As far back as he can remember, Derek Zeolla, general manager and licensed plumber at Zeolla Plumbing & Heating Corp., was running plumbing jobs with his father in downtown Boston as early as seven years old. Derek’s dad was a Boston service plumber that ran a 1- to 2-man shop. “It’s not like this was Read more

boilers

As far back as he can remember, Derek Zeolla, general manager and licensed plumber at Zeolla Plumbing & Heating Corp., was running plumbing jobs with his father in downtown Boston as early as seven years old. Derek’s dad was a Boston service plumber that ran a 1- to 2-man shop. “It’s not like this was common, I was just growing up around it,” says Zeolla (@zeollaplumbing).

Derek Zeolla and his wife Arlene

Derek’s father eventually stopped working as a plumber in the late ’90s. Around this time, while still a teenager, Derek dropped out of school had a baby at the age of 18. Moving forward, “My brother, Doug, and I convinced our dad—also named Doug—to get back into the trade, but before we worked as a family, he sent us off to get experience elsewhere,” recalls Zeolla.

Derek’s father’s company in the ’90s

According to Zeolla, they worked all over the city and jumped around recklessly from company to company, some jobs together, some not. “We always found a way of getting together with a new employer, one of us would talk up the other,” says Zeolla. “It’s funny looking back on that thinking how little we knew back then. My parents were coming off of a divorce and my father was starting to take on some service stuff in our new town Stoughton, Mass. where we grew up and went to high school. Eventually, he had enough work for both of us and we stayed pretty busy,” says Zeolla.

And that’s how Zeolla Plumbing & Heating Corp.—residential service plumbing, drain cleaning, heating, and boiler installation—came to be. “We have built a solid reputation in our area through more than a decade of answering the phone and showing up. Man, we have come a long way since then,” says Zeolla.

The Family Dynamic

Working with his father, brother and one of his cousins most of the time were the best memories in the field for Zeolla. “I can’t explain it, but something about sharing the bond of working together, figuring out problems together, feeling the pride was the best, and I hope to share that with my two boys one day,” says Zeolla.

Derek with his father Doug a few years ago.

But with life, things change. “As many know, my brother passed away. This was tough, and even before that, my father took a step back from the business and went to Florida (but still flies back to Boston from time to time to help out). Add to that, my cousin and I haven’t talked in years so it’s not the same out here anymore,” says Zeolla.

Zeolla says he is blessed that his wife Arlene has filled a void. “She is the savior in the office, and I have a great team.”

Derek also hired his younger cousin Justin last year and he has been phenomenal. “I was out with him today clearing drains on a Sunday and it brought back that feeling again of working with family. Working with a Zeolla,” says Derek nostalgically.

And while Derek puts his father center on the Mount Rushmore of mentors, there were some other people outside the family that were strong influences on Derek. For Zeolla, one of the best was a Greek guy named Alex, who, when Derek was looking for work, took him on for a couple of years. “He taught me how to get shit done; he taught me how to move.”

Derek working with his cousin Justin

Alex was a great mentor yet has since passed away. “Which brings me to, am I a role model? I don’t know, but Alex has two sons. One has come to me looking for mentorship, and it’s just so crazy how things come full circle because now he works with me and he is already just like his father when it comes to plumbing skill.”

Zeolla hopes to be a good role model for him, including and all his younger guys he works with. “I will never steer them in the wrong direction, that’s for sure. This is too important to me,” says Zeolla.

Challenges/Rewards

One of my biggest challenges isn’t the pipes, says Zeolla, it’s the people. “I say this phrase a lot, and I love people in general, and I love my customers, but sometimes when it comes to understanding what we are doing in their homes, it can be challenging. It’s very important to explain things and make sure they feel comfortable. It’s a delicate balance between taking control of a situation and saying, ‘hey, look, I’m the professional here I need you to trust me,’” says Zeolla.

Again, the pipes are the easy part! “I’m lucky that I have great customers. The rewarding part is helping people out, getting someone’s heat back on, clearing a main drain, getting the hot water back, or being told that you are appreciated is probably the best. That ride home to then seeing your family after you helped another family, that’s the reward.”

