Leading water storage tank manufacturer’s Ultonium® tank lining is now infused with Microban® antimicrobial technology, setting a new industry standard for protection Niles Steel Tank, a leading manufacturer of custom water storage tanks and a subsidiary of Bradford White Corporation, announces that its proprietary Ultonium® tank lining will now incorporate Microban® antimicrobial technology to provide additional protection Read more

Bradford White

Leading water storage tank manufacturer’s Ultonium® tank lining is now infused with Microban® antimicrobial technology, setting a new industry standard for protection

Niles Steel Tank, a leading manufacturer of custom water storage tanks and a subsidiary of Bradford White Corporation, announces that its proprietary Ultonium® tank lining will now incorporate Microban® antimicrobial technology to provide additional protection against the growth of bacteria, mold and mildew on the surface of the interior tank lining.

“Microban® enhances our Ultonium® technology and offers our customers an additional layer of protection*,” said Jeremy Waller, vice president and general manager of Niles Steel Tank. “We’re delivering an unprecedented solution that no other water storage tank manufacturer can offer.”

Niles Steel Tank water storage tanks are the only water storage products that offer customers this additional level of tank protection at no additional charge. This innovation is a direct outcome of Niles Steel Tank’s ongoing research and development efforts in response to a wide range of market, technology, regulatory and environmental trends.

Niles Steel Tank water storage tanks are the only water storage products that offer customers this additional level of tank protection at no additional charge. This innovation is a direct outcome of Niles Steel Tank’s ongoing research and development efforts in response to a wide range of market, technology, regulatory and environmental trends.

Ultonium® tank lining with Microban® antimicrobial product protection is now a standard feature on tank-type water heaters from Niles Steel Tank as well. Ultonium® prolongs the life of the water storage tanks by keeping corrosive elements from reaching the steel of the tank and other components. The addition of Microban® antimicrobial technology protects the Ultonium® tank lining against the growth of bacteria, mold and mildew on the surface of the lining.

The Microban® antimicrobial technology is integrated into the Ultonium® formula and then applied to the inside of the tank, coils and/or flue tubes during the manufacturing process. After application, the Ultonium® lining is baked on at approximately 1,600 degrees for a hardened, long-lasting finish. Through this exclusive manufacturing process, the Microban® antimicrobial technology becomes a permanent part of the coating that continues its protection for the lifetime of the water heater.

Antimicrobials have been safely used for many years. The Microban® antimicrobial technology used in Niles Steel Tank products is silver-based, which has been used for decades in a range of applications, and carries both the EPA and European Union approval for direct food contact.

Microban® has been a trusted brand and leader in antimicrobial technologies since 1984. Their technologies can be found in thousands of consumer and industrial products around the world, including a variety of plumbing fixtures and household appliances.

For more information about Microban®, visit https://www.microban.com.

To learn more about Niles Steel Tank, please visit https://nilesst.com or call (269) 683-1910.

For more information about Bradford White Corporation, visit https://www.bradfordwhitecorporation.com.

Leading water heating and storage manufacturer’s Vitraglas® tank lining is now infused with Microban® antimicrobial technology, setting a new industry standard for protection. Ambler, Pa. —Bradford White Corporation, an industry-leading American manufacturer of water heaters, boilers and storage tanks, announces that its proprietary Vitraglas® tank lining will now incorporate Microban® antimicrobial technology to provide additional Read more

Leading water heating and storage manufacturer’s Vitraglas® tank lining is now infused with Microban® antimicrobial technology, setting a new industry standard for protection.

Ambler, Pa. —Bradford White Corporation, an industry-leading American manufacturer of water heaters, boilers and storage tanks, announces that its proprietary Vitraglas® tank lining will now incorporate Microban® antimicrobial technology to provide additional protection against the growth of bacteria, mold and mildew on the surface of the interior tank lining.

