Over the past few years, we’ve heard terms such as IoT, Robotics, Artificial Intelligence (AI) when referring to the future of construction, and one speaker in particular, at a plumbing and heating conference recently, scared the hell out of his audience by saying it’s not long now before humans—jobs in particular—will be taken over by Read more

Featured Articles

Over the past few years, we’ve heard terms such as IoT, Robotics, Artificial Intelligence (AI) when referring to the future of construction, and one speaker in particular, at a plumbing and heating conference recently, scared the hell out of his audience by saying it’s not long now before humans—jobs in particular—will be taken over by “machines” and we should be very worried.

This month’s BIGGEXCHANGE International Symposium had a more level-headed approach to the future of the construction industry. In an effort to seek change and sustainable improvement throughout the construction industry, the two-day event—the brainchild of Dirk Rosenberg, and co-spearheaded by brothers Maik and Christof of Aquatherm—was hosted at the corporate headquarters and manufacturing facility in Attendorn, Germany. “BIGGEXCHANGE is a good brand for social responsibility, sustainability and education,” says Dirk Rosenberg.

The brothers Rosenberg from l to r: Dirk, Maik and Christof.

Named after a nearby lake and the river that flows through the host site, BIGGE is also a play on words to symbolize “Big Buildings and Big Ideas,” and for leaders in the HVAC and construction industry to network and EXCHANGE ideas with fellow industry peers.

“If we don’t start communicating and build stronger alliances, we will never turn the construction industry into something more positive,” says Dirk Rosenberg, urging more collaboration on the jobsite. Usually, says Rosenberg, trade disciplines all act independently of each other, yet they are working on the same product, which is the building. “Bring people together and start communicating—architects, designers, engineers, contractors, distributors—to form a strong alliance to become successful.”

“If we don’t start communicating and build stronger alliances, we will never turn the construction industry into something more positive,” says Dirk Rosenberg, urging more collaboration on the jobsite. Usually, says Rosenberg, trade disciplines all act independently of each other, yet they are working on the same product, which is the building. “Bring people together and start communicating—architects, designers, engineers, contractors, distributors—to form a strong alliance to become successful.”

BIGGEXCHANGE Takeaways

Addressing some of the myths of the scary AI (and robotics), Matthias Horx posed the question: Is it true that 50% of jobs will disappear? “The future of the construction industry, in an age of digitization, still longs for interpersonal contact, and while trivial tasks may disappear, there will be a boom for human and interpersonal activity,” says Horx, of Zukunftsinstitut GmbH, a think tank to further develop prognostic techniques whose resulting knowledge and potential could be used both in the fields of business and politics. “Every trend has an existing counter trend. We either meet it and disperse, or we meet it and it turns into something greater,” says Horx.

Thought leaders from across the globe convened for the first BIGGEXCHANGE hosted by Aquatherm in Attendorn, Germany.

Presenter Stephen Butler, Autodesk, added, “Jobs in the future won’t be replaced, they will evolve.” By 2020, the robotics industry will create 240,000 jobs, he says.

But Butler’s presentation was more about the emerging trends in building design, with Urbanization and Sustainability—which need to go hand in hand—as focal points. According to the World Bank, says Butler, 9.7 billion people will populate the planet and 6.4 billion of them will be living in urban centers. Currently, commercial buildings consume 40% global energy, 25% global water and 30% greenhouse gas emissions.

Matthias Horx kicked off the event with his Power of Megatrends presentation.

During Dr. Ing. Alexander Rieck’s Future Construction Digital—How Building Will Change in the Digital Age, the topic of the lack of skilled tradespeople in the industry was broached. According to Rieck, digitization will help companies become faster, better and cheaper. “We cannot justify higher salaries to attract skilled labor without digital tools,” says Rieck, Fraunhofer IAO and LAVA.

Further, according to Rieck, the digital revolution will lead to creative architecture.

Piggybacking off of the concept of digitization, professor David Chua Kim Huat, National University of Singapore, emphasized reducing construction times and achieving higher profitability using BIM-based prefabrication in his Design for Manufacture and Assembly with BIM presentation.

The moderator (far left) talks to the panel from l to r: Arab Hoballah; Professor Brian Cody; Julia Goerke, thinkstep AG; Jordan Hardy, CEO, Aquatherm; and Jurgen Hahnrath, Cisco Systems GmbH.

Peter Heinrich, Heinrich GmbH-Communications agency, talked about corporate social responsibility in his “People, Planet, Profit—Sustainable Success with Sustainability and Communication” presentation, which talked about a company’s implementation of social, economic and environmental responsibility to society.

