The first and best-known plumbing risk of the winter months is frozen pipes. Water carries a unique property in that freezing causes expansion; as a result, any pipes that carry water that may freeze will be put under additional strain when trying to contain water. As the temperature drops certain pipes are at greater risk Read more

Featured Articles

The first and best-known plumbing risk of the winter months is frozen pipes. Water carries a unique property in that freezing causes expansion; as a result, any pipes that carry water that may freeze will be put under additional strain when trying to contain water. As the temperature drops certain pipes are at greater risk than others, so pay special attention to any outdoor pipes that are likely to be exposed to the extreme cold. This generally includes swimming pool supply lines, outdoor house bibs and lines connected to water sprinklers. However, we also encourage our customers to pay attention to any interior lines that are not in heated areas, such as those that run through basements, crawl spaces, garages, or attics. Lastly, check up on any pipes that run against exterior-facing walls that have little to no insulation from the cold.

To prevent pipe freezing, be sure to keep at-risk areas as warm as possible. Keep garage doors closed and kitchen and bathroom cabinets open; this allows warm air to circulate in these areas and prevent the water in them from freezing. It is also important to keep the heat at roughly 50 degrees F in your house at all times, whether you are there or not. This may incur a slightly higher heating bill, but will prevent much more costly repairs if your pipes were to freeze or burst. If you’ve had problems with frozen pipes before or feel that your house or business is at particular risk, be proactive in your approach.

John Guest, for example, takes a great amount of pride in its ability to keep its customers’ plumbing needs covered year-round. Now that winter is just around the corner, John Guest thought it would be useful to remind its customers of the plumbing risks associated with the upcoming drop in temperature.

John Guest, for example, takes a great amount of pride in its ability to keep its customers’ plumbing needs covered year-round. Now that winter is just around the corner, John Guest thought it would be useful to remind its customers of the plumbing risks associated with the upcoming drop in temperature.

If you do find yourself in that unfortunate circumstance, John Guest has committed time and effort to developing the products necessary to tackle this problem. John Guest Speedfit slip connectors provide plumbers with a quick, simple, and easy fix to the issue of burst pipes. Our slip connectors come in two sizes and can be used to fix pipe bursts on PEX, CPVC, and copper pipes.

John Guest slip connectors feature push-fit connections, allowing for rapid installation that should at least temporarily solve the leakage that comes with burst pipes. The push-fit fitting allows all of this to be accomplished without altering any additional pipe work. Like all John Guest products, our Speedfit slip connectors are made with the most sophisticated technology available, assuring our customers that they are receiving only the highest quality performances from John Guest products.

John Guest slip connectors feature push-fit connections, allowing for rapid installation that should at least temporarily solve the leakage that comes with burst pipes. The push-fit fitting allows all of this to be accomplished without altering any additional pipe work. Like all John Guest products, our Speedfit slip connectors are made with the most sophisticated technology available, assuring our customers that they are receiving only the highest quality performances from John Guest products.

For PHCC president-elect, Ken Nielsen, juggling many duties throughout the work week is a way of life. Nielsen, president of AccuAIre Inc. just outside Boston, keeps himself busy during the week running commercial jobs throughout New England. Established in 1987, AccuAire Inc., and its four-man company, has offered residential and commercial HVAC and hydronics installations Read more

For PHCC president-elect, Ken Nielsen, juggling many duties throughout the work week is a way of life. Nielsen, president of AccuAIre Inc. just outside Boston, keeps himself busy during the week running commercial jobs throughout New England. Established in 1987, AccuAire Inc., and its four-man company, has offered residential and commercial HVAC and hydronics installations and services.

Nielsen also has been very active with PHCC for nearly 20 years where has been chairman of the local PHCC trade show committee since 2011—which hosts PHCC of Massachusetts—the largest one-day local trade show on the East Coast, and through his involvement with the PHCC Educational Foundation and its HVAC Apprenticeship Committee, he has volunteered his time to supervise and judge PHCC HVAC apprenticeship contests over the years.

And more recently, Nielsen has busy been preparing for a Hot Work class, hosted by local wholesaler F.W. Webb, on how to pull a Hot Work Permit. Hot Work, according to OSHA, is any work that involves burning, welding, using fire- or spark-producing tools or that produces a source of ignition.

Mechanical Hub recently talked with Nielsen, prior to be sworn in as PHCC president.

How did you get involved with the trades?

NIELSEN: Since college didn’t work out as planned, I was initially introduced to the industry through my uncle who suggested the trades. I attended the Northeast Institute of Industrial Technology, and I worked as a service manager for 15 employees with a union contractor before starting AccuAire Inc. in 1987 with my wife Alice, serving as CEO and CFO.

What is one of your biggest initiatives as president?