“We’re delivering unprecedented protection that no other water heater manufacturer can offer,” said Louise Prader, senior director of product management for Bradford White. “Microban® antimicrobial product protection* enhances the premium protection of our Vitraglas® technology and offers our customers an additional layer of protection.”

Bradford White water heaters are the only water heating products that offer residential and commercial customers this additional level of tank protection at no additional charge. This innovation is a direct outcome of Bradford White’s ongoing research and development efforts in response to a wide range of market, technology, regulatory and environmental trends.

Vitraglas® tank lining with Microban® antimicrobial product protection is now a standard feature on tank-type water heaters from Bradford White. Vitraglas® prolongs the life of the water heater by keeping corrosive elements from reaching the steel of the tank and other components. The addition of Microban® antimicrobial technology protects the Vitraglas® tank lining against the growth of bacteria, mold and mildew on the surface of the lining.

The Microban® antimicrobial technology is integrated into the Vitraglas® formula and then applied to the inside of the tank, coils and/or flue tubes during the manufacturing process. After application, the Vitraglas® lining is baked on at approximately 1,600 degrees for a hardened, long-lasting finish. Through this exclusive manufacturing process, the Microban® antimicrobial technology becomes a permanent part of the coating that continues its protection for the lifetime of the water heater.

Antimicrobials have been safely used for many years. The Microban® antimicrobial technology used in Bradford White products is silver-based, which has been used for decades in a range of applications, and carries both the EPA and European Union approval for direct food contact.

Microban® has been a trusted brand and leader in antimicrobial technologies since 1984. Their technologies can be found in thousands of consumer and industrial products around the world, including a variety of plumbing fixtures and household appliances.

For more information about Microban®, visit https://www.microban.com.

For more information about Bradford White Corporation, visit https://www.bradfordwhitecorporation.com.

Monumental concerns in the industry—from supply chain issues and inflation concerns to electrification and decarbonization—challenge contractors and manufacturers alike to be ready to rise above the fray. On September 28, Hurricane Ian, a Category 4 storm, hit the Florida coast, leaving a trail of destruction, loss of life, and people without power, and a place Read more

Monumental concerns in the industry—from supply chain issues and inflation concerns to electrification and decarbonization—challenge contractors and manufacturers alike to be ready to rise above the fray.

On September 28, Hurricane Ian, a Category 4 storm, hit the Florida coast, leaving a trail of destruction, loss of life, and people without power, and a place to live. The following week, after the residual rains moved through the South Atlantic states, PHCC CONNECT attendees, exhibitors and staff were fortunate to convene in Charlotte, N.C. for the annual show.

One of the many bright spots during CONNECT was the annual Industry Perspective panel—back by popular demand—which featured some of the industry’s finest: Elisabeth Sutton, Director—Marketing, Professional Channel, Kitchen and Bath Americas, Kohler; Bruce Carnevale, President and CEO, Bradford White Corporation; Randy Roberts, Vice President of Sales and Marketing, Rheem; Scott Teson, Senior Vice President of Skilled Trades, Milwaukee Tool; Jeff Fetters, Chairman, Federated Insurance Companies.

As I prepared for the panel, I would have been remiss if I didn’t mention those people still struggling in the Sunshine State. And the more I thought about what was happening in Florida, the more I could draw some symmetry of what has been plaguing our nation the past few years.

Things like supply chain. Are the right people getting what they need in Florida? Labor shortage. Do we have the manpower to provide assistance? Or, do we have the proper infrastructure in place? What about electrification? I mean, I had just seen a meme that said something like, “2.8 million people without power, time to fire up the Teslas.” Now that could be perceived as a bit naïve, but when you look at California, for instance—declaring no new gas cars sold in the state by 2035—concerns about adequate infrastructure are real.

It’s a good thing we had the right people on the panel to address such concerns. I learned that Federated Insurance sent “catastrophic teams” to Florida to help. “We needed to have boots on the ground as quickly as we could,” said Fetters. “Businesses need to have high expectations for employees to remain safe. Disasters can strike at any time. A risk management culture has to perpetuate through every single employee,” said Fetters.