The event’s shift focused on day 2 to sustainable buildings as the highly anticipated Arab Hoballah, leader, SWITCH-ASIA SCP facility/Senior Sustainability Expert, opened with his “Climate Change & Resource Efficiency, the Sustainable Building Engine” presentation and his concern for the children and grandchildren on this planet as a result of climate change through inefficient buildings. “Yet there is optimism through transformative change,” says Hoballah. “We need to be proactive; it is up to us. Mitigating climate change starts with buildings.”

Arab Hoballah, right, is concerned, yet optimistic about the future.

Hoballah’s “urban metabolism” sees buildings similar to our own bodies, with positive impacts based on what is “ingested.” Pointing out the concept of effective circularity, “If we consume efficiently, population growth is not the problem,” says Hoballah. “Increasing consumption and a wasteful society are problems.” And one way to achieve this is through decoupling in manufacturing—a reduction of material intensity in products.

Hoballah ended his talk with four images: sticks, which represent laws; carrots, which represent incentives; tambourines, which represent making noise, understanding legislation and working together; and drums, which represent showing and being proud of your work.

The numbers are eye opening. (Stephen Butler, Autodesk)

Finally, the BIGGEXHCANGE finale featured a roundtable consisting of some of the presenters who gave opinions on the future of construction. “The only constant today is people, and we will continue to make the same mistakes if we don’t change,” says professor Brian Cody, TU Graz. Cody later said that laws and regulations need to change, “My whole life has been going around laws to build green buildings.”

Jurgen Hahnrath, Cisco Systems GmbH, says to stay curious, well informed and don’t be afraid. Jordan Hardy, CEO of Aquatherm North America, echoes the sentiment and says well-informed people and financial interests need to be aligned. Arab Hoballah says that the more we know, the more we move forward. “Behind the curtain there is light. We can do it.”

The Rosenberg’s will continue to push the message in future BIGGE events. “Starting tomorrow we have to put more energy into this to keep connecting,” says Dirk Rosenberg. “This is only the starting point.”

Members of the trade media gather with the Rosenberg brothers.

Navien’s comb-boiler (NCB) has had its share of criticism and praise alike but in my opinion there is one thing that gets me a little more than excited, the fact that nearly half the boiler must be removed to replace a part that is known to fail more than most other parts on the unit Read more

Navien’s comb-boiler (NCB) has had its share of criticism and praise alike but in my opinion there is one thing that gets me a little more than excited, the fact that nearly half the boiler must be removed to replace a part that is known to fail more than most other parts on the unit. As you’ll see in the video the PCB, main control panel, some internal [and external] piping and circ pump all must be fully removed in order to gain access to a failed 3-way diverter valve.

If you’re not sure what the valve does, you may not be alone but its really quite simple; when idle the valve is in position to supply flow from the heat exchanger’s supply outlet to either the heating system load (hot supply to system) outlet or to the flat plate heat exchanger to satisfy a call for domestic hot water. The problem is that its a piston type valve that can and will fail in a partially open position when there’s a call for DHW. The results are low flow to a potable water faucet at higher than desired temps [hence the reason I always spec and install a thermostatic mixing valve on the domestic side outlet]. The fix, while very time consuming, is relatively simple.

Hopefully this step-by-step video will familiarize the process for you if you’re faced with replacing the valve for the first time.

If you’re interested in a tool that has helped tremendously in making the job just a little easier, check this out:

https://www.instagram.com/p/Bmmab9_nPiM/?taken-by=mechanicalhub

The U.S. Environmental Protection Agency (EPA) has awarded a $699 million low-interest loan to the San Francisco Public Utilities Commission (SFPUC) to help finance its innovative Southeast Treatment Plant Biosolids Digester Facilities Project. Under the EPA’s Water Infrastructure Finance and Innovation Act (WIFIA), a program offering as much as $5.5 billion in loans, SFPUC received Read more

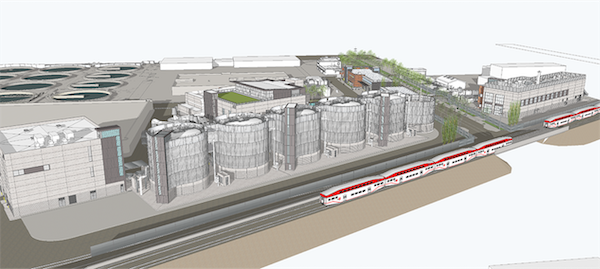

The U.S. Environmental Protection Agency (EPA) has awarded a $699 million low-interest loan to the San Francisco Public Utilities Commission (SFPUC) to help finance its innovative Southeast Treatment Plant Biosolids Digester Facilities Project.

Under the EPA’s Water Infrastructure Finance and Innovation Act (WIFIA), a program offering as much as $5.5 billion in loans, SFPUC received the largest amount issued to date to fund approximately half of the $1.2 billion biosolids and resource recovery project.