NIELSEN: I want to get more HVAC contractors involved with PHCC. Actually, we have a lot of members that started out as plumbers and now do HVAC. That’s why I think putting more focus on HVAC contracting would be beneficial.

In fact, we have some new additions to the PHCC CONNECT show this year. The Refrigeration Service Engineers Society (RSES) and the Radiant Professionals Alliance (RPA) will be co-locating and participating in educational seminars at this year’s CONNECT show.

Also, I would like emphasize the PHCC Academy—online plumbing and HVAC apprenticeships. We have the resources available through PHCC’s website. In fact, the Educational Foundation offers online plumbing and HVACR apprentice courses for apprentices who need a non-classroom based method of receiving their apprenticeship instruction.

What do you see as the biggest concern for the PHCP industry?

NIELSEN: The lack of skilled labor throughout the entire trades, regardless of whether it is plumbing and heating—carpentry, electricians, etc. Kids don’t want to enter the trades anymore. I’ve noticed that while judging contests and talking with apprentices, these students don’t even want to enter the trades upon graduation.

Also, women in the trades need to be recognized more. There are plenty of great, hard-working women in this industry that don’t get the same recognition as their male counterparts.

Anything currently in the works that is a hot issue?

NIELSEN: The Association Health Plans proposal, which PHCC supports. It is moving, yet slowly. There are currently 12 states that are trying to stop the momentum of an association health plan. (According to PHCC, a possible delay in implementation is a lawsuit filed by 12 states which, combined with other factors, may leave insurance carriers hesitant to participate in initial planning efforts, such as providing base line costs.) In essence, the new health plan could provide an option for small employers to offer competitive and affordable health benefits to their employees and increase the number of Americans who receive coverage through their employer.

With your experience industry, what advice what you give to others?

NIELSEN: Be honest with people. Don’t try to take advantage of them. I see that a lot—mechanics on commission that are offering things to customers that aren’t needed.

Also, enjoy what you do. If given the chance, I’d do it all over again.

The Plumbing-Heating-Cooling Contractors — National Association’s (PHCC) Educational Foundation is proud to announce the winners of HVAC Apprentice Contest Winners the national plumbing and HVAC apprentice contests. The contests were held October 10th & 11th in Albuquerque, N.M. on the tradeshow floor during the PHCC—National Association’s CONNECT 2018 event. A total of nineteen plumbing and ten HVAC apprentices from across Read more

HVAC Contest Winner Josiah Tiegs with PHCC Educational Foundation Chair Craig Lewis and HVAC Contest Committee Chair Scott Balmer.

The Plumbing-Heating-Cooling Contractors — National Association’s (PHCC) Educational Foundation is proud to announce the winners of HVAC Apprentice Contest Winners the national plumbing and HVAC apprentice contests.

The contests were held October 10th & 11th in Albuquerque, N.M. on the tradeshow floor during the PHCC—National Association’s CONNECT 2018 event. A total of nineteen plumbing and ten HVAC apprentices from across the nation took part in the contests.

HVAC Apprentice Contest Winners

- 1st Place: Josiah Tiegs, McDowall Comfort Management in Waite Park, Minn., Sponsored by Brasscraft Manufacturing

- 2nd: Daniel Deneve, GSM Services in Gastonia, N.C., Sponsored by NIBCO

- 3rd: Jeffrey Deuel, American Mechanical Services in Denver, Colo., Sponsored by Milwaukee Tool

Plumbing Apprentice Contest Winners

- 1st Place: James Houser, Local 27 in Pittsburgh, Pa., Sponsored by A. O. Smith

- 2nd: Kyle Mao, Lange Plumbing in Las Vegas, Nev., sponsored by AB&I Foundry

- 3rd: Steven Kroope, Deluxe Plumbing & Heating in Bethlehem, Pa., Sponsored by Reed Manufacturing

The HVAC competitors were required to complete a written test, demonstrate proper brazing techniques and perform a hands-on diagnostic on an HVAC package unit, with system errors created by the Foundation’s contractor volunteers for the competition. The competitors also had to perform a pressure and leak test, demonstrate proper refrigerant recovery procedures and the ability to accurately take a variety of instrument readings.

Plumbing Contest Winner James Houser with PHCC Educational Foundation Chair Craig Lewis and Plumbing Contest Committee Chair Jim Steinle.

The plumbing apprentices were required rough-in a bathroom system. The set-up includes a toilet, sink and shower, complete with supply, waste and vent lines, plus cleanouts and extra features designed to test the contestants’ knowledge and skills. The test set-up includes a variety of pipe materials – cast iron, copper, PVC and PEX, and corresponding joining methods.contractor volunteers for the competition.

A dedicated team of contractor volunteers arrived two days before the competitions to assemble the competitor test benches, distribute the materials and supplies and setup the testing areas. They monitor the competitions, evaluate the apprentices’ work and provide constructive feedback on each competitor’s performance following the event.