As a side note, how can contractors prepare for such an event? “Make sure you sit down with an agent to see what it would cost to replace your business, and any personal property in the event of any potential catastrophe,” said Fetters.

Supply Chain Woes

Nonetheless, supply chain issues dominate conversation almost daily among working contractors. “We are still challenged by supply chain issues, and it has forced us as a company to better manage our supply chain. We do things differently now,” said Carnevale.

As a manufacturer, you’re never getting what you need from plastic resins overseas, nickel component slowing lines down to component issue challenges,” said Roberts. “This makes us be creative on managing supply chain.”

According to Sutton, “We see that luxury side of remodeling is still high. The thing impacting supply chain is that distributors are receiving more products, managing inventory for distributors.”

Investments in People/Training

Milwaukee Tool has made an $400 million investment in domestic manufacturing. “We want to control our own destiny,” said Teson. Yet, Teson pointed out that with more commercial construction projects on the books, how do we find the right people to support those jobs? “We need skilled tradesmen and women to support those efforts,” said Teson.

Sutton suggests that technology in products is a viable avenue to attract the younger generation. C’mon, who doesn’t like the way an impact driver or press tool feels in their hands?

Elisabeth Sutton

“We also need to attract people to the industry to show them how wonderful it is, and that should not be specific to one type of person,” said Sutton. “We need more diversity, not just one profile,” continued Sutton.

“This is a fantastic industry, and once people are a part of it, they stay,” said Roberts.

Yet, once in the building, how do we get people to stay? Training. “It has always been a critical part of what we do. We have been very flexible with our training—we will take it to customers and also bring them into our facility,” said Carnevale.

How do employees continue to get better year after year? The panel agreed that it’s about establishing a culture of training in your office. This gives employers a competitive advantage in keeping people and attracting people because they will be seen as investing in them.

Electrification is the Buzzword

According to Carnevale, topics surrounding electrification loom large. For example, will the infrastructure be in place to support the new products? How will the infrastructure build out in a very short time? This puts the consumer in a bad position and puts our national security at risk—i.e., supply chain issues and the country’s fragile relationship with China.

“Electrification and decarbonization, whether we like it or not, we need to be prepared. We have the products available,” said Roberts.

Government Regulations

Carnevale noted that he receives email relating to a regulatory issue almost daily. “The DoE is extremely active, and there’s a requirement that is in the foundational law that once the DOE sets a new minimum efficiency standard, it cannot go backward.”

The panel consisted of (from l to r): John Mesenbrink, moderator; Elisabeth Sutton, Kohler; Bruce Carnevale, Bradford White; Randy Roberts, Rheem; Scott Teson, Milwaukee Tool; Jeff Fetters, Federated Insurance.

According to Rheem’s Roberts, there is an “Install Date Standard for Air Conditioning Systems” looming and, “Contractors will be breaking the law if they install an AC system not rated to the new standard come January, 1 2023.” Efficiency standards dictate that sell through of existing systems will be allowed in the northern states if the product was manufactured prior to January 1, 2023. This is not the case in the South and Southwest. AC systems must comply with the 2023 federal minimums to be installed after January 1, 2023. Current Heat Pump systems can continue to be installed in all regions as long as they were manufactured before January 1.

And who is enforcing this, you may ask? “Contractors and distributors will be self-policing installations to make sure they meet the new standard. In addition, manufacturers cannot ship products that don’t meet the new standards or allow them to be registered for warranties if installed after January 1. A standard based on install date will ultimately create inventory challenges for everyone in the industry,” said Roberts.

That Dreaded ‘R’ Word

There are whispers of the “R” word and I don’t think it means that “relief” is on the way anytime soon. From inflation to fuel prices, contractors have faced economic hardships that may continue to linger into 2023, and beyond. “We’ve been bearish on the economy longer than the financial press has been,” says Carnevale. “It is pretty clear that we are in a recession. There have been some positive signs, the fed is getting aggressive, and we will see significant drop in housing market.”