Leisure Time

Derek and his wife love to travel, and they take their kids literally everywhere they go. AHR Atlanta was their second time leaving them overnight in five years. But basically, there is no leisure time without the phone ringing and Derek coordinating with his six guys, and customers. “My wife and I are like running a telethon while ‘trying’ to be on a vacation. We love it and we are good at it, but she knows I can’t be away from the field long. It’s my therapy and I get depressed if I’m not turning wrenches,” says Zeolla, a self-described workaholic.

As far as spare time close to home, Zeolla enjoys fishing, hiking and hanging out at his cabin nestled in the White Mountains of New Hampshire. “Summer weekends there with my boys are what I work toward every week. When my brother passed, I wanted to find a place to escape, and I found something special,” says Zeolla.

As far as spare time close to home, Zeolla enjoys fishing, hiking and hanging out at his cabin nestled in the White Mountains of New Hampshire. “Summer weekends there with my boys are what I work toward every week. When my brother passed, I wanted to find a place to escape, and I found something special,” says Zeolla.

The Skilled Trades

According to Zeolla, “We” need to push our way into middle schools and high schools to get “our” message heard. Kids need to know that they have options at a younger age, says Zeolla.

“Listen, school isn’t for everyone. You might be told you aren’t good enough, or your attention span is too short, or you can’t listen to lectures all day, but put that kid in front of something hands-on, something he or she can feel—and feel the pride of building something—the sky is the limit. Once you get that feeling of being productive and important, you will open doors you didn’t even know were there,” says Zeolla.

The past few years have been good for contracting businesses, barring component availability and skilled labor woes. For anyone in the trades, operating a plumbing and mechanical company profitably looks different today than it did 20 years ago, but there are still plenty of similarities. Joe Tull, 36, founded Straight Plumbing, LLC seven years ago Read more

The past few years have been good for contracting businesses, barring component availability and skilled labor woes. For anyone in the trades, operating a plumbing and mechanical company profitably looks different today than it did 20 years ago, but there are still plenty of similarities.

Joe Tull, 36, founded Straight Plumbing, LLC seven years ago, and feels as though he’s settled into a sweet spot. Right now, that includes running two trucks and focusing on Maryland’s Hartford County and northern Baltimore County. The company used to be bigger, but not necessarily better, according to Tull.

Roughly 30 percent of Straight Plumbing & Heating’s work is hydronic heat. The rest is residential and commercial plumbing service.

“I’ve always preferred quality over quantity,” he explained. “When I had more employees, I spent a lot of time going behind them and fixing their mistakes or shortcuts. Right now I have a fantastic apprentice, Robert Howard, who’s been with me four years. He’s always respected me and done things my way, which simply means not cutting corners. I’d hire 20 like him, if I could find them.”

Joe grew up working for his father’s plumbing company, but after a while, the two Tulls couldn’t see eye to eye. So Joe left and spent several years on the plumbing service crew for a large company before hanging out his own shingle in Jarrettsville, Md.

Specialization

“Specialization gives the people . . . the opportunity to go further in any direction of study than any other human has gone before.” – Ryan North

“Service is what I knew best, and what I could build a reputation on most rapidly,” said Tull. “Service work also provides the greatest opportunity to solve people’s problems. The new construction side of the business is more volatile. So I specialized in plumbing service, and as soon as I was up and running, I dug into hydronics to expand our offering.”

Joe Tull founded Straight Plumbing, LLC in 2016, after working for his family’s company and several other plumbing firms in the area.

Today, 30 percent of Straight P&H’s work is hydronic heat. The rest is plumbing service, both residential and commercial. Due to the rural nature of his territory and the presence of hard and harsh water, many of their service calls involve well pumps and water conditioning. A deep understanding of water quality has infinity improved Tull’s hydronic and plumbing work.

Forging relationships

“Technology does not run an enterprise, relationships do.” – Patricia Fripp

Tull learned early in his career that relationships are critical to the success of a business. In addition to learning from his father, he had mentors at supply houses, rep firms and within his social circle.

“I had a lot to learn when I first started installing boilers” said Tull. “Jim Bull, at Thomas Somerville became a mentor. He has a wide range of heating knowledge and was always generous with that information. He’d even stop at my jobs in the evening and set me straight if I was in a bind.”

Relationships are as important to Tull today as they were then, when he was still building his portfolio of experience.

