There has been some tough rhetoric coming out of president-elect Trump’s camp regarding tightening the screws on imported goods by implementing a hefty tariff on countries such as China, Mexico and Canada, to name a few. Is this a good attempt to bring more manufacturing stateside? How will this affect the economy? Is this even Read more

cooling

There has been some tough rhetoric coming out of president-elect Trump’s camp regarding tightening the screws on imported goods by implementing a hefty tariff on countries such as China, Mexico and Canada, to name a few. Is this a good attempt to bring more manufacturing stateside? How will this affect the economy? Is this even a good idea? We talk to some industry leaders about tariffs and what it means for the U.S. economy moving forward.

There has been some tough rhetoric coming out of president-elect Trump’s camp regarding tightening the screws on imported goods by implementing a hefty tariff on countries such as China, Mexico and Canada, to name a few. Is this a good attempt to bring more manufacturing stateside? How will this affect the economy? Is this even a good idea? We talk to some industry leaders about tariffs and what it means for the U.S. economy moving forward.

Recently, on the Crosstalk episode of the Make Trades Great Again and Appetite for Construction podcasts, this very topic came up and Andy Mickelson, Mickelson Plumbing and Heating, Missoula, Mont., and Eric Aune, Aune Plumbing, Zimmerman, Minn., were in unison in their view on tariffs. “There will be an impact,” says Mickelson. “Every single item that we touch has some impact from an imported product or good. And to sit back and believe that it’s not going to have a day-to-day impact or a cost increase is foolish.”

“It’s a tax that’s going to kill sales; it’s definitely going to affect us moving forward, especially if we see higher tariffs,” says Aune.

Mickelson continues, “There’s going to be a ‘trickle up’ effect, and along with that we’re going to see a lack of material … we saw brief chunk of this in 2021 when we had the port issues and shipping problems, and you extrapolate that into that into that these items aren’t coming because they are too expensive, how do you get around that? You can’t just flip a switch and just say we’re just going to make it here. We’re not ready for that, and I don’t think that this country is ready to become a manufacturing country. I don’t think there enough people who are willing to work on the assembly line … we can’t get people to sign up right now to become a plumber or an electrician or a data communication person—any of those manufacturing-type jobs are very much so in line with what it means to go out and work with your hands, be in a skilled trade.”

So, the back-and-forth debate continues to brew relating to whether instituting tariffs is beneficial to the American economy and the American worker. Dain Hansen, Executive Vice President, Government Relations, The IAPMO Group, says that economists have different views on the topic of tariffs, but the plumbing industry is well-positioned to support continued domestic production of what our country needs—and increase U.S. exports to other countries.

“Any policy that strengthens our manufacturing muscle is good for the economy and increases job opportunities in the trades. Programs such as the Market Development Cooperator Program and Standards Alliance at USAID, along with the Department of Commerce’s Foreign Commercial Service, provide vital support to U.S. exporters. We hope the administration will continue backing these programs to ensure U.S. products remain competitive overseas. We continue to monitor the impact tariffs are having on our global industry as manufacturing move locations to avoid these costs,” says Hansen.

While IAPMO is cautiously optimistic and vigilant, Plumbing Manufacturers International (PMI) shares concern. “During his campaign, President Trump spoke about his desire to increase tariffs—as high as 60% on Chinese goods, 10% to 20% across the board on all foreign goods, including Europe, and 25% on imports from Mexico, unless they curb the number of immigrants coming across the border. If he’s successful, these tariffs will have an inflationary impact, increasing the costs of production and in turn the costs of products in the marketplace. That’s certainly one of the biggest concerns plumbing manufacturers have right now.

“Our stance on this issue all along is that tariffs are harmful to the economy because they increase costs for manufacturers and have an inflationary impact on customers wishing to purchase plumbing products. These increased costs lead manufacturers to provide fewer jobs and they have less money for compensation as well. From an economic standpoint, we see no benefits from tariffs. PMI has always been an advocate for free and fair trade among nations,” says Kerry Stackpole, CEO and Executive Director, PMI.