Carnevale continued that he is concerned about the macro economy, even though there are some good signs. “Labor shortages continue to be a vexing problem, and we need to focus on the labor participation rate compared to pre-pandemic, meaning there are a lot of people who are choosing not to work,” said Carnevale.

Teson said that interest rates are the real threat. “We’re watching it very closely and trying to make decisions that will make us come out stronger than our competitors.”

Carnevale added that there is a very distinct demand for discretionary vs. non-discretionary products. In the end, “As the demand starts to soften, we are subject to the laws of supply and demand. It is not going got back to where it is pre-pandemic, but will see some softening on pricing.”

Roberts says that overall, we should see a correction. “How do you position yourself to come out stronger than you go into it?” That’s the question.

For more info, visit PHCC.

Online resources have influenced our daily activities. With so much information at our fingertips, we can answer our queries instantly. It’s no wonder people are utilizing online resources to renovate homes themselves rather than having to pay a professional. The same applies to plumbing projects like water heater installation. In theory, the process seems simple Read more

Online resources have influenced our daily activities. With so much information at our fingertips, we can answer our queries instantly. It’s no wonder people are utilizing online resources to renovate homes themselves rather than having to pay a professional.

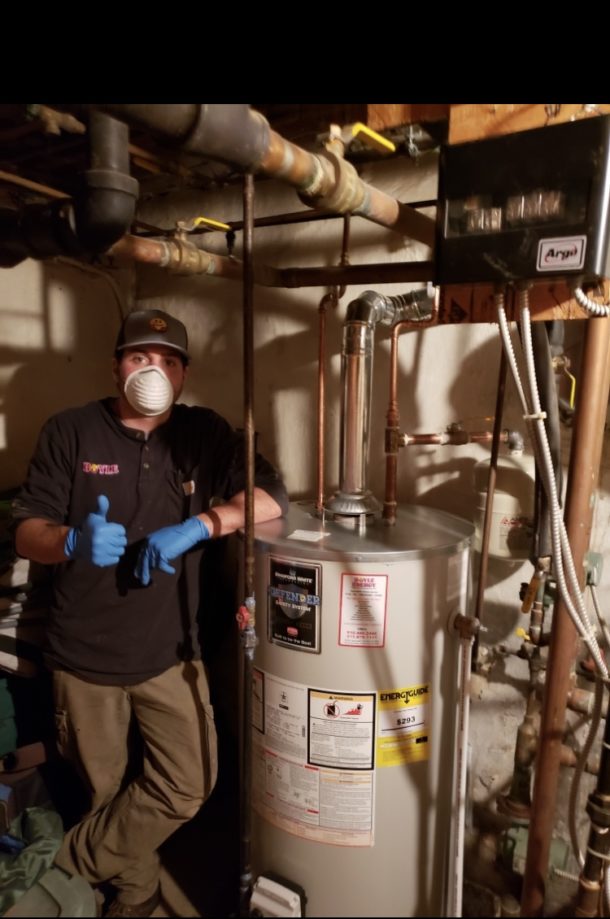

The same applies to plumbing projects like water heater installation. In theory, the process seems simple to follow. But instant knowledge cannot compete with years of experience. Beginners can easily make risky and costly mistakes. To ensure you do not face such consequences, we have highlighted some common installation mistakes and ways you can avoid them.

1. Improper Location

The location of your water heater is crucial for its efficiency and safety. Try not to place them in storage closets and attics. You may rarely visit these parts of your house, and will not know about damage until it is too late. To minimize plumbing, place the water heater closer to its area of use, such as the kitchen. For more efficiency, modern models are more insulated, making them broader. They may not fit in the same position as the old one. Instead, accommodate them in your backyard. Adequately placing water heaters ensures they do not ruin the interior’s appeal while working optimally.