“I try to be an information sponge and do my best to become an asset to the people who add value to my life,” said Tull. “Over the past three years, I’ve worked closely with the reps at ROI Marketing, specifically Dan Byrne, district manager, and Dave Raabe, sales manager. Those guys are never more than a phone call away.”

“I try to be an information sponge and do my best to become an asset to the people who add value to my life,” said Tull. “Over the past three years, I’ve worked closely with the reps at ROI Marketing, specifically Dan Byrne, district manager, and Dave Raabe, sales manager. Those guys are never more than a phone call away.”

Byrne has known Tull for more than 20 years, but has only been his hydronic rep for about three years, after helping Straight P&H sort out some technical issues on a particularly challenging project. Tull installs their line of U.S. Boiler Company condensing and cast iron boilers, ComfortPro PEX, State water heaters and Webstone valves. Some of that equipment comes through Jordan Mitchell, at Northeastern Supply, while some is sourced at other supply houses throughout the area.

Straight Plumbing & Heating used to be a larger company, but Tull intentionally reduced it to two trucks for the sake of quality and consistently.

“Dave and Dan rock,” said Tull. “Their support, and the help I’ve received from the factory tech support at U.S. Boiler has been outstanding. I’ve used other boiler brands with less success and non-existent customer service.”

Byrne and Raabe visit Tull’s jobsites a dozen times or so each year, often on the front end, to provide sizing assistance, system concepts, etc.

“What I observed when I first met Joe was a young guy that wanted to install stuff properly,” said Raabe. “He’s very talented and his work is extremely professional, yet he’s humble and not afraid to ask for help.”

“I wish all our customers were like Joe,” added Byrne. “He takes real pride in his work.”

Referral marketing

“Courteous treatment will make a customer a walking advertisement.”

– James Cash Penney

“I left my previous job because I saw customers being taken advantage of,” Tull said. “I don’t hard-sell anyone. I present their options along with fair pricing and let them decide what they prefer. I want customers for life. If I’m fair and I do the job to the best of my ability, my customers become my salesforce.”

Tull doesn’t just talk the talk. His 38 five-star reviews on Facebook are proof enough. One review states, “Joe came to my house and fixed me up. After I got estimates from other plumbers that were way too expensive, Joe fixed my old water treatment system without pushing me to buy a new one. He simply stated ‘Please think of me when you decide to upgrade.’ And you bet your butt I will.”

Create value

“You don’t get paid for the hour. You get paid for the value you bring to the hour.” – Jim Rohn

Straight Plumbing and Heating creates value as well as anyone in the business. Homeowner Steve Shelley learned this when he first hired Tull to solve some minor plumbing issues. Years later, when it came time to replace the home’s oil-fired boiler, Joe was his first and only call.

“Joe is very responsive, knowledgeable and thorough,” said Shelley. “He doesn’t try to oversell, he’s happy to answer questions, and he’s never in a rush to get things done. I didn’t have to think twice about hiring him to convert our home from oil to propane, which we did mainly for the energy savings.”

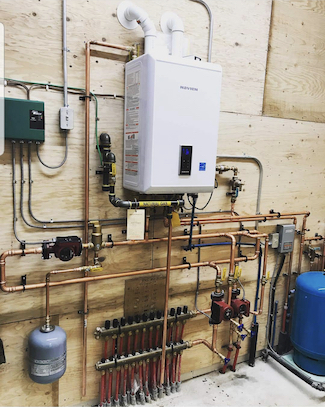

The combi boiler system Tull installed heats the home through a hydronic air handler, while also providing more hot water than the homeowner had ever had in the past.

The home is heated by hot water fan coils, and the existing boiler used to provide DHW through a 40-gallon indirect tank. Shelley estimates that the unit burned 800 gallons of oil each year, or roughly $3,200.

Tull buried a large propane tank in the yard, replaced the existing unit with a 200 MBH Alta Combi boiler, and sidewall vented the new unit.

The retrofit took place in June last year, giving Shelley nearly a year to calculate the energy savings that Straight Plumbing and Heating had provided.

“We used 400 gallons of propane over the winter, and I’m sure we’ve consumed a little more through the fall and spring for hot water,” he Shelley. “With LP at $2.00 per gallon, we’re saving somewhere around $2,000 per year.”

Tull replaced an oil-fired boiler with a new Alta condensing combi boiler for an annual savings of $2,000.

Shelley also noted that the family used to run out of DHW quickly. Now they can shower as long as they want and run multiple taps.

