But the opposite is true. It’s a branding war out there, and nobody can afford to give up an inch. This is the prevailing mindset today.”

After providing truck wraps for a company that hasn’t used them in the past, Cassel gets the same kind of feedback regularly. First and foremost, business owners say that the phone rings more often.

“Contractors tell me that their customers comment on how frequently they notice their wrapped trucks around town,” said Nolt. “They own one or two vans and customers think they own five or 10.”

He explained that trucks with a fresh wrap also go a long way to boost the driver’s pride and professionalism. Most employees tend to take better care of a nice looking vehicle.

Design

“Many contractors come to us because they want to increase their brand awareness, so branding is where we start,” said Nolt. “If a new logo is needed, we can help. If they have a good logo, or if they want to update an existing image, we can work with that, too. There’s really no limit to the process, but we want to help them achieve consistency across all platforms. The message they deliver visually should be current and forward thinking.”

“If you’re going to market yourself, you ought to do it well,” he continued. “If the service you provide is good, shouldn’t your image convey as much?”

The designers at Cassel are excellent at creating a look and scaling it to fit a canvas, whether that canvas be a business card or a brand new box van. But it helps if the customer already have an idea of what they would like to accomplish. At the very least, the service company should know what they don’t like.

“If you’re grasping at straws and starting out fresh, spend some time on Google,” explained Nolt. “What catches your eye? Or, on the flip side of the coin, what makes you cringe? Then identify what it is about those designs that makes you feel the way you do. When you come to a shop like ours, it will help if you already have some direction in mind, even if it’s a vague concept.”

Cassel has been in business in Manheim, Pa., since 1945, and wraps roughly 500 service vans and trucks each year.

While budget is obviously a consideration, it’s not a limiting factor. Cassel insists that there’s a solution for every budget, from small lettering panels to massive, fully wrapped fleets.

“We really try to over-serve customers, even when the budget is small,” said Nolt. “If we provide a good product, and they go out and succeed with it, they’ll be back for more later on.”

To keep things simple, truck lettering and wrapping options are broken into packages: lettering packages, partial wraps & full wraps. Based on the color of the vehicle and the design of the wrap, the appearance of a full wrap can sometimes be achieved without the full cost.

“If the simplest of designs and a small budget will help you grow your brand, we want to help,” said Nolt. “That might only be the company name and number in a nice font. The only thing we discourage is magnets. We can and do make magnets, when requested, but we feel as though magnets tell the world that you’re in this business temporarily. And that’s not a message you want to convey.”

Installation

Modern truck wraps are made of specialized vinyl, 2mm thick with a 1.3mm UV laminate over top. Cassel has a large format printer that can print up to 64” wide. The state-of-the-art printer can produce almost any color at all. A paint reader is used to match vehicle colors, if needed.

Once a design is created and the customer signs the project, the physical work begins.

“A full wrap typically takes a week or two, start to finish,” said Nolt. “Customers will often buy new trucks or vans and bring them directly here from the lot. But in a situation where the van is needed immediately, we can make it happen a lot more quickly.”

A truck wrap is a powerful, long-lasting branding tool, so plenty of thought should go into its design.

Before installation, vehicles are meticulously washed. Door handles and lights are removed, and the whole exterior is wiped down with alcohol. Only then is vinyl applied. After the material is adhered to the body of the vehicle, heat is applied to the edges and stretched areas.

“Like all technologies and products, vinyl has progressed rapidly in the past decade,” explained Nolt. “The material we use requires a 24 to 48 hour bonding period. When first installed, the bond between vinyl and truck exterior is mild, so it’s easier to work with. After settling for a day or two, that bond becomes much stronger.”

The vinyl used today also has microscopic air channels on the backside, allowing the installer to push air bubbles out without much trouble.

In an effort to provide value to the customer, Cassel has done a lot of research on which ink products last the longest. How long a truck wrap lasts will depend on a number of factors, primarily how the vehicle is cared for and the number of miles it’s driven.”

“High pressure washing a wrapped vehicle is fine, but it should be done carefully and sparingly,” explained Nolt. “Generally keeping the truck clean protects the wrap, but that’s something you should be doing anyway, for the sake of the company image.”

A quality, well-installed truck wrap will last roughly the service life of the vehicle, up to 10 years. Wraps look very good for easily five to seven years. Imagine how many customers see your vehicle in a seven year period.

“I like to think that Cassel has grown for the same reason a lot of our customers have grown: we provide an excellent product at a great value,” said Nolt. “But there’s another part of the equation. I’m surrounded by a lot of really bright, ambitious, trustworthy people. I credit Cassel’s success to the team of people that work here. We are a big family. I’m grateful for them, and I’m grateful for the solid business-to-business heritage here in Lancaster.”