The contests are made possible by the generous support of several industry sponsors who provide monetary support and in-kind material and tool donations. Sponsors for the 2018 competition included, AB&I Foundry; A. O. Smith; Bradford White Corp.; BrassCraft Manufacturing Co.; Copper Development Association, Inc.; Daikin; Delta Faucet Co.; Emerson; Fluke, Greene and Associates; IPS Corporation; KOHLER Company; Mechanical Hub Media; Milwaukee Tool; NATE; NIBCO INC.; Oatey; R.E.C. Industries; Reed Manufacturing Co.; RIDGID; State Water Heaters; Tyler Pipe & Coupling; Uponor; Viega, LLC; and Zoeller Pump Company.

Milwaukee Tool made a major contribution to the Plumbing Apprentice Contest this year by donating twenty of their M18 Force Logic Press Tools and jaw kits, with a retail value exceeding $60,000 total. This gift allowed the competitors to gain experience and prove their skill with making press connections during the plumbing competition and will be used in future competitions as well.

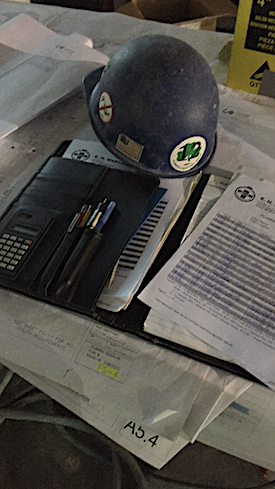

Fourth year apprentice, Chris Pinette with E.H. Marchant Co., a union contractor through the local 12, based out of Quincy, Mass. was sponsored by Mechanical Hub Media.

“These contests are an incredible demonstration of the opportunities that exist because of the Foundation,” reports Foundation Chair Craig Lewis. “You have these amazing apprentices from all over the country coming here to show off their skills. The sponsors are so generous with their support. And then our volunteer committee members and staff are pulling it all together in a new exhibit hall every year. It really is quite a thing to see and I’m very proud everyone involved with these competitions.”

When you’ve been in business for over 130 years, you pick up a few key learnings along the way. That foresight for Kiewit Infrastructure Co. translates into dynamic infrastructure, resource facilities, terminals, bridges, and waterways (to name a few) for people to use and appreciate all over the country. The company builds upon its reputation Read more

When you’ve been in business for over 130 years, you pick up a few key learnings along the way. That foresight for Kiewit Infrastructure Co. translates into dynamic infrastructure, resource facilities, terminals, bridges, and waterways (to name a few) for people to use and appreciate all over the country. The company builds upon its reputation with every project—using each as an opportunity to rise above expectations.

It’s that very groundwork and forward thinking that landed Kiewit the Milwaukee streetcar project. The Fortune 500 contractor took on the project ready to deliver and leave behind a transit system its employees can take pride in and people can rely on.

Project in Motion

The Milwaukee streetcar will transport workforce, residents and tourists to the city center’s businesses and cultural and entertainment destinations. A hop, skip and you’re on your way. It’s expected to spur further developments in the surrounding area, from future routes to restored districts and brand new hot spots.

Phase one covers a 2.5-mile radius, taking riders through downtown to the Historic Third Ward to East Town to the lower east side. The City of Milwaukee aims for a mid-2018 completion, meaning construction complete and a concrete timetable. It’s a big job on the fast track. Any little disruption would set back progress a lot.

Kiewit knew it needed the right materials in place to match its team’s capabilities and meet the trajectory.

“We build and manage major infrastructure and transportation projects across North America,” said Zach Green, Kiewit Guideway superintendant. “For the Milwaukee streetcar, we wanted to go with a local company, but other criteria mattered – pricing, overall design, and time to install. Zurn checked our list. They also consulted with us, which we didn’t expect. We were able to talk to a couple engineers and confirm performance and specs.”

Keeping it Moving

Sometimes jobsites require contractors to customize solutions, especially when there are multiple, bulky pieces to the drain system. The streetcar project required 36 trench drain systems along the route. With time on the line, cumbersome build, makeshift solutions, and extra equipment simply wouldn’t cut it. You run the risk of pipe damage, accidents, and hefty expenses.

“The theme here was about making it easy. We’re a company that focuses on safety and quality. With all of our moving parts on the job, Zurn’s trench drain systems added up to less labor, less costs, and less worry. They’re built to the ideal design and dimensions. Our guys had no problems installing them or pouring the concrete finish around them—no rough edges. The pipe connections were very simple. All set and done, they look good too.”

Set in Time

Zurn’s pre-fabricated trench drain systems come in one long-lasting, yet lightweight piece. It took just two workers to carry them around and set them in place. Kiewit estimated its team installed each drain within two to three hours, making them at least two to three times faster than comparable systems.