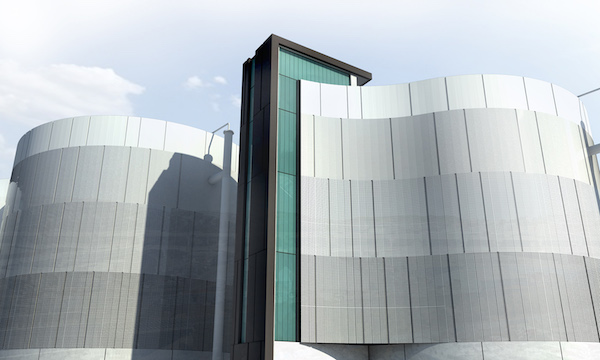

Led by environmental engineering and construction firm Brown and Caldwell, the project involves upgrading critical components of San Francisco’s aging sewer system infrastructure to support the city’s sustainability goals. With the loan, SFPUC will replace its outdated biosolids digester facilities with modern, efficient technology to transform wastewater solids into high-quality biosolids and biogas. The updated infrastructure is designed to maximize energy recovery, reduce emissions, minimize potable water use through recycling, and produce reusable Class A biosolids. Additionally, the new digesters will be located farther away from existing residences, feature advanced odor control, and will be more resilient to earthquakes.

“I am thrilled the EPA has chosen to partner with SFPUC by investing in their infrastructure and the local economy,” said Jay Patil, Brown and Caldwell senior vice president and director of sales, strategy, and marketing. “It speaks volumes about SFPUC’s visionary leadership and culture of environmental and community inclusivity that they received the largest WIFIA loan thus far.”

As the prime firm, Brown and Caldwell leads a team comprising Black & Veatch, CH2M (Jacobs), SRT, STRUCTUS, AEW, and Geotechnical Consultants for engineering; Saylor Consulting Group for estimating; MWA Architects, MEI Architects, Fluidity Design Consultants, and Endrestudio for architecture; and Katz & Assoc., Alfred Williams Consultancy, and BAYCAT for outreach.

Brown and Caldwell assisted the city in its letter of interest for the loan and provided technical documents in support of the application. The SFPUC project was the largest in a pool of 43 letters of interest submitted, and one of 12 projects selected by the EPA to apply for and negotiate a loan.

“SFPUC did an extraordinary job in securing this alternative funding, and our team is proud to have been part of the process,” said Tracy Stigers, Brown and Caldwell vice president and project manager. “Throughout the project, SFPUC and the consultant team have striven for cost savings and efficiencies with the ratepayer in mind. It is a great feeling to be part of an effort that will save ratepayers more than $200 million in financing.”

Located in Bayview-Hunters Point, the Southeast Treatment Plant is the city’s largest wastewater facility. When complete, the modern resource recovery facility will be an aesthetically pleasing community asset that helps protect the health of the community and the environment. The project also brings added employment and education opportunities through more than 3,000 local jobs and career training opportunities.

Project construction is expected to begin in early 2019 with facilities operational by 2025.

Up until now, the specification process derailed the plumbing engineer’s entire day … and then some. It was tedious, manual and ad-hoc. Specifying required combing through old project binders, scanning product specs one by one, searching multiple sites to find compatible parts, verifying and piecing it all together and coordinating p-schedules. There wasn’t really a Read more

Up until now, the specification process derailed the plumbing engineer’s entire day … and then some. It was tedious, manual and ad-hoc. Specifying required combing through old project binders, scanning product specs one by one, searching multiple sites to find compatible parts, verifying and piecing it all together and coordinating p-schedules. There wasn’t really a full-fledged tool to take you from spec to finish.

Zurn Industries, LLC officially launched its digital specification tool. inSpec, powered by Zurn, helps engineers configure plumbing projects faster using the manufacturer’s wide product offering, from drainage to behind the wall and front of the wall systems.

Close up of a designer working on a project. Photo credit: GettyImages

inSpec, powered by Zurn simplifies the process at every point. Users can build endless configurations from Zurn’s full line of plumbing solutions. They know what works with what and what and where to find it. They can find all the necessary product info for their plumbing projects at their fingertips, in an instant. From there, users choose the products they prefer to create a seamless solution. Projects are all managed in one place and can be edited on the fly at any time. Users can pick up where they left off without losing progress or questioning the current status.

“The days of rifling through old project binders or searching from site to site to site for a ‘suitable’ solution are over,” said Dave Krohn, Director of Digital Marketing & Communications. “inSpec, powered by Zurn, speeds up the specifying process, from spec to finish. inSpec users can digitally search and specify Zurn’s wide range of commercial products, quickly and accurately. The platform allows professionals to create unlimited configurations, save them to individual project folders, and access them at any time. The platform is completely intuitive from building configurations to generating the plumbing schedule and submittal.”

