Sixth video in the Tech TV series presents pros and cons of various control strategies. Lindon, UT — Preventing Legionnaires’ disease by controlling the growth of Legionella bacteria in water systems is the topic of the latest Tech TV video from Aquatherm. The video is available at https://aquatherm.com/videos/legionella. Legionnaires’ disease is transmitted through inhalation of Read more

Industry News

Sixth video in the Tech TV series presents pros and cons of various control strategies.

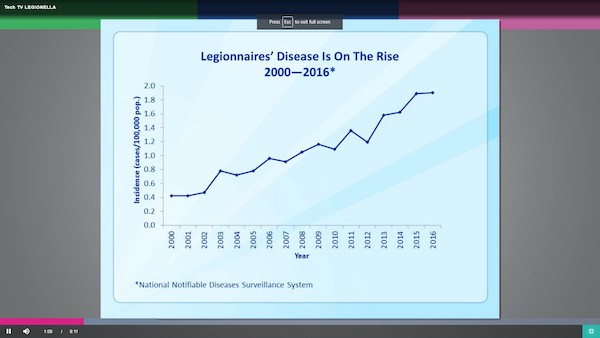

Lindon, UT — Preventing Legionnaires’ disease by controlling the growth of Legionella bacteria in water systems is the topic of the latest Tech TV video from Aquatherm. The video is available at https://aquatherm.com/videos/legionella.

Legionnaires’ disease is transmitted through inhalation of water vapor in which the Legionella bacterium is present. It can present a very serious health risk to susceptible populations. Sources in a building can include misters, humidifiers, whirlpools and spas, evaporative coolers, and open- and closed-loop cooling towers. The best means of controlling Legionnaires’ Disease is by eradicating Legionella from a building’s water supply.

In this Tech TV video, Jim Paschal, P.E., Chief Technology Officer, Aquatherm North America, evaluates the pros and cons of various chemical and non-chemical Legionella control strategies, including hyper chlorination, chlorine dioxide, monochloramine, copper-silver ion generation, heat, and ultraviolet light.

The Legionella video is the sixth in the series of Aquatherm Tech TV videos. Other topics have been mixed systems, temperature, pressure, flow rate, and support considerations. All Tech TV videos can be found here: https://aquatherm.com/video-library. All of the videos in the series are free and available 24/7.

U.S.-based non-profit WaterStep already has some of its safe water equipment on the way to help Hurricane Dorian survivors in the Bahamas, and in the next few days, a full shipment of tools that produce safe water and disinfectant will be deployed. The shipment will include Disaster Relief Kits, M-100 Chlorine Generators and BleachMakers, which Read more

Nebrasky collected supplies from employees and the community throughout the summer Monroe, N.Y. — Nebrasky Plumbing, Heating & Cooling has donated 50 backpacks and countless school supplies to the Backpacks for Hope program in partnership with the Boys & Girls Club. The school supplies were donated from Nebrasky employees and members of the community. The Read more

Nebrasky collected supplies from employees and the community throughout the summer

Monroe, N.Y. — Nebrasky Plumbing, Heating & Cooling has donated 50 backpacks and countless school supplies to the Backpacks for Hope program in partnership with the Boys & Girls Club. The school supplies were donated from Nebrasky employees and members of the community. The Boys & Girls Club will distribute all items to children in need throughout Northern Orange & Sullivan counties.

The backpacks were stuffed with a variety of school supplies, including:

- Pens/pencils

- Erasers

- Markers

- Crayons

- Composition notebooks

- Glue/Glue Sticks

- Children’s scissors

- Lined notebook paper

- Spiral notebooks

- Notepads

- 3 Ring binders

- Folders

“Giving back to the community is an important part of our mission, and all of our employees participate,” said Paul Nebrasky. “We are proud to know that we can help 50 students return to school with the tools they need to be successful.”

Picture (left to right): Nebrasky employees Michelle Ross, Leeanne Rose, Judy Yates and Eileen Barclay with the donated school supplies.