“We’re already recommending them to other jobs in the works—all over the country. We’re telling our guys ‘Hey, these are the drains we’ve found that are the easiest.’”

Kiewit expects to complete the project on time, while upholding its safety and quality business model.

Every year Mechanical Hub is honored to sponsor a plumbing apprenticeship contest entrant, and this year’s PHCC CONNECT in Albuquerque is no different. “Being entered into this contest is an honor. Competing against the best of the best in my trade is a feeling that I cannot explain. I am beyond thankful for this opportunity Read more

Every year Mechanical Hub is honored to sponsor a plumbing apprenticeship contest entrant, and this year’s PHCC CONNECT in Albuquerque is no different. “Being entered into this contest is an honor. Competing against the best of the best in my trade is a feeling that I cannot explain. I am beyond thankful for this opportunity; I am thrilled to show people my passion for plumbing,” says fourth year apprentice, Chris Pinette, E.H. Marchant Co., a smaller union contractor through the local 12 based out of Quincy, Mass.

Most of E.H. Marchant’s work is doing tenant fit outs and restaurants; they also do work in several of the office buildings, hospitals, museums, breweries, schools, universities, sports arenas and many other places surrounding the heart of Boston. The company’s focus is filling the large towers, residential housing and office buildings that are starting to fill the Boston skyline. “My company has a successful service department that is continuing to grow. We have been part of the team that has helped build the Winn casino, which is due to open soon. We also have been a huge part in building up the seaport district in Boston that has been going through an unreal transformation,” says Pinette.

Pinette’s interest in the trades started when he was very young; his grandfather was a “jack-of-all-trades” and had a workshop in his own basement. “Growing up in his house, I had spent a lot of my time down there helping him with many of his projects. I learned a lot from him, and I grew interested in what we had worked on together.

Pinette’s interest in the trades started when he was very young; his grandfather was a “jack-of-all-trades” and had a workshop in his own basement. “Growing up in his house, I had spent a lot of my time down there helping him with many of his projects. I learned a lot from him, and I grew interested in what we had worked on together.

Eventually, when it came down to making a decision on choosing a high school, Pinette, from Rehoboth, Mass., decided to attend a trade school—Tri-County Regional Vocational Technical High School in Franklin, Mass. “This was one of my best decisions I have made to help begin my career. After going through nine training programs at the high school, I narrowed down my search to metal fabrication and plumbing. After much deliberation, I made a final choice to explore the plumbing shop. This was the beginning of my career in plumbing,” says Pinette.

I chose plumbing, recalls Pinette, because it was fascinating to know how plumbing works. As with most in the trades, Pinette enjoys using his hands and he enjoys learning the science behind how plumbing works—knowing how systems are piped, what makes waste go from point A to B, how the atmosphere affects the system and how pressure works to move water. “It makes me believe that plumbers are partly scientist because they need to know how and why plumbing works in order for it to be efficient,” says Pinette.

There are many perks to the job and Pinette is thankful for being part of E.H. Marchant for the better part of four years. One of those perks is that Pinette has had the pleasure to work in a lot of “cool” places in Boston. “Every day is something new; working in these places never becomes a dull moment for me.”

There are many perks to the job and Pinette is thankful for being part of E.H. Marchant for the better part of four years. One of those perks is that Pinette has had the pleasure to work in a lot of “cool” places in Boston. “Every day is something new; working in these places never becomes a dull moment for me.”

Yet what Pinette enjoys most about plumbing is being able to look back at his own work and see his progress. “There is no better satisfaction than seeing my work become effective. Some people have told me they think plumbing is cut and dry, but there’s a lot more to it. Plumbing takes a lot of time and planning; I am always certain that everything in my projects moves as smoothly as it should. Knowing the time and effort I have put into it makes me proud of what I have done,” says Pinette.

Pinette started off as a truck driver delivering tools and material to the job sites. “During my first year working, I applied to local 12 and I was welcomed into the program. Since then I have been working at E.H. Marchant as an apprentice, with the motivation to run work in the future,” says Pinette.

For those thinking of entering the trades? Pinette would highly recommend the plumbing trade. According to Pinette, there is a ton of work out there if you are willing to get your hands dirty. “If I had to give one piece of advice, it would be to listen and learn from the people you are working with and then choose what works for you. You’ll eventually form into the plumber you want to become with all you have learned from your teachers. Work hard and you will be rewarded for it in time,” says Pinette.

Heading into this week’s PHCC plumbing apprenticeship contest, Pinette is beyond thankful for this opportunity. “I am thrilled to show people my passion for plumbing. I am nervous along with feeling anxious because these are big shoes that need to be filled but I believe that I can do it. I was chosen to compete in the apprenticeship contest for a reason, and I cannot wait to show them what I am made of,” says Pinette.