“We have all the hot water we need,” Shelley explained. “We can’t smell oil in the basement anymore, and we don’t hear the boiler start up like we used to.”

“We have about a dozen Alta boilers in the field,” said Tull. “They work very well on LP. Most of the installations in Hartford County are on propane. The Alta is also easy to clean, and access is fantastic because the side panels are removable.”

There’s another reason that Tull installs the Alta. Much like other models in the U.S. Boiler Company lineup, the Alta is available at a variety of local supply houses, including Northeastern Supply, Thomas Somerville and R.E. Michel.

“When it’s cold and a customer needs heat, I can’t come up empty-handed on parts and product,” said Tull. “Having equipment that’s readily available is extremely important.”

Overcoming challenges

“A challenge only becomes an obstacle when you bow to it.” – Ray Davis.

Last heating season, Straight Plumbing and Heating installed 35 boilers. This year, only 20. He suspects the economy has something to do with that, but he’s certain there’s another reason.

According to Tull, many big HVAC companies are pushing homeowners toward inexpensive heat pumps. There are lots of “house flippers” in his territory, as well. Typically, flippers install the cheapest heat pump on the market.

Straight Plumbing & Heating has a dozen Alta boilers in the field, and he’s found them to be reliable and very easy to work.

“I’m not talking about high-efficiency, low-ambient temperature systems,” he said. “I mean the cheap, undersized unitary systems. I’ve had homeowners call me after buying a house with a new heat pump, asking if I can install ‘a real heating system.’ Once winter hits, they’re uncomfortable and their electric bill spikes because the units constantly run on emergency heat.”

It’s hard to sell a premium system against a budget option when the customer doesn’t know the difference before signing the contract.

“I know it will all come full circle,” said Tull. “You only make that mistake once. If I was trying to grow rapidly, I’d be concerned about it, but I’m happy with where the company is. It’ll grow gradually. We’ll continue solving harsh water problems and creating extremely comfortable heating systems. If we do that and remain transparent with our customers, the company will continue to do well.”

While he’s not busy with his day job working on hydronic heating systems, commercial and residential plumbing, backflow prevention and gas work, Chris Massaro (@nwo_plumber) loves playing guitar and recording music. Admiring the recent tattoo to commemorate his daughter’s birth, “I was in a bunch of bands throughout high school and recorded an album once Read more

While he’s not busy with his day job working on hydronic heating systems, commercial and residential plumbing, backflow prevention and gas work, Chris Massaro (@nwo_plumber) loves playing guitar and recording music. Admiring the recent tattoo to commemorate his daughter’s birth, “I was in a bunch of bands throughout high school and recorded an album once. I don’t get around to it as much as I used to or like to, but I’m definitely making more time for that now,” says Massaro, owner/lead tech at Aqua North Plumbing and Heating Ltd., Thunder Bay, Ontario, Canada.

While he’s not busy with his day job working on hydronic heating systems, commercial and residential plumbing, backflow prevention and gas work, Chris Massaro (@nwo_plumber) loves playing guitar and recording music. Admiring the recent tattoo to commemorate his daughter’s birth, “I was in a bunch of bands throughout high school and recorded an album once. I don’t get around to it as much as I used to or like to, but I’m definitely making more time for that now,” says Massaro, owner/lead tech at Aqua North Plumbing and Heating Ltd., Thunder Bay, Ontario, Canada.

I take that back. Massaro also enjoys hanging out with friends and family, golfing and mountain biking. And, he definitely needs to get that grill time in—grill, smoke, BBQ. “Sometimes in that order, in one cook. Most of the time I do use the smoker though. I’ve been on a pulled pork kick lately. My favorite is some nice pork shoulders on the Traeger. It’s the ultimate dad activity, in my opinion,” says Massaro.

The work\life balance has been a struggle for Massaro; he realized one day that when you are running your own small business sometimes there isn’t a balance. You have to make the time and prioritize it. “Do what’s important to you and make time for the people and activities you love. And most importantly, take care of yourself! Because you’re worth it. Time stands still for no one so spend it wisely,” says Massaro.

And that’s why staying physically fit and active is important to Massaro. “I’m always lifting, bending, up and down the stairs all day so it’s helpful to have a training regimen that supports that. And, it really helps to keep me in mental shape as well,” say Massaro.