According to Ben Brubeck, Vice President of Regulatory Labor and State Affairs, Associated Builders and Contractors (ABC), tariffs are a negotiating tool to renegotiate policies with other countries. “While having a hard time getting materials from overseas, resolving the domestic supply chain is a good thing.”

https://vimeo.com/1036092788 We are now the cream filling in the holiday Oreo cookie, as we got through Thanksgiving and we are all positioning ourselves for Christmas, Hanukkah, and the new year. This week we’ll talk about mental health and the trades, Eric’s been busy on the road, our deliciously baked podcasts and a Brown Friday surprise Read more

We are now the cream filling in the holiday Oreo cookie, as we got through Thanksgiving and we are all positioning ourselves for Christmas, Hanukkah, and the new year. This week we’ll talk about mental health and the trades, Eric’s been busy on the road, our deliciously baked podcasts and a Brown Friday surprise. Hey now!

The Plumbing-Heating-Cooling Contractors—National Association (PHCC) has announced the promotion of PHCC Educational Foundation Executive Director Dan Quinonez to PHCC Chief Operating Officer. “I am pleased to announce this expanded role for Dan, as he continues his position as the Executive Director of the PHCC Educational Foundation,” said PHCC CEO Cindy Sheridan. “Drawing on his strong Read more

The Plumbing-Heating-Cooling Contractors—National Association (PHCC) has announced the promotion of PHCC Educational Foundation Executive Director Dan Quinonez to PHCC Chief Operating Officer.

The Plumbing-Heating-Cooling Contractors—National Association (PHCC) has announced the promotion of PHCC Educational Foundation Executive Director Dan Quinonez to PHCC Chief Operating Officer.

“I am pleased to announce this expanded role for Dan, as he continues his position as the Executive Director of the PHCC Educational Foundation,” said PHCC CEO Cindy Sheridan. “Drawing on his strong association management background, strategic mindset, leadership and creative direction, Dan will assist me in driving strategy and operations for the association; he will also oversee most revenue-generating areas of the organization.”

Since joining the Foundation on June 1, 2023, Quinonez has overseen the release of new plumbing and HVAC training materials, an increase in annual giving campaign donations, expanding the PHCC Academy® to develop more post-apprentice courses, the addition of new scholarships for veterans and Latino applicants, and an industry joint effort to train the U.S. competitor for the WorldSkills competition.

“I am truly honored to take on this new role and am excited to collaborate closely with CEO Sheridan, the PHCC team, and all of our members,” said Quinonez. “Together, we will enhance operational performance and remain dedicated to delivering exceptional value to our members, all while upholding the highest standards of quality and service in everything we do.”

Before joining the PHCC Educational Foundation, Quinonez served as a Senior Account Executive for the Kellen Company, a prominent Association Management Company. In this capacity, he served as the Executive Director for the Roof Coatings Manufacturers Association (RCMA) and the Professional Electrical Apparatus Reconditioning League (PEARL), playing a pivotal role in expanding and promoting these organizations through various initiatives, including education, outreach, technical advancement, and advocacy.

His other roles included working with the National Association of Home Builders (NAHB) in Washington D.C., where he advocated for the home building community. In addition, he served in the United States Army Reserves for 12 years.

Quinonez’s appointment was part of an internal structural reorganization of PHCC that is designed to increase membership, sponsorship opportunities and industry exposure.

“I am excited to head into 2025 with this new organizational structure and am looking forward to a new phase of growth for PHCC,” said Sheridan.

Birmingham, Ala., rolls out the crimson red carpet for Plumbing-Heating-Cooling Contractors Association (PHCC) and its attendees. “The Magic City” played host to the annual PHCC CONNECT show and the city pulled out all the stops. With mild October temperatures, it was the perfect setting to connect with fellow attendees and soak in the vibrant culture Read more

Birmingham, Ala., rolls out the crimson red carpet for Plumbing-Heating-Cooling Contractors Association (PHCC) and its attendees.

“The Magic City” played host to the annual PHCC CONNECT show and the city pulled out all the stops. With mild October temperatures, it was the perfect setting to connect with fellow attendees and soak in the vibrant culture of Birmingham.