For more information, visit www.nebraskyplumbing.com

OLFA announced its #OLFAintheTrades initiative today, which aims to give back to men and women in the trades and foster the next generation of professionals. This initiative will support qualified trade education programs by supplying them with top-of-the-line OLFA utility knives and more. Trade instructors can register eligible classes to receive an OLFA 18mm LA-X Read more

OLFA announced its #OLFAintheTrades initiative today, which aims to give back to men and women in the trades and foster the next generation of professionals. This initiative will support qualified trade education programs by supplying them with top-of-the-line OLFA utility knives and more.

OLFA announced its #OLFAintheTrades initiative today, which aims to give back to men and women in the trades and foster the next generation of professionals. This initiative will support qualified trade education programs by supplying them with top-of-the-line OLFA utility knives and more.

Trade instructors can register eligible classes to receive an OLFA 18mm LA-X or L-5 knife for each student, an OLFA banner, and a chance to be featured on the OLFA social channels and website. Trade students who register their new knives will receive tool box stickers, student discounts, and the possibility of participating in the “OLFA All-Pro Team” of ambassadors.

“Without our trade instructors and career education programs, we would not have the continuous advancement and innovation in the trades that we do today,” said Cassie Donnelly, Sr. Brand Manager at OLFA. “Our goal for this project is to contribute to the development of these programs, and make attaining top-quality tools one less cost or concern for both the educators and the students.”

https://youtu.be/IYuPmJXb8Y8

To sign up, instructors need to provide necessary information about their programs. Programs verified by OLFA to meet the requirements will then receive their specified knives – either the LA-X or L-5, and other aforementioned benefits.

To register and learn more about the #OLFAintheTrades initiative, instructors can visit this page: try.olfa.com/instructors/ and students can refer their instructors to register their classes.

Mokena, Ill. — IAPMO Training and Education introduces the new Plumbing Systems Interactive Workshop, a fun, hands-on course that teaches the effective uses of four basic plumbing systems, why/where/when to use each, how to apply code compliant configurations to design and installation, and actual assembly of each system using scaled 3D-printed drainage pattern fittings. The Read more

Mokena, Ill. — IAPMO Training and Education introduces the new Plumbing Systems Interactive Workshop, a fun, hands-on course that teaches the effective uses of four basic plumbing systems, why/where/when to use each, how to apply code compliant configurations to design and installation, and actual assembly of each system using scaled 3D-printed drainage pattern fittings.

The eight-hour course, developed and instructed by Steve Hart, senior plumbing plans examiner with Public Health – Seattle and King County (PHSKC), is delivered in three parts repeated for each plumbing system addressed:

- Part One: Attendees learn/review the code requirements for one of the plumbing systems—horizontal wet vent, circuit vent, vertical wet vent or combination waste and vent

- Part Two: Separate into groups of five and apply this knowledge to assemble the particular plumbing system using 3D-printed fittings, focusing on best engineered practices for mitigating health and safety risk and achieving code compliance

- Part Three: Discussion and debrief, repeat for next system

“IAPMO is constantly looking for ways to improve the learning experience for our students,” said Tony Marcello, vice president of IAPMO Training and Credential Services. “This hands-on offering is unique and innovative, and allows for a large amount of learning to occur in a fun and engaging way. Steve Hart, the developer of the concept and primary instructor, has poured his heart and soul into this learning method and we could not be more excited to introduce this training opportunity to the plumbing industry.”

The Plumbing Systems Interactive Workshop seeks to facilitate cooperation between building officials/building inspectors, apprentice/journeyperson plumbers, and design professionals to enhance public health and safety.

“I found the Plumbing Systems Interactive Workshop to be one of the best workshop experiences I have attended,” said Robert J. Heavey, plumbing plans examiner, city of Bellevue, Wash. “Instructor Steve Hart knows his subject inside out, and is able to present it in a way that reaches all levels of attendees, from the experienced plumbers and designers to those who are still struggling with the multiple venting options offered by the code. The interactive experience of actually building scale models of a waste and vent system, showing in turn each of the venting options, allows the attendees to try out the knowledge they gained in the first half of the session. Mistakes are made, and the collaboration within each group works well to help reach a correct resolution.”

Three upcoming workshops will be presented at the Simpson Strong-Tie Training Center in Kent, Wash., on Sept. 11, Oct. 5, and Dec. 4. The cost is $250 ($225 for IAPMO members). For more information or to enroll in an upcoming workshop, direct your browser to www.bit.ly/iapmo-psi-signup.