And that’s why staying physically fit and active is important to Massaro. “I’m always lifting, bending, up and down the stairs all day so it’s helpful to have a training regimen that supports that. And, it really helps to keep me in mental shape as well,” say Massaro.

Even more important is eating right, says Massaro. “We use a lot of energy in a day in the trades so we have to keep that fire fed. All of this allows me to stay energized all day and still have plenty of gas in the tank when I get home for family time,” continues Massaro.

Massaro’s foray into the trades started when he starting working for the family business as a plumbing apprentice at the age of 13. “Made best friends with my shovel and we went to work. Thankfully, I graduated from digging trenches and went on to start really learning about the ins and outs of the trade,” recalls Massaro.

Over the next few years, Massaro spent most days plumbing residential systems with a few commercial jobs sprinkled in here and there while working for my father. “It was nice to be doing a bit of everything and not just strictly one area of the trade, which I felt was important to be a well-rounded tech.

Once Massaro had a few years under his belt, he did a lot of remote northern work for fly-in communities. “Those big jobs we did up there really sharpened my time and material management skills,” says Massaro.

In addition, the high school Massaro attended offered a cooperative education program where he was able to gain work experience hours toward his apprenticeship if he chose to stick with plumbing. “I would go to regular classes for the morning periods then co-op at Aqua North in the afternoon,” says Massaro.

In addition, the high school Massaro attended offered a cooperative education program where he was able to gain work experience hours toward his apprenticeship if he chose to stick with plumbing. “I would go to regular classes for the morning periods then co-op at Aqua North in the afternoon,” says Massaro.

As a side note, Massaro says that if your local high school offers a cooperative education program, he highly recommends getting involved. “It’s a really pressure-free way to get your feet wet in whatever trades the school offers,” says Massaro. “I always try to take on one co-op student per year and leave them with a positive experience in the trade. I feel that’s the best way for kids to feel out what they want to do. And, don’t be afraid to ask questions!”

Next, after getting all of his trade school and work hours complete, Massaro then wrote his exam for his certificate of qualification in plumbing. Shortly thereafter, Massaro bought the family business, and the rest is history.

As fourth-generation plumber, Massaro has had some great mentors in his career, with plenty of help and guidance from his father and grandfather in learning new and old ways of plumbing. “If my great grandfather was around then I’m sure he would have some real old school stuff to show me.”

As fourth-generation plumber, Massaro has had some great mentors in his career, with plenty of help and guidance from his father and grandfather in learning new and old ways of plumbing. “If my great grandfather was around then I’m sure he would have some real old school stuff to show me.”

And while Massaro doesn’t consider himself a role model, he’s always willing and ready to help others to do their best at work, and life in general. “I’ve learned a lot over the years and sharing the experiences and knowledge with up-and-coming tradespeople is paramount,” says Massaro.

For Massaro, he loves building something from nothing and executing the job. “Sometimes just sitting back after the job is done and being like ‘damn we really did that.’”

Perception Change

The perception of the industry needs to change, says Massaro. “I think the wheels are turning on that as we speak but we’ve got a long way to go.”

Social media is that vehicle for the instrument of change as it’s an easy way to showcase contractor work, and connect with other professionals. “There’s a solid amount of tradespeople out there doing an amazing job. If we can show people that there’s more to plumbing than just plunging toilets, fixing leaks, and back-breaking work, then I think that’s a win,” says Massaro.

Social media is that vehicle for the instrument of change as it’s an easy way to showcase contractor work, and connect with other professionals. “There’s a solid amount of tradespeople out there doing an amazing job. If we can show people that there’s more to plumbing than just plunging toilets, fixing leaks, and back-breaking work, then I think that’s a win,” says Massaro.

Whether it’s new and better tools, techniques, business knowledge, etc., Massaro has learned so much on social media. “It’s awesome that we can connect with people and have such a great community sharing tricks of the trade, meet-ups or even debate if it’s tape then dope—which it is—or dope then tape,” says Massaro.

In the end, as Massaro sets his sights on his career and further enriching his life, a good bucket list item to check off would be getting a recreational pilot’s license. “Always wanted to get into aviation in some way.”

The sky’s the limit.