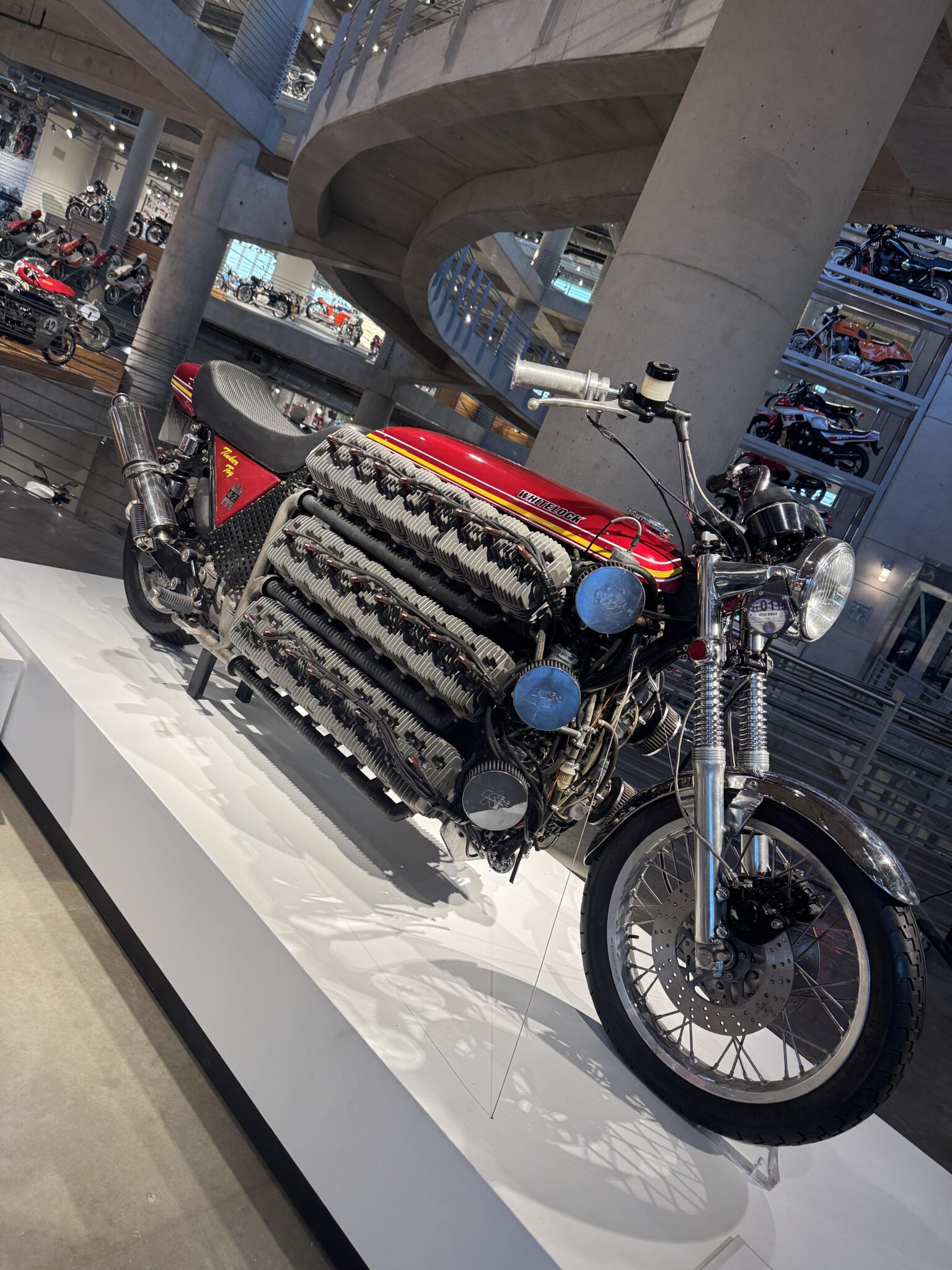

The CONNECT show began with an opening reception at the Barber Vintage Motorsports Museum—recognized by the Guinness World Records as the world’s largest motorcycle collection and home to other rare cars—and ended with an Alabama Tailgate Party at Birmingham Citywalk, where visitors could enjoy an array of food trucks serving local delicacies and engage in fun games.

The trade show floor was buzzing with latest in products and technology. New this year—although one needed to be a member to gain full access to the entire CONNECT experience—the Products & Technology Showcase floor was open free of charge to local walk-ins. This indeed brought in dozens more from the greater Birmingham area.

“This is the best place to do all of the networking,” says Erica Barnes, president, General Plumbing & Air Conditioning, Inc., Lake Worth, Fla. “I love getting new ideas form the floor and seeing what’s developing over time, such as artificial intelligence (AI) or seeing what new tools are coming out.”

A cool moment during PHCC president Joe Cornetta’s CONNECT opener, 94-year-old James Lindsey of Lindsey Brothers Plumbing and Heating in Norfolk, Va., was recognized for his contributions to PHCC and the industry. Starting his plumbing career at 16, he founded his own business, which will celebrate its 60th anniversary in 2026.

