OLFA announced its #OLFAintheTrades initiative today, which aims to give back to men and women in the trades and foster the next generation of professionals. This initiative will support qualified trade education programs by supplying them with top-of-the-line OLFA utility knives and more. Trade instructors can register eligible classes to receive an OLFA 18mm LA-X Read more

Uncategorized

OLFA announced its #OLFAintheTrades initiative today, which aims to give back to men and women in the trades and foster the next generation of professionals. This initiative will support qualified trade education programs by supplying them with top-of-the-line OLFA utility knives and more.

OLFA announced its #OLFAintheTrades initiative today, which aims to give back to men and women in the trades and foster the next generation of professionals. This initiative will support qualified trade education programs by supplying them with top-of-the-line OLFA utility knives and more.

Trade instructors can register eligible classes to receive an OLFA 18mm LA-X or L-5 knife for each student, an OLFA banner, and a chance to be featured on the OLFA social channels and website. Trade students who register their new knives will receive tool box stickers, student discounts, and the possibility of participating in the “OLFA All-Pro Team” of ambassadors.

“Without our trade instructors and career education programs, we would not have the continuous advancement and innovation in the trades that we do today,” said Cassie Donnelly, Sr. Brand Manager at OLFA. “Our goal for this project is to contribute to the development of these programs, and make attaining top-quality tools one less cost or concern for both the educators and the students.”

https://youtu.be/IYuPmJXb8Y8

To sign up, instructors need to provide necessary information about their programs. Programs verified by OLFA to meet the requirements will then receive their specified knives – either the LA-X or L-5, and other aforementioned benefits.

To register and learn more about the #OLFAintheTrades initiative, instructors can visit this page: try.olfa.com/instructors/ and students can refer their instructors to register their classes.

The all-expenses-paid 3-day trip involved a variety of VIP professional and networking experiences, including the opportunity to build their own iconic RIDGID custom pipe wrench, a featured spot in a RIDGID photoshoot, a premium fishing excursion on Lake Erie and more. Winners also received a behind-the-scenes tour of the RIDGID plant, getting a sneak peek Read more

The all-expenses-paid 3-day trip involved a variety of VIP professional and networking experiences, including the opportunity to build their own iconic RIDGID custom pipe wrench, a featured spot in a RIDGID photoshoot, a premium fishing excursion on Lake Erie and more.

Winners also received a behind-the-scenes tour of the RIDGID plant, getting a sneak peek at the latest RIDGID innovations that have yet to hit the market and providing insight for future product developments. “You think plumbing, you think RIDGID,” said John Thompson, contest winner and owner of Thompson Family Plumbing in Hesperia, California. “It’s iconic. We’re proud and honored to be here and see how this company operates and develops tools for tradesmen and women.”

“Having these hardworking professionals come into our facilities and hearing them talk with the men and women who make the products they use is inspiring for all of us,” said Becky Brotherton, manager, marketing communications, RIDGID. “Getting to spend a few days celebrating the passion of the RIDGID Experience winners is something we look forward to every year.”

“Having these hardworking professionals come into our facilities and hearing them talk with the men and women who make the products they use is inspiring for all of us,” said Becky Brotherton, manager, marketing communications, RIDGID. “Getting to spend a few days celebrating the passion of the RIDGID Experience winners is something we look forward to every year.”

Details on the next RIDGID Experience Contest will be announced in early 2020. Visit the RIDGID Facebook page for details. Emerson’s professional tools business, which includes RIDGID as well as the Greenlee and Klauke brands, provides the industry’s broadest portfolio of advanced, reliable tools and technologies for the mechanical, electrical and plumbing trades globally. Visit emerson.com/professionaltools for more information.

Matco-Norca offers Lead Free Brass Cold Expansion PEX & MNPT Ball Valves in three sizes. These full port cUPC approved ball valves have C46500 forged brass stems, bodies, balls and bonnets, and are available in 1/2”, 3/4” and 1” sizes. Equipped with blowout proof stems and capable up to 400 PSI (CWP), they are NSF Read more

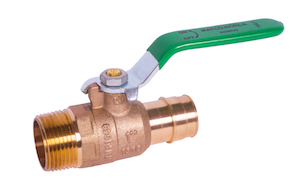

Matco-Norca offers Lead Free Brass Cold Expansion PEX & MNPT Ball Valves in three sizes. These full port cUPC approved ball valves have C46500 forged brass stems, bodies, balls and bonnets, and are available in 1/2”, 3/4” and 1” sizes.

Matco-Norca offers Lead Free Brass Cold Expansion PEX & MNPT Ball Valves in three sizes. These full port cUPC approved ball valves have C46500 forged brass stems, bodies, balls and bonnets, and are available in 1/2”, 3/4” and 1” sizes.

Equipped with blowout proof stems and capable up to 400 PSI (CWP), they are NSF 14/61 approved and their cold expansion PEX fitting ends comply with ASTM F1960. Their MNP threads comply with ASME B1.20.1.

For additional product info and to view the full line of ball valves from Matco-Norca, visit www.matco-norca.com and click on Valves/Brass Ball Valves.

Zurn’s EZ Gear-Driven Sensor Faucets deliver reliability, precision, and efficiency to commercial restrooms. With the dual action of the ceramic disc cartridge and the same motor gear-driven operation found in E-Z Flush units, the EZ Gear-Driven Sensor Faucet outperforms and outlasts other faucets—withstanding over 1,000,000 cycle tests. It intuitively senses the user without delay, too Read more

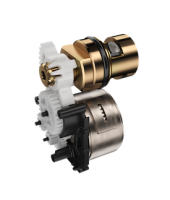

Zurn EZ Gear Driven Sensor Faucet

Zurn’s EZ Gear-Driven Sensor Faucets deliver reliability, precision, and efficiency to commercial restrooms. With the dual action of the ceramic disc cartridge and the same motor gear-driven operation found in E-Z Flush units, the EZ Gear-Driven Sensor Faucet outperforms and outlasts other faucets—withstanding over 1,000,000 cycle tests. It intuitively senses the user without delay, too much force, or wasting water.

Zurn Camaya Series Faucet

The new faucet is available in two designs—the Cumberland Series and the Camaya Series with matching soap dispensers in chrome (standard) or brushed nickel finishes. The faucets are ADA compliant with a 30-second time-out feature, motor gear-driven ceramic valve, and multiple flow control options to meet EPA WaterSense® standards. www.zurn.com

This isn’t a technical comparison, just some simple observations from the field. On the left: Webstone EXP 2 complete tankless water heater kit On the right: Navien Plumb Easy valve kit https://www.youtube.com/watch?v=QFfo2-DDkr0 Read more

This isn’t a technical comparison, just some simple observations from the field.

On the left: Webstone EXP 2 complete tankless water heater kit

On the right: Navien Plumb Easy valve kit