The new floor-standing FT Series Combination Boiler and Water Heater is the only residential combi boiler that delivers uninterrupted home heat and on-demand hot water simultaneously. Laars Heating Systemsannounces the launch of its powerful, ultra-high efficiency floor-standing FT Series Combination Boiler and Water Heater, the only residential combi boiler that simultaneously supplies abundant home heat Read more

The new floor-standing FT Series Combination Boiler and Water Heater is the only residential combi boiler that delivers uninterrupted home heat and on-demand hot water simultaneously.

Laars Heating Systemsannounces the launch of its powerful, ultra-high efficiency floor-standing FT Series Combination Boiler and Water Heater, the only residential combi boiler that simultaneously supplies abundant home heat and endless hot water without interruption.

“Home heat and hot water are critical to health and comfort in our daily lives,” said Chuck O’Donnell, director of marketing for Laars Heating Systems. “The Laars floor-standing FT Series Combination Boiler and Water Heater, like the rest of the FT Series of products, is built to meet the needs for space heating and domestic hot water reliably, efficiently and economically.”

“Home heat and hot water are critical to health and comfort in our daily lives,” said Chuck O’Donnell, director of marketing for Laars Heating Systems. “The Laars floor-standing FT Series Combination Boiler and Water Heater, like the rest of the FT Series of products, is built to meet the needs for space heating and domestic hot water reliably, efficiently and economically.”

The FT Series Combination Boiler and Water Heater includes a unique, integrated domestic hot water mini-indirect tank that delivers stable hot water on demand. Advanced smart technology coordinates uninterrupted space heating with domestic hot water demand and ensures continuing hot water supply for multiple heating events.

With industry-leading capacity, the FT Series Combination Boiler and Water Heater can deliver six gallons per minute of hot water in the first minute and 5.2 gallons per minute continuous delivery at a 70°F temperature rise. Other features include domestic hot water recirculation compatible; built-in low loss header for ease of installation; robust stainless-steel fire-tube heat exchanger; top piping connections for flexible installation; and large front access for service and maintenance.

“The Laars floor-standing FT Series Combination Boiler and Water Heater offers a unique combination of performance, efficiency and convenience,” O’Donnell said. “Based on extensive feedback from heating professionals, multiple features have been incorporated that make installation and service straightforward and accessible, and also provide options for homeowners.”

For more information, visit http://www.laars.com.

Bradford White Corporation subsidiary recognizes the experienced executive’s contributions to the company and industry with promotion to senior VP and general manager post Bradford White Corporation, an industry-leading manufacturer of commercial, residential and industrial water heating and storage applications, has named Rich Simons senior vice president and general manager of Laars® Heating Systems Company. “I’ve Read more

Bradford White Corporation subsidiary recognizes the experienced executive’s contributions to the company and industry with promotion to senior VP and general manager post

Bradford White Corporation , an industry-leading manufacturer of commercial, residential and industrial water heating and storage applications, has named Rich Simons senior vice president and general manager of Laars® Heating Systems Company.

, an industry-leading manufacturer of commercial, residential and industrial water heating and storage applications, has named Rich Simons senior vice president and general manager of Laars® Heating Systems Company.

“I’ve often said that Rich is the epitome of a general manager, because he can bring insight and ideas to every facet of the Laars Heating System’s business,” said Bruce Carnevale, president and CEO of Bradford White Corporation. “His broad knowledge base, tireless work ethic and industry experience have made him an invaluable part of our corporate leadership team.”

Simons, a graduate of Case Western Reserve University and the University of Minnesota Carlson School of Business, joined Laars in 2016 as vice president and general manager. His responsibilities encompass the overall operation of the business as well as its strategic direction and financial results. Simons has more than 30 years of experience in the boiler industry.

“The opportunities that we are taking to deliver innovative customer solutions have never been better and we are excited about our future,” Simons said. “It’s about our customers and our people, and as a member of the Bradford White family, I am very proud of what we have accomplished. I believe we embody a customer commitment that is second to none as one of the industry’s premier boiler manufacturers.”

In January, Simons was appointed to the board of directors of the American Boiler Manufacturers Association.

“When Rich arrived at Laars, his priority was to spend time with our customers and manufacturers’ representatives so he could truly understand their needs and learn about any challenges they were experiencing,” Carnevale said. “Under his leadership, the Laars team has brought new products to market in record time and implemented improvements across the major functional areas of the company.”