A cool moment during PHCC president Joe Cornetta’s CONNECT opener, 94-year-old James Lindsey of Lindsey Brothers Plumbing and Heating in Norfolk, Va., was recognized for his contributions to PHCC and the industry. Starting his plumbing career at 16, he founded his own business, which will celebrate its 60th anniversary in 2026.

The annual CONNECT Show opens with an opening breakfast emceed by Bruce Carnevale, CEO, Bradford White, a staunch supporter of the association and the skilled trades. Carnevale gave an update on the company and talked about the impending NAECA 4 regulations coming down the pike in 2029, with the eventual movement away from atmospheric venting to all condensing. The Department of Energy (DOE) says the standards will require minor updates to gas-fired storage water heaters, while electric storage water heaters more than 35 gallons will require heat pump technology.

A yearly staple at the CONNECT show is the PHCC Educational Foundation’s National Plumbing and HVACR apprentice contests where plumbing apprentices roughed-in a bathroom—including the drain, waste and vent lines, a toilet, a sink and shower. HVACR apprentices demonstrated their knowledge with a written test, and put their hands-on skills to the test with brazing, pressure testing, refrigerant recovery, and diagnosing and repairing a package unit system. This year, Logan Cunningham with John J. Maurer Inc., Cataumet, Mass., took top prize for plumbing, while Dane Gonser with Emcor Services Fagan, Kansas City, Kansas, was the winner of the HVAC portion.

This year’s theme, “Authentic Connections,” highlighted the importance of building trust and fostering relationships within the industry. From the daily keynotes featuring best-selling author and Navy commander Mary Kelly, who uncovered the key factors behind leadership success and failure to Jeff Butler, who with the help of the three “Cs”—cadence, collaboration and communication—explored actionable strategies to effectively manage cross-generational challenges and leverage the diversity of your multi-generational workforce as a competitive advantage.

Another highly informative and interactive session featured some of the industry’s most recognizable social media personalities who gave advice in a session aptly named, “What the Hell Is an Influencer?” In addition to friends George DeJesus, George’s Drains LLC, Morris County, N.J., and Mike Prencavage Jr., The Family Plumber, Los Alamitos, Calif., last-minute, heavy-hitter fill-ins, Dustin Van Orman, Any Hour Services, Orem Utah, and Roger Wakefield, Richardson, Tex., stepped in to inform attendees how to use social media in an effective way, for business of course.

The final keynote on reverse mentoring, moderated by yours truly, featured Erica Barnes, president, General Plumbing & Air Conditioning; Daniel Birmingham, project manager, JRC Mechanical, Chesapeake, Va.; Chris Johnson, owner, Charles Chester Plumbing & Heating, Elko, Nev.; Chase Johnson, general manager, Charles Chester Plumbing & Heating; and Tyler Arndt, Arndt & Sons Plumbing, Brooklyn, Wis., as they shared their experiences and how their ideas and contributions could help their companies thrive in the future.

The final keynote on reverse mentoring, moderated by yours truly, featured Erica Barnes, president, General Plumbing & Air Conditioning; Daniel Birmingham, project manager, JRC Mechanical, Chesapeake, Va.; Chris Johnson, owner, Charles Chester Plumbing & Heating, Elko, Nev.; Chase Johnson, general manager, Charles Chester Plumbing & Heating; and Tyler Arndt, Arndt & Sons Plumbing, Brooklyn, Wis., as they shared their experiences and how their ideas and contributions could help their companies thrive in the future.

Also new this year to CONNECT was live podcasting from the tradeshow floor. The magic of spontaneous discussions, solutions, and insights came alive with some of the industry’s top podcasters. These media personalities hosted high-profile guests as they shared their particular insights to the industry.

Oh, and why is Birmingham called the Magic City, you may ask? Including other names such as “The Iron City” or “The Pittsburgh of the South,” Birmingham is referenced as the Magic City because its soil contained the three necessary elements to produce steel: limestone, coal and iron ore.

Next year’s CONNECT will take place in Grand Rapids, Mich.

The other day I performed a Google search for ‘How to detect an air leak’. Not surprisingly it came up with millions of results, over 18 million in fact. Whether solving the problem in a commercial establishment or a domestic home environment, the majority of search results pointed to one solution. Namely, soapy water! Before Read more

The other day I performed a Google search for ‘How to detect an air leak’. Not surprisingly it came up with millions of results, over 18 million in fact.