“The majority of plumbing products that specifying architects, engineers and design-build contractors need to complete their projects are included within the inSpec platform,” added Eric Loferski, Zurn Director of Marketing. “inSpec is also designed to be collaborative. Users can share projects with colleagues or email output documents to other influencers on the project. Ultimately, inSpec will save specifiers time by getting them to a completed submittal package faster than traditional methods.”

More reasons it’s a work (and sanity) saver? The editing, sharing and copying capabilities. With a few clicks, project owners can share projects with colleagues, gather feedback and collaborate. The project sharing function is secured, requiring the same company email address as the original project owner/user. Projects cannot be shared with any user who uses a public email domain (gmail, Hotmail, etc.) Users can also download their project’s submittal package, send p-schedules, build off a basis of design for a similar configuration, and duplicate an existing project to start a new one (instead of starting from square one again). At the end, the p-schedules can be sent to any individual with any email domain, no matter if it’s outside the company or public address.

Technology is a part of the customer journey, from reviewing a selection to long after purchase. Years back, Zurn launched an innovative specification solution for its time, called the Zurn One System specifier. This cracked the door for developing a comprehensive digital specification platform (inSpec). After spending nearly a year with various engineering firms to understand their wants and requirements, Zurn brought inSpec to market in July 2018.

Essentially, engineers are empowered like never before. Now projects can happen at their pace instead of a race against the clock with every obstacle possible out in front of them. Users can be confident that the work they put in will work in the end. inSpec, powered by Zurn, simplifies plumbing projects (and their job), from spec to finish.

Engineers’ input continues to be the biggest catalyst for future phases of the specification tool. Plumbing engineers are the experts actually using inSpec on a regular basis. The tool will continue to evolve with technology and the company.

The following are excerpts taken from a story written by Matt Parke, Working Nation. We highly stress that you visit their site for the rest of the story, and abundance of information regarding the hard truths about the looming unemployment crisis and bring the country together to create and amplify solutions for a changing economy Read more

The following are excerpts taken from a story written by Matt Parke, Working Nation. We highly stress that you visit their site for the rest of the story, and abundance of information regarding the hard truths about the looming unemployment crisis and bring the country together to create and amplify solutions for a changing economy.

The annual SkillsUSA National Leadership and Skills Conference (NLSC) and the SkillsUSA Championships features more than 18,000 attendees working an event the size of 20 football fields. A diverse group of students puts their training to the test in events ranging from cosmetology and construction to broadcasting and information technology. The NLSC is the future of work on display and SkillsUSA students are fired up to be a part of it. This past June, SkillsUSA members descended on the Kentucky Exposition Center in Louisville and turned it into a model city filled with skilled talent

The national nonprofit organization brings the country together to promote the technical and soft skills that employers desire and SkillsUSA students have. It is where analog skills, such as swinging a hammer, are on par with digital ones found in robotics and 3D printing.

SkillsUSA is the first student organization for trade and industrial education and has served more than 13 million members since 1965. The organization trains more than 340,000 middle school, high school, post-secondary and college students across 130 occupational skill areas. Its continuing mission is to develop the next generation of workforce leaders and promote the value of Career and Technical Education (CTE) programs.

SkillsUSA’s strategy to develop skilled workers comes at a critical time in the U.S. labor market. Widespread labor shortages are happening across a majority of sectors.

Welding together copper pipes for the project’s indoor plumbing. Photo Credit: Jonathan Barenboim

Reversing the college or bust trend requires raising awareness about the opportunities for younger workers without a four-year degree. SkillsUSA also makes the trades more appealing to a new generation by elevating them to competition status. The same reverence that sports legends receive is bestowed on competitors whether they are a master at applying mortar to bricks or can control a robotic arm.

“We need young people that are engaged in the trades, excited about the trades, have passion about the trades and the professions that we serve to enter that talent pipeline,” Lawrence said.

Examining the project’s blueprints. Photo credit: Jonathan Barenboim

Getting students to have that passion will take convincing them and their families about the ample career opportunities that await after graduation or obtaining a technical certificate. SkillsUSA makes employment a priority for students by treating the NLSC as a giant job fair. Each student must bring a resume and meet with employers who are looking to recruit talent from the competition floor.

The event space is spread across multiple buildings. Photo credit: Jonathan Barenboim

While many SkillsUSA students compete in the more than 100 events as individuals, the event’s TeamWorks contest tests the combined abilities of trades students representing four aspects of construction: carpentry, masonry, plumbing and electrical work. In only 16 hours, all teams must plan, present and build a structure from the same blueprints provided by SkillsUSA.