2. Poor Drainage

Your heater must drain extra water whenever it gets too hot or builds up excess pressure. Connect the drain line from your tank to the TPR valve, which should discharge into a drain below. If there is no drain beneath, you must place a correctly sized drain pan. The drain pan should be at least 1.5 inches tall and 2 inches broad and made of corrosion-resistant materials. Place the drain correctly to avoid leaks. Otherwise, mold may develop due to subsequent water damage.

3. Improper Installation of Relief Valves

Relief valves are safety features that help regulate temperature and pressure in geysers. The tank will likely blow up if you install them incorrectly, dousing everything within a few feet of the tank. To avoid any accidents, be careful in installing the valves. Mount the valve to the tank’s side 6 inches above the floor, and connect a threaded drain tube to the valve outlet for additional protection. Regardless of your skills in installations, we recommend taking professional help. A mistake can cause harm to your property and loved ones.

4. Incompatible Metal Connection

Some people don’t consider the compatibility of metal pipes when connecting them. Even a 0.1mm difference in the pipes’ diameter can result in their corrosion. If your water pipes are made of copper, you should use brass connectors. Combining copper pipes and galvanized steel connectors will result in a poor connection since they are incompatible. These connections will eventually corrode, cause water leaks and reduce the water heater average lifespan.

5. Soldering of Pipes

Soldering is undoubtedly the best technique for connecting the water line and the tank, but its heat can harm the plastic. Avoid soldering and bringing the propane torch near the water tank. Instead, unscrew the pipe’s nipples from the tank. Create a tiny extra segment, and solder it to the nipples. This way, you won’t need to get the propane torch close to the tank. Consider getting help from heater installation service companies for safer and improved results.

Endnote

Incorrectly Installing water heaters can lead to many problems, such as the ones mentioned above. Avoid these issues by following the proper instructions and staying away from experimentation. In technical projects like this, prioritize your safety by adhering to certain precautions. If you are a beginner or unsure about the process, consider leaving the installation to experienced hands. By trusting a professional, you will worry less and can enjoy the warm water.

Top water heating manufacturer and non-profit service organization continue mission to support plumbers around the world and ensure access to safe water supplies Bradford White Corporation, an industry-leading manufacturer of water heaters, boilers and storage products, announces a continued partnership with Plumbers Without Borders, a grassroots non-profit organization working to increase global access to safe water Read more

Top water heating manufacturer and non-profit service organization continue mission to support plumbers around the world and ensure access to safe water supplies

Bradford White Corporation, an industry-leading manufacturer of water heaters, boilers and storage products, announces a continued partnership with Plumbers Without Borders, a grassroots non-profit organization working to increase global access to safe water and sanitation.

The partnership re-affirms Bradford White’s commitment to advance the plumbing and HVAC industries through strategic partnerships and programs and supports Plumbers Without Borders’ ongoing contributions to professional training, promoting careers in the trades and maintaining the industry’s commitment to the highest standards of quality for products and services.

“Plumbers Without Borders is focused on improving lives and shares our deep commitment to elevate the work of industry professionals and the essential role they have in supporting the health, safety and sanitation in communities.” said Rebecca Owens, senior manager of communications for Bradford White. “Through our charitable giving program Industry Forward™, our company is dedicated to providing the tools and resources needed to make a positive impact in communities where we live and work. We are proud to continue our relationship with Plumbers Without Borders and increase their capacity to support individuals and families around the globe.”

Plumbers Without Borders was founded in 2010. The organization connects volunteer plumbers and other skilled tradespeople with projects around the world that are establishing safe plumbing and sanitary systems and promoting related health and safety education. Plumbers Without Borders selects partners based on quality, service, craftsmanship and training.

“We are proud and humbled to have Bradford White Corporation’s continuing support. By creating and investing in their “Industry Forward” program, Bradford White leads the way in exemplifying our industry’s most important goals and initiatives that will help shift the global equation towards improving lives, everywhere.” said Domenico DiGregorio, president and co-founder of Plumbers Without Borders.

For more information about Bradford White, visit https://www.bradfordwhitecorporation.com.