Whether solving the problem in a commercial establishment or a domestic home environment, the majority of search results pointed to one solution. Namely, soapy water!

Before we all ridicule the idea as belonging to a bygone era, take a vehicle with a slow puncture to a tyre fitting depot and the chances are they remove the wheel and spin it in water to determine the leak. It’s a simple time proven method for determining leaks from pressurized systems.

But of course, not all equipment can be placed in soapy water. What if a system is known to be losing pressure and yet the lines carrying the compressed air from the source are located 10 metres above the ground, and dismantling the system is out of the question? Thankfully there is a fast and effective solution to hand.

But of course, not all equipment can be placed in soapy water. What if a system is known to be losing pressure and yet the lines carrying the compressed air from the source are located 10 metres above the ground, and dismantling the system is out of the question? Thankfully there is a fast and effective solution to hand.

Each time air or indeed any gas, leaks from a pressured system there is an associated sound. If the leak is significant, it can be audible to the human ear and therefore easily identified and rectified accordingly. However, most leaks in high pressure systems are extremely small and are out of the range of a human ear.

Think about a pressured air system on a large factory delivering compressed air from a bank of compressors to various stages of production throughout the manufacturing process. The chances are there are hundreds if not thousands of connections in the form of joints, reducers, valves, elbows, condensers etc. Each of these has the potential to leak small amounts of air, reducing the pressure of the system.

One leak might make very little difference but multiply this by the number of potential leaking joints and efficiency can be significantly compromised. The compressor will seek to compensate for any pressure loss by simply working harder. However, as any engineer will know, compressors can be expensive to operate in terms of energy and therefore will certainly increase an operators energy consumption.

With electricity costs being so much higher in Europe due to geopolitical factors in recent years, most companies are seeking to reduce the amount of energy used. Having a compressor work overtime to compensate for leaking joints is certainly not something senior management would smile about!

These scenarios are certainly not uncommon, in fact one European compressor manufacturer has stated that in some industrial settings, up to 80% of air generated is lot in leaks. So clearly identifying these small leaks can make a real difference to a company’s energy bills.

Although the sound produced by a small leak is inaudible to the human ear a high performance acoustic imaging camera such as the FLIR Teledyne Si2 – LD will have absolutely no problem identifying the source. Launched earlier this year the camera is capable of detecting leaks of 0.05 litres per minute at a distance of 10 metres, meaning those elevated air lines pose no problem for this latest instrument in the FLIR acoustic imaging camera line up.

For closer work the camera is even more sensitive and can detects minute leaks of 0.0032 litres per minute at a distance of 2.5 metres. Coupled with this improvement, the third-generation camera has improved microphones now capable of detecting sounds over an extremely wide frequency range, namely 2 – 130 kHz.

Areas of plant are often dark or dimly lit. for this reason FLIR have fitted the FLIR Si2-series of cameras with two powerful LED lights to make component identification easy even in poorly lit conditions.

Of course, it’s not just compressed air that the camera is capable of detecting; noise emitted by any escaping gas is identified by the powerful microphones. However that’s only part of the story.

The FLIR Si2-LD has built in software termed Industrial Gas Quantification. If the leaking gas is ammonia, hydrogen, helium, or carbon dioxide, very commonly used gases in a number of industries, the software is capable of quantifying the financial loss caused by the leak. By simply entering factors such as the cost per litre, the software identifies the amount each leak is causing over a given period of time. Such data is invaluable to financial analysts and senior management within an organisation.

It goes without saying that the financial considerations are only one aspect of leaking gas. The gases mentioned above all carry significant health hazards and can present a variety of dangers to personnel if allowed to leak for any period of time. Ammonia and carbon dioxide can cause serious breathing problems and asphyxiation even in smaller concentrations, whereas hydrogen can explode in the presence of oxygen. Clearly the cost of such problems goes way beyond any financial considerations.

We’ve come a long way since the ‘soap and water’ approach. See how the latest technology from FLIR Teledyne can help in reducing downtime, lower energy bills and improve safety in your organisation.

Visit www.flir.com or contact you local FLIR Teledyne agent or distributor.

Author: Darrell Taylor

Author: Darrell Taylor

Email: Darrell.Taylor@teledyne.com